Professional Documents

Culture Documents

ABS 2005 Steel Vessels Corrigenda January 2005

Uploaded by

Erick Cruz MontañezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ABS 2005 Steel Vessels Corrigenda January 2005

Uploaded by

Erick Cruz MontañezCopyright:

Available Formats

RULES FOR BUILDING AND CLASSING

STEEL VESSELS

2005

CORRIGENDA/EDITORIALS – 12 January 2005

CORRIGENDA/EDITORIALS – 11 March 2005

Page No. Paragraph Comments

Part 1 Conditions of Classification

Chapter 1 Scope and Conditions of Classification

Section 3 Classification Symbols and Notations

13 1-1-3/3 Add notations “Liquefied Gas Carrier” and “Chemical Carrier” after

“Oil or Bulk/Ore (OBO) Carrier”, and add “(See the “List of ABS

Notations and Symbols” on the ABS website “www.eagle.org/rules/

downloads.html” for more information on the notations.)” at end of

paragraph. Also, “Ore or Oil Carriers” to read “Ore or Oil Carrier”.

Part 2 Rules for Materials and Welding

Chapter 1 Materials for Hull Construction

Section 5 Hull Steel Castings

46 2-1-5/13.7 Title of referenced Guide to read “ABS Guide for Nondestructive

Examination of Marine Steel Castings”.

47 2-1-5/13.11 Title of referenced Guide to read “ABS Guide for Nondestructive

Examination of Marine Steel Castings” (2 places).

Part 2 Rules for Materials and Welding

Chapter 2 Equipment

Section 3 Rolled Steel Bars for Chain

81 Section 2-2-3 Title to read “Rolled Steel Bars for Chain, Cast and Forged Materials for

Accessories and Materials for Studs”.

Part 2 Rules for Materials and Welding

Chapter 3 Materials for Machinery, Boilers, Pressure Vessels and Piping

Section 7 Steel Machinery Forgings

145 2-3-7/1.17 Renumber last list item as “viii)”.

154 2-3-7/5.7.1 Reference “2-3-7/Table 4” to read “2-3-7/Table 6”.

Part 2 Rules for Materials and Welding

Chapter 3 Materials for Machinery, Boilers, Pressure Vessels and Piping

Section 9 Steel Castings for Machinery, Boilers and Pressure Vessels

171 2-3-9/1.1 In second-to-last line, “040%” to read “0.040%”.

Part 2 Rules for Materials and Welding

Chapter 3 Materials for Machinery, Boilers, Pressure Vessels and Piping

Section 14 Bronze Castings

209 2-3-14/3.9 Revise Note 4 of table to read as follows: “See 2-1-1/Figure 2”.

ABS RULES FOR BUILDING AND CLASSING STEEL VESSELS . 2005 1

Corrigenda/Editorials – 12 January 2005

11 March 2005

Page No. Paragraph Comments

Part 2 Rules for Materials and Welding

Chapter 4 Welding and Fabrication

Section 3 Weld Tests

310 2-4-3/Table 1 Add new Note 7 “See 2-4-4/5.11 applicable for pipe welding.”. Last cell of

first column to read “For tack welders (Note 7)”.

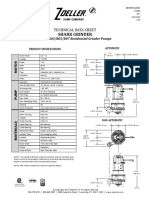

319 2-4-3/Figure 9 Add arrows to “Direction of plate rolling” as shown below:

For Plate Material 19.1 mm (3/4 in.) or less

Direction of plate rolling

29 mm

Discard (1 1/8 in.)

Face bend 38 mm

(1½in.)

150 mm

(6 in.)

38 mm

Root bend (1½in.)

29 mm

Discard (1 1/8 in.)

250 mm (10 in.)

60°

Warping 5° max. Diameter of electrode

core wire

9.5mm (3/8 in.)

6mm (1/4 in.) min.

25 mm

(1 in.)

319 2-4-3/Figure 9 Add new Note 2 “Thickness of test assembly is to be reduced to 5 mm

(3/16 in.) for qualifying construction material less than 9.5 mm (3/8 in.) per

Note 1 of 2-4-3/Table 1.” and renumber existing Notes accordingly.

324 2-4-3/Figure 12 Text at top of figure to read “For Tack Welders (See 2-4-4/5.11 – applicable

for pipe welding.)”.

Part 2 Rules for Materials and Welding

Chapter 4 Welding and Fabrication

Section 4 Piping

330 2-4-4/5.11 In second line, “qualified welders” to read “qualified pipe welders”.

Part 2 Rules for Materials and Welding

Appendix 2 Requirements for the Approval of Filler Metals

Section 1 General

339 2-A2-1/1.5 Add new Paragraph 2-A2-1/1.5 as follows:

(New)

“1.5 Aluminum Filler Metals

Approval of aluminum filler metals is covered in Appendix 2-5-A2 of

the ABS Rule Requirements for Materials and Welding – Aluminum

and Fiber Reinforced Plastics (FRP).”

2 ABS RULES FOR BUILDING AND CLASSING STEEL VESSELS . 2005

Corrigenda/Editorials – 12 January 2005

11 March 2005

Page No. Paragraph Comments

Part 2 Rules for Materials and Welding

Appendix 2 Requirements for the Approval of Filler Metals

Section 2 Electrodes for Shielded Metal Arc Welding

355 2-A2-1/9.7.1 Heading of third table column to read “Grades Y, Y400 and YQ”.

Part 3 Hull Construction and Equipment

Chapter 5 Equipment

Section 1 Anchoring, Mooring and Towing Equipment

249 3-5-1/ Equations for Fxi, Fyi to read “Fxi = (Px – αgM)/N” and “Fyi = (Py – αgM)/N”,

11.3.2(b)ii) respectively.

Part 4 Vessel Systems and Machinery

Chapter 2 Prime Movers

Section 1 Diesel Engines

27 4-2-1/1.9.5 Revise third paragraph to read “Torsional vibration analysis for propulsion

shafting systems for all modes of operation including the condition of one

cylinder misfiring”.

40 4-2-1/7.3.3 Revise first paragraph to read “Electronic speed governors fitted to main

propulsion diesel engines, and which form part of a remote propulsion control

system, are to comply with the following:”.

51 4-2-1/13.9.2 Title to read “Engines Driving Propellers”.

51 4-2-1/13.9.2 First sentence to begin: “Main propulsion engines driving propellers…”.

Part 4 Vessel Systems and Machinery

Chapter 3 Prime Movers

Section 6 Propulsion Redundancy

255 4-3-6/1.3ii) Reference “4-3-6/7.1” to read “4-3-6/7.3”.

Part 4 Vessel Systems and Machinery

Chapter 7 Fire Safety Systems

Section 3 Fire-extinguishing Systems and Equipment

498 4-7-3/1.5.3v) Add the following new text after existing text:

“(2004) It is to be demonstrated by calculation that the total suction head and

net positive suction head of the pump are satisfied at:

• The lightest seagoing condition, with account being taken of 22.5° roll

and 10°pitch (1) and

• A loading condition without cargo or ballast water, with 10% stores and

fuel remaining, roll and pitch not being taken into account.

Upon completion of the emergency fire pump installation, a performance test

confirming the capacity required in 4-7-3/1.5.3i) is to be carried out. As far as

practicable, the test is to be carried out at lightest seagoing draft at the suction

position.

Note 1 Where the length of the vessel exceeds 100 m (328 ft), the pitch angle may be taken

as 500/L degrees, where L is the length of the vessel in meters (1640/L degrees,

where L is the length of the vessel in feet), as defined in 3-1-1/3.1.”.

