Professional Documents

Culture Documents

Doc053 52 35150

Uploaded by

Edmond DsilvaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Doc053 52 35150

Uploaded by

Edmond DsilvaCopyright:

Available Formats

SWAS Panel Applications

• Power

• Steam systems

• Cogeneration

Simple to install. Safe to operate.

Hach®’s Steam and Water Analysis System (SWAS) measures degassed cation conductivity, silica, and

sodium, and helps to protect and reduce the downtime of your plant. This comprehensive approach also

includes a steam reduction unit as well as preinstalled hydraulic and electrical connections for standard

fittings and electrical I/O signals.

Reliable Measurements Easy and Safe Operation

A new way of water quality monitoring saves you critical The SWAS panel system is easy to install und requires only

time and effort. Less process downtime due to reliable low annual maintenance time. Safe operation through shut-

results delivered by Hach’s 8310 conductivity sensor, 5500 sc off valves for hot samples, safety valves for cooling water,

silica analyser, 9240 sodium analyser, and Polymetron 9500 protection screen for hot parts, and certified pressure tests.

controller.

Compact Assembly of Panels and Analysers

Complete Solution Sampling and analysers are mounted on a size-optimised single

Everything from one single source: pre-configured panel, panel. The efficient cooler design ensures the need of less

service, digital learning modules, in-house chemical production, cooling water and a wide sample pressure and temperature

and quality control. The single platform minimises time required range.

to teach and learn product operations, getting new systems in

use faster.

2 SWAS Panel

Technical Data*

Sample conditions

Sample pressure < 345 bar

Sample temperature 540 °C maximum

Flow rate 200 mL/min for degassed cation conductivity

150 mL/min for 5500 sc silica analyser

90 mL/min for 9240 sodium analyser

Plus 350 mL/min for grab sample

Cooling water conditions

Water after treatment (at least decarbonised water of after filter quality)

Pressure range 3 - 6 bar

Temperature Up to 40 °C (pressure drop downstream of cooler: 0.3 - 0.7 bar)

Turbidity < 50 NTU

pH range 7 - 12 pH

Conductivity < 100 µS/cm

Permissible Chloride < 250 mg/L for sample temperature 25 - 180 °C

range

< 100 mg/L for sample temperature 180 - 290 °C

< 25 mg/L for sample temperature 290 - 550 °C

For higher concentrations Inconel coolers have to be used.

*Subject to change without notice.

Order Information

Panel

LYP105.99.01001 SWAS Panel, 2 Parameters

Includes: 08310=A=0000 conductivity sensor, 5500.KTO.S0.A2E 5500 sc silica analyser, 9500.99.00604 Polymetron

9500 controller, 3-way low pressure flush valve HAM-LET, cooler FLR6225 (0.2-2.7 m3/h) + safety valve (10 bar),

TSV thermal shut-off valve (latching), total flow indicator, BPRV back pressure regulating valve, panel SS 304

LYP105.99.01002 SWAS Panel, 3 Parameters

Includes: 08310=A=0000 conductivity sensor, 5500.KTO.S0.A2E 5500 sc silica analyser, 09240=A=0002 9240

sodium analyser, 9500.99.00604 Polymetron 9500 controller, 3-way low pressure flush valve HAM-LET, cooler

FLR6225 (0.2-2.7 m3/h) + safety valve (10 bar), TSV thermal shut-off valve (latching), total flow indicator,

BPRV back pressure regulating valve, panel SS 304

Be confident with Hach Service

DOC053.52.35150.Mar18

Start-Up/Commissioning: Our service technicians visit your site and setup instrumentation, provide basic end-user training on

operations and maintenance, and validate settings and performance to get you started.

Service Agreement: Hach provides on-site and in-factory repair, preventive maintenance, and calibration programs for your

instruments to ensure reliability and instrument up-time. We have services to fit your specific needs.

www.hach.com

You might also like

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Doc033 52 30458Document6 pagesDoc033 52 30458Thịnh Khổng TrườngNo ratings yet

- SWAS Analyzers - SWAS Stands For Steam & Water Analysis SystemDocument7 pagesSWAS Analyzers - SWAS Stands For Steam & Water Analysis Systemsoumen sardarNo ratings yet

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- ABB Pressure Transmitter2Document18 pagesABB Pressure Transmitter2Supawat RangsiwongNo ratings yet

- 9190A Ultra-Cool Field Metrology Well: Ultra-Cool Dry-Block Calibrator With Best-In-Class StabilityDocument5 pages9190A Ultra-Cool Field Metrology Well: Ultra-Cool Dry-Block Calibrator With Best-In-Class StabilityAnonymous IXswcnWNo ratings yet

