Professional Documents

Culture Documents

SCP WallMount FullSheet

Uploaded by

dadanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SCP WallMount FullSheet

Uploaded by

dadanCopyright:

Available Formats

SUPER

DUPER

Thank you for purchasing a Scott Creek Pottery clay extruder!

This tool has been manufactured from the finest quality materials and fabricated with

great attention to every detail to ensure years of use. The things that you can make

CLAY

with your new extruder are only limited by your imagination.

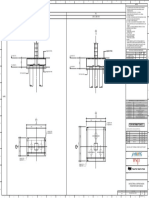

Installation Instructions - 4” & 5” Extruders:

EXTRUDER

Tools required: Cordless Drill/Driver, Stud Finder, Level, 2x4 cut to at least 20“ long, 3” screws

-Please read installation instructions fully before proceeding

-We recommend mounting your Wall Mount Extruder to a 2x4 wall stud. You could also mount to a solid

wood post/beam if that’s what available in your studio space

-If mounting to a wall stud first you will need to locate your selected stud using a stud finder. Studs are commonly placed 16” apart on

center. Be sure to mark to edges of the stud so you can find the center point for maximum strength

-Determine the proper mounting height for your extruder, you should be able to look down through the (3) BARREL from a standing

position

-Using screws of appropriate length/size attach your pre-cut 2x4 to the studs ensuring it is level. This block of wood will give you the wall

spacing necessary to accomodate an Expansion Box as well as provide additional working room when extruding

-Then use the provided lag screws which fit into the holes in the (1) BACKBAR ASSEMBLY to attach the extruder to the mounted 2 x 4

-Next, connect the (2) PLUNGER to the (6) HANDLE using the bolt and nut provided

-Use the (4) CAP PINS to hold the (5) ALUMINUM CAP in place. Please observe that the pins go into the holes at the bottom of the barrel.

The downward pressure of the plunger and clay will keep the cap on if the pins are in the holes

SOFT CLAY IS RECOMMENDED.

Any clay is usuable for extruding, but properly pugged and deaired clay works the best. Coarse clay with a high percentage of grog, if

deaired works fine. Clay that is too soft and poorly wedged may tear and have air bubbles in it as it is extruded. Trying to extrude clay that

is too hard through a small hole will put stress on the extruder and may cause damage to the extruder as well as strain your body.

Basic Operation:

-Remove the (6) HANDLE and (2) PLUNGER from the (3) BARREL and set aside

-Remove the (4) CAP PINS holding the (5) ALUMINUM CAP

-Select the die you’d like to use a place it inside the (5) ALUMINUM CAP, then using the (4) CAP PINS reinstall the cap to the (3) BARREL

-Form a fat coil of soft clay, to fit the size of the barrel and then drop the coil in the top of the(3) BARREL

-Grab the (6) HANDLE and (2) PLUNGER and place the plunger surface through the top of the (3) BARREL until it rests on your loaded

clay. Then gently place the pin at the top end of the (6) HANDLE into the top notch of the (1) BACKBAR ASSEMBLY

-Gently pull the (6) HANDLE downward. When the (6) HANDLE is depressed to it’s lowest point, remove the handle pin, ratchet down the

backbar one pin space, and gently pull the handle down. Repeat until all clay is expressed

-When using the inner die holder to make hollow extrusions, do not put the handle in the last notch on the backbar. This will cause the

inner die holder to break

Helpful Tips

-To keep the handle and plunger out of the way while loading and changing dies, screw a 3” long screw into the wall next to your extruder

to use it as a hook for your handle and plunger.

-When making extrusions, use firm slow pressure to pull the handle down. If you have to use the full force of your adult weight on the

handle, the clay is too stiff or the size of the opening in the die is too small. If the size of the opening in the die is too small, drill additional

holes in the die.

scan for more

instructions

and info

Please See Reverse for a Diagram of the Clay Extruder

Find us on Instagram @scottcreekextruders and share your work!

