Professional Documents

Culture Documents

SensAlert Four-Channel Controller

Uploaded by

David MtzOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SensAlert Four-Channel Controller

Uploaded by

David MtzCopyright:

Available Formats

Four-Channel Gas Detection Controller

• Visual and Audible Annunciation

• Discrete LED and LCD Displays

• Automatic Sensor Recognition

• 4-20 mA Analog Outputs

• RS-485 Modbus RTU Output

• NEMA 4X, UL Listed Enclosure

• 115/230 VAC or 24 VDC

The SensAlert 4-Channel Controller powers and

monitors up to 4 channels of gas detection. With

three alarm relays per channel plus a common fault

relay, the Controller provides local or remote alarm

annunciation via the optional strobe and standard

90 dB buzzer. The controller has a latched alarm

reset button and discrete LED value displays plus LCD

displays for gas name or type and value. Discrete 4-20

mA and RS-485 Modbus RTU outputs are standard. Four Channel with Strobe shown (PNº 7013227-4)

Most SensAlert, SensAlert Plus, and SensAlert ASI

transmitters, when used with this controller, will

automatically configure the controller to display the

Common Industries and Applications:

gas type, range and factory default alarms, making

• Manufacturing • Chlor-Alkali Plants

system set up quick and easy.

Hazardous Material Storage Coatings Manufacturing

• Pharmaceutical • Fertilizer Plants

Semiconductor Fabrication NGL Facilities & Pipelines

• Methane Remediation • Ferrous Metals

Natural Gas Processing Coke Oven Batteries

• Hydrocarbon Pipelines • Non-Ferrous Smelting

Float Glass Making Specialty Chemicals

• Transportation Garages • Poultry & Meat Processing

Plating Processes Ore Processing

• Water & Waste Treatment Precious Metals Mining

HVAC Industry Beverage Plants

• Petrochemical (Plastics) • Petroleum Refining

Utility Rooms Cold Storage Facilities

• Specialty Gas Bottling • Battery Rooms

Solvent Recovery Fruit & Vegetable Storage

• Annealing Processes • Electricity Generation

Typical Installation Configuration Air Separation Plants Textile Dyes & Chemicals

SensAlert Four-Channel Controller

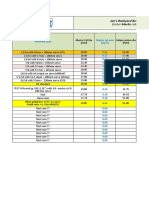

4-Channel Specifications

Electrical

Power........................................... 85-264 VAC, 50/60 Hz or 24 VDC

Check Points �����������������������������Provides reading of output

current (as 40–200 mV)

without breaking loop.

Termination Resistance �������������100 ٠fixed

Input �������������������������������������������Four 4-20 mA (2 or 3-wire signals).

Can use Sensidyne I.S. Barrier.

Outputs ��������������������������������������Discrete non-isolated 4-20 mA (750 ohm

load), and 2-wire RS485 Modbus RTU

Strobe ������������������������������������������Red lens strobe (NEMA 4X); optional

Relays ������������������������������������������13 on-board Form C, potential free

User Interface

Four Channel with Strobe shown (PNº 7013227-4) LCD Display �������������������������������Backlit Alphanumeric (Value, Gas, &

Units)

LED Display ������������������������������3 Digit x 1.5 Inch Wide Red LED (Value)

SAMPLE A & E SPECIFICATION Controls �������������������������������������Internal push-button programming for all

variables with security capability.

Contractor shall supply and install a single point gas Reset button for alarms and calibration

mode

monitoring and alarming system in a NEMA 4X, UL listed

Environmental

enclosure for (specify gas) to be mounted outside the

Temperature ������������������������������32° to 113°F (0° to 45°C)

(specify area). The system shall have integral relays, Humidity ������������������������������������5-95 %RH, non-condensing

a strobe and horn for local alarming purposes, plus a Enclosure

failure alarm relay contact. Local LEDs (3) shall provide Material �������������������������������������Lockable wall mount NEMA 4X, fiber-

alarm status. Plug-in sensors for Oxygen and all common glass with 3/4 inch EMT connector

Dimensions �������������������������������11.2” W x 12.8” H x 6.3” D

toxic and combustible gases shall be interchangeable 28.4 W x 32.5 H x 16.0 D cm.

without any reprogramming of the system. Weight ���������������������������������������10.0 lbs. (4.5 Kg)

Approval Ratings

The unit will display the monitored gas value on a 1.5 UL listed NEMA 4X Enclosure

inch minimum height, ultra-bright, 3 digit LED display,

Note: Refer to certification documents and datasheets for

and also have a separate display for the gas name specific approval and configuration information.

and engineering units. 4-20 mA and RS-485 (Modbus

protocol) outputs will be provided.

The sensor shall be temperature compensated and

intelligent to minimize drift and maintenance intervals,

and will be mounted in the (floor, breathing, or ceiling)

zone. The contractor will provide a one year supply of

spare parts, calibration gas and kit, system start-up and

training of owners’ personnel.

