Professional Documents

Culture Documents

TD-esc-02-De-En-16-014 Rev001 Unloading Segments (DOS) Delivery On Site

Uploaded by

Felipe SilvaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TD-esc-02-De-En-16-014 Rev001 Unloading Segments (DOS) Delivery On Site

Uploaded by

Felipe SilvaCopyright:

Available Formats

Technical Information

Unloading segments (DOS) Delivery on site

Scope of application

This document applies to: International

Mechanical Induction Installation Update Precast concrete tower – Installation

Electrical Rotor blade Grid connection Concrete repair Precast concrete tower – Prestressing

BF 82 11 01 BF 97 17 01 BF 107 17 01 BF 122 25 01 BF 133 37 01

BF 82 17 05 BF 97 20 01 BF 107 23 01 BF 131 36 04 BF 137 24 01

BF 83 17 01 BF 97 20 02 BF 107 23 05 BF 131 36 05 BF 137 25 02

BF 83 17 02 BF 97 20 05 BF 107 29 05 BF 132 31 01 BF 147 31 01

BF 90 14 01 BF 102 17 01 BF 112 24 02 BF 133 27 01 BF 147 31 02

BF 90 14 02 BF 102 17 02 BF 120 33 01 BF 133 27 02 BF 147 36 01

Document details

Document ID TD-esc-02-de-en-16-014 Rev001 Unloading segments (DOS) Delivery on site

Confidentiality INTERNAL

Date Language DCC Plant/Department

2016-06-23 en DD Service Deutschland GmbH/Concrete Engineering

© ENERCON GmbH. All rights reserved.

Revision table

Revision Date Section Change

000 2016-04-14 - Document created

001 2016-06-23 3.1 Table value (8) modified

TD-esc-02-de-en-16-014 Rev001 Unloading segments (DOS) Delivery on site i

Technical Information

Unloading segments (DOS) Delivery on site

Table of contents

1 General information ...............................................................................................................1

2 Safety instructions .................................................................................................................1

3 Lifting tackle assembly for unloading segments .................................................................2

3.1 4-point lifting tackle assembly for unloading segments ......................................................2

3.2 3-point lifting tackle assembly for unloading segments ......................................................3

3.3 Lifting tackle assembly for complete segments..................................................................4

© ENERCON GmbH. All rights reserved.

TD-esc-02-de-en-16-014 Rev001 Unloading segments (DOS) Delivery on site ii

Technical Information

Unloading segments (DOS) Delivery on site

1 General information

This document illustrates how to attach the individual precast concrete tower segments. For this

purpose, shackles, round slings and load rings are used.

The manufacturing tolerance of the round sling length is ± 2 %. Because of this, there may be dif-

ferences in length between the individual legs in the lifting tackle assembly plans. The differences

can be balanced out by attaching shackles with the corresponding lifting capacity.

Be sure to read and understand all safety instructions before commencing work.

The diagrams are intended for illustration purposes only and may differ from the parts actually in-

stalled.

2 Safety instructions

Improper conduct in or around the WEC

Death or serious injury

ENERCON health and safety regulations apply.

Follow all relevant ENERCON instructions for safe use as well as the manufacturers’ operating

manuals and instructions.

Should the safety standards of the respective country be more stringent than those required by

© ENERCON GmbH. All rights reserved.

ENERCON, the national regulations apply.

TD-esc-02-de-en-16-014 Rev001 Unloading segments (DOS) Delivery on site 1 of 4

Technical Information

Unloading segments (DOS) Delivery on site

3 Lifting tackle assembly for unloading segments

3.1 4-point lifting tackle assembly for unloading segments

This leg is not used for unloading

one-third shells and half shells with 4

attachment eyes. It is used for the 3-

point lifting tackle assembly. For the

4-point lifting tackle assemblies, it is

OK to leave this leg on the crane

hook; however, make sure to lift and

fasten it.

© ENERCON GmbH. All rights reserved.

