Professional Documents

Culture Documents

Wood Toy News WOOD TOY NEWS ToymakingPlans Com Fun To PDFDrive

Wood Toy News WOOD TOY NEWS ToymakingPlans Com Fun To PDFDrive

Uploaded by

Zosmo Simiao CostaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wood Toy News WOOD TOY NEWS ToymakingPlans Com Fun To PDFDrive

Wood Toy News WOOD TOY NEWS ToymakingPlans Com Fun To PDFDrive

Uploaded by

Zosmo Simiao CostaCopyright:

Available Formats

WOOD TOY NEWS

Wood Toy News

February 4, 2014 Tuesday

How to Super Simple Play Pals

by Toymaker Susan Burkhart

Quickly Make

Multiple Toy

Parts Using

Router Bits.

by Imants Udris “Udie”

Even if you’ve never used a router bit or

are not familiar with routers you’ll want

to read this article. This may be a tool

you’ll want to add to your wood shop!

Some toy projects require making multiples of many Udie prepares to cut multiple

pieces. You also may want to make multiples of

specific toys. You can save a lot of time and reduce

Play Pals car bodies using a router bit.

the repetition of some steps and processes by

creating templates you can use with a router.

Watch the Video!

How to Quickly Make

Multiple Toy Parts Using Router Bits

Watch the step-by-step video on our

For this article Udie used the FREE* Super Simple Play Pals website at: http://ow.ly/tclO0

*The Play Pals plan set is free for a limited time.

plan set available on our website at www.toymakingplans.com.

1 February 4, 2014 Tuesday www.toymakingplans.com © 2014 continued next page ...

Wood Toy News

I’ll be describing and demonstrating the use of Making a Set of Router Templates STEP 1 - Make the Plywood Blanks

Flush Trim Router Bits. These are router bits with a

I’ll first make a set of router templates with 1/2” Start with 1/2” plywood to make your router

bearing on the top which follow a template, trimming

plywood sawn on a scroll saw, then I’ll use these templates. Check your scrap bin for pieces. Cut

the attached wood below it to the exact profile of the

templates to cut multiple parts with a 1/2” router. I’ll some blank boards

template. The template will be first created with my

explain all the steps in this article. to accommodate the

scroll saw. I’ll then use my scroll saw template to cut

maximum size of the

multiples of each part using my router bits.

These templates will be used with a router and paper pattern this

Let’s first start by taking a closer look at the router router table to make multiple Play Pals VW cars, plan set requires. In

bits. Here’s a 3/8” and a 1/2” bearing mounted flush Pickup Trucks, Mini Vans, Tractor Trailers and Bat 1/2” thick this case the finished

trim router bit: Cars from common 3/4” pine board stock and 3/4” plywood plywood blanks

MDF. scraps needed to be 2” x 4”.

Why was 1/2” plywood

selected for the

1/2” thickness of the Play

3/8” dia.

dia. Pals templates?

The thickness of the

template was driven

Above: 3/8” dia. flush trim router bit.

Right: 1/2” dia. flush trim router bit.

by the characteristics

of the selected router bit. A “Bearing Mounted

I’ll be making templates and then will cut multiple Flush Trim Router Bit” is required. This is a bit

parts from the templates using the Super Simple that has a bearing attached to one end. I could’ve

Play Pals Free plan set. These plans are free to set of router made templates out of 1/4” and 3/8” plywood, MDF

templates cut

with a scroll saw or hardboard if desired. I’ll explain why below.

plywood

Above: A set of Play Pals templates cut with a scroll saw from template

1/2” thick plywood.

VW Bug

by Toymaker Susan Burkhart 1/32”

bearing router cutting

blades

1/2” dia. bearing

mounted flush trim

router bit

download and use from the ToymakingPlans.com

website for a limited time. Look for the “5 Free Full

Here is a 1/2” bearing mounted flush trim router bit

Size Wood Toy Plans” box on the website home

My VW Bug went from a rough cut piece of wood to positioned on a piece of 1/2” plywood. Two (2) lines

page and click on the “Download Now” button.

a finished cut out vehicle using the following steps are drawn on the green tape, one is 1/4” from the

Enter your email address to download your FREE

and materials. bottom edge of the plywood and the upper line is

Super Simple Play Pals plan set today.