ORDERING INFORMATION

Description Part Number

Four Channel Controller..................................7013227-3

Four Channel Controller w/ Strobe.................7013227-4

SensAir Compatible Four Channel Controllers

Four Channel Controller..................................7013227-5

Four Channel Controller w/ Strobe.................7013227-6

Sensidyne, LP | 1000 112th Circle North, Suite 100 | St. Petersburg, Florida 33716 A company of the SCHAUENBURG International Group

Tel: 800-451-9444 / +1 727-530-3602 | E-mail: info@Sensidyne.com | Web: www.Sensidyne.com

You might also like

- Beacon410 PDFDocument2 pagesBeacon410 PDFABDUL GHAFOORNo ratings yet

- Commercial Series Data Sheet 1Document2 pagesCommercial Series Data Sheet 1Magderson CorreaNo ratings yet

- Qa16 Qa01 Qa05 Qa06Document2 pagesQa16 Qa01 Qa05 Qa06Jhimnel BuhayanNo ratings yet

- Phasec2d Data SheetDocument2 pagesPhasec2d Data SheetMaria DazaNo ratings yet

- CX-IR Toxic PDSDocument2 pagesCX-IR Toxic PDSAbdul Hakeem MohammedNo ratings yet

- S 2 G 2Document2 pagesS 2 G 2WayneNo ratings yet

- IntelliSAW IRM READER - DatasheetDocument4 pagesIntelliSAW IRM READER - DatasheetMarco CornelioNo ratings yet

- Vek M4D / Vek M4Dc 4-Channel Loop Detectors For Traffic Light Systems and Car Park CountingDocument3 pagesVek M4D / Vek M4Dc 4-Channel Loop Detectors For Traffic Light Systems and Car Park CountingFJGV7No ratings yet

- Ac121 Hiperface EncoderDocument4 pagesAc121 Hiperface Encodervyshnavi nallaNo ratings yet

- GEN 2000 Electronics Radiation-Based Weigh Systems For ConveyorsDocument2 pagesGEN 2000 Electronics Radiation-Based Weigh Systems For ConveyorsJR RZNo ratings yet

- Enersol Lithium 200Document2 pagesEnersol Lithium 200jasonsivertsenNo ratings yet

- Model IN042: ApplicationsDocument2 pagesModel IN042: ApplicationsAlmira GhaisaniNo ratings yet

- ALS CL 15 - ALS CL 17 - ALS CL 20 - ALS CL 23 - ALS CL 25 - Specs - NaDocument2 pagesALS CL 15 - ALS CL 17 - ALS CL 20 - ALS CL 23 - ALS CL 25 - Specs - NaAnonymous 60esBJZIjNo ratings yet

- Macurco Product Overview 2019Document16 pagesMacurco Product Overview 2019Vincent GabrielNo ratings yet

- IR400 Data SheetDocument2 pagesIR400 Data Sheets muraNo ratings yet

- Dual Channel Shaft Vibration Transmitter MMS 3110: ApplicationsDocument4 pagesDual Channel Shaft Vibration Transmitter MMS 3110: ApplicationsMohamad YusufNo ratings yet

- AlfanarDocument44 pagesAlfanarpratham sutharNo ratings yet

- 1762sc IF8u DatasheetDocument2 pages1762sc IF8u Datasheetambresh.09No ratings yet

- Chlorine Gas Monitoring DetectorDocument2 pagesChlorine Gas Monitoring DetectorNaqib FuadNo ratings yet

- Analog Servo Drive: ADVANCED Motion Controls 3805 Calle Tecate, Camarillo, CA, 93012Document8 pagesAnalog Servo Drive: ADVANCED Motion Controls 3805 Calle Tecate, Camarillo, CA, 93012Diego MejiaNo ratings yet

- LV PDFDocument44 pagesLV PDFGyanesh BhujadeNo ratings yet

- C40-A Multisignal Panel Meter: Technical Specifications Dimensions (MM)Document4 pagesC40-A Multisignal Panel Meter: Technical Specifications Dimensions (MM)danielNo ratings yet

- Ss40F, Ss40Af: Bipolar Hall-Effect Digital Position Sensor IcsDocument6 pagesSs40F, Ss40Af: Bipolar Hall-Effect Digital Position Sensor IcsNaur AvilaNo ratings yet

- Single Mode Family: Data Sheet 09/97Document12 pagesSingle Mode Family: Data Sheet 09/97Сергей КолосовNo ratings yet

- Circutor FT - CVM-NET4-DatasheetDocument2 pagesCircutor FT - CVM-NET4-DatasheetAmir AliNo ratings yet

- Tech Specs: 8channel TemperaturescannerDocument2 pagesTech Specs: 8channel Temperaturescannermukul9040No ratings yet

- Controller: Main Applications Main FeaturesDocument4 pagesController: Main Applications Main FeaturesJulio ArianaNo ratings yet

- ISRO Technology TransfersDocument203 pagesISRO Technology Transferskoustubh007No ratings yet

- Fire Alarm Control Panel: Product OverviewDocument3 pagesFire Alarm Control Panel: Product OverviewBharaneeNo ratings yet