SUPER

DUPER

Making Hollow Extrusions:

We use a unique 2 part system for making hollow extrusions. Scott Creek Pottery’s extruder uses a

floating inner die holder which makes it possible to easily change the thickness of the extrusion’s wall as

CLAY

well as the inner and outer shapes. ( Most dies are fixed, meaning the inner die is a permanent part of

outer die) Our unique floating die system allows you to combine dies that are differant in size and shape.

For example you could use a square outer die and a cicular inner die to form an extrusion that has a

square exterior and a round interior gap.

EXTRUDER

The challenge in using the floating dies is keeping the gap between the inner and outer die fixed until the

clay is forced through the inner die. A simple solution is to gently load the clay into the barrel and to slowly

depress the plunger. Once the clay is compressed around the inner die holder it will not move until you

want to switch dies.

Another solution is to create wooden shims that are the same thickness as the wall in your extruded shape

and use them to hold the inner and outer die. Here’s how to use the shims:

1. Back Bar Assembly

Looking up into the extruder from the bottom opening wedge 3 or 4 shims between the outer and inner

dies. When the clay is compressed between the two dies, remove the shims. At this point the clay will

keep the floating die in a fixed position

Custom Dies:

All dies that are sold for the extruder are made of 1/8” aluminum. These will not bend but are easy to

cut with a simple carpenters coping saw. Simply draw your design on to the die, drill a pilot hole in

the center of the design. Cut out the design with the coping saw. Finish the shape with a file and you

have a die that will last indefintely. To make a multi-shape die you may cut several small shapes from

one die and block out the ones you do not want to use with a stiff piece of plastic or metal.

Slab Making with the Expansion Box:

2. Plunger

Using the hollow round die extrude semi soft clay into a pipe form approximately 36” long. Place

the extrusion horizontally on brown craft paper and cut one side in a straight line. Open the form

cutting down the the long way to produce a “slab, 36” long. Place paper on the surface and extrude

another, using the paper as a seperator.

We think extruded slabs are superior to rolled ones, perhaps because particles are aligned in a

differant way. In any event they seem more stable.

Cleaning Your Extruder:

-Extrude out as much clay as you can. Let the remaining clay dry out in the barrel

-Remove the barrel from the backbar and knock out the dry clay.

3. Barrel

-Drop the barrel into a 5 gallon bucket of water. Wait 5-10 minutes until it soaks clean.

-Use a sponge to scrub any excess clay left in the barrel.

4. Cap Pins

5. Aluminum Cap

6. Handle

For more tools, dies and replacement parts please visit www.scottcreekpottery.net

You might also like

- CanoePlansPart1 PDFDocument20 pagesCanoePlansPart1 PDFcockybundoo80% (5)

- Build a Cremation CaskDocument7 pagesBuild a Cremation CaskJeffrey Michael Atencio100% (1)

- Jewelry Box: Woodworks: Beginner Project 2009-2010Document7 pagesJewelry Box: Woodworks: Beginner Project 2009-2010Sal GNo ratings yet

- Bamboo Water GardenDocument9 pagesBamboo Water GardenMuhammad Rafiq RavinNo ratings yet

- How To CabDocument8 pagesHow To CabSarah Immel100% (2)

- Duct Tape Engineer: The Book of Big, Bigger, and Epic Duct Tape ProjectsFrom EverandDuct Tape Engineer: The Book of Big, Bigger, and Epic Duct Tape ProjectsRating: 5 out of 5 stars5/5 (1)

- 400 Full-Size Mini Clock PatternsDocument132 pages400 Full-Size Mini Clock PatternsAndreea OanaNo ratings yet

- Slim Ballpoint Pen Hardware Kit: Preparing The Material BlanksDocument4 pagesSlim Ballpoint Pen Hardware Kit: Preparing The Material BlanksLachaud YvonNo ratings yet

- Re Cource Guide 2018Document44 pagesRe Cource Guide 2018Maria PopaNo ratings yet

