Professional Documents

Culture Documents

Doc9b Sample Preparation EN 6498-4

Uploaded by

Razel Elaine Grace CataluñaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Doc9b Sample Preparation EN 6498-4

Uploaded by

Razel Elaine Grace CataluñaCopyright:

Available Formats

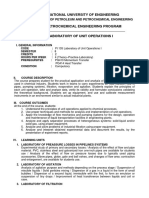

TOP 7

EN ISO 6498 – Animal Feeding Stuffs –

Guidelines for Sample Preparation

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 1

EN ISO 6498 – Animal Feeding Stuffs –

Guidelines for Sample Preparation

SAMPLING

à take a representative lab sample from a lot

SAMPLE PREPARATION

à prepare a representative test sample

from a lab (sub) sample

ANALYSIS

à follow the (microscopical, microbiological, chemical)

method protocols

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 2

EN ISO 6498 – Animal Feeding Stuffs –

Guidelines for Sample Preparation

Contents Page

Foreword iv

1 Scope 1

2 Normative References 1

3 Principle 1

4 Definitions and examples of animal feeding stuffs characteristics 2

5 Considerations to sample preparation errors 8

6 Safety precautions 11

7 Equipment 11

8 Procedure 13

9 Performance tests (quality control) 24

10 Annexes: Categories of feeds – special remarks and flow charts 27

Annex A (informative) Calculations, examples and tables to minimum mass 46

Bibliography 50

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 3

Foreword

…

The main task of technical committees is to prepare International

Standards. Draft International Standards adopted by the technical

committees are circulated to the member bodies for voting. Publication as

an International Standard requires approval by at least 75 % of the member

bodies casting a vote.

…

ISO 6498 was prepared by Technical Committee ISO/TC 34, Food

products, Subcommittee SC 10, and by Technical Committee CEN/TC 327,

Animal feeding stuffs in collaboration.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 4

1 Scope

This International Standard specifies guidelines for the preparation of test

samples from laboratory samples of animal feeding stuffs including pet

foods mostly quoted from Association of American Feed Control Officials

guidelines.

The guidelines are overruled by special instructions and regulations for

sample preparation demanded by specific analysis methods for feeding

stuffs (e.g. ISO, CEN, IEC).

NOTE This International Standard does not include special guidelines for

sample preparation for microbiological analysis of microorganisms like

yeasts, bacteria and molds, but for microorganisms which are used as feed

additives (probiotics) some important aspects to sample preparation are

given.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 5

2 Normative References

ISO 6497:2002, Animal feeding stuffs – Sampling

ISO 664:2008, Oilseeds – Reduction of laboratory sample to test sample

Association of American Feed Control Officials Incorporated (AAFCO),

Guidelines for Preparing Laboratory Samples, prepared by : AAFCO

Laboratory Methods and Service Committee – Sample Preparation Working

Group (Nancy Thiex, Lawrence Novotny, Charles Ramsey, George Latimer,

Laszlo Torma, Robert Beine), Second Edition March 2003

Commission Regulation (EC) No 152/2009 of 27 January 2009 laying

down the methods of sampling and analysis for the official control of feed

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 6

3 Principle (1)

All the sample preparation steps depend

- on the different properties of the feedstuffs and

- on the parameters to be analyzed.

In every case the special instructions of the analysis

methods concerning sample preparation have to be

considered !

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 7

3 Principle (2)

The sample preparation guidelines describe the

procedure for preparing a sample coming to a laboratory

(in general with minimum weight of 0,5 kg) to get a

homogeneous test sample (with minimum weight of

100g) with the same constitution, with the same

composition and without any contamination.

NOTE In some cases the laboratory sample size could

be less than 500 g (i.e. standards of feed additives) but

statutory regulations have to be followed and in every

case the sample size needs to be homogeneous.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 8

3 Principle (3)

In general the whole laboratory sample is reduced in

mass and in particle size to obtain one or more test

samples for the analysis of stable and unstable

parameters, for microscopy analysis and for reserve.

If the analysis protocol and the intended proceeding of

the reserve sample permit it, the laboratory sample

should be preferably 'pre-grinded' completely at first to

an adequate coarse particle size and then mass reduced

to ensure homogeneity of the test samples.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 9

3 Principle (4)

From a test portion (of 0,5g up to 25 g and more) for

weighing to feedstuff analysis…

representative results

…should be achieved of the laboratory sample and

finally of the whole lot from which the sample was

drawn.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 10

3 Principle (5)

Therefore all the steps for sample preparation should be

done rather quickly, under convenient and very clean

conditions so there could be no degradation of sensitive

analytes, no contaminations and no oxidation process

due to influences of too high temperatures, daylight, air

or from residues of apparatus used or from samples

prepared before or simultaneously.

Especially contamination from sample to sample should

be prevented.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 11

3 Principle (6)

A loss or a change of moisture during sample

preparation should be avoided.

In any case it must be taken into account that for official

control results have to be corrected (to origin moisture

content, 88 % or 100 % of dry mass).

For feedstuffs with a higher moisture content (dry matter

< 85 %) partial drying or freeze drying before mass

reduction could be necessary.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 12

3 Principle (7)

For feedstuffs with lumps or particle sizes > 6 mm

coarser grinding of the whole laboratory sample to a

particle size of < 6 mm before mass reduction /

subsampling is absolutely necessary.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 13

3 Principle (8)

The samples have to be stored at every stage of the

sample preparation under adequate conditions (e.g. at

room temperature, refrigerated, frozen, air-tight, light-

protected / dark) to maintain their integrity.

NOTE For microbiological analysis all steps of sample

preparation have to be done under aseptic conditions;

laboratory samples should not be frozen or heated

(>40°C) and not set to vacuum or higher oxygen

influence.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 14

4 Definitions – concerning sample (1)

lot

quantity of material that is assumed to be of the same

production process and represented by sampling according

to the rules of regulation (EC) No. 152/2009.

laboratory sample (lab sample)

sample as prepared (from the lot) for sending to the

laboratory and intended for inspection or testing.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 15

4 Definitions – concerning sample (2)

test sample

(sub-) sample prepared from the laboratory sample and from

which test portions will be taken.

test portion

quantity of material drawn from the test sample (or from the

laboratory sample if both are the same).

reserve sample

left material from the laboratory sample where splitted /

subsampled test samples are taken away from and where no

further particle size reduction is done.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 16

4 Definitions – concerning parameter (3)

parameters

analytes or constituents or microorganisms for which the

feeding stuff is to be analysed by microscopic, (micro-)

biological- or chemical procedures.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 17

4 Definitions – concerning parameter (4)

stable parameters

analytes or constituents or microorganisms which do not

degrade during sample preparation on common handling or

storage at room temperature of 20 °C to 25 °C.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 18

4 Definitions – concerning parameter (5)

unstable parameters

analytes or constituents or microorganisms which degrades

during sample preparation on common handling or storage

at room temperature of 20 °C to 25 °C because they are

volatile, degradable, temperature sensitive or sensitive to

light, enzymatic degradation or chemical oxidation.

NOTE Stability of parameters in this context refers only to

influences of sample preparation to them like e.g. intensive

grinding and not to given minimum durability from

producers or from labelling e.g. for a feed (additive).