Part 4 Vessel Systems and Machinery

Chapter 8 Electrical Systems

Section 4 Shipboard Installation and Tests

609 4-8-4/21.17.2(d) Delete last sentence “Subparagraph 4-8-4/21.17.2 does not alleviate the

requirements for emergency feeders in 4-8-4/21.17.1.”.

ABS RULES FOR BUILDING AND CLASSING STEEL VESSELS . 2005 3

Corrigenda/Editorials – 12 January 2005

11 March 2005

Page No. Paragraph Comments

Part 4 Vessel Systems and Machinery

Chapter 9 Remote Propulsion Control and Automation

Section 2 Remote Propulsion Control

657 4-9-2/7.3 Add new first paragraph and revise existing paragraph to read as follows:

“Remote propulsion control stations fitted in vessels having the propulsion

machinery space manned are to be provided with the alarms, displays and

controls as listed in 4-9-2/Table 1, items A1 through C2 as a minimum.

Where a remote propulsion control station is provided in or in the vicinity of

the propulsion machinery space for the purpose of full remote operation of a

locally manned propulsion machinery space, such a station is to be fitted

with:

Remote propulsion control station, as in 4-9-2/7.1

Alarms, displays and controls, as required in 4-9-3/Table 2

Alarms and displays of 4-9-4/Table 3A through 4-9-4/Table 8, as

applicable”.

Part 4 Vessel Systems and Machinery

Chapter 9 Remote Propulsion Control and Automation

Section 4 ACCU Notation

674 4-9-4/15.5.2 In second line, add reference “4-9-3/13.11.2” after existing two references.

In last line, reference “4-9-3/13.11.2” to read “4-9-3/13.11.3”.

Part 4 Vessel Systems and Machinery

Chapter 9 Remote Propulsion Control and Automation

Section 7 Equipment

698 4-9-7/13.5 In third line, reference “4-9-7/13.1” to read “4-9-7/13.3”.

Part 5 Specific Vessel Types

Chapter 1 Vessels Intended to Carry Oil in Bulk (150 meters (492 feet) or more in Length)

Section 7 Cargo Oil and Associated Systems

158 5-1-7/3.3.4(e) Add new reference after IMO Resolution A.497 (XII) as follows: “IMO

Resolution A.897 (21) Amendments to the revised specifications for the

design, operation and control of crude oil washing systems [Resolution A.446

(XI) as amended by resolution A.497 (XII)]”.

Part 5 Specific Vessel Types

Chapter 3 Vessels Intended to Carry Ore or Bulk Cargoes (150 meters (492 feet) or more in Length)

Section 6 Hull Structure Beyond 0,4L Amidships

483 5-3-6/5.3 In definition of p, delete items iv) through vii).

483 5-3-6/5.5 Add the following sentence to the end of existing text: “Side shell plating in

upper and lower wing tanks, see 5-3-6/5.9.”.

483 5-3-6/5.7 Add the following sentence to the end of existing text: “Side shell plating in

upper and lower wing tanks, see 5-3-6/5.9.”.

4 ABS RULES FOR BUILDING AND CLASSING STEEL VESSELS . 2005

Corrigenda/Editorials – 12 January 2005

11 March 2005

Page No. Paragraph Comments

Part 5 Specific Vessel Types

Chapter 3 Vessels Intended to Carry Ore or Bulk Cargoes (150 meters (492 feet) or more in Length)

Section 6 Hull Structure Beyond 0,4L Amidships

484 5-3-6/5.9 In definition of p, revise item iv) to read as follows:

iv) (1999) In the upper wing tank and lower wing tank which is

connected to the upper wing tank by trunks or double sides, the

internal pressure, pi, in such tanks may be calculated by the

following equation:

pi = pia − puo

pia is internal pressure in the wing tanks, in N/cm2 (kgf/cm2,

lbf/in2), as defined in 5-3-3/Table 3 for side shell plating.

puo is as defined in 5-3-4/9.1.

484 5-3-6/5.11 In Item iv), reference “5-3-6/5.3iv)” to read “5-3-6/5.9iv)”.

Part 5 Specific Vessel Types

Chapter 5 Vessels Intended to Carry Containers (130 meters (427 feet) to 350 m (1148 feet) in Length)

Section 3 Load Criteria

678 5-5-3/11.3.3 5

In definition of dk, equation to read “0.2 ∑ bTi ”.

i

Part 5 Specific Vessel Types

Chapter 5 Vessels Intended to Carry Containers (130 meters (427 feet) to 350 m (1148 feet) in Length)

Section 4 Initial Scantling Criteria

708 5-5-4/11.17 Definition of k1 for vertically stiffened plating to read “0.500k2”.

Part 5 Specific Vessel Types

Chapter 8 Vessels Intended to Carry Liquefied Gases in Bulk

Section 4 Cargo Containment

992 5-8-4/4.1 Revise to read as follows:

“Integral tanks are to be designed and constructed in accordance with

the requirements of these Rules. The scantlings of the tank boundary

plating and stiffening are to be not less than required by the

following:

• For LNG (L ≥ 150 m) refer to the ABS Guide for Building and

Classing Membrane Tank LNG Vessels.

• For LNG (L < 150 m) refer to SVR Part 5, Chapter 2.

The application of SH notation for vessels less than 150 m in length

may be considered on a case-by-case basis and application of Rule

requirements will be discussed between the applicant and the

Bureau.”

Part 7 Rules for Survey After Construction

Chapter 2 Survey Intervals

Section 2 Vessels in Great Lakes Service

23 7-3-2/15 Relocate second through last sentences of second paragraph to new

Subsection 7-5-1/7.

41 7-3-2/1.5.2 Relocate to 7-6-2/1.7.1.

41 7-3-2/1.5.2 Reinstate text moved to 7-6-2/1.7.1.

ABS RULES FOR BUILDING AND CLASSING STEEL VESSELS . 2005 5

Corrigenda/Editorials – 12 January 2005

11 March 2005

Page No. Paragraph Comments

Part 7 Rules for Survey After Construction

Chapter 3 Hull Surveys

Section 2 Vessels for Unrestricted Service

42 7-3-2/1.7 Title to read “Bulk Carriers – Non Double Skin ESP and Bulk Carrier

Features of Combination Carriers – Non Double Skin ESP”.

45 7-3-2/1.13.2 Relocate to 7-6-2/1.3.8.

45 7-3-2/1.13.2 Reinstate text moved to 7-6-2/1.3.8.

45 7-3-2/1.13.3 Relocate to 7-6-2/1.3.9.

45 7-3-2/1.13.3 Reinstate text moved to 7-6-2/1.3.9.

45 7-3-2/1.13.4 Relocate last two paragraphs to 7-6-2/1.3.10 and renumber as 7-3-2/1.13.2.

45 7-3-2/1.13.4 Reinstate text moved to 7-6-2/1.3.10 and renumber as 7-3-2/1.13.4.

(1.13.2 New)

45 7-3-2/1.13.5 Renumber as 7-3-2/1.13.3.

45 7-3-2/1.13.5 Renumber as 7-3-2/1.13.5.

(1.13.3 New)

46 7-3-2/1.13.6 Relocate items (c), (d), (e), (f), (g), (h) and (k) to 7-6-2/1.3.12 and renumber

remaining items accordingly. Renumber as 7-3-2/1.13.4.

46 7-3-2/1.13.6 Renumber as 7-3-2/1.13.6.