2 February 4, 2014 Tuesday www.toymakingplans.com © 2014 continued next page ...

Wood Toy News

3/8” from the bottom edge. Notice the gap between radius. For example, the rear section of the Bat Car stock material for cutting.

the bottom edge of the bearing and the top of the requires a smaller diameter router bit. You can try

router cutting blades. On this bit the gap is quite the 1/2” router bit first and change to the 3/8” router STEP 3 - Attach the Paper Pattern

small around 1/32”, and the distance from the top bit if necessary. Safety is the main reason these This step is very straight forward and you may have

edge of the bearing to the top of the cutting blades templates were made from 1/2” plywood. Plus the done it hundreds of times. Different methods involve

is about 3/16”. What this means is there would be fact my scrap bin had no 3/8” stock, only 1/2”. brushing glue on to the back of your paper pattern,

no problems using this flush trim router bit with any printing on peel-n-stick labels or spraying on an

1/4” , 3/8” or 1/2” thick template. The bearing has a Bat Car

by Toymaker Susan Burkhart adhesive. All of these methods work successfully.

sufficient amount of wood to make contact with and

ride along the edge of the template for safe use. Here’s a tip to save a little money on pattern

adhesion. Thanks to Ken Martin, another

Below is the 3/8” Flush Trim router bit positioned ToymakingPlans.com woodworker for passing this

against the tip along. Ken likes to use this method regularly.

same piece of Whether you are applying glue or using a spray

marked 1/2” adhesive stop looking for old newspapers and use

plywood. a magazine. Why use these magazines such as the

Remember, the It’s very important to always remember it’s

1/8” SAFETY FIRST when freehanding stock on the Renters Guide magazine

3/8” dia. lower line is 1/4”

bearing router table. shown here?

mounted flush from the bottom

trim router bit edge and the They’re free! Most grocery

upper line is 3/8”. STEP 2 - Prepare the Wood Blank for stores have racks of free

the Paper Pattern advertising magazines for

This is where it is important to understand the renting, home buying, etc.

characteristic of each of your router bits. Notice Here’s a tip: Apply a strip of clear packing tape to

the surface of the stock before attaching the paper located at the exit doors.

the gap between the bottom edge of the bearing in Pick up one or two and keep

relation to the top edge of the cutting blades. pattern. The packing tape acts as a lubricant for

the scroll saw blade when cutting. them in your workshop for

On the 3/8” flush trim router bit, this gap is much your next gluing project.

larger, at least 1/8”, and the distance to the top of When removing

the bearing is 1/4” to 5/16”. A 1/4” thick template the paper pattern,

it’s much easier Watch the Video!

should never be used with this router bit. The

bearing doesn’t allow for a sufficient amount of to peel the paper

wood to make contact with and follow safely around pattern and the

the template profile. packing tape off

at the same

It is much safer to use a piece of 3/8” plywood for time. There is no

the templates if using this router bit. The bearing will residual adhesive

have a safe amount of wood to make contact with to remove. This How to Quickly Make

and follow the template. process works not Multiple Toy Parts Using Router Bits

When creating toy templates the 1/2” Flush Trim only for making

router bit works great and does the job. Change router templates. Watch the complete step-by-step video

router bits for template profiles with a smaller It can be used for attaching paper patterns to any on our website at: http://ow.ly/tclO0

3 February 4, 2014 Tuesday www.toymakingplans.com © 2014 continued next page ...

Wood Toy News

paper pattern The paper pattern is attached to the 1/2” plywood STEP 5 - Transfer Template’s Footprint

template wood blank. to 3/4” Stock Pine

Check your scrap bin again for a piece of 3/4”

thick pine board and some 3/4” MDF. Rather than

adhering cut out paper patterns to stock wood,

save time by tracing the template footprint of the

VW Bug multiple times. These will become rough

STEP 1 - Cut the Template Pattern

Open the magazine, place your paper pattern The VW Bug router template shown below has been

and apply your adhesive with glue or spray to the cut using the scroll saw. The template has been

backside as you normally do. The tip is to simply sanded to ensure a smooth edge for the bearing of

flip the page over and now you have a new clean the flush trim router bit to follow.

surface to glue or spray your second paper pattern. cut patterns that will be sawn to exact size later

Keep the magazine in the shop on standby for the when using your router bit.

next gluing or spraying job. When all the pages Multiple patterns can be quickly laid out for the

are stuck together discard the magazine and start best usage of the wood and preferred grain

a new one. There is no cost to you because the directions hence reducing waste. If you know you’ll

magazines were free. You have eliminated that be making many of these toys a solid template will

pile of old newspapers in your workshop. You don’t come in handy for quick rebuilds.

have to look for a clean spot to work and you’ve

contained the mess. These magazines are also STEP 6 - Cut Out the Rough Shapes

handy for painting jobs.

But … there are a couple of other handy things you

can do to this template at this stage.

Using a 5/64” drill bit, drill holes in the template

where the center of the axles will be and the

center location rough

for the vehicle’s cut parts

window. The drill bit

diameter selected

allows you to use

Here, the spray adhesive is applied to the VW Bug 1-1/4” finishing nails

paper pattern. in a future step.

4 February 4, 2014 Tuesday www.toymakingplans.com © 2014 continued next page ...

Wood Toy News

Using a band saw or a scroll saw with a coarse

tooth blade, a rough outline of the VW Bug can be Why Use Router Templates? I used a router template to make these

cut out quickly. Extra cut outs can be made while at wagon bench wheels with complex interior cuts and NO sanding!

