0% found this document useful (0 votes)

318 views7 pagesUnconfined Compression Test Guide

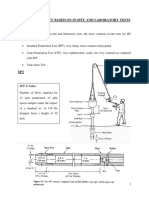

The unconfined compression test is a laboratory test that measures the unconfined compressive strength (UCS) of rock specimens without lateral pressure. Rock cores are sampled and prepared with smooth, flat ends in a cylindrical shape. The test applies increasing axial stress until failure while measuring axial and lateral deformation to determine elastic properties. At least 5 samples are tested to obtain a reliable UCS value for characterizing rock strength.

Uploaded by

amit kumar guptaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

318 views7 pagesUnconfined Compression Test Guide

The unconfined compression test is a laboratory test that measures the unconfined compressive strength (UCS) of rock specimens without lateral pressure. Rock cores are sampled and prepared with smooth, flat ends in a cylindrical shape. The test applies increasing axial stress until failure while measuring axial and lateral deformation to determine elastic properties. At least 5 samples are tested to obtain a reliable UCS value for characterizing rock strength.

Uploaded by

amit kumar guptaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd