Professional Documents

Culture Documents

Sitransl LVS100 Fi01en

Uploaded by

Natasa SindjelicOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sitransl LVS100 Fi01en

Uploaded by

Natasa SindjelicCopyright:

Available Formats

Level instruments

Point level measurement - Vibrating switches

SITRANS LVS100

■ Overview ■ Configuration

Installation

Rigid extension with

sliding sleeve Position tines vertically to

* avoid product build-up: use

a 50 mm open-end wrench

to turn the process con-

nection until the tine orien-

tation marking faces up or

down.

L

? Protection in case of high

material loading.

Cable gland faces downward

to avoid water penetration.

Tine orientation marking

SITRANS LVS100 is a vibrating point level switch for bulk solids. facing sideways.

5 ■ Benefits Use angle mounting for flowing

material only. If angle mounting

• High resistance to mechanical forces is required with high material

loading, customer-supplied

• Strong resistance to external vibrations protection from falling material

• Rotatable enclosure for ease of installation and wiring must be in place.

• Suitable for point level detection of materials starting at a bulk *

density of 60 g/l (3.8 lb/ft3) max. deviation from max. length L

vertical ?

• Customer desired extensions up to 2000 mm (78.74")

5° 2m

• Durable short fork option starting at 170 mm (6.7") insertion

length 45° 1.2 m

>45° 0.6 m

■ Application

SITRANS LVS100 detects high, low or demand levels of dry bulk

solids in bins, silos or hoppers. SITRANS LVS100 installation

SITRANS LVS100 has a compact design and can be top, side,

or angle mounted. The vibrating fork design ensures the tines

are kept clean. The unique design of the fork and crystal assem-

bly eliminates false high level readings even if tines become

damaged.

A signal from the electronic circuit excites a crystal in the probe

causing the fork to vibrate. If the fork is covered by material, the

change in vibration is detected by the electronic circuitry which

causes the relay to change state after a one second delay. When

the fork is free from material pressure, full vibration resumes and

the relay reverts to its normal condition.

• Key Applications: dry bulk solids in bins, silos, hoppers

5/2 Siemens FI 01 · 2009

Level instruments

Point level measurement - Vibrating switches

SITRANS LVS100

■ Technical specifications Power supply • 19 to 230 V AC, +10%,

50 to 60 Hz, 8 VA

Mode of operation • 19 to 50 V DC, +10%, 1.5 W

Measuring principle Vibrating point level switch Certificates and approvals

Input • CSA/FM General Purpose

Measured variable High, low and demand • CE

Measuring frequency 200 Hz • CSA/FM Dust Ignition Proof

Output • C-TICK

• ATEX II 1/2 D

• Relays DPDT relay

• Relay delay • From loss of vibration: approxi-

mately 1 second

• From resumption of vibration:

approximately 1 to 2 seconds

• Signal delay • Probe uncovered to covered:

approximately 1 second

• Probe covered to uncovered:

approximately 1 to 2 seconds

• Relay fail-safe High or low, switch selectable

• Alarm output • Relay 8 A at 250 V AC, non-in-

ductive

• Relay 5 A at 30 V DC, non-induc-

Sensitivity

tive

High or low, switch selectable

5

Rated operating conditions

Installation conditions

• Location Indoor/outdoor

Ambient conditions

• Ambient temperature -40 to +60 °C (-40 to +140 °F)

• Installation catagory III

• Pollution degree 2

Medium conditions

• Process temperature -40 to +150 °C (-40 to +302 °F)

• Max. threaded bushing tempera- +80 °C (+176 °F)

ture

• Max. enclosure surface tempera- +90 °C (+194 °F)

ture (Category 2D)

• Max. extension surface tempera- +150 °C (+302 °F)

ture (Category 1D)

• Pressure (vessel) Max. 10 bar (145 psi) European

Pressure Directive 97/23/EC:

Category 1

• Minimum material density • approx. 60 g/l (3.8 lb/ft3)

Design

• Material

- Enclosure Epoxy coated aluminum

• Process connection • Thread 1¼" NPT [(Taper),

ANSI/ASME B1.20.1], R 1½"

[(BSPT), EN 10226]

• Thread R 1½ " [(BSPT),

EN 10226], ½" NPT [(Taper),

ANSI/ASME B1.20.1], sliding

sleeve [min. length 500 mm

(19.69")]

• Thread material: stainless steel

304 (1.4301) or 316TI (1.4571)

depending on configuration

• Tine material Stainless steel 316TI (1.4571)

• Degree of protection IP66/Type 4/NEMA 4

• Conduit entry 2 x M20x1.5 or 2 x ½" NPT

• Weight • Standard version, no exten-

sions: approx 1.7 kg (3.7 lbs)

Siemens FI 01 · 2009 5/3

Level instruments

Point level measurement - Vibrating switches

SITRANS LVS100

Selection and Ordering data Order No.