This simple template cutout demonstrates the steps we’ve been

discussing. The time and effort you can save is more obvious when

you have to duplicate multiple items that are more complex, larger

patterns as well as toys

notice the interior

that include inside cutouts. radiuses from using

no interior By using the router you’ll a router bit

radiuses eliminate or greatly reduce

the time needed for sanding.

In the photo on the left notice

the rough cutouts for the wheel

spokes. The template cutouts

near the hub and on the inside

rough edge of the outer rim are not

cut parts

rounded. They don’t have to

be. The bearing mounted flush

the saw. I like using a band saw for rough cutting. trim bit will do that for you.

Above: My rough cut wagon wheels

It’s a wonderful tool that cuts through thick stock This is where a lot of time and

effortlessly. My rough cut stack of Play Pal cars effort can be saved. The router makes a clean cut and practically

and trucks are ready for the next step. I’ll be using eliminates any additional need for sanding. You can go right to the

my original sanded scroll saw template to quickly painting stage.

and easily convert these rough cut parts to finished

parts ready to be painted or stained.

STEP 7 - Attach the Template to the Rough Cut Out

Attaching the template is quite simple: a couple The wood template is now securely mounted to the

Watch the Video!

strips of double-sided tape does the job. rough VW Bug cut out. Notice the ledge of visible

wood around the entire template.

template

rough

How to Quickly Make cut part

Multiple Toy Parts Using Router Bits

Watch the complete step-by-step video

on our website at: http://ow.ly/tclO0 ledge

5 February 4, 2014 Tuesday www.toymakingplans.com © 2014 continued next page ...

Wood Toy News

STEP 8 - Route the Rough Cut with the the cutting blades don’t extend past the diameter While keeping a constant pressure against the guide

Wood Template of the bearing. You will not cause any damage to pin at point ‘C’, pivot the work piece into the spinning

your template because the diameter of the bearing router bit shown by the direction of arrow number ‘1’.

WARNING: Using a router mounted in a router is exactly the same diameter of the diameter of the By gradually applying pressure into the router bit, the

table with an exposed high RPM spinning bit can cutting blade. Lock this setup in place. wood of the rough cut part will be removed until the

be quite dangerous. If you are uncomfortable Install the guide pin (below). This is a very important router bearing makes contact with the template. The

with this – DON’T DO IT! Freehand routing and step. The guide pin provides a solid contact point dot at the tip of arrow number ‘1’ is the starting point.

small template routing can be very dangerous. allowing you to pivot the wood piece into the router Feed the wood towards the guide pin (to the left). You

This method is not for a novice, but for more bit safely, while maintaining total control. Without the can refer to the video to see this action more clearly.

advanced toymakers who have experience guide pin there is a high possibility small pieces could wood

using a router table and understand its torque be ripped out of your hands as you feed the wood into template

potentials and dangers. the router bit. Your fingers could easily be drawn into

router

Novices should always start with much larger the spinning router bit during the same occurrence. bearing

size templates first. Gaining experience,

understanding the process and getting a feel for

guide

their tool and its strengths and hazards is critical. pin

I offer a tip at the end of this article on how you can

router

make a jig that adds additional safety measures blade

when cutting smaller parts such as the Play Pals

cars and trucks bodies.

Install the flush trim router bit in the router following

the manufacturer’s instructions. Raise the router

bit so that the entire thickness of the bearing will

be making contact with the wood template. You

will notice that a small part of the router bit cutting Position the edge of the rough cut blank against the rough cut part

blades should be above the thickness of the stock guide pin, making a solid contact at point ‘C’ (below).

material you will be routing. That’s okay because

wood

Watch the Video!

template

point C

How to Quickly Make

Multiple Toy Parts Using Router Bits

rough cut part Watch the complete step-by-step video

on our website at: http://ow.ly/tclO0

6 February 4, 2014 Tuesday www.toymakingplans.com © 2014 continued next page ...

Wood Toy News

Once you have completed following the template the job is done. Inspect your work to ensure it’s acceptable

and that you did follow the template. If not go over the area again and clean it up. Remove the wood

template from the final part and attach it to another rough cut part and repeat the process.

template removed

wood template

final part routed with paper template

from the rough cut removed

Once the bearing is in contact with the template, STEP 9 - Sand the Edges

router the rough cut part in the direction of arrow The only things left to sand are the edges of the car body profile and a light pass over the routed surfaces.

number ‘2’ until you reach the beginning of the curve Using 150 grit sandpaper I removed the sharp edges of the profile. The router does a wonderful job

(above). Remember while doing this you are still following the template and keeps all the surfaces nice and smooth. Prior to painting there will be an

keeping a constant pressure of the rough cut part inspection of the cutouts and additional sanding if necessary.

blank against the guide pin. This greatly reduces

the risk of the wood from being ripped out of your Now, let’s get this VW Bug finished! In the next steps I’ll drill the holes for the wheel axles and car window.

hands. And I’ll share more router tips.