- Silica AnalyzerDocument4 pagesSilica AnalyzeravikbhaiNo ratings yet

- 9245 Sodium Analyzer - DatasheetDocument4 pages9245 Sodium Analyzer - DatasheetNavneet SinghNo ratings yet

- Air Cooled Chillers1Document6 pagesAir Cooled Chillers1jonathandacumosNo ratings yet

- Ametek 241 PDFDocument2 pagesAmetek 241 PDFdikastaloneNo ratings yet

- KENCO Thermal Differential SwitchDocument4 pagesKENCO Thermal Differential SwitchBilly Isea DenaroNo ratings yet

- LabTech water chiller cooling solutions for analytical labsDocument6 pagesLabTech water chiller cooling solutions for analytical labsrajesh_rbpNo ratings yet

- Permanent-Downhole Monitoring SystemsDocument6 pagesPermanent-Downhole Monitoring SystemsSanjyogNo ratings yet

- Water Chillers - Cooling SolutionsDocument6 pagesWater Chillers - Cooling SolutionsShan aliNo ratings yet

- Data Sheet Sla5800Document12 pagesData Sheet Sla5800Bhavmit AfricawalaNo ratings yet

- 9610 SC Silica Analyzer: Lower Maintenance, Less DowntimeDocument4 pages9610 SC Silica Analyzer: Lower Maintenance, Less DowntimeRangga TaufiqurahmanNo ratings yet

- Brookfield Process CatalogDocument24 pagesBrookfield Process CatalogenzopandolfiNo ratings yet

- Airpax 6700Document5 pagesAirpax 6700fpdaxNo ratings yet

- Endress-Hauser Cerabar S PMP75 ENDocument8 pagesEndress-Hauser Cerabar S PMP75 ENGleb RozhkovNo ratings yet

- Steam Quality AnalyzerDocument7 pagesSteam Quality Analyzerdaniel adamNo ratings yet

- Norwater As Brochure 2013Document16 pagesNorwater As Brochure 2013pramodtryNo ratings yet

- Product Specification VC25 SRV 12BDocument6 pagesProduct Specification VC25 SRV 12BAnuradha SivakumarNo ratings yet

- FMC PresentationDocument61 pagesFMC PresentationPrakash Chandran100% (1)

- Series 500 ValumassDocument4 pagesSeries 500 ValumassFrancoNo ratings yet

- Xylem Tank-Based Aquaculture Catalog Featuring YSI, Flygt, Wedeco and MoreDocument32 pagesXylem Tank-Based Aquaculture Catalog Featuring YSI, Flygt, Wedeco and MoreYSI, a Xylem brandNo ratings yet

- Custody transfer metering systems for crude oil pipelinesDocument23 pagesCustody transfer metering systems for crude oil pipelinesMOSES EDWINNo ratings yet

- ND OLR ProdSheet ENG-AL-1Document2 pagesND OLR ProdSheet ENG-AL-1hamsterNo ratings yet

- BR - HV Pass Family (En) D - 2gja708398 08.2013Document22 pagesBR - HV Pass Family (En) D - 2gja708398 08.2013hansamvNo ratings yet

- Sitrans CV: Accurate, Cost-Saving and Reliable Natural Gas Analyzer SITRANS CVDocument6 pagesSitrans CV: Accurate, Cost-Saving and Reliable Natural Gas Analyzer SITRANS CVpkbijuNo ratings yet

- Ati q45s SpecDocument4 pagesAti q45s SpecBulbul AhmedNo ratings yet

- CLS50Document16 pagesCLS50sopan saNo ratings yet

- Analiza-Termica BROSCHUREDocument68 pagesAnaliza-Termica BROSCHUREPiranha TourniquetNo ratings yet

- In-Line Electronic Flow Switches: Ameritrol Inc. Ameritrol IncDocument6 pagesIn-Line Electronic Flow Switches: Ameritrol Inc. Ameritrol IncRuben AlvaradoNo ratings yet

- Aqua Smart ManualDocument36 pagesAqua Smart ManualDan AdamsNo ratings yet

- Lauda PDFDocument6 pagesLauda PDFdaroo242003No ratings yet

- Flyer LabTouch-Aw EDocument2 pagesFlyer LabTouch-Aw EArturo EspinozaNo ratings yet

- Endress-Hauser Analog Chlorine Dioxide Sensor CCS50 ENDocument3 pagesEndress-Hauser Analog Chlorine Dioxide Sensor CCS50 ENTrân Nguyễn Đoàn QuếNo ratings yet