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 19

4 Definitions – parameter classification (6)

Stable Unstable parameters Reason(s) for degradation / change

parameters

Nutrients (Crude) protein,

fat, ash, fibre Moisture Temperature (volatile)

Starch, sugar, Ammonia Temperature (volatile)

lactose

In vitro tests

(e.g. gas Organic acids (e.g. lactic acid,

production, acetic acid, butyric acid, citric Temperature (volatile)

enzyme soluble acid, fumaric acid, formic acid)

organic

substance)

Minerals (e.g. Air oxidation (might be change to short-

Ca, P, Mg, Na, K, Unsaturated fatty acids chain fatty acids)

Cl)

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 20

4 Definitions – parameter classification (7)

Stable parameters Unstable parameters Reason(s) for

degradation / change

Feed Trace elements (e.g. Temperature, UV-light,

additives Cu, Zn, Mn, Fe, Se, Vitamins (e.g. vitamin A, C, D, E) air oxidation (sensitive)

Co)

Amino acids (e.g.

lysine, methionine, 1,2-propandiol, glycol Temperature (volatile)

tryptophan)

Enzymes (e.g.

phytases, none- Microorganisms like probiotics (e.g. Temperature (freezing),

starch- Saccharomyces cerevisiae, Enterococcus pressure (sensitive)

polysaccharide faecium)

enyzmes)

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 21

4 Definitions – parameter classification (8)

Stable parameters Unstable parameters Reason(s) for

degradation / change

Mycotoxins (e.g. aflatoxin B1, Mold growth and change

Undesirable Heavy metals (e.g. of mycotoxins possible at

deoxynivalenol, fumonisins, ochratoxin A, room

substances As, Pb, Cd, Hg) T-2 and HT-2 toxin, zearalenone, ergot temperature; UV-

alkaloids) light (sensitive –aflatoxin

B1)

Dioxins and PCB-like Drugs, antibiotics, pesticides Temperature (sensitive)

Dioxins

Hydrocyanic acid Temperature (volatile)

Banned Proteins of animal Banned drugs, banned antibiotics Temperature (sensitive)

substances origin

(Other) Temperature (sensitive),

Micro- Antibiotics, yeasts, bacteria, molds dryness (Anaerobiosis),

organisms influx of oxygen

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 22

4 Example of feed characteristics (9)

For identification and grouping a laboratory sample to the

terms and annexes used within these guidelines some

examples of animal feeding stuffs characteristics are given in

this document.

NOTE Definitions of animal feeding stuffs are given by

legislation worldwide. As an example definitions of European

directives and for straight feeds in an alphabetical list from a

German committee are mentioned within the bibliography.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 23

4 Example of feed characteristics (10)

dry feeds

feed ingredient or complete animal feed which typically

contains not more than 15 % moisture.

NOTE Dry feed pellets are an agglomerated dry feed by a

mechanical process.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 24

4 Example of feed characteristics (11)

green fodder

edible parts of plants, other than separated grain, that can

provide feed for grazing animals or that can be harvested for

feeding, including browse, herbage, and mast.

NOTE Generally, the term refers to more digestible material

(i.e. what is called pasturage, hay, silage, dehydrated and

green chop) in contrast to less-digestible plant material,

known as roughage.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 25

4 Example of feed characteristics (12)

silage

forage preserved in a succulent condition by organic acids

produced by anaerobic fermentation of sugars in the forage.

roughage

fibrous, coarsely textured parts of plants.

NOTE Examples for fibrous, coarsely textured parts of plants

are stovers, straws, hulls, cobs, and stalks.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 26

4 Example of feed characteristics (13)

hay

the aerial portion of grass or herbage especially cut and

cured for animal feeding.

haylage

forage preserved in a succulent condition by organic acids

produced by anaerobic fermentation of sugars in the forage

with about 45 % moisture.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 27

4 Example of feed characteristics (14)

total mixed ration (TMR)

a single mixture of all feed ingredients (forages, grains, and

supplements) that is supplied to an animal for a 24-hour

period.

NOTE In practice, the 24-hour allotment of the mixture may

be offered in one or more feedings.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 28

4 Example of feed characteristics (15)

by-product

product which remaining during process-procedures for the

production of ingredients from plant material.

EXAMPLE Dried destillers grains with solubles (DDGS)

from fermentation.

oilseed

any seed from which oil is expressed.

EXAMPLE sunflower seeds

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 29

4 Example of feed characteristics (16)

mineral mix

supplementary feed that mainly consists of mineral

ingredient in either granular, bead, or small pelleted form

and which is as entire mix free flowing.

NOTE Mineral pellets are an agglomerated mineral feed

formed by a mechanical process.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 30

4 Example of feed characteristics (17)

premixture

uniform mixture of one or more micro-ingredients with

diluent and/or carrier.

NOTE Premixtures are used to facilitate uniform dispersion

of the micro-ingredients (i.e. vitamins, probiotics, drugs,

antibiotics, and/or pharmaceuticals) in a large mix.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 31

4 Example of feed characteristics (18)

canned pet food

feed product for pets which has been processed, packaged,

sealed, and sterilized for preservation in cans or similar

containers.

semi-moist feed

meat based feed product for pets or aquatic animals that has

been partially dried to prevent microbial decomposition.

NOTE The moisture content may range from 15 % to 40 %.

The product generally is in the form of strips or cubes and is

designed to be stored at room temperature.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 32

4 Example of feed characteristics (19)

dog chew

meat and skin/peel strips that have been completely dried to

a leather-like consistency.

NOTE Dog chews are also known as `rawhide bones´.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 33

4 Example of feed characteristics (20)

range cube and alfalfa hay cubes

agglomerated feed formed by compacting and forcing the

mix through die openings by a mechanical process.

NOTE The pellets are about 2 cm of diameter and 5 cm of

length (+/- 16 cm3) and may contain molasses; this definition

applies also to alfalfa cubes (chopped alfalfa hay) larger than

the mentioned dimension.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 34

4 Example of feed characteristics (21)

texturized and sticky feed

mix of assorted grains and commercial feed (generally

pelleted) all of which has been treated with a coating of

molasses.

NOTE Some of the grains may have been steam heated and /

or rolled prior to incorporating into the texturized fee

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 35

4 Definitions – sample prep procedure (22)

homogeneity

degree to which a property or a constituent is uniformly

distributed throughout a quantity of material.

NOTE Homogeneity may be considered to have been achieved in a

practical sense when the sampling error of the processed portion is

negligible compared to the total error of the measurement system; since

homogeneity depends on the size of the units under consideration, a

mixture of two materials may be inhomogeneous at the molecular or

atomic level, but homogenous at the particulate level; however, uniform

visual appearance does not ensure compositional homogeneity.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 36

4 Definitions – sample prep procedure (23)

partial drying

part of the sample preparation procedure for feedstuff

samples with a high moisture content (dry mass < 85 %) in

which the sample is carefully dried to allow subsequent

sample preparation procedures to be applied like particle

size reduction by grinding with a mill.

NOTE 1 Partial drying procedure depends on the heat stability of the parameters

(e.g. 70 °C ± 10 °C for drugs and antibiotics trace elements and heavy metals).

NOTE 2 Samples for microbiological analysis should not be dried (at

temperatures > 40 °C).

NOTE 3 Partial drying can also be done by freeze drying procedure which is a

careful drying process in the vacuum in order to sublimate the moisture.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 37

4 Definitions – sample prep procedure (24)

coarse grinding

a firstly grinding step of the whole sample in cases when the

laboratory sample contains large lumps or its particle size is

high of about 6 mm before mass reduction.