Once you have completed this step you can safely

remove the guide pin and continue routing, following

the template. Take your time. You can move the

rough cut part away from making contact with the

router bit at any time. Reposition your hands for a

better grip. Take a break and then gently feed the

rough cut part until the bearing makes contact with

the template where you have previously removed

wood and continue from that point.

This is very important to remember: Do not try to

feed the wood into an area that has not been routed. VW Bug

It could easily be ripped from your hands. The by Toymaker Susan Burkhart

bearing must make contact with the template before

you continue following the template.

7 February 4, 2014 Tuesday www.toymakingplans.com © 2014 continued next page ...

Wood Toy News

STEP 10 - Mark Locations of Axle and Now these parts can be drilled for the axles and Each time you drill a hole, move your work piece

Window Holes window. to a new location on the backer board. Try not to

Marking the hole locations for the axles and windows drill through and into an existing hole in the backer

is straight forward. board that defeats the purpose of the backer board.

Watch the video to see how I use the backer board

Insert the 1-1/4” finishing nails into the pre-drilled to prevent tear out.

holes from Step 1 and give each nail head a tap

with the hammer. Remove the nails and remove the You will know when you have drilled through the part

wood template from the final part and repeat the and are beginning to drill the backer board because

process on the next cutout part. the wood chips of the backer board will spiral up and

My actual process is to mark the locations just after out of the hole. You can watch me doing this in the

routing the part while the template is still adhered video. Usually these chips will be a different color.

to the cutout. The video shows me doing this after If there is any tear out after drilling the axle holes,

each piece has been routed and before the wood this is not a big deal. The wheel will hide this small

template was removed. imperfection. But ‘tear out’ after drilling a window

detail is not a result you want to see. That is why

you must drill from both sides of the cutout.

For the window hole, set the depth stop of the

drill press so that the tip of the brad point bit just

penetrates through the work piece. This makes a

STEP 11 - Drill Axle Holes and Window little hole that will assist in aligning the Forstner bit

I used a 1/2” Forstner bit for the windows and a 1/4” center tip. Continue drilling from the opposite side.

Brad Point bit for the axle holes in the drill press.

Using a flat piece of backer board is very important In the video you can see I experienced a little problem

when drilling the part. The backer board helps with the depth gauge not holding its position. I had

reduce and in most cases eliminates tear out as the to redrill a couple of times after readjusting the

bit passes through the wood. depth stop gauge. But the hole was nice and clean

with no tear out.

Watch the Video! 1/4” brad

point bit If a 1/2” straight drill bit is used instead of a Forstner

1/2” bit, it might help to pre-drill a small hole in the wood

forstner bit template for the window’s location. You can use a

5/64” drill bit. Drill completely through the cutout.

Don’t be concerned about tear out, but still use a

backer board. This will allow you to drill the window

How to Quickly Make detail from one side. About half way through the

Multiple Toy Parts Using Router Bits thickness of the wood flip the wood over and let the

5/64” hole on the other side guide the tip of the 1/2”

drill bit into position. Continue drilling from this side.

Watch the complete step-by-step video

on our website at: http://ow.ly/tclO0

If your guide hole was drilled correctly, you will have

a perfectly located and drilled window detail.

8 February 4, 2014 Tuesday www.toymakingplans.com © 2014 continued next page ...

Wood Toy News

NOTE: I used a round 1/2” drilled hole for my VW BONUS ROUTER SAFETY TIPS

Bug window. You may want to drill a small hole and

scroll saw out the car window with the paper pattern If you are uncomfortable having your fingers so

in place. close to the exposed router bit while it is mounted in

the router table, here is a tip for you.

scroll sawed

window • Attach a piece of 1/4 “clear Plexi-glass to your

VW Bug

by Toymaker Susan Burkhart template.

• Screw it down permanently with two or more

screws.

• Now you will be able to run the wood piece along

the router bit bearing … with your fingers safely

away from the bit, while still maintaining total control

over the work piece.

• Don’t be concerned about damaging the template

STEP 12 - Results with the screw holes, it can be replaced with little effort.

Let’s review the steps and the final results:

• From the paper pattern (top left corner in photo

right), we mounted the pattern onto a plywood blank

to make the complete Play Pals template set.

• Then each vehicle template was cut out using the

scroll saw and sanded until the profile was exactly

what we wanted.

• The templates were then pre-drilled for the axle template.

and window hole locations.

• Using 150 grit sandpaper I sanded over the profile

• Each vehicle shape was traced onto the selected removing the sharp edges.

wood and the router wood templates were mounted

• The axle holes were drilled using a 1/4” Brad

onto these rough cut wood parts.

Point bit. The window detail was drilled using a 1/2”

• A 1/2” Bearing Mounted Flush Trim router bit was Forstner bit.

installed into a router table.

• That’s it … the routing is done.