Position Required tools Quantity SAP number

1 25 t round sling, 6 m 2 SAP 77368

2 Bow shackle; hex-head pin, 35 t 2 SAP 32904

3 25 t round sling, 6 m 2 SAP 77368

4 Bow shackle; hex-head pin, 55 t 2 SAP 32906

5 Round sling; 15 t, 8 m in Ո shape 1 SAP 59668

4” shackle for textile slings with S-253 bolt, 20.5 t 4 SAP 114190

6 or

4 SAP 42420

bow shackle w/ hex-head bolt, 25 t

7 Segment load ring; RD52 LGR, 20 t 4 SAP 54479

8 Round sling; 15 t, 8 m in Ո shape 1 SAP 59668

TD-esc-02-de-en-16-014 Rev001 Unloading segments (DOS) Delivery on site 2 of 4

Technical Information

Unloading segments (DOS) Delivery on site

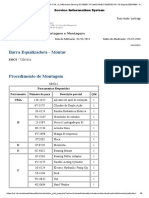

3.2 3-point lifting tackle assembly for unloading segments

© ENERCON GmbH. All rights reserved.

Position Required tools Quantity SAP number

1 25 t round sling, 6 m 2 SAP 77368

2 Bow shackle; hex-head pin, 35 t 2 SAP 32904

3 25 t round sling, 6 m 2 SAP 77368

4 Bow shackle; hex-head pin, 55 t 2 SAP 32906

5 15 t round sling, 4 m 2 SAP 42905

6 4” shackle for textile slings with S-253 bolt, 20.5 t 3 SAP 114190

or

bow shackle w/ hex-head bolt, 55 t 3 SAP 42420

7 Segment load ring; RD52 LGR, 20 t 3 SAP 54479

8 25 t round sling, 6 m 1 SAP 77368

9 Bow shackle; hex-head pin, 35 t 1 SAP 32904

10 25 t round sling, 6 m 1 SAP 77368

11 Bow shackle; hex-head pin, 55 t 1 SAP 32906

12 8 t round sling (8 m) on crane hook in U shape 1 SAP 48369

TD-esc-02-de-en-16-014 Rev001 Unloading segments (DOS) Delivery on site 3 of 4

Technical Information

Unloading segments (DOS) Delivery on site

3.3 Lifting tackle assembly for complete segments

© ENERCON GmbH. All rights reserved.

Position Required tools Quantity SAP number

1 15 t round sling (8 m) on crane hook in Ո shape 1 SAP 59668

2 Bow shackle; hex-head pin, 35 t 4 SAP 32904

3 25 t round sling, 6 m 4 SAP 77368

4” shackle for textile slings with S-253 bolt, 20.5 t 4 SAP 114190

4 or

4 SAP 42420

bow shackle w/ hex-head bolt, 25 t

5 Segment load ring; RD52 LGR 20 4 SAP 54479

6 15 t round sling, 4 m 2 SAP 42905

TD-esc-02-de-en-16-014 Rev001 Unloading segments (DOS) Delivery on site 4 of 4

You might also like

- Transfer: Workshop ManualDocument92 pagesTransfer: Workshop ManualmailforspamNo ratings yet

- WEFIC WELLHEAD Rig Book KOM-103013-03 REV 0Document258 pagesWEFIC WELLHEAD Rig Book KOM-103013-03 REV 0tongsabaiNo ratings yet

- Servicemanual Fluorostar 2nd EDDocument386 pagesServicemanual Fluorostar 2nd EDalex lzgNo ratings yet

- Solar Kit BrochureDocument2 pagesSolar Kit BrochureSolarKing2100% (1)

- 300-5617 Cooler DisassemblyDocument6 pages300-5617 Cooler Disassemblyharikrishnanpd3327No ratings yet

- H-005 Ecc Piping Design Instructions-Rev3Document39 pagesH-005 Ecc Piping Design Instructions-Rev3vermaakash22100% (1)

- Caterpillar Cat 320d2 Excavator Prefix XBB Service Repair Manual Xbb00001 and Up 1588418222Document23 pagesCaterpillar Cat 320d2 Excavator Prefix XBB Service Repair Manual Xbb00001 and Up 1588418222rayendraNo ratings yet

- Media Search - REHS2210 - Assembly Procedure For The 793D Off-Highway Truck (7000, 7006, 7960)Document383 pagesMedia Search - REHS2210 - Assembly Procedure For The 793D Off-Highway Truck (7000, 7006, 7960)Deyvi0% (1)

- Caterpillar Cat 320 GC Excavator (Prefix KTN) Service Repair Manual (KTN00001 and Up)Document21 pagesCaterpillar Cat 320 GC Excavator (Prefix KTN) Service Repair Manual (KTN00001 and Up)kfmuseddk75% (8)