NOTE Coarse grinding finally is a kind of particle size

reduction to ensure homogeneity of the laboratory sample

for subsampling purposes.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 38

4 Definitions – sample prep procedure (25)

mass reduction

part of the sample preparation procedure to reduce the

mass of a laboratory sample by splitting or subsampling it by

the use of (stationary or rotary) dividers or by fractional

(alternate) shoveling without changing the consistence of

the sample.

NOTE After mass reduction all subsamples should have the

same properties like the original laboratory sample.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 39

4 Definitions – sample prep procedure (26)

particle size reduction

part of the sample preparation procedure done by chopping,

crushing, cutting, blending (homogenizing), macerating,

milling (grinding), pressing, pulverizing to obtain a

homogenous test sample for further analysis.

NOTE In general the particle size reduction follows the mass

reduction step of the sample preparation procedure with

different sieve-size-options to ensure integrity of the test

sample(s).

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 40

5 Considerations to sample prep errors (1)

Sample preparation steps have been shown

to be some of the largest error of laboratory error.

This error, which is generally overlooked, may be much

larger than the error in subsequent analytical procedures.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 41

5 Considerations to sample prep errors (2)

5.1 Subsampling and other errors

Errors deriving from sample heterogeneity may add to the

total subsampling error on two levels:

5.1.1 Constitution heterogeneity

5.1.2 Distributional heterogeneity

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 42

5 Considerations to sample prep errors (3)

5.1.1 Constitution heterogeneity

On a first level this is a result when not all of the particles of

the laboratory sample have the same composition (shape,

size, density, etc.).

If a great overall composition-wise difference between the

individual fragments exists, the constitution heterogeneity is

large, but if the fragments are more homogeneous

constitution heterogeneity is lower. The total contribution to

heterogeneity is never zero, however, as that would be the

case of all fragments being strictly identical.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 43

5 Considerations to sample prep errors (4)

5.1.1 Constitution heterogeneity

Mixing and blending does not change constitution

heterogeneity.

The only way to alter the constitution heterogeneity of any

given material would be by cominution (crushing/cutting) or

by other methods changing the physical properties of a

sample. The reduction of the average grain-size is the

dominating factor in reducing constitution heterogeneity by

such means.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 44

5 Considerations to sample prep errors (5)

5.1.1 Constitution heterogeneity

Therefore a firstly coarse grinding ('pre-grinding') of the

whole laboratory sample before subsampling/splitting

reduces constitution heterogeneity.

This fundamental subsampling error can be controlled by the

appropriate choice of the test sample mass.

Therefore collect enough mass to ensure that all of the

particles of different composition are contained in the

subsample/split.

The larger the particle size of a material the larger the mass

of the subsample must be to minimize error.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 45

5 Considerations to sample prep errors (6)

5.1.2 Distributional heterogeneity

On a second level this is the non-random distribution of

particles in the sample, results mainly from the forces of

gravity to particles of different densities, sizes and shapes

which leads to a grouping and segregation of all particles.

Particles with large differences in size and/or density tend to

segregate or stratify heavily, with the smallest and/or

densest particles at the bottom of the sample.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 46

5 Considerations to sample prep errors (1)

5.1.3 Other errors

Other errors that arise from sample preparation include

losses and gains in analyte concentration from such

mechanisms as grinding, excessive heat, loss of fines,

contamination, electrostatic separation, etc.

These errors can be large and are usually a result of

carelessness or lack of knowledge.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 47

5 Considerations to sample prep errors (1)

5.2 Minimum mass

To properly represent a laboratory sample, the subsample or

split must contain adequate mass with view to fundamental

subsampling error and maximum particle size.

The amount of mass required depends on the acceptable

error in the subsample or split, on the density, heterogeneity

and concentration of the analyte particles, and on the largest

particle size.

(Calculations with 3 examples - see Annex B)

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 48

5 Considerations to sample prep errors (1)

Table 1 — Minimum mass: expected relative standard deviation (RSD) from laboratory subsampling;

assumed density = 1 g/cm³

FSE (expected RSD) 15 % 10 % 5% 2% 1%

maximum particle size (d)

0,5 mm 0,06 g 0,13 g 0,5 g 3g 12,5 g

0,75 mm 0,2 g 0,4 g 2g 10,5 g 42 g

1 mm 0,4 g 1g 4g 25 g 100 g

2 mm 4g 8g 32 g 200 g 400 g

5 mm 56 g 125 g 500 g 3 130 g 12 500 g

3

NOTE For materials with densities other than 1 g/cm , this table can be modified by multiplying the entries by the

density of the material of interest; for example the subsampling of a material with largest particle size of 2 mm, a tolerable

3

subsampling RSD of 5 % and a density of 0,5 g/cm would require 16 g.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 49

5 Considerations to sample prep errors (1)

5.3 Errors associated with splitting techniques

The data in Figure 2 and Table 3 demonstrate the error

associated with various splitting techniques:

Figure 2 for a model mixture of wheat, rape seed and glass

Table 3 for a model mixture of sand particles

(60% coarse sand with 40% fine sand)

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 50

5 Considerations to sample prep errors (1)

5.3 Errors associated with splitting techniques - Figure 2

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 51

5 Considerations to sample prep errors (1)

5.3 Errors associated with splitting techniques -Table 3

Coarse+fine sand number of standard variance (sr)2, estimated maximum

(60/40) Increments deviation (sr) (%)2 sample error, %

à Splitting method A) of samples, %

coning &

quartering 2 6,81 46,4 22,7

stationary riffling 10 to 12 1,01 1,02 3,4

rotary riffling > 100 0,125 0,016 0,42

random variation 0,076 0,0058 0,25

A) stationary rifflers with a higher number of increments and less subsampling error are available [6]

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 52

6 Safety precautions (1)

The mills for crushing, cutting and grinding have sharp

moving blades.

- Never put hands or fingers past the edges of the

introduction chamber.

- Never open the mills until they have completely stopped.

- Check to see that safety interlocks on all equipment are

operating properly.

Wear appropriate personnel protective equipment as

required in the laboratory. Safety is of great importance

during the sample preparation phase of the analysis.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 53

6 Safety precautions (2)

Operate the dust ventilation system during dust generation

procedures.

To minimize dust, use a vacuum cleaner to clean the hood

area, mills, and work area.

Check that all electrical equipment is properly grounded and

maintained.

Do not place metal item or aluminum foil in the microwave

oven when using it for drying samples.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 54

7 Equipment (1)

7.1 Equipment for sample preparation in general

• Brushes for cleaning grinders, etc.