• The proper height of the router bit was adjusted so

• This is how easy it is to make multiple sets of

that the entire bearing was making contact with

the FREE “Super Simple Play Pals” plans from

the template and locked into position.

ToymakingPlans.com.

• Wearing eye protection and hearing protection, the

• The cut out toys are now ready for painting and

rough cut part was routed following the profile of the

final assembly.

9 February 4, 2014 Tuesday www.toymakingplans.com © 2014 continued next page ...

Wood Toy News

• Pre-drill the screw holes in the wood template to better than the original template. Notice the nice

prevent splitting. radius where the truck’s cab meets the truck’s bed.

This was not on the original template. A bearing

mounted bit was used routing into the corners.

Next, mount a new rough cut blank of 1/2” plywood

with double sided tape to the original template.

The best part of using a piece of clear plexi-glass is Finally, adjust the height of the bearing mounted flush You can watch me in the video make the plexi-glass

you can see exactly what you are doing. trim router bit in the router table and continue to route jig and use the jig to cut the wood toy part on the router

a new template. Your hands and fingers will be at a

For the Pick Up Truck below I drilled three (3) holes

safe distance at all times and away from the spinning BEARING MOUNTED FLUSH TRIM ROUTER BIT

in the plexi-glass to secure the screws. Then I

router bit. Remember to keep the work piece flat on CHARACTERISTICS

placed the plexi-glass over the wood template and

the router table when following the template’s profile.

marked the holes to be drilled in the wood template. Below is a test piece which includes most of the

Once routing is completed, remove the screws

I set the plexi-glass aside and pre-drilled the holes profiles commonly found in templates. This piece

holding the plexi-glass to the template and detach

directly into the original wood template to reduce the includes round cutouts, a square cutout, a triangular

the routed piece from the template.

possibility of splitting the plywood. I then screwed cutout, straight edges, outside corners and a

the plexi-glass to the wood template. Quick – easy – and simple – and most importantly, diagonal outside edge. Let’s see how each profile

pre-drill holes in finished with safety in mind. was made.

your template wood template wood template

This replacement Pickup Truck template is even

Watch the Video!

rough cut part final routed part

ready for router

How to Quickly Make

Multiple Toy Parts Using Router Bits

Watch the complete step-by-step video

on our website at: http://ow.ly/tclO0

10 February 4, 2014 Tuesday www.toymakingplans.com © 2014 continued next page ...

Wood Toy News

The first thing you’ll notice is that the square cutout mounted flush trim router bit will reduce and possibly

in the final routed part doesn’t have square inside eliminate the need for additional edge surface

final routed

corners. The triangular cutout also does not have part with inside sanding. So remember your results will only be as

a square inside corner in the finished piece. Each diameter good as your template. Any flaws in the template

corner exhibits a small radius. will be reproduced on each routed piece.

Square inside corners are not possible when using Making a set of router templates to create the fleet

a bearing mounted flush trim bit. The reason for this of Play Pal vehicles can be a big time-saver. We

is the router bit bearing diameter is 1/2”. Therefore hope you found this article helpful as an introduction

to the procedure of making router templates and

using your router table to make multiples parts and

original

wood template

profiles. Be sure to watch the video! Download your

copy of the FREE Play Pals plans to make your

own fleet of vehicles at www.toymakingplans.com.

A smaller bit was considered when making the Bat Udie can be contacted at: udris@cogeco.ca

Car tail profile. After comparing the results against the Visit www.toymakingplans.com and download your

original paper template and the wood template, there free Play Pals plan set today!

1/2” dia. bearing

was no need to change the 1/2” bit to a 3/8” bit.

mounted flush The resulting tail section profile for both the MDF

trim router bit

stock and Pine Stock were quite acceptable.

While looking at

the other profiles

the cutting edges of the bearing mounted flush trim of the test piece

bit would also be 1/2” in width. The smallest radius you can see

this bit can produce would be a 1/4” radius in each that the router

square corner. (Radius = diameter divided by 2. In bit followed the

this case it was 1/2” ÷ 2 = 1/4”). Changing to a 3/8” template perfectly,

bearing mounted flush trim bit would reduce the mimicking each

radius to 3/16” (3/8” ÷ 2 = 3/16”). outside corner,

Bat Car rounded cutouts,

using a 1/2” the diagonal edge

A smaller router bit and all inside and

bearing outside straight

diameter edges. This is what a bearing mounted flush trim bit

results in a is capable of producing. When used with a template,

smaller inside the results are 100% repeatable.