- Connecting Rod Repair GuideDocument32 pagesConnecting Rod Repair GuideJorge Espinoza100% (1)

- Energypac Fashions Ltd. Monipur, Hpotapara, Gazipur Sadar, GazipurDocument2 pagesEnergypac Fashions Ltd. Monipur, Hpotapara, Gazipur Sadar, GazipurasmjewelNo ratings yet

- SINAMICS S120 Connectivity To EtherNet/IPDocument40 pagesSINAMICS S120 Connectivity To EtherNet/IPCharoon SuriyawichitwongNo ratings yet

- Installation Des Protections de Joint D'entraînement Final (4050, 4052, 7172, 7561) (REHS0010-12)Document23 pagesInstallation Des Protections de Joint D'entraînement Final (4050, 4052, 7172, 7561) (REHS0010-12)Laouini GhaithNo ratings yet

- Armado de Transmision 924G - 101803Document30 pagesArmado de Transmision 924G - 101803linko estradaNo ratings yet

- Instalar Blade PDFDocument20 pagesInstalar Blade PDFMauricio GonzalezNo ratings yet

- TD-esc-02-De-En-15-045 Rev002 Current Status of Investigations Into Service HoistsDocument5 pagesTD-esc-02-De-En-15-045 Rev002 Current Status of Investigations Into Service HoistsFelipe SilvaNo ratings yet

- 300-5617 Cooler AssemblyDocument13 pages300-5617 Cooler Assemblyharikrishnanpd3327No ratings yet

- Sauter Head Type Tool TurretDocument27 pagesSauter Head Type Tool TurretmaddyaugNo ratings yet

- Bench Test Procedure For A R2900G and R3000H Load Haul Dump TransmissionDocument18 pagesBench Test Procedure For A R2900G and R3000H Load Haul Dump TransmissionNELSON ASENJONo ratings yet

- Continuous Vertical Lift Spare PartsDocument14 pagesContinuous Vertical Lift Spare PartsManuel Alvidrez RodriguezNo ratings yet

- 6F2T0188 PDFDocument19 pages6F2T0188 PDFDwi SanjayaNo ratings yet

- Product Information: Air Impact WrenchDocument56 pagesProduct Information: Air Impact WrenchApoorva Vikram SinghNo ratings yet

- Asssemble Service Brake 14H ASEDocument10 pagesAsssemble Service Brake 14H ASEAlberto BastidasNo ratings yet

- Front Track Roller Frame - Install CAT D9TDocument5 pagesFront Track Roller Frame - Install CAT D9Tiwan nawiNo ratings yet

- 2.4 Meter 2 Piece Az/El Installation Instructions: 4096-476 October 15, 2002 Revision DDocument27 pages2.4 Meter 2 Piece Az/El Installation Instructions: 4096-476 October 15, 2002 Revision DRoberto RizaldyNo ratings yet

- Installation Calculation Report: New - Project FullDocument28 pagesInstallation Calculation Report: New - Project FullDino MahmutovićNo ratings yet

- Lắp bánh đà 3508Document6 pagesLắp bánh đà 3508huy trầnNo ratings yet

- Service Manual: KEH-P4010RDocument46 pagesService Manual: KEH-P4010RRobert PartNo ratings yet

- Track Master Link (Clamp) - Remove and Install - Systemone TrackDocument4 pagesTrack Master Link (Clamp) - Remove and Install - Systemone TrackRajan MullappillyNo ratings yet

- Assembly Procedure For R1600G Load Haul Dump (7000, 7960)Document28 pagesAssembly Procedure For R1600G Load Haul Dump (7000, 7960)Martin Delgado RiveraNo ratings yet

- DOC1304647Document11 pagesDOC1304647mediacampaigncc24No ratings yet

- Arme de La Bomba 330cDocument37 pagesArme de La Bomba 330cEckard GuendelNo ratings yet

- Guia Soporte de Producto Pro 8200EX - 8200S - 8210S - 8220S PDFDocument69 pagesGuia Soporte de Producto Pro 8200EX - 8200S - 8210S - 8220S PDFcaratulinNo ratings yet