• Compressed air blower for cleaning

• Vacuum cleaner

• Systems for germ reduction of mills for disinfection and

flame treatment

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 55

7 Equipment (2)

7.2 Drying systems

• Lyophilization system, forced-air drying oven set at 55 °C

±5 °C and / or microwave oven, household type and / or

vacuum oven

• Moisture dish (pan) made of plastic, aluminum, glass, e.g.

with • 50 mm diameter, • 40 mm deep

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 56

7 Equipment (3)

7.3 Equipment for mass and particle size reduction of

'wet' feeds (e.g. forages, silages)

• Garden pruning clippers for cutting forages or a paper cutter for small

sample volumes or a laboratory forage chopper for large volumes and

a ceramic cutter especially when of trace elements are of interest

• Cutting mill with 6 mm and 1 mm screens

• Shearing type mill with forage head and 1 mm screen

• Riffle sample splitter, the minimum chute width is to be at least two

times the diameter of the largest particle + 5 mm

• Sterile cutter and/or fumigated mill when microbiological analysis of

probiotics is of interest

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 57

7 Equipment (4)

7.4 Equipment for mass and particle size reduction of

'dry' feeds (e.g. cereals, mineral mixtures, pelleted feeding

stuffs)

• Riffle splitter

• Rotary splitter with vibratory feeder

• Shearing grinding mill equipped with 1,0 mm, 0,5 mm and

< 0,5 mm – sieves

• Cutting mill with 4 mm to 6 mm screen

• Shearing blending mill (e.g. household coffee mill)

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 58

7 Equipment (5)

7.5 Equipment for the storage of samples

• Sterile bottles with air-tight lids (e.g. brown glass bottles

for unstable parameters like vitamins) and especially for

microbiological purposes

• Wide mouth bottles with screw cap, plastic

• Plastic bags with low germ content, airtight lockable or for

setting to vacuum for microbiological purposes

• Refrigerator

• Freezer

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 59

8 Procedure (1)

After registration and a check including temperature of a

laboratory sample (see 8.1) the homogenization procedure

consists in a mass reduction step (see 8.2).

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 60

8 Procedure (2)

In the second step the particles in the test samples are

reduced to adequate sizes to minimize the subsampling error

that arises when the test portion is taken from the test

sample. Particle size reduction should be performed without

deteriorating the integrity of the substance to be analysed

(see 8.3).

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 61

8 Procedure (3)

For feedstuffs with higher moisture content (dry mass < 85%)

firstly a partial drying below 55 °C - 60 °C could be necessary

to grind a subsample by a mill to particle sizes of 1,0 mm for

analysis of stable analytes (see 8.4).

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 62

8 Procedure (4)

For feedstuffs containing lumps or consisting of particle sizes

> 6 mm, firstly a grinding or a chopping to particle sizes

below 4 mm to 6 mm could be necessary before

subsampling is possible (see 8.5).

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 63

8 Procedure (5)

For some fatty and/or sticky feedstuffs (e.g. oilseeds, pet

foods, molasses block feed) special sample preparation

procedures are useful/necessary (see 8.6).

Finally the samples are stored (see 8.7).

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 64

8 Procedure (5)

NOTE Samples taken for routine analysis by NIR should reflect the

sample preparation carried out to derive the calibration. By its very

nature, NIR requires minimal or no sample preparation and is often used

to analyze samples that are either fresh or have been dried and only

coarsely chopped. However, when building a calibration it should be

recognized that, because spectra may be collected and averaged over

large samples it may be necessary to dry, finely grind, and then reduce in

mass using a splitter to obtain a subsample suitable for reference

analysis. Although the spectra represent an average of a larger sample

than used to obtain the reference value this is acceptable practice.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 65

8.1 Sample check

Firstly the laboratory sample will be registered and uniquely

identified (e.g. with a unique code number).

Before starting the proper sample preparation procedure

some laboratory sample checks have to be done:

• Check of sample constitution

• Check of feeding stuff properties

• Check of substances to be analyzed

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 66

8.1.1 Check of sample constitution (1)

Check of sample constitution

• When arriving to the laboratory the sample should have

no damages and still should be cooled or frozen if

necessary (check of temperature).

• Furthermore the sample protocol should be in accordance

to the received sample and all information concerning the

sample should be available and complete.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 67

8.1.1 Check of sample constitution (2)

• Deficiencies (e.g. no information about the type of

feeding stuff, container of the laboratory sample is

opened, the sample protocol does not fit to the sample

container) should be documented and subsequently

reported to the principal. If possible, the deficiency shall

be corrected.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 68

8.1.1 Check of sample constitution (3)

• When this is not possible, and the observed deficiency

might affect the analytical result (e.g. when there is not

enough sample mass or when there is already mold in the

laboratory sample because of too high moisture content

or because the sample was not sufficiently cooled during

the transport to the laboratory), another sample from the

same lot is necessary.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 69

8.1.2 Check of feeding stuff properties (1)

The laboratory sample should be identified for grouping to

the feeding stuffs cited within the definitions and categories

(see 4.3).

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 70

8.1.2 Check of feeding stuff properties (2)

The moisture content of a laboratory sample determines the

initial steps of sample preparation:

`wet samples´ with higher moisture content (dry mass <85%)

should be prepared as soon as possible or stored at low

temperatures, otherwise deterioration starts.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 71

8.1.2 Check of feeding stuff properties (3)

For forages with moisture contents too high for direct

grinding (dry mass < 85 %) the whole laboratory sample

should be chopped to pieces of about 1 cm.

If necessary, the laboratory sample is subsampled by

alternate shovelling and subsequently partially dried.

The above is recommended for stable analytes and for the

whole or at least remaining sample for mycotoxin analysis.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 72

8.1.2 Check of feeding stuff properties (4)

For unstable (volatile) analytes (e.g. organic acids, ammonia,

hydrocyanic acid, and for GMOs, organic residues) just as for

microbiological analysis it is recommended to analyze a test

sample as such, without previous drying of the sample.

Alternatively, vacuum drying at low temperatures or freeze-

drying could be performed when samples are to be analyzed

for non volatile components.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 73

8.1.2 Check of feeding stuff properties (5)

For 'dry feeding stuffs' composed of lumps or with particles

larger than 6 mm firstly a coarser grinding of the whole

sample (e.g. with a jaw crusher) to particles sizes of 4 mm to

6 mm is recommended before mass reduction / subsampling

is initiated.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 74

8.1.3 Check of substances to be analyzed (1)

The number of test samples depends on the analytes to be

done.

For the analysis of stable substances, unstable analytes and

for microscopy analysis and for microbiological analysis

separate test samples should be prepared. The remaining

sample is used as reserve (backup).

This enables that for stable analytes the test sample could be

reduced to adequate particle sizes at once and subsequently

stored at room temperature until further analysis.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 75

8.1.3 Check of substances to be analyzed (2)

Test sample for unstable analytes should be stored at low temperatures and,

in order to prevent degradation, they should only be reduced to adequate

particle size at the day of analysis (and not long in advance).

For testing the composition of feeding stuffs by microscopy and for

(microbiological) analysis of probiotics it is important that no particle size

reduction by grinding (milling) is done. Test samples for analysis of probiotics

should not be frozen only refrigerated (4 °C to 10 °C).

For mycotoxins and analysis of GMOs by PCR if possible the whole laboratory

sample or at least the greater part of the remaining laboratory sample

should be used for particle size reduction and then subsampled if necessary.

After mass reduction, in general test samples for stable and unstable

analytes of the following particle size classes should be prepared under

adequate (temperature) conditions: see table 7 and table 8.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 76

8.1.3 Check of substances to be analyzed (3)

For mycotoxins and analysis of GMOs by PCR if possible the

whole laboratory sample or at least the greater part of the

remaining laboratory sample should be used for particle size

reduction and then subsampled if necessary.