3/8” dia. bearing cut radius.

mounted flush The router is the perfect tool when making multiple Play Pals

trim router bit piece parts or outside edge profiles. The bearing by Toymaker Ken Martin

11 February 4, 2014 Tuesday www.toymakingplans.com © 2014 continued next page ... 11

You might also like

- Boxes. Bowls and BasketsDocument116 pagesBoxes. Bowls and BasketsPatricia Arias G100% (4)

- Wooden Puzzle Vault GIZSIP 327278258Document3 pagesWooden Puzzle Vault GIZSIP 327278258magoleija2010100% (1)

- Pinewood Derby Jeep Pattern 1Document1 pagePinewood Derby Jeep Pattern 1Patricia CardosoNo ratings yet

- Strat - Template Illustrated Reader Spreads PDFDocument20 pagesStrat - Template Illustrated Reader Spreads PDFlittlericky100% (2)

- Digital Patterns: Designed by Steve GoodDocument5 pagesDigital Patterns: Designed by Steve GoodEmilian Baluta100% (1)

- Human Figure Drawing (PDFDrive)Document10 pagesHuman Figure Drawing (PDFDrive)Lai Teo KuanNo ratings yet

- 101 Gag Ideas - Companion To The One Minute Caricature (PDFDrive)Document188 pages101 Gag Ideas - Companion To The One Minute Caricature (PDFDrive)Lai Teo Kuan100% (1)

- Wooden Toy Spacecraft: Explore the Galaxy & Beyond with 13 Easy-to-Make Woodworking ProjectsFrom EverandWooden Toy Spacecraft: Explore the Galaxy & Beyond with 13 Easy-to-Make Woodworking ProjectsRating: 5 out of 5 stars5/5 (1)

- AK Interactive - AK Learning Series 09 - Buildings in Dioramas The Ultimate Guide To MakeDocument92 pagesAK Interactive - AK Learning Series 09 - Buildings in Dioramas The Ultimate Guide To MakeAgustin Maldonado Octavio100% (12)

- Scroll Saw ClocksDocument5 pagesScroll Saw Clocksrichardppz124100% (1)

- DecalArt MikeNMolly Dairyland 1Document16 pagesDecalArt MikeNMolly Dairyland 1Sergei100% (1)

- AMS 2649 - Rev - CDocument7 pagesAMS 2649 - Rev - CRathnakumara Kemmara100% (1)

- Digital Patterns: Designed by Steve GoodDocument10 pagesDigital Patterns: Designed by Steve Goodhulusi67No ratings yet

- Tree Puzzle Pattern: Size To Thickness of Your StockDocument1 pageTree Puzzle Pattern: Size To Thickness of Your StockGeorgeta Tuță100% (2)

- Whatnot Dish: The Ideal Gift BowlDocument5 pagesWhatnot Dish: The Ideal Gift BowlMarcos R. Hernández M.No ratings yet

- Wooden Toy TruckDocument1 pageWooden Toy TruckRon Rivas100% (1)

- Making A Prallel Jaw Bar ClampDocument34 pagesMaking A Prallel Jaw Bar ClampHomayoon GeramifarNo ratings yet

- Wooden Construction ToysDocument6 pagesWooden Construction ToysDaniel RodriguezNo ratings yet

- Mustang Rocking Horse: John W. Designs and Builds TheDocument11 pagesMustang Rocking Horse: John W. Designs and Builds ThemazarocomazarocoNo ratings yet

- 1912 Ford Model TDocument12 pages1912 Ford Model TLeonardo Santos GomesNo ratings yet

- Gergaji Triplek PDFDocument7 pagesGergaji Triplek PDFriorhaNo ratings yet

- Coffe TableDocument15 pagesCoffe TableJun Vargas100% (1)

- PF940C™ Pistol Frames, 80% Instructions: Please Read The Instructions Completely Before Doing Any WorkDocument17 pagesPF940C™ Pistol Frames, 80% Instructions: Please Read The Instructions Completely Before Doing Any Workjferrell4380No ratings yet

- Wood Working Plans - Toys - Rocking Horse PDFDocument6 pagesWood Working Plans - Toys - Rocking Horse PDFBen GerezNo ratings yet

- Toys Bi-Plane PlansDocument14 pagesToys Bi-Plane PlansMatija Repinc100% (1)

- 003 May 1988Document24 pages003 May 1988Glodean100% (1)

- With A Finger-Safe Hinge On The Roof, An Operabl em Exit and A Working Sign This Incredibly Cut S Busisasaf Bet For y Gift ListDocument6 pagesWith A Finger-Safe Hinge On The Roof, An Operabl em Exit and A Working Sign This Incredibly Cut S Busisasaf Bet For y Gift ListJuanRodriguezNo ratings yet

- Quick N Easy Super TrainDocument48 pagesQuick N Easy Super TrainJean PoirierNo ratings yet

- DM Idea: Tiny Scroll Saw BowlsDocument2 pagesDM Idea: Tiny Scroll Saw BowlsmatteoNo ratings yet

- Quick & Easy Scroll Saw Toy Patterns - John W. & Cynthia A. LewmanDocument29 pagesQuick & Easy Scroll Saw Toy Patterns - John W. & Cynthia A. Lewmanrhgnicanor100% (1)