- $20 Combat Crossbow, TheDocument8 pages$20 Combat Crossbow, TheKaryllongNo ratings yet

- Guide To Making Percussion Caps2Document12 pagesGuide To Making Percussion Caps2Dave Markowitz100% (2)

- Aquarail JetskiDocument6 pagesAquarail Jetskitony_williams_4No ratings yet

- Wooden Toy Spacecraft: Explore the Galaxy & Beyond with 13 Easy-to-Make Woodworking ProjectsFrom EverandWooden Toy Spacecraft: Explore the Galaxy & Beyond with 13 Easy-to-Make Woodworking ProjectsRating: 5 out of 5 stars5/5 (1)

- ARCHITECTURALDocument9 pagesARCHITECTURALJerico NamucoNo ratings yet

- Art q1105Document6 pagesArt q1105Bijouterie Du MondeNo ratings yet

- LapidaryDocument7 pagesLapidarykkeshner100% (1)

- DIY Air Dry Clay Projects Fun and Easy PR - Jose EscobarDocument52 pagesDIY Air Dry Clay Projects Fun and Easy PR - Jose EscobarHady Soenarjo100% (4)

- Whatnot Dish: The Ideal Gift BowlDocument5 pagesWhatnot Dish: The Ideal Gift BowlMarcos R. Hernández M.No ratings yet

- How to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideFrom EverandHow to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideNo ratings yet

- #P574 - Pendulum Clock: 15"H. Order Movement #C131 & Hands #C137 or #C138Document11 pages#P574 - Pendulum Clock: 15"H. Order Movement #C131 & Hands #C137 or #C138eruadan100% (3)

- Easy To Build Stirling Engine FanDocument14 pagesEasy To Build Stirling Engine Fanpatel_kalpesh1241100% (1)

- DIY Paintball Cannons, Grenades & Silencer PlansDocument12 pagesDIY Paintball Cannons, Grenades & Silencer PlansAinis ŠtelemėkasNo ratings yet

- Carve Your Clay: Techniques to Bring the Ceramics Surface to LifeFrom EverandCarve Your Clay: Techniques to Bring the Ceramics Surface to LifeRating: 5 out of 5 stars5/5 (2)

- A Round Kitchen Classic - Bent Laminated Cherry TableDocument8 pagesA Round Kitchen Classic - Bent Laminated Cherry TableJainar BerlianaNo ratings yet

- Book Case - Barrister 1Document6 pagesBook Case - Barrister 1Cris CondeNo ratings yet

- Beginners Segmented Bowl Rev3Document14 pagesBeginners Segmented Bowl Rev3Victor SanhuezaNo ratings yet

- Skateboard VeneerDocument10 pagesSkateboard VeneerFernando JaimeNo ratings yet

- Pressing Matters: Making Platters With MoldsDocument5 pagesPressing Matters: Making Platters With MoldsStefan Van CleemputNo ratings yet

- Reloj DP665Document9 pagesReloj DP665jesusNo ratings yet

- Kato Polyclay Projekcts - AutumnDocument2 pagesKato Polyclay Projekcts - AutumnAlma Zorko100% (2)

- Rocket Motor Construction TutorialDocument19 pagesRocket Motor Construction TutorialAzher Uddin100% (1)

- Saw HandleDocument7 pagesSaw Handleانغي رحمنيNo ratings yet

- DP571 Victorian QueenDocument24 pagesDP571 Victorian QueenAntonio GatoNo ratings yet

- Building Cost EstimateDocument8 pagesBuilding Cost EstimatemohsinciviljmiNo ratings yet

- Photo Guide - Make A Wooden TableDocument41 pagesPhoto Guide - Make A Wooden TableSkorrogan Skontar100% (1)

- 3-piece kayak construction with quick-release boltsDocument5 pages3-piece kayak construction with quick-release boltsSylvia GoiburuNo ratings yet

- T-Nuts in FoamDocument6 pagesT-Nuts in Foamscribd4uall100% (1)