SITRANS LVS100, standard 7ML 5 7 3 5 -

Vibrating point level switch for high or low level

7 77 - 7A 0

detection of bulk solids Sensitivity > 60 g/l.

Input Voltage

DPDT Relay - 19 to 230 V AC, 19 to 50 V DC 1

Process temperature

up to +150 °C (+302 °F) A

Process connection

Threaded

R 1½" [(BSPT), EN 10226] A

1¼" NPT [(Taper), ANSI/ASME B1.20.1] B

R 1½ " [(BSPT), EN 10226] DIN 2999 thread, sliding C

sleeve - min. length 500 mm (19.69")

½" NPT [(Taper), ANSI/ASME B1.20.1] , sliding D

sleeve [min. length 500 mm (19.69")]

Extension length

Stainless steel 316TI (1.4571)

Standard length, 170 mm (6.69") 11

Add order code Y01 and plain text: “Insertion

length ...mm"

Stainless steel 304 (1.4301)

5

• 300 to 500 mm (11.81 to 19.69") 12

• 501 to 1000 mm (19.72 to 39.37") 13

• 1001 to 1500 mm (39.41 to 59.06") 14

• 1501 to 2000 mm (59.09 to 78.74") 15

Approvals

CSA/FM General Purpose, CE A

CSA/FM Class II, Div. 1, Group E,F, G, Class III, B

ATEX II 1/2 D

Further designs Order code

Please add “-Z" to Order No. and specify Order

code(s).

Total insertion length: Enter the total insertion length Y01

in plain text description, max. 2000 mm (78.74")

Signal bulb inserted in M20 cable gland A20

Instruction manual Order No.

Multi-language 7ML1998-5FT63

This device is shipped with the Siemens Milltronics

manual CD containing the complete ATEX Quick

Start and instruction manual library.

Spare parts

Replacement Electronics Module LVS100 DPDT 7ML18301NS

Relay (19 to 253 V AC, 19 to 55 V DC)

R 1½ " [(BSPT), EN 10226] DIN 2999 thread, sliding 7ML18301NT

sleeve

½" NPT [(Taper), ANSI/ASME B1.20.1] , sliding 7ML18301NU

sleeve [min. length 500 mm (19.69")]

5/4 Siemens FI 01 · 2009

Level instruments

Point level measurement - Vibrating switches

SITRANS LVS100

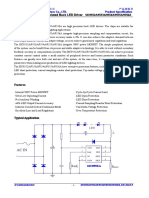

■ Dimensional drawings ■ Schematics

60 mm

(2.36 )75 mm

(2.95 )

60 mm

(2.36 )

120 mm

(4.72 )

tine 150 mm

orientation (5.91 )

marking

threaded bushing

[max. temp.

Zone 21

(Cat. 2)

SITRANS LVS100 connections 5

+80 °C (+176 °F)] Zone 20

(Cat. 1)

customer supplied

process flange

170 to 2000 mm (6.69 to 78.74 ):

customer specified rigid

tine

125 mm (4.92 ):

standard fork

SITRANS LVS100 dimensions

Siemens FI 01 · 2009 5/5

You might also like

- Safety On Transmission Tower Erection, Cable Stringing & CommissioningDocument28 pagesSafety On Transmission Tower Erection, Cable Stringing & CommissioningAshutosh Dubey100% (5)

- Catalogo Llave de VarillaDocument38 pagesCatalogo Llave de VarillaWilson Cendales100% (1)

- Numerical Sheet Control SystemsDocument20 pagesNumerical Sheet Control SystemsKAMARAJU SAI VAMSHINo ratings yet

- Technical Specification of 315-2500 KVA Distribution TransformerDocument51 pagesTechnical Specification of 315-2500 KVA Distribution Transformertsraj1083% (6)

- LVS 100Document3 pagesLVS 100Dicky KurniantoNo ratings yet

- Continuous Level Measurement Guided Wave Radar TransmittersDocument43 pagesContinuous Level Measurement Guided Wave Radar TransmittersAlen KušecNo ratings yet