- Distek 6100Document2 pagesDistek 6100SutarnoNo ratings yet

- Water For Injection Measurements: Pharmaceutical IndustryDocument2 pagesWater For Injection Measurements: Pharmaceutical IndustryAhmad Adel El TantawyNo ratings yet

- Wellwatcher Flux: Multizonal Reservoir Monitoring SystemDocument2 pagesWellwatcher Flux: Multizonal Reservoir Monitoring Systemheqinghai heNo ratings yet

- HS2410 Rev5.0Document31 pagesHS2410 Rev5.0ChinhNo ratings yet

- 380K Portable TriGas AnalyzerDocument2 pages380K Portable TriGas AnalyzerGheorghe VasileNo ratings yet

- Aquion Prosystems Whole House Water Filter ManualDocument24 pagesAquion Prosystems Whole House Water Filter ManualGreg Reyneke100% (1)

- Kt8200datasheet GB2Document2 pagesKt8200datasheet GB2rani hindiNo ratings yet

- 100 Lab-1 SpectrophotometerDocument16 pages100 Lab-1 SpectrophotometerHamzah AlbrakaniNo ratings yet

- 9 BE0 BD 01Document6 pages9 BE0 BD 01Azka AiraNo ratings yet

- Introduction To Swas Steam and Water Analysis SystemDocument41 pagesIntroduction To Swas Steam and Water Analysis SystemvaishnaviNo ratings yet

- Pentair Rotary Valve Whole House Carbon Filter ManualDocument28 pagesPentair Rotary Valve Whole House Carbon Filter Manualsquadron2k19No ratings yet

- Ventil HC100 19BDocument6 pagesVentil HC100 19BLeandro HerreraNo ratings yet

- Clibration Laboratory LayoutDocument16 pagesClibration Laboratory Layoutjrlr65No ratings yet

- 5-Station Solid Block Bath for Gum TestingDocument1 page5-Station Solid Block Bath for Gum TestingSN Louis0% (1)

- TurbidityDocument4 pagesTurbidityVishalNo ratings yet

- Honeywell Sensing Temperature Sensors Line Guide 0 1109480Document12 pagesHoneywell Sensing Temperature Sensors Line Guide 0 1109480X'mix ĐreamerNo ratings yet

- Salt in Crude Analyser ASTM D3230 IP 265: Key Features Principles of OperationDocument2 pagesSalt in Crude Analyser ASTM D3230 IP 265: Key Features Principles of Operationابوالحروف العربي ابوالحروفNo ratings yet

- Brosur 9586 Hydrazine AnalyzerDocument4 pagesBrosur 9586 Hydrazine AnalyzerCahyo WicaksonoNo ratings yet

- Siemens MV Gas Insulated Switch GearDocument14 pagesSiemens MV Gas Insulated Switch GearSajesh Thykoodan T VNo ratings yet

- Honeywell Sensing Airflow Sensors Line Guide 008150 7 en PDFDocument6 pagesHoneywell Sensing Airflow Sensors Line Guide 008150 7 en PDFmoabdolyNo ratings yet

- Zonecheck BrochureDocument4 pagesZonecheck Brochuresai3942No ratings yet

- Amtax SC Ammonia AnalyzerDocument4 pagesAmtax SC Ammonia AnalyzerprannoyNo ratings yet

- Arabnet - KFAS - Hospitality Publication - ENDocument27 pagesArabnet - KFAS - Hospitality Publication - ENEdmond DsilvaNo ratings yet

- SO01090B60EN012021 Portfolio Brochure Food Beverages SCREENDocument48 pagesSO01090B60EN012021 Portfolio Brochure Food Beverages SCREENEdmond DsilvaNo ratings yet

- ChatGPT Cheat Sheet PDFDocument1 pageChatGPT Cheat Sheet PDFEdmond Dsilva0% (1)

- ChatGPT Marketing Cheat SheetDocument1 pageChatGPT Marketing Cheat SheetEdmond DsilvaNo ratings yet

- Technical Information Liquiline CM442/CM444/CM448Document60 pagesTechnical Information Liquiline CM442/CM444/CM448Edmond DsilvaNo ratings yet

- Technical Information Flexdip CYA112: Immersion Assembly For Water and WastewaterDocument24 pagesTechnical Information Flexdip CYA112: Immersion Assembly For Water and WastewaterEdmond DsilvaNo ratings yet

- Oxymax COS61DDocument16 pagesOxymax COS61DEdmond DsilvaNo ratings yet

- Solar and Wind Energy Trainer Llc-Swd-1X WL-13033-01 IMPOINTERDocument2 pagesSolar and Wind Energy Trainer Llc-Swd-1X WL-13033-01 IMPOINTERmartunasNo ratings yet