- Ceramic Tile Manufacturing ProcesssDocument20 pagesCeramic Tile Manufacturing ProcesssMike Cajes AsiadoNo ratings yet

- MCJM F12 BLAD WebDocument2 pagesMCJM F12 BLAD WebInterweaveNo ratings yet

- Product: Bubbledeck Structure SolutionsDocument11 pagesProduct: Bubbledeck Structure SolutionsmichelzzNo ratings yet

- Technical Guidance Notes Level 1 Intro Design Loads Analysis DrawingsDocument1 pageTechnical Guidance Notes Level 1 Intro Design Loads Analysis DrawingsAhmet TukenNo ratings yet

- Stora Enso CLT Documentation On Fire Protection EnglishDocument51 pagesStora Enso CLT Documentation On Fire Protection EnglishВадим ГуцкалNo ratings yet

- Salero y PimenteroDocument11 pagesSalero y PimenterokevineliNo ratings yet

- How To Make Quick & Easy Amtgard-Legal Jugging' EquipmentDocument0 pagesHow To Make Quick & Easy Amtgard-Legal Jugging' EquipmentRochelle DeNo ratings yet

- Berea Hardwoods Baron Roller Ball and Fountain Pen (Berea #0405R/-)Document3 pagesBerea Hardwoods Baron Roller Ball and Fountain Pen (Berea #0405R/-)Doru GujbaNo ratings yet

- DL50 Discus Launch GliderDocument16 pagesDL50 Discus Launch GliderAri SutiknoNo ratings yet

- 3 - Foundry&Casting - Shop 1Document9 pages3 - Foundry&Casting - Shop 1Mansi NegiNo ratings yet

- Carved Walking Stick: Project 16695EZDocument3 pagesCarved Walking Stick: Project 16695EZBSulli100% (2)

- Shrike Build Option - Multi-PartDocument25 pagesShrike Build Option - Multi-PartRonald ZezeanuNo ratings yet

- Building A Wire TrellisDocument9 pagesBuilding A Wire TrelliscristiankiperNo ratings yet

- EZVeneer BraceletDocument3 pagesEZVeneer BraceletBSulliNo ratings yet

- Headliner Kit For 700 and 900 Sedans and Wagons: Installation InstructionsDocument6 pagesHeadliner Kit For 700 and 900 Sedans and Wagons: Installation InstructionsjbouzaNo ratings yet

- Analog Circuit Design Discrete and Integrated 1St Edition Franco Solutions Manual Full Chapter PDFDocument36 pagesAnalog Circuit Design Discrete and Integrated 1St Edition Franco Solutions Manual Full Chapter PDFlanora.graham908100% (16)

- PMCCProject Valentines GiftsDocument3 pagesPMCCProject Valentines GiftsLampros KatsarosNo ratings yet

- Build Your Own Bottle RocketDocument13 pagesBuild Your Own Bottle RocketKyle MasonNo ratings yet

- WarYoga Tool ManualDocument10 pagesWarYoga Tool ManualJulius AdamsNo ratings yet

- El Cheapo Sugar RocketsDocument23 pagesEl Cheapo Sugar RocketsFrank-nomustardNo ratings yet

- In The: CavityDocument9 pagesIn The: Cavitybrowar444No ratings yet

- Lockheed SR-71 BlackbirdDocument4 pagesLockheed SR-71 BlackbirdAviation/Space History Library0% (1)

- How To Make A Skateboard (With Pictures) - WikiHowDocument10 pagesHow To Make A Skateboard (With Pictures) - WikiHowNelastaBandeiraNo ratings yet

- KNO3 / Sorbitol J-425 Segmented 3-Grain Motor Construction TutorialDocument19 pagesKNO3 / Sorbitol J-425 Segmented 3-Grain Motor Construction TutorialMark D VillanuevaNo ratings yet

- wj089 Salt-Pepper ShakersDocument5 pageswj089 Salt-Pepper ShakersRileyNo ratings yet