(1.13.4 New)

46 7-3-2/1.13.6 In first line, reference “7-3-2/1.13.1 through 1.13.5” to read “7-3-2/1.13.1

through 1.13.3”.

46 7-3-2/1.13.6 In first line, reference “7-3-2/1.13.1 through 1.13.3” to read “7-3-2/1.13.1

(1.13.4 New) through 1.13.5”.

46 7-3-2/ Reference “7-3-2/1.13.3” to read “7-6-2/1.3.9”.

1.13.6(c)

46 7-3-2/1.13.6(c) Reference “7-6-2/1.3.9”to read “7-3-2/1.13.3”.

(1.13.4(c) New)

46 7-3-2/1.13.7 Renumber as 7-3-2/1.13.5.

46 7-3-2/1.13.7 Renumber as 7-3-2/1.13.7.

(1.13.5 New)

46 7-3-2/1.13.7 In first line, reference “7-3-2/1.13.1 through 1.13.5” to read “7-3-2/1.13.1

through 1.13.3”.

46 7-3-2/1.13.7 In first line, reference “7-3-2/1.13.1 through 1.13.3” to read “7-3-2/1.13.1

(1.13.5 New) through 1.13.5”.

47 7-3-2/ Relocate subitems ii), iii), iv), v), vi), viii), ix), xii), xiv), xv) and xvi) to

1.13.7(b) 7-6-2/1.3.11 and renumber remaining items accordingly.

47 7-3-2/ Reference “7-3-2/1.13.3” to read “7-6-2/1.3.9”.

1.13.7(b)vi)

50 7-3-2/1.19 In title, “Combination Carriers – Double Hull ESP” to read “Combination

Carriers – Non Double Skin ESP”.

53 7-3-2/3.7 Title to read “Bulk Carriers – Non Double Skin ESP and Bulk Carrier

Features of Combination Carriers – Non Double Skin ESP”.

6 ABS RULES FOR BUILDING AND CLASSING STEEL VESSELS . 2005

Corrigenda/Editorials – 12 January 2005

11 March 2005

Page No. Paragraph Comments

Part 7 Rules for Survey After Construction

Chapter 3 Hull Surveys

Section 2 Vessels for Unrestricted Service

53 7-3-2/3.7.6 In second and third lines, delete “(rev. 1, June 2003)”.

55 7-3-2/3.9.3 Reference “7-3-2/515.3” to read “7-3-2/5.15.3”.

59 7-3-2/3.19 In title, “Combination Carriers – Double Hull ESP” to read “Combination

Carriers – Non Double Skin ESP”.

60 7-3-2/ References “7-3-2/3.1.1.1(a)” and “7-3-2/3.1.1.1(b)” to read “7-3-2/3.1.1(a)”

3.19.3(a)i) and “7-3-2/3.1.1(b)”, respectively.

63 7-3-2/5.1.8 In sixth bullet, reference “7-3-2/5.5.1(f)” to read “7-3-2/5.5.1(c)”.

63 7-3-2/5.1.8 In sixth bullet, reference “7-3-2/5.5.1(c)” to read “7-3-2/5.5.1(f)”.

63 7-3-2/5.1.8 Tenth bullet to read “Tankers ESP (Oil Carriers and Oil Carrier Features of

Combination Carriers – Non Double Hull and Chemical Carriers), see

7-3-2/5.13.4.”.

63 7-3-2/5.1.8 Eleventh bullet to read “Tankers ESP (Oil Carriers and Oil Carrier Features

of Combination Carriers – Double Hull), see 7-3-2/5.14.4.”.

65 7-3-2/5.1.10 Delete the following text:

“(1 July 2003) Confirmation of the satisfactory operation of all

mechanically operated hatch covers is to be made, including:

• Stowage and securing in open condition.

• Proper fit and efficiency of sealing in closed condition.

• Operational testing of hydraulic and power components, wires,

chains and link drives.”

65 7-3-2/5.1.10 In sixth line, “Confirmation of the effectiveness…” to read “Checking the

effectiveness…

65 7-3-2/ Relocate to 7-6-2/3.3.2 and renumber remaining items accordingly.

5.1.11(c)

65 7-3-2/ Relocate to second paragraph of 7-6-2/3.3.1 and renumber remaining items

5.1.11(d) accordingly.

71 7-3-2/5.5.1 Relocate items (b), (c) and (d) to 7-6-2/3.5 and renumber remaining items

accordingly.

71 7-3-2/5.5.1 Reinstate text moved to 7-6-2/3.5 and renumber remaining items accordingly.

77 7-3-2/5.7.7 In third and fourth lines, delete “(Rev. 1, Corr. 3, January 2004)”.

77 7-3-2/5.11 In first line, reference “7-3-2/1.13.7” to read “7-3-2/1.13.5”.

77 7-3-2/5.11 In first line, reference “7-3-2/1.13.5” to read “7-3-2/1.13.7”.

77 7-3-2/5.11.1 Relocate items (c), (d), (e), (l), (m) and (p) to 7-6-2/3.3.4 and renumber

remaining items accordingly.

77 7-3-2/ In first paragraph, reference “7-3-2/5.1.11(f)” to read “7-3-2/5.1.11(c)”.

5.11.1(b)

ABS RULES FOR BUILDING AND CLASSING STEEL VESSELS . 2005 7

Corrigenda/Editorials – 12 January 2005

11 March 2005

Page No. Paragraph Comments

Part 7 Rules for Survey After Construction

Chapter 3 Hull Surveys

Section 2 Vessels for Unrestricted Service

80 7-3-2/ Relocate subitems i) through v) to 7-6-2/3.3.5 and renumber remaining

5.13.1(a) subitem accordingly.

80 7-3-2/ Relocate to 7-6-2/3.3.5.

5.13.1(b)

80 7-3-2/5.13.2 Relocate second paragraph to 7-6-2/3.3.3.

82 7-3-2/ In second-to-last line, “transverses” to read “web frame rings”.

5.13.3(c)ii)

82 7-3-2/ In second-to-last line, “web frame rings” to read “transverses”.

5.13.3(c)iii)

85 7-3-2/5.14.2 Relocate second paragraph to 7-6-2/3.3.3.

87 7-3-2/ Title to read “Special Periodical Survey No. 4 and subsequent Special

5.14.3(d) Periodical Surveys (Age > 15 years)”.

90 7-3-2/5.15.1 Relocate second paragraph to 7-6-2/3.7.1.

94 7-3-2/5.19 In title, “Combination Carriers – Double Hull ESP” to read “Combination

Carriers – Non Double Skin ESP”.

98 7-3-2/7.3 Title to read “Bulk Carriers – Non Double Skin ESP and Bulk Carrier

Features of Combination Carriers – Non Double Skin ESP”.

109 7-3-2/7.9 In title, “Combination Carriers – Double Hull ESP” to read “Combination

Carriers – Non Double Skin ESP”.

115 7-3-2/11.3 In last bullet, “Survey Planning” to read “Survey Program”.

117 7-3-2/15.3 In third paragraph, reference “7-A-9/9” to read “7-A-9/Report 1”.

Part 7 Rules for Survey After Construction

Chapter 3 Hull Surveys

Section 3 Vessels in Great Lakes Service

119 7-3-3 In second introductory sentence, “The ESP Vessel requirements” to read

“The ESP and ESDC Vessel requirements”.

Part 7 Rules for Survey After Construction

Chapter 3 Hull Surveys

Section 4 Vessels Rivers and Intracoastal Waterways Service

121 7-3-4 In second introductory sentence, “The ESP Vessel requirements” to read

“The ESP and ESDC Vessel requirements”.