- G43 UfDocument44 pagesG43 UfdwilhNo ratings yet

- PreviewDocument254 pagesPreviewIgor OkNo ratings yet

- PSS Pash DSP 00001Document3 pagesPSS Pash DSP 00001Regis RomaryNo ratings yet

- Company Profile 2021Document26 pagesCompany Profile 2021Sharad DangeNo ratings yet

- TD-esc-02-De-En-16-003 Rev000a Power Supply To Tendon Uncoiling DeviceDocument2 pagesTD-esc-02-De-En-16-003 Rev000a Power Supply To Tendon Uncoiling DeviceFelipe SilvaNo ratings yet

- Bomba de Lubricação Automatca de MarteloDocument53 pagesBomba de Lubricação Automatca de MarteloDaniel F BarrosNo ratings yet

- Sistema de Llenado Rápido CombustibleDocument22 pagesSistema de Llenado Rápido CombustibleHugo VillcaNo ratings yet

- 12165-70 - 1 Sundry Instr.Document328 pages12165-70 - 1 Sundry Instr.kodrysNo ratings yet

- Cambridge Audio Azur 640c Service ManualDocument34 pagesCambridge Audio Azur 640c Service ManualMartin Szathmári100% (1)

- Rosemount 3051 Press. FieldBusDocument20 pagesRosemount 3051 Press. FieldBusQuynhtnNo ratings yet

- Service Manual: Issue Date: 30 November 2004Document29 pagesService Manual: Issue Date: 30 November 2004CapitanSalamiNo ratings yet

- Si 912013914016Document10 pagesSi 912013914016Jordão JordãoNo ratings yet

- Climbing Formwork: July 2008, English Keep For Later Use!Document36 pagesClimbing Formwork: July 2008, English Keep For Later Use!Muamer Jasna ĐulovićNo ratings yet

- Job Card: 32-41-12-400-001-A - Installation of The NLG WheelDocument7 pagesJob Card: 32-41-12-400-001-A - Installation of The NLG WheelbillyNo ratings yet

- Ingersoll Rand 2130 Series Air Impact Wrench Product Information PDFDocument60 pagesIngersoll Rand 2130 Series Air Impact Wrench Product Information PDFGer DclNo ratings yet

- Hak Retrofit Instalacja EN ESDocument28 pagesHak Retrofit Instalacja EN ESiwo3211231No ratings yet

- Ed5 - E Floor Sand RammerDocument56 pagesEd5 - E Floor Sand RammerJeffrey ArandiaNo ratings yet

- DIS 8.6.1 Iris StopDocument26 pagesDIS 8.6.1 Iris StopAshraf Ismail HassenNo ratings yet

- Technical Information - CardanDocument10 pagesTechnical Information - CardanRafael MendesNo ratings yet

- d6t Track-Type Tractor STD, XL Differential Steering Gct00001-Up (Machine) Powered by c9 Engine (Sebp4963 - 45) - Barra Equalizadora - MontarDocument5 pagesd6t Track-Type Tractor STD, XL Differential Steering Gct00001-Up (Machine) Powered by c9 Engine (Sebp4963 - 45) - Barra Equalizadora - MontarDouglas FernandesNo ratings yet

- Bevel and Transfer Gears - AssembleDocument14 pagesBevel and Transfer Gears - AssembleIginio Malaver VargasNo ratings yet

- 15-ScanJet SC 15TW Instruction ManualDocument43 pages15-ScanJet SC 15TW Instruction Manualogurmehmetali07No ratings yet

- Boite DemontageDocument32 pagesBoite Demontageait mimouneNo ratings yet

- Assembly Procedure For The 793D Off-Highway Truck (7000, 7006, 7960) (REHS2210-22)Document248 pagesAssembly Procedure For The 793D Off-Highway Truck (7000, 7006, 7960) (REHS2210-22)Anderson Oliveira SilvaNo ratings yet

- Kenr8577 00 01 AllDocument20 pagesKenr8577 00 01 AlldavidNo ratings yet

- SIN 2348 Rev. K Service Instruction Manual 206B Driveshaft 2Document39 pagesSIN 2348 Rev. K Service Instruction Manual 206B Driveshaft 2kenji roberto santanaNo ratings yet

- 773e Off-Highway Truck Bda00001-Up (Machine) Powered by 3412e Engine (Sebp3401 - 105) - DocumentaciónDocument3 pages773e Off-Highway Truck Bda00001-Up (Machine) Powered by 3412e Engine (Sebp3401 - 105) - DocumentaciónCarlos Andres Campos TorresNo ratings yet