- Build Workbranch 1Document14 pagesBuild Workbranch 1cu-bisNo ratings yet

- How to Cut Glass Bottles with a DIY CutterDocument12 pagesHow to Cut Glass Bottles with a DIY Cuttercoldflame81No ratings yet

- Artes, 22 de Septiembre de 2009: Construcción de Obstáculos: La RuedaDocument15 pagesArtes, 22 de Septiembre de 2009: Construcción de Obstáculos: La RuedaAramat LarraNo ratings yet

- 05 50 00csbDocument9 pages05 50 00csbJerico NamucoNo ratings yet

- ADAPTIVE REUSE 2 Group 1Document23 pagesADAPTIVE REUSE 2 Group 1Namrata PuroNo ratings yet

- Fiber Craft IndustryDocument26 pagesFiber Craft IndustryMuzammil YounasNo ratings yet

- Uel Sugarcrete Slab Report - 7 Nov 2022Document85 pagesUel Sugarcrete Slab Report - 7 Nov 2022Eng_RochaNo ratings yet

- Sika Marine Application GuideDocument45 pagesSika Marine Application GuideLin LinNo ratings yet

- Ancon EdjPro EPHIMini Edge Lifting SystemDocument2 pagesAncon EdjPro EPHIMini Edge Lifting SystemsashilaNo ratings yet

- (Thesis) New Materials in Structural DesignDocument57 pages(Thesis) New Materials in Structural DesignShaileshRastogiNo ratings yet

- Hotmix and mechanical methods for 1km roadDocument3 pagesHotmix and mechanical methods for 1km roadPrashant VermaNo ratings yet

- Hume PipesDocument3 pagesHume PipesSathish100% (1)

- University Design Research: IIM Ahmedabad and NID GandhinagarDocument9 pagesUniversity Design Research: IIM Ahmedabad and NID Gandhinagarriyagautamkumar patelNo ratings yet

- Zano - Hoa4 - Midterm Notes PDFDocument85 pagesZano - Hoa4 - Midterm Notes PDFFaith Mary ZañoNo ratings yet

- Iocl Proce BidDocument63 pagesIocl Proce BidSankara Naga Srinivas NNo ratings yet

- Ns2-Vk02-P0ucb-171650 - CHS Electrical & Control Building - Foundation Re-Bar Schedule - Fi-2Document1 pageNs2-Vk02-P0ucb-171650 - CHS Electrical & Control Building - Foundation Re-Bar Schedule - Fi-2Doan Ngoc DucNo ratings yet

- Frank Lloyd WrightDocument32 pagesFrank Lloyd WrightAhmad Monis AnsariNo ratings yet

- 1.chemical (V3) Web PDFDocument88 pages1.chemical (V3) Web PDFAlvin NimerNo ratings yet

- Otmc CH06Document14 pagesOtmc CH06Gabriel ParksNo ratings yet

- AlgaFlex TXDocument12 pagesAlgaFlex TXpedroppaulo77No ratings yet

- 8 Pile Foundation-TheoryDocument6 pages8 Pile Foundation-TheoryRajesh KhadkaNo ratings yet

- Ultimate Guide To Total Coating SolutionsDocument20 pagesUltimate Guide To Total Coating SolutionsNippon Paint Total Coating and Construction SolutionsNo ratings yet

- SECTION 02605 Manholes: Part 1. GeneralDocument11 pagesSECTION 02605 Manholes: Part 1. GeneralDaniel KariukiNo ratings yet

- 1972.04.10-Width of BridgeDocument2 pages1972.04.10-Width of BridgeRanaware NandkishorNo ratings yet

- Belt Hood CoverDocument4 pagesBelt Hood CoverKendra TerryNo ratings yet

- FINNA OROMIA CEMENT REQUIREMENT PROJECTDocument2 pagesFINNA OROMIA CEMENT REQUIREMENT PROJECTAbel100% (1)