8 ABS RULES FOR BUILDING AND CLASSING STEEL VESSELS . 2005

Corrigenda/Editorials – 12 January 2005

11 March 2005

Page No. Paragraph Comments

Part 7 Rules for Survey After Construction

Chapter 5 Tailshaft Surveys

Section 1 Survey Requirements

133 7-5-1/7 Relocate second through last sentences of second paragraph of 7-2-2/15 to

(New) new Subsection 7-5-1/7 as follows:

7 Vessels in Great Lakes Service (2005)

7.1 Tailshaft Survey

Where arrangements are such as to permit an effective nondestructive

examination by a surface crack-detection method (such as magnetic

particle or dye penetrant) all around the shaft in way of the forward

portion of the taper section, including the end of keyway (if fitted),

the shaft need not be drawn for examination in its entirety. Where

arrangements of the flanged tailshaft permits effective examination of

the flange fillet by a surface crack detection method, bearing

weardown measurement and shaft seal effectiveness (oil-lubricated

bearings), the shaft need not be withdrawn. The flange coupling bolts

are to be examined by means of a surface crack detection method

whenever they are removed. The Controllable-Pitch propeller hub is

to be tested under operating conditions for oil tightness.

Part 7 Rules for Survey After Construction

Chapter 6 Machinery Surveys

Section 2 Survey Requirements

145 7-6-2/1.3.8 Add new Subparagraph 7-6-2/1.3.8 with relocated text from 7-3-2/1.13.2 as

(New) follows and renumber existing 7-6-2/1.3.8 as 7-6-2/1.3.11:

“1.3.8 Cargo Piping Systems

Cargo, crude oil washing, bunker, ballast and tank vent

piping systems above the weather deck and in the cargo

pump room and pipe tunnels. Where suspect, the piping may

be required to be pressure-tested at the working pressure,

thickness measured or both.

Cargo and stripping pumps including foundations, gland

seals, operation of remote control and shut-down devices.

Confirmation that cargo discharge pressure gauges and level

indicator systems are operational.”

145 7-6-2/1.3.8 Relocate text back to 7-3-2/1.13.2.

(New)

145 7-6-2/1.3.9 Add new Subparagraph 7-6-2/1.3.9 with relocated text from 7-3-2/1.13.3 as

(New) follows and renumber existing 7-6-2/1.3.9 as 7-6-2/1.3.12:

“1.3.9 Electrical Bonding and Equipment

Electrical bonding arrangements on weather deck and in

cargo pump rooms, including bonding straps, where fitted, of

cargo piping systems carrying flammable liquids and piping

systems routed through hazardous areas. Bonding to hull,

where applicable, of cargo tanks is to be examined.

ABS RULES FOR BUILDING AND CLASSING STEEL VESSELS . 2005 9

Corrigenda/Editorials – 12 January 2005

11 March 2005

Page No. Paragraph Comments

Confirmation that electrical equipment in hazardous

locations including cargo pump room, have been properly

maintained, including the following items. The list required

by SVR 4-8-1/5.3.2 may be referred to during the

confirmation.

• Intrinsically safe and explosion-proof features of

electrical equipment installed in the hazardous areas, in

particular any associated sealing arrangement.

• The physical condition of cables (wiring) and fixtures

and test of insulation resistance of the circuits. In cases

where a proper record of testing is maintained,

consideration may be given to accepting recent readings.

• The cable supports and the means of cable protection

from mechanical damage, as originally provided.

• Gas detection system in the cargo pump room, if fitted.

• Temperature-sensing devices fitted on bulkhead shaft

glands, pump bearings and casings.”

145 7-6-2/1.3.9 Relocate text back to 7-3-2/1.13.3.

(New)

145 7-6-2/1.3.10 Add new Subparagraph 7-6-2/1.3.10 with relocated text from 7-3-2/1.13.4 as

(New) follows:

“1.3.10 Cargo Pump Room

Operation of pump room bilge pumping system.

Pump room ventilation system including ducting, dampers

and screens.”

145 7-6-2/1.3.10 Relocate text back to 7-3-2/1.13.4.

(New)

145 7-6-2/1.3.11 Renumber existing 7-6-2/1.3.8 as 7-6-2/1.3.11 and replace existing text with

the following:

“1.3.11 Liquefied Gas Carriers

1.3.11(a) Interbarrier Space Venting System. The venting

system or other arrangements provided for the emergency

removal of gas from the interbarrier spaces (i.e., between the

primary and secondary barriers) is to be confirmed in

satisfactory condition.

1.3.11(b) Cargo Tank Venting System (1 July 2003). The

venting system for the cargo tanks and hold spaces is to be

confirmed in satisfactory operating condition. Vent line

drainage arrangement is to be examined.

1.3.11(c) Instrumentation and Safety Systems (1 July 2003).

Gas leakage detection equipment, including indicators and

alarms, is to be confirmed in satisfactory operating

conditions. Systems for temperature, pressure and liquid

10 ABS RULES FOR BUILDING AND CLASSING STEEL VESSELS . 2005

Corrigenda/Editorials – 12 January 2005

11 March 2005

Page No. Paragraph Comments

level indication of the cargo, cargo tank, insulation, the hull

adjacent to the cargo containment system, and cargo

refrigerating installations where fitted, including alarms, are

to be confirmed in satisfactory operating condition. The

piping of the gas detection system is to be visually examined

for corrosion and damage and the integrity of the line

between suction points and analyzing units is to be confirmed

as far as possible.

1.3.11(d) Environmental Control of Hold Spaces (1998).

Inert gas and dry air systems, including indicators and

alarms, are to be confirmed in satisfactory operating

condition. Means for prevention of backflow of cargo vapor

into gas-safe spaces is to be confirmed in satisfactory

operating condition.

1.3.11(e) Cargo Handling Piping and Machinery (1998).

All piping, cargo hoses, emergency shut-down valves,

remote operating valves, machinery and equipment for

loading, unloading, venting, compressing, refrigerating,

liquefying, heating or otherwise handling the liquefied gas or

vapor is to be examined, as far as possible. Stopping of the

cargo pumps and compressors upon emergency shut-down of

the system is to be confirmed. See also 7-6-2/1.3.9.

1.3.11(f) Heating Coils. Heating coils and other heating

systems which are fitted and essential for the heating of the

hull structure to ensure that the temperature of the structure

does not fall below the minimum allowable value for the

material used are to be proven in satisfactory operating

condition.

1.3.11(g) Ventilating System (1998). Examination of the

ventilation system is to be made for all spaces in the cargo

area, including air locks, cargo pump rooms, cargo

compressor rooms, cargo control rooms and spaces used for

cargo handling operations. All portable ventilating equipment

required for use in the cargo area is to be examined.

Provision of spares for cargo area mechanical ventilation

fans recommended by manufacturer is to be confirmed.

1.3.11(h) Gas Burning Installations (1998). Gas burning

installations, including instrumentation and safety systems,

are to be examined and confirmed in satisfactory operating

condition.

1.3.11(i) Fire Protection and Fire Extinguishing Equipment.

The fire water main equipment, water spray equipment, dry

chemical powder fire extinguishing systems in the cargo

area, and fixed inerting and fixed smothering installations in

gas-dangerous spaces are to be examined and operationally

tested, in so far as practicable.