- Heavy-Duty Vibrating FeedersDocument4 pagesHeavy-Duty Vibrating FeedersErsin SucuNo ratings yet

- Sitrans LVL200Document16 pagesSitrans LVL200Aida Vivanco LunaNo ratings yet

- CTS Sterlite MergedDocument20 pagesCTS Sterlite MergedAvidip DeyNo ratings yet

- Mason Industries, Inc.: TYPE "C" Spring Mountings Provide A Packaged Solution ToDocument4 pagesMason Industries, Inc.: TYPE "C" Spring Mountings Provide A Packaged Solution ToFrancisco BujandaNo ratings yet

- Resilient CouplingsDocument7 pagesResilient CouplingsAriyanNo ratings yet

- Deep Sea Construction TechniquesDocument66 pagesDeep Sea Construction TechniquesSrinivas MallickNo ratings yet

- Siemens LVL 100Document7 pagesSiemens LVL 100Stenio LanzaNo ratings yet

- H7GbjVKSTKQ9CCha8gOQ - Elexon Mining - Tailings Dam MonitoringDocument17 pagesH7GbjVKSTKQ9CCha8gOQ - Elexon Mining - Tailings Dam MonitoringJuan MedinaNo ratings yet

- LVL 100Document6 pagesLVL 100Dicky KurniantoNo ratings yet

- LVL 200Document16 pagesLVL 200Dicky KurniantoNo ratings yet

- Butterfly Valves (S) - Rev 02-05-2019Document2 pagesButterfly Valves (S) - Rev 02-05-2019arjun 11No ratings yet

- BASIC Wireline (Narong T)Document54 pagesBASIC Wireline (Narong T)Tiwakorn DarajitNo ratings yet

- LHPEw-L50. Off Track SwitchDocument2 pagesLHPEw-L50. Off Track SwitchAhmet HrustićNo ratings yet

- 44Document4 pages44Bhanuka SamarakoonNo ratings yet

- Stingray Mobile Shiploader: Self-Contained, Highly Portable Machine For Fast Vessel LoadingDocument2 pagesStingray Mobile Shiploader: Self-Contained, Highly Portable Machine For Fast Vessel LoadingRAUL PEREZ NEGREIROSNo ratings yet

- Patented! Rotating Hand Chain GuideDocument15 pagesPatented! Rotating Hand Chain GuideElsad HuseynovNo ratings yet

- DataSheet IRSDocument2 pagesDataSheet IRSpawan yadavNo ratings yet

- Method InclinometerDocument2 pagesMethod InclinometerJamjam100% (1)

- Anderson Greenwood Liquid Storage Internal Tank ValvesDocument10 pagesAnderson Greenwood Liquid Storage Internal Tank ValvesMichael J. BaneNo ratings yet

- SL 12 Sliding CutsheetDocument1 pageSL 12 Sliding CutsheetLiam RazoNo ratings yet

- Bridge 2Document30 pagesBridge 2Hefon MarketerNo ratings yet

- Delta Industrial Product Guide April 2020Document24 pagesDelta Industrial Product Guide April 2020JayaramNo ratings yet

- Fall Protection Updated QuizDocument51 pagesFall Protection Updated QuizALBERTONo ratings yet

- L07 - RisersDocument31 pagesL07 - RisersU Kyaw Kyaw Naing100% (4)

- Olympus Type: Wide 3.7 MM Channel Suits A Wide Spectrum of ERCP Procedures Including Placement of A 10 Fr. StentDocument3 pagesOlympus Type: Wide 3.7 MM Channel Suits A Wide Spectrum of ERCP Procedures Including Placement of A 10 Fr. StentHAITHM MURSHEDNo ratings yet

- North American Rated Devices: Pin & SleeveDocument3 pagesNorth American Rated Devices: Pin & Sleevesmsm280No ratings yet

- NOVA Mechanical Edge of Dock Leveler BrochureDocument2 pagesNOVA Mechanical Edge of Dock Leveler BrochureAhmed Emad AhmedNo ratings yet

- Technical Data Sheet: Zwaluw Fix-O-Chem (Styrene Free)Document2 pagesTechnical Data Sheet: Zwaluw Fix-O-Chem (Styrene Free)Tudor GolbanNo ratings yet

- CN-DT-002 - ENG - Concrete Lining Vs Mattresses - Rev. 0 PDFDocument2 pagesCN-DT-002 - ENG - Concrete Lining Vs Mattresses - Rev. 0 PDFszemianNo ratings yet