- Service Manual: Fm/Am Compact Disc PlayerDocument52 pagesService Manual: Fm/Am Compact Disc PlayerGsmHelpNo ratings yet

- TD Esc 02 de en 15 043 Rev001 Change in Resin SystemDocument2 pagesTD Esc 02 de en 15 043 Rev001 Change in Resin SystemFelipe SilvaNo ratings yet

- TJ Full Cage Kit Install: Parts ListDocument7 pagesTJ Full Cage Kit Install: Parts ListMark BarberaNo ratings yet

- Token Ring Technology ReportFrom EverandToken Ring Technology ReportNo ratings yet

- TD-esc-02-De-En-16-018 Rev000a Obligation To Wear Safety Goggles On Construction SitesDocument3 pagesTD-esc-02-De-En-16-018 Rev000a Obligation To Wear Safety Goggles On Construction SitesFelipe SilvaNo ratings yet

- TD-esc-02-De-En-15-038 Rev000 Concession For Construction Hoist Crossbeam Type 3000 and 4300Document2 pagesTD-esc-02-De-En-15-038 Rev000 Concession For Construction Hoist Crossbeam Type 3000 and 4300Felipe SilvaNo ratings yet

- TD-esc-02-De-En-16-020 Rev000 Changeover From Fine Grain To Coarse Grain Grout E-101 - BF - 97!17!01Document3 pagesTD-esc-02-De-En-16-020 Rev000 Changeover From Fine Grain To Coarse Grain Grout E-101 - BF - 97!17!01Felipe SilvaNo ratings yet

- TD-esc-02-De-En-16-007 Rev000 Implementation of Electrical Once-Off Instructions For MV - HV PremisesDocument3 pagesTD-esc-02-De-En-16-007 Rev000 Implementation of Electrical Once-Off Instructions For MV - HV PremisesFelipe SilvaNo ratings yet

- TD Esc 02 de en 16 017 Rev000a Air Flow Generator E 101 and E 115Document15 pagesTD Esc 02 de en 16 017 Rev000a Air Flow Generator E 101 and E 115Felipe SilvaNo ratings yet

- TD-esc-02-De-En-16-005 Rev000a Handling Permit To Work As Per en 50110 Part 1 For MV - HV SystemsDocument7 pagesTD-esc-02-De-En-16-005 Rev000a Handling Permit To Work As Per en 50110 Part 1 For MV - HV SystemsFelipe SilvaNo ratings yet

- TD-esc-02-De-En-13-027 Rev003a Delivery of Hazardous Substances or Goods For WECsDocument3 pagesTD-esc-02-De-En-13-027 Rev003a Delivery of Hazardous Substances or Goods For WECsFelipe SilvaNo ratings yet

- TD-esc-02-De-En-15-040 Rev000 Documenting Inspection of Load Bolts On 3 M - 3.8 M Steel Section CrossbeamDocument3 pagesTD-esc-02-De-En-15-040 Rev000 Documenting Inspection of Load Bolts On 3 M - 3.8 M Steel Section CrossbeamFelipe SilvaNo ratings yet

- TD-esc-02-De-En-16-006 Rev000 Handling of Permit To Switch For MV - HV SystemsDocument8 pagesTD-esc-02-De-En-16-006 Rev000 Handling of Permit To Switch For MV - HV SystemsFelipe SilvaNo ratings yet

- TD-esc-02-De-En-10-060 Rev010 List of Limit Values For E-58 To E-92Document26 pagesTD-esc-02-De-En-10-060 Rev010 List of Limit Values For E-58 To E-92Felipe SilvaNo ratings yet

- TD Esc 02 de en 10 004 Rev004 WEC ConfigurationDocument4 pagesTD Esc 02 de en 10 004 Rev004 WEC ConfigurationFelipe SilvaNo ratings yet

- TD-esc-02-De-En-10-001 Designation of Technical Documentation at ENERCON Service Center Rev004Document11 pagesTD-esc-02-De-En-10-001 Designation of Technical Documentation at ENERCON Service Center Rev004Felipe SilvaNo ratings yet

- Analysis and Computer Modelling of A Rate of ChangDocument7 pagesAnalysis and Computer Modelling of A Rate of ChangFelipe SilvaNo ratings yet