1.3.11(j) Electrical Equipment (1998). Electrical equipment

in gas-dangerous spaces or zones is to be examined. This

examination is to include the physical condition of electrical

cables and supports, intrinsically safe, explosion proof, or

ABS RULES FOR BUILDING AND CLASSING STEEL VESSELS . 2005 11

Corrigenda/Editorials – 12 January 2005

11 March 2005

Page No. Paragraph Comments

increased safety features of electrical equipment, functional

testing of pressurized equipment and associated alarms,

testing systems for de-energizing electrical equipment which

is not certified for use in gas-hazardous areas but which is

located in spaces protected by airlocks (e.g., electrical motor

rooms or cargo control rooms), and insulation resistance

readings of circuits. Where a proper record of testing is

maintained, consideration may be given to accepting recent

readings.

1.3.11(k) Relief Valves (1999). All relief valves in the cargo

containment and venting system are to be examined,

including protective screens and flame screens, if provided,

and seals confirmed intact. Records of opening and closing

pressures of relief valves are to be confirmed onboard.”

145 7-6-2/1.3.11 Renumber as 7-6-2/1.3.8.

145 7-6-2/1.3.11(e) Reference “7-6-2/1.3.9” to read “7-3-2/1.13.3”.

145 7-6-2/1.3.12 Renumber existing 7-6-2/1.3.9 as 7-6-2/1.3.12 and replace existing text with

the following:

“1.3.12 Chemical Carriers

1.3.12(a) Cargo Handling Piping and Machinery. All

piping, cargo hoses, emergency shutdown valves, remote

operating valves, machinery and equipment for loading,

unloading, venting, heating/cooling or otherwise handling

chemicals are to be examined. Pump pressure gauges are to

be examined. See also 7-6-2/1.3.9.

1.3.12(b) Ventilating Systems. Those systems for all spaces

in the cargo area, including air locks, cargo pump rooms,

cargo control rooms and spaces used for cargo handling

operations are to be examined. Closing devices of all air

intakes and openings into the accommodation service and

control spaces are to be examined. All portable ventilating

equipment required for use in the cargo area is to be

examined.

1.3.12(c) Cargo Tank Vent System. The venting system

including liquid-level indicators and alarms for the cargo

tanks, as required, are to be confirmed in satisfactory

operating condition. Vent line drainage arrangement is to be

examined.

1.3.12(d) Environmental Control of Vapor Space in Cargo

Tanks and Void Spaces Surrounding Such Tanks. Where a

controlled atmosphere is required, an examination of the

control provided and verification that an adequate supply of

the specified medium is onboard or can be produced

onboard, as required.

1.3.12(e) Pump and Pipeline Identification. Verification of

pipe and pump markings.

12 ABS RULES FOR BUILDING AND CLASSING STEEL VESSELS . 2005

Corrigenda/Editorials – 12 January 2005

11 March 2005

Page No. Paragraph Comments

1.3.12(f) Vapor Detection. Verify, as required, the means

provided for detection and testing for toxic and flammable

vapor concentrations including proper working conditions.

1.3.12(g) Fire Protection and Fire Extinguishing Equipment.

The fire main equipment, water spray equipment, dry

chemical powder fire extinguishing systems in the cargo

area, and fixed inerting and fixed smothering installations are

to be examined and operationally tested in so far as

practicable.”

145 7-6-2/1.3.12 Renumber as 7-6-2/1.3.9.

145 7-6-2/1.3.12(a) Reference “7-6-2/1.3.9” to read “7-3-2/1.13.3”.

146 7-6-2/1.7 Add new Paragraph 7-6-2/1.7 with relocated text from 7-3-2/1.5.2 as follows:

(New)

“1.7 Barges

1.7.1

For manned barges Annual Survey is to include the

following:

• Fire safety measures.

• Fire extinguishers.

• Power supply including emergency source of power.

• Lifesaving appliances and equipment.

• Radio communication installation.

• Windlass, anchors and chains.

• Firemains are to be pressurized to the working pressure

and surveyed over their full length, where accessible.”

146 7-6-2/1.7 Relocate text back to 7-3-2/1.5.2.

(New)

151 7-6-2/3.3.1 Relocate text of 7-3-2/5.1.11(d) to new second paragraph of 7-6-2/3.3.1 as

follows:

“3.3.1 Cargo Handling Systems

On tankers, an examination is to be made of cargo handling

systems, including cargo pumps and drives, cargo piping,

vent piping, valves and equipment. All remotely operated

valves in the cargo piping system are to be examined and

tested. For independent cargo tanks, see 7-3-2/5.1.11.

All piping, machinery, and equipment for loading, venting,

compressing, refrigerating, liquefying, heating or otherwise

handling the cargo are to be generally examined. All quick-

closing and emergency shut-off valves in the cargo piping

systems are to be examined and tested.”

ABS RULES FOR BUILDING AND CLASSING STEEL VESSELS . 2005 13

Corrigenda/Editorials – 12 January 2005

11 March 2005

Page No. Paragraph Comments

Part 7 Rules for Survey After Construction

Chapter 6 Machinery Surveys

Section 2 Survey Requirements

151 7-6-2/3.3.2 Add new Subparagraph 7-6-2/3.3.2 with relocated text from 7-3-2/5.1.11(c)

(New) as follows and renumber existing 7-6-2/3.3.2 as 7-6-2/3.3.4:

“3.3.2 Independent Cargo Tank Venting Systems and Liquid-

level Indicators

Venting systems for the cargo containment systems are to be

examined. All relief valves are to be opened, examined,

tested and readjusted, as necessary. Liquid-level indicators

are to be proven in order. Where a proper record of

continuous overhaul and retesting of individually identifiable

relief valves is maintained, consideration will be given to

acceptance on the basis of opening, internal examination and

testing of a representative sampling of valves including each

size of each type of relief valve in use, provided there is

logbook evidence that the remaining valves have been

overhauled and tested since the crediting of the previous

Special Periodical Survey. The testing and setting of relief

valves may be carried out in place or after removal.”

151 7-6-2/3.3.3 Add new Subparagraph 7-6-2/3.3.3 with relocated text from second

(New) paragraph of 7-3-2/5.13.2 or 7-3-2/5.14.2 as follows:

“3.3.3 Cargo Piping on Deck (2001)

Cargo piping on deck, including Crude Oil Washing (COW)

piping, and all piping systems within the above tanks and

spaces are to be examined and operationally tested under

working pressure to attending Surveyor’s satisfaction to

ensure that tightness and condition remain satisfactory.

Special attention is to be given to ballast piping in cargo

tanks and any cargo piping in ballast tanks and void spaces.

Surveyors are to be advised on all occasions when this

piping, including valves and fittings, is open during repair

periods and can be examined internally.”

151 7-6-2/3.3.4 Renumber existing 7-6-2/3.3.2 as 7-6-2/3.3.4 and replace existing text with

the following:

“3.3.4 Liquefied Gas Carriers

3.3.4(a) Interbarrier Space Venting System (1 July 2003).

Venting systems, relief valves or other arrangements

provided for emergency removal of gas from the interbarrier

spaces and hold spaces are to be opened, inspected, tested

and readjusted as necessary.

3.3.4(b) Cargo Tank Venting System and Liquid-level

Indicators (2001). Relief valves, liquid-level indicators and

venting systems for the primary cargo containment system

are to be examined. All relief valves are to be opened,

inspected, tested and readjusted as necessary. If the cargo

tanks are equipped with relief valves with non-metallic

membranes in the main or pilot valves, such non-metallic

14 ABS RULES FOR BUILDING AND CLASSING STEEL VESSELS . 2005

Corrigenda/Editorials – 12 January 2005

11 March 2005

Page No. Paragraph Comments

membranes are to be replaced. Liquid-level indicators and

alarms are to be proven satisfactory. Where a proper record

of continuous overhaul and retesting of individually

identifiable relief valves is maintained, consideration will be

given to acceptance on the basis of opening, internal

examination and testing of a representative sampling of

valves including each size of each type of liquefied gas or

vapor relief valve in use, provided there is logbook evidence

that the remaining valves have been overhauled and tested

since the crediting of the previous Special Periodical Survey.