- Hazard Sheet 23: Safety in The Use of Harnesses & Temporary LifelinesDocument6 pagesHazard Sheet 23: Safety in The Use of Harnesses & Temporary LifelinescerajibNo ratings yet

- LWH Novotechnik LWHDocument4 pagesLWH Novotechnik LWHGerardo Espinosa EspinosaNo ratings yet

- BSF - CT 4281-8 in - 36-5 PDFDocument6 pagesBSF - CT 4281-8 in - 36-5 PDFHugh O'Brien GwazeNo ratings yet

- 12 - Cast Iron Tapping MachinesDocument14 pages12 - Cast Iron Tapping MachinesaurabloodNo ratings yet

- Captain 57series Cutsheet RequeridDocument4 pagesCaptain 57series Cutsheet RequeridEricNo ratings yet

- Installation of Solar PanelsDocument4 pagesInstallation of Solar PanelsManafNo ratings yet

- Theo20fw enDocument3 pagesTheo20fw enForum PompieriiNo ratings yet

- Transducer CatalogDocument7 pagesTransducer CatalogJ. Rodrigo Rizatti Rodrigo RizattiNo ratings yet

- TENSA®FINGER Typ GF International EN (Eversion) PDFDocument4 pagesTENSA®FINGER Typ GF International EN (Eversion) PDFSanjaNo ratings yet

- 3R80 Knee Spec Sheet DigitalDocument2 pages3R80 Knee Spec Sheet DigitalardsunNo ratings yet

- VME-Cable-Trenches DesignDocument10 pagesVME-Cable-Trenches DesignPrince kademaNo ratings yet

- Tegra FRA RangeDocument2 pagesTegra FRA RangejopejiNo ratings yet

- Tegra FRA RangeDocument2 pagesTegra FRA RangejopejiNo ratings yet

- Telescopic Mooring Device With Smooth Damping Characteristics Adjusting Its Length According To Changing Water LevelsDocument5 pagesTelescopic Mooring Device With Smooth Damping Characteristics Adjusting Its Length According To Changing Water LevelsjausingchiNo ratings yet

- Rod-Type Borehole Extensometers: Model A-3, A-4, A-5, A-6Document4 pagesRod-Type Borehole Extensometers: Model A-3, A-4, A-5, A-6Luis Enrique GonzalezNo ratings yet

- Fig. 26-54 Fig. 26-55: 26 General Equipment For Welding ShopsDocument7 pagesFig. 26-54 Fig. 26-55: 26 General Equipment For Welding ShopsWilly UioNo ratings yet

- Standard Membrane: Hyperpl SDocument1 pageStandard Membrane: Hyperpl SKHUSHBUNo ratings yet

- 8290 SERIES: Angle Body Piston ValvesDocument12 pages8290 SERIES: Angle Body Piston ValvesCarlos Giovanni Camperos GaitanNo ratings yet

- Additional Material For Underground SupportsDocument80 pagesAdditional Material For Underground SupportsReymark DoriaNo ratings yet

- 6350 Vibrating Wire Tiltmeter - UnlockedDocument2 pages6350 Vibrating Wire Tiltmeter - UnlockedGerardo Pacheco PalominoNo ratings yet

- Seb Sapura 3000Document1 pageSeb Sapura 3000azedine KACHERNo ratings yet

- Job Description: Area Owner: JSA Control Number: Prepared By: Department/Location: Reviewed By: Date/Time: Approved By: Supervised byDocument1 pageJob Description: Area Owner: JSA Control Number: Prepared By: Department/Location: Reviewed By: Date/Time: Approved By: Supervised bybadrul hisyamNo ratings yet

- Offshore Coupling PDFDocument8 pagesOffshore Coupling PDFkhanh123ctmNo ratings yet

- Lecture 5Document3 pagesLecture 5Reesha Anne SebastianNo ratings yet

- SIC9552A SISemiconductorsDocument9 pagesSIC9552A SISemiconductorsDiego OliveiraNo ratings yet

- Adfm 201700905Document28 pagesAdfm 201700905Rana Sabouni TabariNo ratings yet

- One Mark QuestionsDocument2 pagesOne Mark QuestionsC V VIJAY KUMASRNo ratings yet

- Tele Supply As: 5. JTM-30C NDB Operator User ManualDocument14 pagesTele Supply As: 5. JTM-30C NDB Operator User ManualHai AuNo ratings yet