- 1719 10541 1 PBDocument9 pages1719 10541 1 PBFelipe SilvaNo ratings yet

- Analysis and Computer Modelling of A Rate of ChangDocument7 pagesAnalysis and Computer Modelling of A Rate of ChangFelipe SilvaNo ratings yet

- Muhammad Umair Ismail Mechanical Engineer: Cell Phone: EmailDocument2 pagesMuhammad Umair Ismail Mechanical Engineer: Cell Phone: EmailUmairIsmailNo ratings yet

- Viewsat Ultra Manual V01Document21 pagesViewsat Ultra Manual V01Frank BarrettoNo ratings yet

- NSN For XafpDocument25 pagesNSN For XafpTeget1975No ratings yet

- ShipRight - Design Code For Unmanned Marine Systems - 2017Document39 pagesShipRight - Design Code For Unmanned Marine Systems - 2017RISHABH JAMBHULKARNo ratings yet

- Lab Activity 6 - Bsece 3-1 - GomezDocument11 pagesLab Activity 6 - Bsece 3-1 - GomezChristian GomezNo ratings yet

- Ce 2766Document19 pagesCe 2766Alexe VictorNo ratings yet

- Automatic Transfer Switch ATS021: Installation and Operating Instructions 34ATS021 / 1SDH000759R0002Document36 pagesAutomatic Transfer Switch ATS021: Installation and Operating Instructions 34ATS021 / 1SDH000759R0002ase.olgaNo ratings yet

- Industrial Training Report GuideDocument4 pagesIndustrial Training Report GuideDhanush SNo ratings yet

- Case Study 1Document3 pagesCase Study 1ramtwinsmeNo ratings yet

- Bill Payment: Details On Breb (Prepaid) ConfigurationDocument12 pagesBill Payment: Details On Breb (Prepaid) ConfigurationMd Tanvir Hossain100% (1)

- MTK Modul 2 Pendalaman MateriDocument48 pagesMTK Modul 2 Pendalaman Materizul hendraNo ratings yet

- Digitised Industries Nagpur Region ListDocument203 pagesDigitised Industries Nagpur Region ListAnjani TewariNo ratings yet

- Seeding To A Plan: by ShivanaDocument31 pagesSeeding To A Plan: by ShivanaShivanagowda SannagowdarNo ratings yet

- Financial Proposal - 4unitsDocument33 pagesFinancial Proposal - 4unitsEyob AdNo ratings yet

- 04 CUDA Fundamental OptimizationDocument30 pages04 CUDA Fundamental OptimizationNagaraj SNo ratings yet

- Lebw4982 02Document52 pagesLebw4982 02alexanderponomarevNo ratings yet

- AMS Connection - PROFIBUS PA Via DP - PA Coupler - TopWorx Engineering WikiDocument10 pagesAMS Connection - PROFIBUS PA Via DP - PA Coupler - TopWorx Engineering Wikishafi ullaNo ratings yet

- Manual CN Lab 2017 PDFDocument71 pagesManual CN Lab 2017 PDFSuhas h rNo ratings yet

- Best Android 4Document17 pagesBest Android 4Ishan LakhwaniNo ratings yet

- Case 4Document2 pagesCase 4Anas Study Platforms iiuiNo ratings yet

- Instruction Set of 8085 MicroprocessorDocument3 pagesInstruction Set of 8085 Microprocessormadhan_21No ratings yet

- A Lucky Boy Seventh Grade Reading Worksheets Reading Comprehension Worksheets, Comprehension Worksheets, Reading WorksheetsDocument1 pageA Lucky Boy Seventh Grade Reading Worksheets Reading Comprehension Worksheets, Comprehension Worksheets, Reading WorksheetsAarav DesaiNo ratings yet

- 6 Plus Price in Pakistan - Google SearchDocument1 page6 Plus Price in Pakistan - Google SearchZeeshan UmraniNo ratings yet

- Cloud security and virtualized data center: Micro-segmentation assessmentDocument19 pagesCloud security and virtualized data center: Micro-segmentation assessmentmanishNo ratings yet

- An Introduction To: AndroidDocument14 pagesAn Introduction To: AndroidAbhiram HollaNo ratings yet

- 2g Audit TrakerDocument24 pages2g Audit TrakerPankaj KumarNo ratings yet