After mass reduction, in general test samples for stable and

unstable analytes of the following particle size classes should

be prepared under adequate (temperature) conditions: see

Table 7 and Table 8.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 77

8.1.3 Check of substances to be analyzed (4)

Table 4 — Recommended particle sizes of test sample(s) for stable

analytes and for microscopy

1,0 mm nutrients (e.g. crude protein, crude fat, crude ash, crude fibre, sugar, lactose) if not grinded

with a sieve size of 0,5 mm and minerals, trace elements, heavy metals if not grinded with

a sieve size of 0,5 mm or 0,1 mm

0,5 mm starch, amino acids, methionine hydroxy analogue (MHA)

0,1 mm in mineral mixes for minerals, trace elements and heavy metals (see EN 15510 : 2007)

no grinding microscopy analysis (e.g. composition) or NIR/NIT analysis or NMR oil analysis

or phytase activity (if not grinded with a sieve size of 1 mm)

cutting to pieces

of 1 cm,

followed by a in forages for analysis of the corresponding test sample

reduction to

0,5 mm or 1 mm

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 78

8.1.3 Check of substances to be analyzed (4)

Table 5 — Recommended particle sizes of test sample(s) for unstable

(degradable, volatile, heat-sensitive, microbiological) analytes

in dry feed for moisture, vitamins, organic acids, propandiol, organic residues like PCBs,

1,0 mm

OCDs, other pesticides, banned antibiotics, veterinary drugs and mycotoxins

in dry feed for mycotoxins because of non-uniform distribution within a (laboratory/test)

0,5 mm

sample if not grinded with a sieve size of 1,0 mm

for cereals and pressed feeds which do not break down sufficiently in suspension solutions

coarse grinding

for microbiological analysis

no grinding but

soft treating by

in dry feed - pelleted or as meal - for microbiological analysis (i.e. probiotics)

solving under

light pressure

in mineral mixes and premixtures for vitamins, antibiotics, drugs and probiotics when the

no grinding particle size distribution is sufficient, otherwise grind briefly to 1,0 mm to avoid heat

generation

no grinding but

in forages for analysis of the corresponding test sample with origin moisture content of

cutting to

organic acids, ammonia, hydrocyanic acid, carotene, bacteria, yeasts and moulds

pieces of 1 cm

no grinding but

macerating with in forages for organic residues like pesticides, banned antibiotics, veterinary drugs

a thermo mixer

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 79

8.2 Mass reduction (1)

Laboratory samples can be mass reduced by splitting devices

or subsampling.

Mass reduction with the use of rotational dividers or riffle

splitters is recommended and the techniques can be used for

the reduction of the 100 g test sample to < 1,0 g test

portions without serious problems.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 80

8.2 Mass reduction (2)

If it has been established that the mass reduction error is

insignificant or if it is not possible to mass reduce with

correct mass reduction devices (i.e. rotary or riffle splitters),

the mass reduction can be accomplished with subsampling.

With subsampling, anywhere from a single increment to as

many as several hundred increments are selected at random

from the primary sample to form the subsample.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 81

8.2 Mass reduction (3)

Unfortunately, it is a common practice to take only a few

increments. If only a small number of increments are

selected, there can be very large subsampling errors due to

sample heterogeneity.

The number of increments should not be determined by

what is easy, but rather what is acceptable from an error

point of view.

Rotary riffle splitting is the most accurate splitting method,

coning & quartering is a very poor method and should never

be used.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 82

8.2 Mass reduction (4)

If it is known that the material is not segregated, then fewer

than 10 increments can be selected. If the material is known

or suspected to be heavily segregated, then more than 10

increments should be selected.

Many materials have a wide range of particle sizes when

they arrive to the lab and need more increments to properly

represent them (consider more than 10 increments).

During the sample preparation of grinding and sieving, the

range of particle sizes is reduced and fewer increments can

be taken.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 83

8.2 Mass reduction - devices (1)

Riffle splitters

Criteria for the design:

• even number of chutes;

• greater number of chutes is desirable;

• rifflers must be from durable, inert materials (e.g.

stainless steel);

• rifflers with bent chutes or any defects must never be

used.

• …

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 84

8.2 Mass reduction - devices (2)

Riffle splitters

Criteria for the proper use:

• the riffler should be on a firm, level plane;

• do not feed the sample too fast (the chutes can fill up and

overflow)

• fine powders should be fed with care, as they can clog the

chutes;

• fines may stick to the splitter due to static electricity; if this

occurs and measurement of the fines is important, you may try

grounding the riffler or using an anti-static mat.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 85

8.2 Mass reduction - devices (3)

Rotational dividers

Criteria for the design:

• should be made of inert material;

• cutting edge should be radial from center (pie shaped);

• maintain constant speed;

• minimize drop from feeding chute to cutting edge to

prevent dust formation;

• fine powders should be fed with care as they can clog the

holes.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 86

8.2 Mass reduction - devices (4)

Rotational dividers

Criteria for the proper use:

• use a vibratory feeder to feed the material into the rotary

splitter; hand feeding results in uneven feeding rates and

therefore non-uniform incremental splitting;

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 87

8.2 Mass reduction - devices (5)

Rotational dividers

Criteria for the proper use:

• adjust the feeder rate so that the material flows through

the feeder at a continuously slow even rate without

overflowing into the rotary splitter; each split (bottle)

should contain around 200 increments per split. 50

increments is the recommended minimum of increments

per split (bottle); a slower feeding rate results in more

increments per split (bottle) and therefore in a more

representative subsample;

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 88

8.2 Mass reduction - devices (6)

Rotational dividers

Criteria for the proper use:

• after splitting each bottle should contain an equal volume

of material; if the volumes are not equal, this indicates

that one or more of the splitting chutes became clogged;

when the volumes are not equal, then all of the material

needs to be recombined together and resplit again.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 89

8.2 Mass reduction - alternate shoveling (7)

It is a very simple splitting technique with following

advantages:

• can be implemented in the lab or field;

• does not involve extra equipment (e.g. rifflers);

• has minimal clean up and decontamination requirements;

• any number of splits can be generated;

• has very low sample splitting error.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 90

8.2 Mass reduction - alternate shoveling (8)

The laboratory sample is split into the desired number of

samples by collecting increments from the lab sample. The

increments from the lab sample are alternately placed into

containers or piles to form the split subsamples.

If a sample is to split into two equal subsamples, one split

would contain the odd increments and the other subsample

would contain the even increments.

If a sample is to be split into three subsamples, the first split

would contain increments 1, 4, 7, and so on, the second split

would contain increments 2, 5, 8, and so on, and the third

split would contain increments 3, 6, 9, and so on.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 91

8.2 Mass reduction - alternate shoveling (9)

NOTE

Towards the end of the splitting process there can be a small

amount of fines; it is advisable to reduce the increment size

so that the fines are equally apportioned among the splits

with at least 10 increments each; if this is not done, it is

possible that all fines will end up in only one of the splits.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 92

8.3 Particle size reduction (1)

General methods

• chopping: a material is mechanically cut into smaller

parts;

• crushing: applying pressure to fragment larger particles

into smaller fragments; specially, variable jaw crushers

reduce large, hard samples to 1-15 mm diameter particle

size;

• cutting: cutting mills reduce soft to medium-hard and

fibrous materials using rotating and stationary cutting

knives; reduced size depends on sieves used in

combination with mill;

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 93

8.3 Particle size reduction (2)

General methods

• blending (homogenizing): materials are broken into

smaller parts and blended to make them more uniform in

texture and consistency;

• macerating: a soft material is torn, chopped, or cut into

smaller pieces;

• milling / grinding: grinding of materials to mechanically

reduce particle size is accomplished by cutting, shearing,

impacting and attrition using various mills;

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 94

8.3 Particle size reduction (3)

Requirements for choosing size reduction equipment

Requirements for suitable size reduction methods differ

widely and depend on the sample material.