The testing and setting of relief valves may be carried out in

place or after removal.

3.3.4(c) Cargo Handling and Piping Material (1 July 2003).

All piping, machinery and equipment for loading, unloading,

venting, compressing, refrigerating, liquefying, heating or

otherwise handling the liquefied gas or vapor and liquid

nitrogen, and gas burning installations is to be examined

including removal of insulation and opening for examination,

as deemed necessary. Where deemed suspect, a hydrostatic

test to 1.25 times the Maximum Allowable Relief Valve

Setting (MARVS) for the pipeline is to be carried out. After

reassembly, the complete piping is to be tested for leaks.

Where water cannot be tolerated and the piping cannot be

dried prior to putting the system into service, the Surveyor

may accept alternative testing fluids or alternative means of

testing. All emergency shut-down valves and remote

operating valves in the cargo piping systems are to be

inspected and proven operable. The pressure relief valves are

to be function-tested. A random selection of valves is to be

opened for examination and adjusted.

3.3.4(d) Electrical Bonding. Electrical bonding

arrangements, including bonding straps where fitted, of the

piping systems located within cargo tanks, ballast tanks, pipe

tunnels, cofferdams and void spaces bounding cargo tanks

are to be examined.

3.3.4(e) Drainage Arrangements (1 July 2003). Systems for

removing water or cargo from interbarrier spaces and holds

are to be examined and tested as deemed necessary.

3.3.4(f) Miscellaneous (1 July 2003). The hoses and spool

pieces used for segregation of piping systems for cargo, inert

gas and bilge are to be examined.”

151 7-6-2/3.3.5 Renumber existing 7-6-2/3.3.3 as 7-6-2/3.3.5 and replace existing text with

the following:

“3.3.5 Chemical Carriers

3.3.5(a) Chemical Carriers ESP

i) Cargo Pump Rooms. Examine for leakage and

drainage arrangements, including operational test of

the bilge system.

ABS RULES FOR BUILDING AND CLASSING STEEL VESSELS . 2005 15

Corrigenda/Editorials – 12 January 2005

11 March 2005

Page No. Paragraph Comments

ii) Cargo Transfer and Control System. Examine cargo

transfer system including operational test of remote

shut-down devices and remote operating valves, as

fitted. Verify that the cargo hoses are compatible

with the cargo carried, and suitable for the cargo

temperature and working pressures.

iii) Temperature Control. The cargo heating or cooling

systems, as required, are to be examined including

temperature indicating devices and alarm systems.

iv) Electrical Equipment. Electrical equipment in

hazardous locations, spaces or zones is to be

examined.

v) Bonding. The electrical bonding arrangements

including bonding straps, where fitted, for

independent cargo tanks and for the piping systems

located within cargo tanks, ballast tanks, pipe

tunnels, cofferdams and void spaces bounding cargo

tanks are to be examined.

3.3.5(b) Chemical Carriers ESP > 10 Years of Age (1 July

2001). Selected steel cargo pipes outside cargo tanks and

ballast pipes passing through cargo tanks are to be:

• Thickness measured at random or selected pipe lengths

to be opened for internal examination.

• Pressure tested to the maximum working pressure.

Special attention is to be given to cargo/slop discharge piping

through Ballast Tanks and Void Spaces.”

151 7-6-2/3.5 Add new Paragraph 7-6-2/3.5 with relocated text from 7-3-2/5.5.1 as follows:

(New)

“3.5 Barges

3.5.1 Pumps and Piping Arrangement (1995)

Pumps and piping arrangements, including valves, cocks,

pipes and strainers, are to be examined. The Surveyor is to be

satisfied with the operation of the bilge system, where fitted.

Other systems are to be tested as considered necessary.

3.5.2 Heat Exchangers and Unfired Pressure Vessels (1995)

Heat exchangers and other unfired pressure vessels with

design pressures over 6.9 bar (7 kgf/cm2, 100 psi) are to be

examined, opened out or thickness gauged and pressure

tested as considered necessary, and associated relief valves

proven operative. Evaporators that operate with a vacuum on

the shell need not be opened, but may be accepted on basis of

satisfactory external examination and operational test or

review of operating records.

16 ABS RULES FOR BUILDING AND CLASSING STEEL VESSELS . 2005

Corrigenda/Editorials – 12 January 2005

11 March 2005

Page No. Paragraph Comments

3.5.3 Fire Extinguishing Apparatus (1995)

An examination of the fire extinguishing apparatus required

for classification as outlined in Section 19 of the Rules for

Building and Classing Steel Barges is to be made in order

that the Surveyor may satisfy himself as to its efficient state.”

151 7-6-2/3.5 Relocate text back to 7-3-2/5.5.1.

(New)

151 7-6-2/3.7 Add new Paragraph 7-6-2/3.7 with relocated text from 7-3-2/5.15.1 as

(New) follows:

“3.7 General Dry Cargo Vessels (ESDC) (2004)

3.7.1 Overall Survey Requirements

All piping systems within the cargo holds, salt water ballast

tanks, including double bottom tanks, pipe tunnels,

cofferdams and void spaces bounding cargo holds, decks and

outer hull are to be examined and tested under working

conditions to ensure that the condition remains satisfactory.”

151 7-6-2/3.7 Renumber as 7-6-2/3.5.

(New)

Part 7 Rules for Survey After Construction

Chapter 9 Survey Requirements for Additional Systems and Services

Section 7 Vapor Emission Control Systems

185 7-9-7/1.1.4 Reference “section 2.2.5 of the Guide for Cargo Vapor Emission Control

Systems on board Tank Vessels” to read “SVR 5-1-7/21.9.4”.

Part 7 Rules for Survey After Construction

Appendix

Section 1 Guide for Underwater Inspection in lieu of Drydocking Surveys

265 7-A-1/5.4 In last sentence, insert “condition” between “physical” and “and securing

arrangements”.

Part 7 Rules for Survey After Construction

Appendix

Section 4 Guide for Hull Thickness Measurement

295 7-A-4/Table 2 Add new Note 1 to read as follows: “Maximum loss of deck or bottom area is

20 percent of Rule required area.”.

Part 7 Rules for Survey After Construction

Appendix

Section 9 Reporting Principles for ESP Vessels

367 Appendix Delete first paragraph and Subsections 1, 3 and 5. Renumber 1.0, 2.0, 3.0 and

7-A-9 4.0 as 1, 3, 5 and 7, respectively.

367 Appendix In first paragraph, “bulk carriers and oil carriers” to read “bulk carriers, oil

7-A-9 carriers and chemical carriers”.

Part 7 Rules for Survey After Construction

Appendix

Section 9 Reporting Principles for ESP Vessels

369 7-A-9/3.0 In last bullet, reference “4.2” to read “7-A-9/7” (refers to renumbered

Subsection above).