- Digital Patterns: Designed by Steve GoodDocument9 pagesDigital Patterns: Designed by Steve GoodGlodeanNo ratings yet

- Planos para DP571 Victorian QueenDocument24 pagesPlanos para DP571 Victorian QueenJosue SantiagoNo ratings yet

- Digital Patterns: Designed by Steve GoodDocument10 pagesDigital Patterns: Designed by Steve GoodWilson Roberto de OliveiraNo ratings yet

- Wooden 3D PuzzleDocument2 pagesWooden 3D PuzzleWilson Roberto de Oliveira100% (1)

- 19 Scroll Saw Patterns: Wooden Toy Plans HomeDocument27 pages19 Scroll Saw Patterns: Wooden Toy Plans HomeHülya HanımNo ratings yet

- How To Draw With Colored Pencils On Toned Paper - in Realistic StyleDocument30 pagesHow To Draw With Colored Pencils On Toned Paper - in Realistic StyleLai Teo Kuan50% (2)

- Army Jeep: Finished Puzzle Size 1" Thick X 6-7/16" Tall X 10-1/2" WideDocument3 pagesArmy Jeep: Finished Puzzle Size 1" Thick X 6-7/16" Tall X 10-1/2" Widehulusi67No ratings yet

- ScrollSaw Woodworking & Crafts - 2019 - 75 - SummerDocument92 pagesScrollSaw Woodworking & Crafts - 2019 - 75 - SummerNikolai Paskar100% (1)

- Bowl Basics 2Document5 pagesBowl Basics 2api-522254901No ratings yet

- Digital Patterns: Designed by Steve GoodDocument6 pagesDigital Patterns: Designed by Steve GoodAntonio Carlos Basso100% (1)

- Intarsia TeddyDocument12 pagesIntarsia TeddyramjoceNo ratings yet

- Planos de Juguete de Madera, Perrito en AutoDocument15 pagesPlanos de Juguete de Madera, Perrito en Autokevineli100% (1)

- Digital Patterns: Designed by Steve GoodDocument3 pagesDigital Patterns: Designed by Steve Goodrichardppz124No ratings yet

- 73 Toy Trucks From 2x4s Full Sized PatternsDocument4 pages73 Toy Trucks From 2x4s Full Sized PatternsJuanRodriguezNo ratings yet

- City CarDocument9 pagesCity CarDominique VoirinNo ratings yet

- Plywood ProjectDocument2 pagesPlywood ProjectWellingtonNo ratings yet

- Tren de BloquesDocument26 pagesTren de Bloquesmecrishatt100% (1)

- Peg Solitaire PuzzleDocument4 pagesPeg Solitaire PuzzleMayur GurikarNo ratings yet

- Sheilalandrydesigns Free Pattern SampleDocument5 pagesSheilalandrydesigns Free Pattern Samplemedomx100% (2)

- Old-Fashioned Push-Along Toys: Running Rosy Making The ToyDocument8 pagesOld-Fashioned Push-Along Toys: Running Rosy Making The ToyRamon RamosNo ratings yet

- 4 X 4 Off RoaderDocument6 pages4 X 4 Off Roaderhulusi67100% (1)

- Scroll Saw PatternDocument3 pagesScroll Saw Patternachtungbaby-ace50% (2)

- Wooden Puzzle Box PDFDocument18 pagesWooden Puzzle Box PDFBen GerezNo ratings yet

- 2 X 4Document2 pages2 X 4hulusi67No ratings yet

- RTR - Assembly Instruction Butt-And-Wrap Lamination Joint (16 Bars) - BONDSTRANDDocument8 pagesRTR - Assembly Instruction Butt-And-Wrap Lamination Joint (16 Bars) - BONDSTRANDPiping_Specialist100% (15)

- Adding An Epoxy InlayDocument2 pagesAdding An Epoxy InlayarenasrubenNo ratings yet

- Digital Patterns: Designed by Steve GoodDocument4 pagesDigital Patterns: Designed by Steve GoodRichard PerezNo ratings yet

- Lloyds Man TGX 1Document71 pagesLloyds Man TGX 1Luis Miguel Grados AzabacheNo ratings yet

- Wooden CalendarDocument5 pagesWooden CalendarCathy Linares100% (1)

- Relogio Patricia PDFDocument9 pagesRelogio Patricia PDFWilson Roberto de OliveiraNo ratings yet

- Installation Training Manual 20-2-12 Rev0Document38 pagesInstallation Training Manual 20-2-12 Rev0halil guneyNo ratings yet

- Army Tank: Finished Puzzle Size 1" Thick X 6-7/16" Tall X 10-1/2" WideDocument3 pagesArmy Tank: Finished Puzzle Size 1" Thick X 6-7/16" Tall X 10-1/2" WideSergeiNo ratings yet

- Herramientas para Trazar y Medir2Document88 pagesHerramientas para Trazar y Medir2Franco Mauricio60% (5)