The equipment should not corrupt the subsequent results of

analysis (e.g. cause contamination with trace elements or

heavy metals like chrome or nickel from abrasion). Identical

results must be achievable in the same lengths of time when

the same grinding tools are used.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 95

8.3 Particle size reduction (4)

Considerations for selecting size reduction equipment for a

specific application include the following:

• Type of material: How hard is the material? What are the

physical and chemical properties? Is the size reduction

process affected by heat generation, moisture change or

chemical reactions?;

• The initial maximum particle size (e.g. chunks, powder,

...etc.);

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 96

8.3 Particle size reduction (5)

• The final desired particle size (mm, µm) and the range of

permissible particle sizes;

• Quantity of material to be ground and number of

laboratory samples to be processed daily or weekly;

• Amount of time available for size reduction in the overall

sample processing;

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 97

8.3 Particle size reduction (6)

• Abrasion resistance of the grinding tools: Contamination

due to wear of the grinding or cutting elements by the

grinding tools is a constant threat and must be absolutely

avoided. It is important to select suitable grinding

elements that are constructed from materials that will not

interfere with the analysis. Typically, particle size

reduction tools are made of stainless steel, tungsten

carbide, agate, sintered alumina, hard porcelain, and

zirconium. A tool with harder surfaces than the lab

sample material is desirable and it will minimize

contamination;

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 98

8.3 Particle size reduction (7)

• Versatility of grinding equipment: Due to the nature of

some sample materials, wet grinding may be necessary or

the sample must have to be cooled or embrittled during

size reduction. Some materials must be ground in an inert

atmosphere, with liquid nitrogen, or in a vacuum;

• Requirements for operator time and cleaning equipment.

It is impossible to grind laboratory samples without

loosing minute amounts of sample because some adheres

to the grinding surface. This material is lost during the

cleaning.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 99

8.3 Particle size reduction (8)

Types of particle size reduction equipment

Crushers

Reduce particle size by crushing the material. They are

generally used to reduce a very large particle size (diameters

as large as 150 mm) to 0,5 mm to 1 mm fragments. Other

types of mills can then be used to further reduce particle

size.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 100

8.3 Particle size reduction (9)

Types of particle size reduction equipment

• Cutting (shearing) mills

• Grinding mills

• Ball mills

• Centrifugal mills

• Disk or burr mills

• Etc.

…..with detailed descriptions!

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 101

8.3 Particle size reduction (10)

Maintaining integrity of the laboratory sample

• To minimize moisture loss and preserve the integrity of

materials that contain thermally labile or volatile

components, heating during the grinding process must be

minimized.

• Dry ice sometimes can be added directly to a mortar or

ball mill to keep samples cool during grinding (dry ice

should be prepared from CO2 that is free from impurities

that could contaminate the sample).

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 102

8.3 Particle size reduction (11)

Maintaining integrity of the laboratory sample

• Some mills can be fitted with a cooling block to permit the

circulation of cool liquid during grinding.

• Pulverizing the material under liquid nitrogen can be

performed in a cryogenic mill if lower temperatures are

necessary to solidify a material.

• When using cooling agents, it is necessary to avoid

condensation of moisture on the material to preserve the

integrity of the sample.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 103

8.4 Partial drying (1)

For 'wet' feeds with less than 85 % dry matter (e.g. forages,

total mixed rations, but not for liquids), it is necessary to

partially dry them prior to fine grinding to analyze stable

substances; for unstable substances a partial drying is not

possible.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 104

8.4 Partial drying (2)

Partial drying can be done by using either a forced-air oven

or a microwave oven. The goal is to dry the feeding stuff

while keeping sample temperature below 55 °C – 60 °C so

that chemical composition is minimally affected.

Drying at higher temperature (greater than 60 °C) causes

chemical changes in the feeding stuff (e.g. protein

degradation).

(….)

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 105

8.5 Coarse drying

When a 'dry feed' is composed of lumps or its particle sizes are

more than 6 mm the whole laboratory sample should be grinded

by a jaw crusher or a cutting mill or chopped to particle sizes of 4

mm – 6 mm before mass reduction / subsampling is initiated.

Of course a coarse grinding of the whole laboratory sample to an

adequate uniform low(er) particle size before mass reduction is

initiated is recommended to ensure homogeneity. But this is a

very time consuming procedure and aspects for unstable

substances are to consider (e.g. heat generation, grinding at the

day of analysis) otherwise deterioration starts.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 106

8.6 Special sample preparation procedures

For samples consisting of high fat, gelatin, and/or molasses

some special sample preparation procedures helps to get a

representative subsample and fine grinded test samples:

• place the entire laboratory sample in a freezer overnight

and prepare the sample in a frozen or chilled state;

• use dry ice during splitting and grinding to keep the

sample cold enough to prevent clumping or melting;

• use of blending type mills, blend in intervals of 30 s;

• first coarse grind the whole laboratory sample to pass a 6

mm sieve.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 107

8.7 Storage (1)

Once a representative test sample has been prepared from

the laboratory sample, it is essential to maintain its integrity

throughout its duration in the laboratory, including all

analytical process, reporting of data and the ultimate

disposal of any remaining material.

Proper storage may include storage at reduced temperature

(refrigeration or freezing), protection from moisture gain or

loss, protection from UV light, and so on to avoid the

harmful effect of too many microorganisms which can break

down the organic compounds.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 108

8.7 Storage (2)

The proper storage conditions will vary among the various

types of feed materials and substances which are to analyze.

In deciding upon the proper storage conditions for each

material and analyte combination, the laboratories need to

consider the effect that composition, matrix interactions,

chemical and/or enzymatic activity have on the analyte(s).

Storage and disposal policy should be established and

documented within the laboratory to address these issues.

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 109

9 Performance tests (quality control)

Performance test for mass reduction (splitting)

Performance test for particle size reduction (grinding)

• Grind quality and recovery

• Carryover

Performance test for mixing

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 110

10 Flowcharts – e.g. Premixtures

Flowchart – premixtures

laboratory sample

reserve sample test sample

refrigerate or freeze no grinding option grind through a 1 mm

screen

refrigerate or freeze freeze

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 111

Annex B with Examples to calculate

sample preparation error

Table 8 — Minimum mass of a subsample where methionine was added to a mineral mixture

Minimum sample (g)

d (mm) / FSE

20 % 15 % 10 % 5% 2%

(expected RSD)

0,1 0,002 0,003 0,01 0,02 0,2

0,2 0,01 0,02 0,05 0,2 1

0,5 0,2 0,3 0,8 3 16

1 2 3 6 20 61

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 112

Figure 1 — Illustration of definitions concerning 'sample', 'substances', and 'sample preparation

procedure'

'SAMPLING' choice from lot

'SAMPLE PREPARATION' laboratory sample(s) (≥ 500 g) with:

dry matter < 5 % dry matter ≥ 85 % lumps

or big particles (> 6 mm)

partial (or freeze) drying

(optionally) coarse grinding

mass reduction (subsampling / splitting) reserve

sample

test sample(s) (100 g) for:

particle size reduction

-

microscopy

with different sieve-size options - analysis of stable

parameters

(1,0 mm, 0,5 mm, < 0,5 mm, no grinding) - analysis of unstable parameters

'ANALYSIS' test portion(s) (0,05 g to 25 g)