- Company Description: 2.1 Brief History and Nature of SAMTECHDocument9 pagesCompany Description: 2.1 Brief History and Nature of SAMTECHCaren Ss123No ratings yet

- Delta Modulation: EE 442 - Spring SemesterDocument12 pagesDelta Modulation: EE 442 - Spring SemesterAkash kumar100% (1)

- Modular Design of Automated Biochemistry Analyzer: Swati Kapoor Vikas GoelDocument5 pagesModular Design of Automated Biochemistry Analyzer: Swati Kapoor Vikas GoelnmmMJKJNo ratings yet

- Fine Tuner TD181 - Iss A - Illustrated Troubleshooting and Set Up Guide For EL PositionersDocument7 pagesFine Tuner TD181 - Iss A - Illustrated Troubleshooting and Set Up Guide For EL PositionerskaleesuwariNo ratings yet

- Assignment-1 Sub: Basic Electronics SUB CODE: 2110016Document15 pagesAssignment-1 Sub: Basic Electronics SUB CODE: 2110016khyatichavdaNo ratings yet

- Aerodynamic Measurements in Dysarthria: Dr. SwapnaDocument45 pagesAerodynamic Measurements in Dysarthria: Dr. SwapnaAppas SahaNo ratings yet

- QUINT-ORING/24DC/2X10/1X20: Active Redundancy ModuleDocument17 pagesQUINT-ORING/24DC/2X10/1X20: Active Redundancy Modulek v s s GuptaNo ratings yet

- ULN2004 Datasheet PDFDocument8 pagesULN2004 Datasheet PDFVarga RichardNo ratings yet

- Baldor Drives CatalogDocument196 pagesBaldor Drives CatalogarturobatallasNo ratings yet

- What Kind of Residual Current Device (RCD) Should You Use For Protection?Document5 pagesWhat Kind of Residual Current Device (RCD) Should You Use For Protection?buraqtech49No ratings yet

- STM Assignment: Lingayas VidyapeethDocument10 pagesSTM Assignment: Lingayas VidyapeethGunjanNo ratings yet

- Datasheet SCR 106 PDFDocument5 pagesDatasheet SCR 106 PDFNìcòlàs HedNo ratings yet

- P.21.028 NHÀ MÁY BYD - PHÚ THỌ-T2Document245 pagesP.21.028 NHÀ MÁY BYD - PHÚ THỌ-T2KenyDuyệtNo ratings yet

- Datasheet - 378R12Document8 pagesDatasheet - 378R12Amanda BentoNo ratings yet

- TV Productor Service Manual: Approved SignaturesDocument61 pagesTV Productor Service Manual: Approved SignaturesJCNo ratings yet

- ELECTRICAL QUESTIONS AND ANSWERS-MCQ-9A - ETO - Electro Technical OfficerDocument11 pagesELECTRICAL QUESTIONS AND ANSWERS-MCQ-9A - ETO - Electro Technical Officeramit100% (2)

- 1.0 Greenheat Corp - Cost Roposal (03162022)Document4 pages1.0 Greenheat Corp - Cost Roposal (03162022)simeon james villacrusisNo ratings yet

- Basic MOSFET Logic Gates: 3.1 InverterDocument9 pagesBasic MOSFET Logic Gates: 3.1 Invertertooba mukhtarNo ratings yet

- VAMP 221: Arc Protection SystemDocument164 pagesVAMP 221: Arc Protection SystemPaulo BraggioNo ratings yet

- Hitachi Energy Power Factor Controller RVC RVTDocument7 pagesHitachi Energy Power Factor Controller RVC RVTParashar PathakNo ratings yet

- Scimitar: Fused Ring Main Units Up To 17.5kVDocument4 pagesScimitar: Fused Ring Main Units Up To 17.5kVkhaldoun samiNo ratings yet

- Modicon X80 Modules - BMXXBE2005Document3 pagesModicon X80 Modules - BMXXBE2005vaitomanocuNo ratings yet

- (PDF) BD Advands Diagnostic and Trouble Shooting GECB-LV - 2013!06!17Document17 pages(PDF) BD Advands Diagnostic and Trouble Shooting GECB-LV - 2013!06!17boneyNo ratings yet

- Reach Compliance With AS / NZS 61439 Series: Switchboard Manufacturers & Designers Partner With InsulectDocument8 pagesReach Compliance With AS / NZS 61439 Series: Switchboard Manufacturers & Designers Partner With InsulectManav IyerNo ratings yet