ABS RULES FOR BUILDING AND CLASSING STEEL VESSELS . 2005 17

Corrigenda/Editorials – 12 January 2005

11 March 2005

Page No. Paragraph Comments

Part 7 Rules for Survey After Construction

Appendix

Section 11 Guide for Repair and Cladding of Shafts

403 7-A-11/5.9 Revise to read as follows : “Upon the completion of the test weld and after

the required stress relief heat treatment, a test coupon 292 mm ± 6.4 mm

(111/2 ± 1/4 in.) long with the weld in the center is to be prepared. Test

specimens in 7-A-11/Figure 3 are to be machined, and tested in the presence

of a Surveyor. Test results are to be submitted to the Materials Department in

Houston.”.

410 7-A-11/Figure 3 Revise Notes as follows:

“1 Two transverse tension tests, see 2-4-3/Figure 3 of the ABS Rules for Materials

and Welding – Part 2

2 Three metallographic and hardness specimens

3 Three side bend tests, see 2-4-3/Figure 4 of the ABS Rules for Materials and

Welding – Part 2

4 Two all base metal 12.5 ± 0.25 mm (0.500 ± 0.010 in.) diameter tension

specimens (circumferential direction)

5 One all base metal 12.5 ± 0.25 mm (0.500 ± 0.010 in.) diameter tension

specimen (longitudinal direction)

6 Two all weld metal 12.5 ± 0.25 mm (0.500 ± 0.010 in.) diameter tension

specimens (circumferential direction) Tensile and yield strength are to be

compatible with the base metal.

7 Spare”

Part 7 Rules for Survey After Construction

Appendix

Section 14 Guide for Survey Based on Preventative Maintenance Techniques

420 7-A-14/11.1 Reinstate inadvertently deleted text “…analysis, shaft position indicating and

bearing temperatures are not affected and are to continue to be monitored by

the crew at least on a quarterly basis.” at and of first paragraph and “The

annual Owner’s report is to clearly indicate that this alternative is being

utilized and must include both semi-annual signatures for…” at beginning of

second paragraph.

18 ABS RULES FOR BUILDING AND CLASSING STEEL VESSELS . 2005

You might also like

- Metal Bar Grating Manual: Ansi/Naamm Standard American National StandardDocument36 pagesMetal Bar Grating Manual: Ansi/Naamm Standard American National StandardDidier MarouaniNo ratings yet

- Grating Design ManualDocument36 pagesGrating Design ManualAidaFarzanaNanaNo ratings yet

- ABS Welding With Backing StripDocument1 pageABS Welding With Backing StripAbuBakarSiddkeRumiNo ratings yet

- Cladding Mechanical TestingDocument1 pageCladding Mechanical TestingMohammedNo ratings yet

- MBG531 15Document34 pagesMBG531 15Per DCNo ratings yet

- Norma Rejillas Tránsito Vehicular - ANSI NAAMM MBG532-00Document75 pagesNorma Rejillas Tránsito Vehicular - ANSI NAAMM MBG532-00JuanNo ratings yet

- SHEF30 SalesDocument2 pagesSHEF30 Salesallen_worstNo ratings yet

- Acople Inteva TGWDocument12 pagesAcople Inteva TGWIMPO FREICONo ratings yet

- API 660 Vs TEMA RequirementsDocument3 pagesAPI 660 Vs TEMA Requirementstndeshmukh88% (8)

- Api 650 RTDocument3 pagesApi 650 RTAdi QCNo ratings yet

- MBG - 531-09 Metal Bar Grating ManualDocument36 pagesMBG - 531-09 Metal Bar Grating ManualCarlo Monsalve100% (1)

- Normal Grating Manual 531-09Document36 pagesNormal Grating Manual 531-09esaraviaNo ratings yet

- WPS - Api 5L X52 - Codigo Api1104Document1 pageWPS - Api 5L X52 - Codigo Api1104Cristhian Camilo Quiroga WalterosNo ratings yet

- Tooling Standard (Die Casting)Document39 pagesTooling Standard (Die Casting)Kmilo GiraldoNo ratings yet

- General Lubrication Products: Fittings & AccessoriesDocument1 pageGeneral Lubrication Products: Fittings & AccessoriesZahir KhiraNo ratings yet

- Dimensional Tolerances For Cold Close Radius Pipe Bending and Forming 670.231Document11 pagesDimensional Tolerances For Cold Close Radius Pipe Bending and Forming 670.231puwarin najaNo ratings yet

- MBG 531 2017 GratingDocument34 pagesMBG 531 2017 GratingErik Jhonattan Jara YpanaqueNo ratings yet

- Millermatic® 350P MIG Welder: SpecificationsDocument2 pagesMillermatic® 350P MIG Welder: Specificationsyasser awadallhNo ratings yet

- LPS Pricelist 1-4-2018Document20 pagesLPS Pricelist 1-4-2018Prabhat MishraNo ratings yet

- Shell and Tube Heat Exchangers (API 660 vsTEMA)Document3 pagesShell and Tube Heat Exchangers (API 660 vsTEMA)Aravind MadhuNo ratings yet

- Service SinkDocument4 pagesService SinkAnita CabassaNo ratings yet

- Bus Bar Bolting - TorqueDocument2 pagesBus Bar Bolting - TorquePrince KumarNo ratings yet

- 01 - 50 - 912 - BDocument27 pages01 - 50 - 912 - Bh_eijy2743No ratings yet

- C955 09Document4 pagesC955 09jacr27No ratings yet

- API 660 Vs TEMADocument5 pagesAPI 660 Vs TEMAALONSO GOMEZNo ratings yet

- WKM Dynaseal 210 and 310 Floating Ball Valves PDFDocument44 pagesWKM Dynaseal 210 and 310 Floating Ball Valves PDFJose LuisNo ratings yet

- Elkay LK945 PartsDocument1 pageElkay LK945 PartswadeflNo ratings yet

- Die Design PresentationDocument24 pagesDie Design PresentationIsrar Equbal100% (1)

- Especificaciones Kwik BoltDocument12 pagesEspecificaciones Kwik BoltjaimepwpsNo ratings yet

- ION 6200 RMD Retrofit Instructions: Location & MountingDocument3 pagesION 6200 RMD Retrofit Instructions: Location & MountingAzar TajNo ratings yet

- Ficha Tecnica E803Document2 pagesFicha Tecnica E803Zenen AlarconNo ratings yet

- Schem DrawingDocument2 pagesSchem DrawingMohamed ArafaNo ratings yet

- Bi-Metal Tek Screw: Product DatasheetDocument1 pageBi-Metal Tek Screw: Product Datasheetbravo deltafoxNo ratings yet

- WKM Dynaseal 210 and 310 Floating Ball ValvesDocument43 pagesWKM Dynaseal 210 and 310 Floating Ball Valvesjhon jairo GonzalezNo ratings yet

- To Study Mechanical Behavior by Using Variant in Gas Metal Arc WeldingDocument4 pagesTo Study Mechanical Behavior by Using Variant in Gas Metal Arc Weldinganil kasotNo ratings yet

- Replace With EXACT Text Entries From The 2015 Edition, Which Are Shown On Pages 3 and 4 of This Proposal FileDocument4 pagesReplace With EXACT Text Entries From The 2015 Edition, Which Are Shown On Pages 3 and 4 of This Proposal FileMadhubalan PNo ratings yet

- Todo Safety Break Away CouplingsDocument8 pagesTodo Safety Break Away CouplingsKamalNo ratings yet

- MECH3660 9660 Tutorial Sheet Metal and Welding 2015Document2 pagesMECH3660 9660 Tutorial Sheet Metal and Welding 2015divaaaaaaaaaNo ratings yet

- KBV Expansion Anchor Product DescriptionDocument10 pagesKBV Expansion Anchor Product DescriptionRodrigo MachadoNo ratings yet