6./7.Dec 2011 Workshop ANKARA TOP 1 + 2 Intro 113

You might also like

- Determination of ExtractivesDocument12 pagesDetermination of ExtractivesjessineiNo ratings yet

- EURASIA RESEARCH PHARMA HIRING KEY STAFFDocument10 pagesEURASIA RESEARCH PHARMA HIRING KEY STAFFErine FelipeNo ratings yet

- Lab. QADocument205 pagesLab. QAMai HanyNo ratings yet

- Evaluation of Isolation Gowns Sop LS-061-00Document4 pagesEvaluation of Isolation Gowns Sop LS-061-00Akoso DanielNo ratings yet

- Chapter One 1.1 SIWES and Its ObjectivesDocument46 pagesChapter One 1.1 SIWES and Its Objectivesjessica EmmanuelNo ratings yet

- Chapter One 1.1 SIWES and Its ObjectivesDocument46 pagesChapter One 1.1 SIWES and Its Objectivesjessica EmmanuelNo ratings yet

- Me Lab1 Group3Document20 pagesMe Lab1 Group3DECIPOLO, KENNETH JOHN E.No ratings yet

- CH 431 Lab ManualFullDocument28 pagesCH 431 Lab ManualFullHân BảoNo ratings yet

- GFLPDocument40 pagesGFLPayu kristiyaningrumNo ratings yet

- Metabolism Lab ManualDocument70 pagesMetabolism Lab ManualmismaelNo ratings yet

- DRINKING WATER LAB METHODSDocument70 pagesDRINKING WATER LAB METHODSԼուսինե ՀովսեփյանNo ratings yet

- Astm E1645Document5 pagesAstm E1645Fernando Berrospi GarayNo ratings yet

- Spe Rerence Manual and User's GuideDocument50 pagesSpe Rerence Manual and User's Guideadolfo olmosNo ratings yet

- Glycolysis Assay Extracellular Acidification Protocol Book V12a Ab197244 (Website)Document28 pagesGlycolysis Assay Extracellular Acidification Protocol Book V12a Ab197244 (Website)ieviukasNo ratings yet

- Week 1. FST 3112 Lab. Manual FST3112-2012-2013-2 PDFDocument83 pagesWeek 1. FST 3112 Lab. Manual FST3112-2012-2013-2 PDFchoon lee minNo ratings yet

- Introduction of QC in Pharma IndustryDocument28 pagesIntroduction of QC in Pharma IndustryAnggia Bia AmandaNo ratings yet

- Lab Manual Bte3212 Vers 5Document89 pagesLab Manual Bte3212 Vers 5IyadJordanNo ratings yet

- Cfb40503 Lab ManualDocument21 pagesCfb40503 Lab ManualAziemah AulanNo ratings yet

- Hach Method 10225 Spadns IIDocument8 pagesHach Method 10225 Spadns IIDavidSargFolgarNo ratings yet

- UiTM Reservoir & Gas Lab BriefingDocument20 pagesUiTM Reservoir & Gas Lab BriefingMark KaiserNo ratings yet

- Good Food Laboratory Practices (GFLPS)Document41 pagesGood Food Laboratory Practices (GFLPS)Abhishek BanerjeeNo ratings yet

- Auditing The Microbiology LaboratoryDocument68 pagesAuditing The Microbiology LaboratoryMohammed Yousffi94% (18)

- SMS LabDocument64 pagesSMS LabDivya DiyaNo ratings yet

- Iso 6887 1 1999Document9 pagesIso 6887 1 1999Uno Borrame100% (1)

- 317LabManual2020 - Fall For The Class1Document38 pages317LabManual2020 - Fall For The Class1shanicejames7867No ratings yet

- Operational Procedures Manual: Water Microbial SamplingDocument6 pagesOperational Procedures Manual: Water Microbial SamplingGilbert NdibeNo ratings yet

- 2008 11 25 Methods Method Biological 1684-BioDocument16 pages2008 11 25 Methods Method Biological 1684-Bioகுமார் எஸ்No ratings yet

- Oecd Guidelines For The Testing of ChemicalsDocument22 pagesOecd Guidelines For The Testing of ChemicalsClaudia Flores VargasNo ratings yet

- LABORATORY MANUAL FOR A MINI PROJECT: MSCB 1113 BIOCHEMISTRY & MICROBIAL PHYSIOLOGYFrom EverandLABORATORY MANUAL FOR A MINI PROJECT: MSCB 1113 BIOCHEMISTRY & MICROBIAL PHYSIOLOGYNo ratings yet

- OECD 211 Daphnia ReprocdutionDocument21 pagesOECD 211 Daphnia ReprocdutionEllóra Diniz GomesNo ratings yet

- Lab Manual KC 31001 Laboratory 6: Semester 2 2016/2017Document70 pagesLab Manual KC 31001 Laboratory 6: Semester 2 2016/2017Debrah DebbieNo ratings yet

- Jimmie W. Hodgeson Jeffrey Collins (Technology Applications, Incorporated) W.J. Bashe (Technology Applications, Incorporated)Document28 pagesJimmie W. Hodgeson Jeffrey Collins (Technology Applications, Incorporated) W.J. Bashe (Technology Applications, Incorporated)a2k3leeNo ratings yet

- Folin Ciocalteau Phenolic Quantification Assay KitDocument11 pagesFolin Ciocalteau Phenolic Quantification Assay KitNaye VillalónNo ratings yet

- Oecd 202 211 Daphnia MagnaDocument0 pagesOecd 202 211 Daphnia MagnaHeidita SanchezNo ratings yet

- Experiments of Chemical EngineeringDocument91 pagesExperiments of Chemical EngineeringdilsahNo ratings yet

- Compliance To GLP FINAL PDFDocument25 pagesCompliance To GLP FINAL PDFSathish VemulaNo ratings yet

- Lab Sheet (Drilling Eng. Lab) - Update 27 Ogos 2019Document34 pagesLab Sheet (Drilling Eng. Lab) - Update 27 Ogos 2019Albert ChongNo ratings yet

- Vitamin E Analysis (Meat) : 1. ApplicationDocument2 pagesVitamin E Analysis (Meat) : 1. ApplicationAashay PatilNo ratings yet

- CYC 517 Physical Chemistry Lab II MSC 3rd SEMDocument36 pagesCYC 517 Physical Chemistry Lab II MSC 3rd SEMDebanjan DasNo ratings yet

- STK1211 Practical Analytical ChemistryDocument39 pagesSTK1211 Practical Analytical Chemistrylox agencyNo ratings yet

- Lab Quality Manual Rev 10 (031119)Document17 pagesLab Quality Manual Rev 10 (031119)paeg6512No ratings yet

- Phy Chem 1 Lab Manualedited PDFDocument65 pagesPhy Chem 1 Lab Manualedited PDFJohn CaoileNo ratings yet

- Lab Report Food Analysis Moisture ContentDocument9 pagesLab Report Food Analysis Moisture ContentAirish AirishNo ratings yet

- 2014 Electronic Cigarette Aerosol Parameters StudyDocument89 pages2014 Electronic Cigarette Aerosol Parameters StudyRigoberto CastroNo ratings yet

- Brand Comparison (Silliker)Document15 pagesBrand Comparison (Silliker)heruhartadi02No ratings yet