- Saudi Aramco Inspection Checklist: Concrete Coatings Pre-Installation Inspection SAIC-H-1003 15-Nov-17Document8 pagesSaudi Aramco Inspection Checklist: Concrete Coatings Pre-Installation Inspection SAIC-H-1003 15-Nov-17Abdul HannanNo ratings yet

- Duck Pull Toy: Project 19247EZDocument3 pagesDuck Pull Toy: Project 19247EZBSulliNo ratings yet

- Digital Patterns: Designed by Steve GoodDocument4 pagesDigital Patterns: Designed by Steve GoodRichard PerezNo ratings yet

- Digital Patterns: Designed by Steve GoodDocument4 pagesDigital Patterns: Designed by Steve GoodRichard Perez100% (1)

- Army Jeep: Finished Puzzle Size 1" Thick X 6-7/16" Tall X 10-1/2" WideDocument3 pagesArmy Jeep: Finished Puzzle Size 1" Thick X 6-7/16" Tall X 10-1/2" WideWilson Roberto de Oliveira100% (2)

- Digital Patterns: Designed by Steve GoodDocument5 pagesDigital Patterns: Designed by Steve GoodticleanulNo ratings yet

- Segmentation Basic 1Document26 pagesSegmentation Basic 1Anonymous p2cFoXbjDNo ratings yet

- Digital Patterns: Designed by Steve GoodDocument6 pagesDigital Patterns: Designed by Steve GoodRichard PerezNo ratings yet

- Aquatec Red Oxide Primer: Technical Data SheetDocument2 pagesAquatec Red Oxide Primer: Technical Data SheetLai Teo KuanNo ratings yet

- Uk Aad Product Catalogue 2015 PDFDocument109 pagesUk Aad Product Catalogue 2015 PDFWOLFWBEARWNo ratings yet

- Fuman Industries Inc. Company ProfileDocument6 pagesFuman Industries Inc. Company ProfileRey Michael PamadoNo ratings yet

- Industrial Arts Week 2 Levi 1Document25 pagesIndustrial Arts Week 2 Levi 1LV BENDANANo ratings yet

- Decopol Microtop Cememtetious Polymer Modified MicrotoppingDocument4 pagesDecopol Microtop Cememtetious Polymer Modified Microtoppingtejas_tNo ratings yet

- 20 - Nordic - Mood 2021aDocument22 pages20 - Nordic - Mood 2021adisiya238No ratings yet

- Body RepairDocument19 pagesBody RepairPUTRA SANINo ratings yet

- Cryptic CalendarDocument61 pagesCryptic CalendarGabriel Antonio NájeraNo ratings yet

- K643 Series - D130 Copper Corrosion - Technical DatasheetDocument2 pagesK643 Series - D130 Copper Corrosion - Technical Datasheetmoh_ichwanuddinNo ratings yet

- Iso 8503-1 1988Document8 pagesIso 8503-1 1988Guilherme de BarrosNo ratings yet

- Nax Balance Tint 3 Naxpremila2K Balance Tint 3000: Product DescriptionDocument4 pagesNax Balance Tint 3 Naxpremila2K Balance Tint 3000: Product DescriptionMahmoud KhairyNo ratings yet

- Technical HandbookDocument21 pagesTechnical Handbooksaifulamree19No ratings yet

- Coating Maintenance and Cleaning Guide-TIBDocument2 pagesCoating Maintenance and Cleaning Guide-TIBStuart BaylissNo ratings yet

- R/C Soaring Digest - May 2007Document60 pagesR/C Soaring Digest - May 2007Aviation/Space History LibraryNo ratings yet

- Activities 1.0 (Earthquakes and Faults)Document6 pagesActivities 1.0 (Earthquakes and Faults)Ramir Becoy100% (1)

- WoodTech Polyester ClearDocument2 pagesWoodTech Polyester ClearSharon Paul HarrisNo ratings yet

- Dof Omm Ss Skirting Sk-02Document8 pagesDof Omm Ss Skirting Sk-02Ideal DesignerNo ratings yet

- Milwaukee Heavy Duty Sanders and Grinders Manual de UsuarioDocument36 pagesMilwaukee Heavy Duty Sanders and Grinders Manual de UsuarioAbelNo ratings yet

- Spec 2022-Appendix A-13 Qualicoat 3.0 - V02Document11 pagesSpec 2022-Appendix A-13 Qualicoat 3.0 - V02yaser elmasryNo ratings yet

- JT 59 PDFDocument2 pagesJT 59 PDFAndone AnutuNo ratings yet

- Owner's Manual: Model No. 315.116360Document14 pagesOwner's Manual: Model No. 315.116360Juan PillajoNo ratings yet

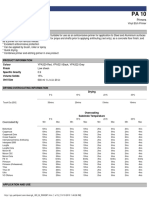

- Pa 10Document3 pagesPa 10LymeParkNo ratings yet