- Fastener Spacing and Margin DataDocument13 pagesFastener Spacing and Margin DataLONG VUNo ratings yet

- Voestalpine Stahl GMBH - CC8 Caster For High-Quality Grades and Exposed Automotive Steel Using Danieli TechnologyDocument10 pagesVoestalpine Stahl GMBH - CC8 Caster For High-Quality Grades and Exposed Automotive Steel Using Danieli TechnologyJJNo ratings yet

- Chain Link ManualDocument32 pagesChain Link ManualJunaid TylorNo ratings yet

- Material Specifications: Table 1 - Hilti HSL-3 SpecificationsDocument1 pageMaterial Specifications: Table 1 - Hilti HSL-3 SpecificationsVenkatesh HebbarNo ratings yet

- 1KW Horizontal Users ManualDocument17 pages1KW Horizontal Users ManualSean SmithNo ratings yet

- Specification of MEFG Fixed TypeDocument6 pagesSpecification of MEFG Fixed TypeDharmavir SinghNo ratings yet

- Radiographic Method API 650Document4 pagesRadiographic Method API 650Riza Ahmad Sofikul Irfan0% (1)

- Design and Manufacturing Simulation of PDocument9 pagesDesign and Manufacturing Simulation of PAnkit SahuNo ratings yet

- SRM-51-47-00 Fastener Pitch and Edge Distance DataDocument13 pagesSRM-51-47-00 Fastener Pitch and Edge Distance DataJelpi Duvan LariosNo ratings yet

- Welding Parameters For Inconel 625 Overlay On Carbon Steel Using GMAWDocument6 pagesWelding Parameters For Inconel 625 Overlay On Carbon Steel Using GMAWSyarief Nahdi100% (1)

- Ford Spot Weld SpecDocument12 pagesFord Spot Weld SpecJonathan Davies0% (1)

- Procedures For Collision RepairDocument10 pagesProcedures For Collision Repairvinhquangbk10No ratings yet

- MBG 533-09Document19 pagesMBG 533-09apply19842371No ratings yet

- PEM Self Clinching Self Locking FastenersDocument4 pagesPEM Self Clinching Self Locking FastenersAce Industrial SuppliesNo ratings yet

- 1082 DDocument21 pages1082 DbilsaitNo ratings yet

- MM4455US PartsandAccessories2013Document32 pagesMM4455US PartsandAccessories2013Edgar HuimanNo ratings yet

- Parts Cut To Length: Ted SlezakDocument8 pagesParts Cut To Length: Ted SlezaksolquihaNo ratings yet

- RS CNC Mechanical Manual Assembly-1Document117 pagesRS CNC Mechanical Manual Assembly-1Pedro MartinhoNo ratings yet

- Plastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3From EverandPlastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3No ratings yet

- CD 4069Document7 pagesCD 4069Ch S SrinivasNo ratings yet

- All Clear kl8 Unit3 Extra Test ADocument3 pagesAll Clear kl8 Unit3 Extra Test AKaRtonEkNo ratings yet

- Basic Preventive Maintenance Check List For ReciprocatingDocument4 pagesBasic Preventive Maintenance Check List For Reciprocatingsubramanyanvenkat6185100% (1)

- Semester Syllabus For M. Sc. in Chemistry: School of Chemistry (AutonomousDocument22 pagesSemester Syllabus For M. Sc. in Chemistry: School of Chemistry (AutonomousDachou GeetuNo ratings yet

- DB en Quint4 Ps 1ac 110dc 4 109530 en 00Document48 pagesDB en Quint4 Ps 1ac 110dc 4 109530 en 00Asad NaeemNo ratings yet

- Aakas Aiats 2020 Test1 29-07-2019Document119 pagesAakas Aiats 2020 Test1 29-07-2019gyandatt100% (3)

- Barracuda Lite 19 WS RegularDocument2 pagesBarracuda Lite 19 WS RegularcarlosorizabaNo ratings yet

- Fluid MechanicsDocument35 pagesFluid MechanicsJohn Ely Collado Bantog0% (1)

- Project On Global WarmingDocument22 pagesProject On Global WarmingHilda DsouzaNo ratings yet

- CREW Radon 1 ReportDocument26 pagesCREW Radon 1 ReportDragos MihaiNo ratings yet

- Unit 1 Solar EnergyDocument176 pagesUnit 1 Solar EnergyAkhil Dayalu100% (1)

- Sunlight Battery 12V 12ahDocument1 pageSunlight Battery 12V 12ahCarolyn MunozNo ratings yet

- 8015-0151-ENTR-41-411-EL-MS-41205 - A0 Method Statement For Cathodic Protection PDFDocument9 pages8015-0151-ENTR-41-411-EL-MS-41205 - A0 Method Statement For Cathodic Protection PDFCripoNo ratings yet

- Generic Requirements Specification of Design For EnvironmentDocument6 pagesGeneric Requirements Specification of Design For EnvironmentAxel CornaloNo ratings yet

- 1.TareaParticipacion 2do - ParcialDocument19 pages1.TareaParticipacion 2do - ParcialLeonardo EstradaNo ratings yet

- Cleaning of Pipes by Gas Discharge Back PuffingDocument1 pageCleaning of Pipes by Gas Discharge Back PuffingVamsi MahantiNo ratings yet

- Cross-Curricular Focus: Life Science: NameDocument2 pagesCross-Curricular Focus: Life Science: NameAndreea Dragomir67% (3)

- Detailed CalculationsDocument14 pagesDetailed CalculationsrozNo ratings yet

- Parts-Gm3 0Document43 pagesParts-Gm3 0ناصرقوجيلNo ratings yet

- A Study of Integrated Choke Characteristic For EMI Filter DesignDocument4 pagesA Study of Integrated Choke Characteristic For EMI Filter DesignDiego GutierrezNo ratings yet

- 250 WATT Power Inverter: Power Small Appliances From Your Car or Any Other 12-Volt Source With Our 250-Watt InverterDocument3 pages250 WATT Power Inverter: Power Small Appliances From Your Car or Any Other 12-Volt Source With Our 250-Watt Invertertaner56No ratings yet

- UT Dallas Syllabus For Phys3341.001.11f Taught by Mark Lee (mxl101000)Document5 pagesUT Dallas Syllabus For Phys3341.001.11f Taught by Mark Lee (mxl101000)UT Dallas Provost's Technology GroupNo ratings yet

- UL Cyber ParkDocument9 pagesUL Cyber ParkGeet RangNo ratings yet

- Insulation CoordinationDocument75 pagesInsulation CoordinationDundi Kumar BevaraNo ratings yet

- Braking Capacity of Railway Wheels - State-Of-The-Art SurveyDocument19 pagesBraking Capacity of Railway Wheels - State-Of-The-Art SurveyManjunath AithalNo ratings yet

- PIPEPHASE Application BriefsDocument219 pagesPIPEPHASE Application Briefsarmando0212-1No ratings yet

- Introduction To MicroWavesDocument5 pagesIntroduction To MicroWavesKrish_666No ratings yet

- Part Cat-Soil Compactor BW 212Document218 pagesPart Cat-Soil Compactor BW 212Dhru Ti100% (7)

- MA 40 - Premium Quality Stationary Gas Engine OilDocument2 pagesMA 40 - Premium Quality Stationary Gas Engine OilRaden ArdyNo ratings yet

- TM 9 4935 601 14 3&PDocument137 pagesTM 9 4935 601 14 3&Pkhaerul jannahNo ratings yet