- 5013 12 2-2004Document6 pages5013 12 2-2004Lam Thanh NguyenNo ratings yet

- Student Lab ManualDocument25 pagesStudent Lab ManualCucu AlbertNo ratings yet

- BSK1402 ORGANIC CHEMISTRY MANUAlDocument25 pagesBSK1402 ORGANIC CHEMISTRY MANUAlaayana angelNo ratings yet

- QC PROCEDURES PESTICIDE RESIDUESDocument30 pagesQC PROCEDURES PESTICIDE RESIDUESMd. Badrul IslamNo ratings yet

- National University of EngineeringDocument2 pagesNational University of EngineeringMarco A. Castillo LudeñaNo ratings yet

- SKC Passive (Diffusive) SamplesDocument4 pagesSKC Passive (Diffusive) SamplesPietro MatosNo ratings yet

- Nutrient Analysis Tropical Mar1 N Waters: Terg Ove Rrne Tal Oceanographic CommissionDocument25 pagesNutrient Analysis Tropical Mar1 N Waters: Terg Ove Rrne Tal Oceanographic CommissionNaliana LupascuNo ratings yet

- Guidance Document Food Laboratory 16-02-2018Document45 pagesGuidance Document Food Laboratory 16-02-2018Thirulogachandar AsokanNo ratings yet

- Good Elisa Practice Manual en 2020-06Document38 pagesGood Elisa Practice Manual en 2020-06leon CaNo ratings yet

- Polyphenols (Folin Ciocalteu) Assay: (Cat. # BAQ056)Document6 pagesPolyphenols (Folin Ciocalteu) Assay: (Cat. # BAQ056)Izzat ZakwanNo ratings yet

- Shelf LifeDocument8 pagesShelf LifeDeysi Suarez GomezNo ratings yet

- Life-Cycle Assessment of BiorefineriesFrom EverandLife-Cycle Assessment of BiorefineriesEdgard GnansounouNo ratings yet

- Handbook of Solid Phase MicroextractionFrom EverandHandbook of Solid Phase MicroextractionJanusz PawliszynRating: 5 out of 5 stars5/5 (2)

- Liquid Sample Introduction in ICP Spectrometry: A Practical GuideFrom EverandLiquid Sample Introduction in ICP Spectrometry: A Practical GuideRating: 4 out of 5 stars4/5 (6)

- 1 Agricultural Sciences 2012Document36 pages1 Agricultural Sciences 2012Razel Elaine Grace CataluñaNo ratings yet

- Preparing For Future Products of Biotechnology PDFDocument231 pagesPreparing For Future Products of Biotechnology PDFRazel Elaine Grace CataluñaNo ratings yet

- Preparing For Future Products of Biotechnology PDFDocument231 pagesPreparing For Future Products of Biotechnology PDFRazel Elaine Grace CataluñaNo ratings yet

- HPLC Analysis of AspirinDocument4 pagesHPLC Analysis of AspirinRazel Elaine Grace CataluñaNo ratings yet

- Biosphere 2 Is An American Earth System Science Research Facility Located in Oracle, Arizona. It WasDocument5 pagesBiosphere 2 Is An American Earth System Science Research Facility Located in Oracle, Arizona. It WasAdinaCh11No ratings yet

- Acid Bases and Salts - Shobhit NirwanDocument26 pagesAcid Bases and Salts - Shobhit NirwanAlok RahateNo ratings yet

- OrganicDocument5 pagesOrganicTempNo ratings yet

- Cassava ThesisDocument46 pagesCassava ThesisUsama AliNo ratings yet

- Plant Ferritin-A Source of Iron To Prevent Its DeficiencyDocument18 pagesPlant Ferritin-A Source of Iron To Prevent Its DeficiencyLara Ayu LestariNo ratings yet

- Seaweed Biorefinery PDFDocument54 pagesSeaweed Biorefinery PDFJavier Andres Davila RinconNo ratings yet

- B-Complex Vitamins Role in Energy ReleaseDocument5 pagesB-Complex Vitamins Role in Energy ReleaseEno WijayantiNo ratings yet

- Assignment C - Part 2.i: Authentic TextDocument4 pagesAssignment C - Part 2.i: Authentic TextZakir Ahmed100% (5)

- 3RD Term S2 Agricultural ScienceDocument24 pages3RD Term S2 Agricultural ScienceFootball FlameNo ratings yet

- Module EppDocument95 pagesModule EppRei YoshiharaNo ratings yet

- Carbohydrates: Dr. Shahab UddinDocument12 pagesCarbohydrates: Dr. Shahab UddinShahabNo ratings yet

- Nutrients of Bitter GourdDocument2 pagesNutrients of Bitter GourdEva Arian JoyNo ratings yet

- Sources of Soil Pollution by Heavy Metals and Their Accumulation in Vegetables: A ReviewDocument9 pagesSources of Soil Pollution by Heavy Metals and Their Accumulation in Vegetables: A Reviewsarah.saxenaNo ratings yet

- Golden Apple Snail Background 1Document1 pageGolden Apple Snail Background 1yna calneaNo ratings yet

- Aquatic products and herbal supplements for home businessDocument3 pagesAquatic products and herbal supplements for home businessKaoful JalilNo ratings yet

- Advances in Agronomy v.32Document173 pagesAdvances in Agronomy v.32luisiunes0% (1)

- Ensuring Food Quality with Synthetic AntioxidantsDocument3 pagesEnsuring Food Quality with Synthetic AntioxidantsAna RidaoNo ratings yet

- Organic Agriculture Enhanced TrainingDocument105 pagesOrganic Agriculture Enhanced Trainingbaitan dadiganNo ratings yet

- Exsc 223 CH 24 Practice ExamDocument4 pagesExsc 223 CH 24 Practice Examkimber brownNo ratings yet

- Formula 1639 Red Clay Mask StickDocument1 pageFormula 1639 Red Clay Mask StickEricaDalcinNo ratings yet

- Topic 3 Baking IngredientsDocument20 pagesTopic 3 Baking IngredientsMars MaguenNo ratings yet

- 4.3 Reaction Stoichiometry: Example 4.8Document8 pages4.3 Reaction Stoichiometry: Example 4.8Triesha GervacioNo ratings yet

- As 252 Principles of Animal NutritionDocument92 pagesAs 252 Principles of Animal NutritionSuhuyineNo ratings yet

- Instant Download Ebook PDF Encyclopedia of Food Chemistry PDF ScribdDocument41 pagesInstant Download Ebook PDF Encyclopedia of Food Chemistry PDF Scribdhoward.linkovich475100% (45)

- VanillaDocument20 pagesVanilla19BFT Food TechnologyNo ratings yet

- Ecosystems: Concept, Types and Basic Structure of An EcosystemDocument5 pagesEcosystems: Concept, Types and Basic Structure of An EcosystemAbhishekNo ratings yet

- Vitamin C Experiment Literature ReviewDocument5 pagesVitamin C Experiment Literature Reviewaflsjcibl100% (1)

- Consumers Perception Towards Organic Products in DehradunDocument63 pagesConsumers Perception Towards Organic Products in Dehradunyatra goNo ratings yet

- Production of Carotenoids From Rhodotorula Mucilaginosa and Their Applications As Colorant Agent in Sweet CandyDocument7 pagesProduction of Carotenoids From Rhodotorula Mucilaginosa and Their Applications As Colorant Agent in Sweet CandyEspinosa Balderas GenaroNo ratings yet

- SA Cocamide MEADocument8 pagesSA Cocamide MEAAPJ HollywoodsistersNo ratings yet