- CompressorDocument20 pagesCompressorS R Akhil KrishnanNo ratings yet

- Steam Turbine Maintenance Manual-1Document244 pagesSteam Turbine Maintenance Manual-1Trie Wahyudi100% (4)

- Solution: TET401: Material Engineering & ThermofluidDocument2 pagesSolution: TET401: Material Engineering & Thermofluidantima meena100% (1)

- Hydrogen as a Renewable and Secure Energy SourceDocument74 pagesHydrogen as a Renewable and Secure Energy SourceMario O.No ratings yet

- Chashma Hydro Power Plant Internship ReportDocument10 pagesChashma Hydro Power Plant Internship ReportSaeed Anwar KhanNo ratings yet

- Solar Updraft TowerDocument14 pagesSolar Updraft TowerAmeen OmerNo ratings yet

- NHPC Training ReportDocument85 pagesNHPC Training ReportShadab Khan100% (2)

- Chemistry Presentation On Renewable EnergyDocument17 pagesChemistry Presentation On Renewable EnergyReal NoobNo ratings yet

- ShipmentsDocument2 pagesShipmentsSaul ChampacNo ratings yet

- Printable Turbine To Make Electricity Out of WindDocument2 pagesPrintable Turbine To Make Electricity Out of WindHOLMANVELANDIANo ratings yet

- Level controllers for steam generators and pressurized tanksDocument2 pagesLevel controllers for steam generators and pressurized tanksArio BharataNo ratings yet

- Techno-Economic Comparative Analysis of Biomass Integrated Gasification Combined Cycles With and Without CO2 CaptureDocument12 pagesTechno-Economic Comparative Analysis of Biomass Integrated Gasification Combined Cycles With and Without CO2 CaptureMugdho HossainNo ratings yet

- Fuel Injection: Delphi Pump Diagnostic TroubleshootingDocument3 pagesFuel Injection: Delphi Pump Diagnostic TroubleshootingBryan Edu Curay ZavalaNo ratings yet

- Thermodynamic Cycles (Power Plant Engineering)Document6 pagesThermodynamic Cycles (Power Plant Engineering)Ravjit SinghNo ratings yet

- Testing Engine Blow-ByDocument11 pagesTesting Engine Blow-ByAdolfo Montes MorenoNo ratings yet

- Scope of Work for 400 Rooftop Solar PV Plants Totaling 40 MWDocument5 pagesScope of Work for 400 Rooftop Solar PV Plants Totaling 40 MWAbhishek SenguptaNo ratings yet

- Predicting performance curves for centrifugal pumps without OEM dataDocument17 pagesPredicting performance curves for centrifugal pumps without OEM datajack100% (1)

- Module 03 Vapor Compression RefrigerationDocument10 pagesModule 03 Vapor Compression RefrigerationUkas RiyupiNo ratings yet

- Propeller Turbine Vs Kaplan TurbineDocument26 pagesPropeller Turbine Vs Kaplan TurbineUmarKhan0% (1)

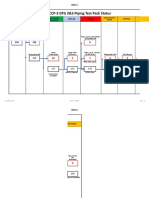

- GTG-3 Piping Test Pack ReviewDocument383 pagesGTG-3 Piping Test Pack Reviewasfaruk2556No ratings yet

- Capital Cost EstimatorDocument14 pagesCapital Cost Estimatoramirho3einNo ratings yet

- AC and Refrigeration PlantsDocument23 pagesAC and Refrigeration PlantsSyifa Alfiah Andini PutriNo ratings yet

- CPD Assignmnet 3 (CH-16059)Document3 pagesCPD Assignmnet 3 (CH-16059)Juni Sidd100% (1)

- Air Compressor ProblemsDocument9 pagesAir Compressor ProblemsChristian Diano100% (4)

- 1 s2.0 S036031991930014X MainDocument12 pages1 s2.0 S036031991930014X MainAmeen KhanNo ratings yet

- Technologies for Hydro Development in the Pacific NorthwestDocument31 pagesTechnologies for Hydro Development in the Pacific NorthwestMandar pachegaokarNo ratings yet

- Refrigeration and Air-Conditioning - Unit 3 - Week-2Document5 pagesRefrigeration and Air-Conditioning - Unit 3 - Week-2Kali DassNo ratings yet

- Paper-2 Set-A KeyDocument14 pagesPaper-2 Set-A Keydkhatri01No ratings yet

- Minimum Flow-MergedDocument39 pagesMinimum Flow-MergedRahul Chandrawar100% (1)