- Manning EC-F2 DatasheetDocument4 pagesManning EC-F2 DatasheetEduardo JoseNo ratings yet

- compactRIO FlyerDocument4 pagescompactRIO FlyerZealot FiveNo ratings yet

- Continuous, Multi-Function Oil Condition SensingDocument2 pagesContinuous, Multi-Function Oil Condition SensingTairon lopezNo ratings yet

- jf5018-00 Rev4c (14317)Document12 pagesjf5018-00 Rev4c (14317)larryNo ratings yet

- SCAN200EADocument2 pagesSCAN200EAAltayyeb AlfaryjatNo ratings yet

- XLT 898 Data SheetDocument4 pagesXLT 898 Data Sheetmohammad alajarmehNo ratings yet

- Medidor ElectromagneticoDocument10 pagesMedidor ElectromagneticoChristian Yamir Cordero VázquezNo ratings yet

- Controller GEFRAN-1600-1800-dataDocument4 pagesController GEFRAN-1600-1800-dataSuperhypoNo ratings yet

- NewNewMasibus UT94 - R4F - 1216 - Universal TransmitterDocument2 pagesNewNewMasibus UT94 - R4F - 1216 - Universal TransmitterArchire SigjhNo ratings yet

- Brochure Borri RTB OMG60307revA 06-19Document4 pagesBrochure Borri RTB OMG60307revA 06-19rakesh bardepurNo ratings yet

- 1 LTDocument3 pages1 LTRamesh SharmaNo ratings yet

- 12-Bit Monitor and Control System With Multichannel Adc, Dacs, Temperature Sensor, and Current SenseDocument47 pages12-Bit Monitor and Control System With Multichannel Adc, Dacs, Temperature Sensor, and Current SenseMichael SaligaoNo ratings yet

- Re 717MZ Rev 03 - 18 - 9 enDocument3 pagesRe 717MZ Rev 03 - 18 - 9 enmohammed.ibn.hassaanNo ratings yet

- Baykon bx23Document2 pagesBaykon bx23Godfried SimonNo ratings yet

- Siemens CLS 200Document16 pagesSiemens CLS 200Stenio LanzaNo ratings yet

- AD694-Circuito Transmisor de 4-20ma, 0-10VDocument17 pagesAD694-Circuito Transmisor de 4-20ma, 0-10VNolan Alexis Rosales SanchezNo ratings yet

- 2080sc-If4u Micro830 and Micro850 Series PLCsDocument2 pages2080sc-If4u Micro830 and Micro850 Series PLCsrajavinugmailcomNo ratings yet

- ALS-10 ALS-15 ALS-18 ALS-20 ALS-23 Specs NaDocument2 pagesALS-10 ALS-15 ALS-18 ALS-20 ALS-23 Specs NaAnonymous 60esBJZIjNo ratings yet

- Applied Measurements LTD.: Dcell Miniature Load Cell DigitiserDocument5 pagesApplied Measurements LTD.: Dcell Miniature Load Cell DigitiserOlivier GouveiaNo ratings yet

- Integritas Industrial Battery Charger: Application Industries FeaturesDocument4 pagesIntegritas Industrial Battery Charger: Application Industries Featurescelimo0710No ratings yet

- Re-717mc-Rev-04 en 10 12 2020Document2 pagesRe-717mc-Rev-04 en 10 12 2020Ahmad Saepul BahriNo ratings yet

- FT - M5 - CVM-BD - EN Power AnalyzersDocument2 pagesFT - M5 - CVM-BD - EN Power AnalyzersDino BradaricNo ratings yet

- Borri Rcb.E: Compact Rectifi Er Battery ChargerDocument2 pagesBorri Rcb.E: Compact Rectifi Er Battery ChargerAditya AdiaksaNo ratings yet

- Wireless Receivers With Relay Outputs RF RX SW915-4S 24VDC Material Number: 1370677Document2 pagesWireless Receivers With Relay Outputs RF RX SW915-4S 24VDC Material Number: 1370677asepNo ratings yet

- VS-VSKD56.., VS-VSKE56.., VS-VSKJ56.., VS-VSKC56.. Series: Vishay SemiconductorsDocument9 pagesVS-VSKD56.., VS-VSKE56.., VS-VSKJ56.., VS-VSKC56.. Series: Vishay SemiconductorsDjimiNo ratings yet

- Enersol Lithium 51 100 Battery DatasheetDocument2 pagesEnersol Lithium 51 100 Battery DatasheetjasonsivertsenNo ratings yet

- 206.008 Iss 02 CMP ICMKAZ2 ENDocument5 pages206.008 Iss 02 CMP ICMKAZ2 ENAzmi AhmadNo ratings yet

- TD Focus-Scan: Multi-Function Ultrasonic Inspection SystemsDocument2 pagesTD Focus-Scan: Multi-Function Ultrasonic Inspection SystemsYajaira SandovalNo ratings yet

- GF 9900 DatasheetDocument8 pagesGF 9900 DatasheetKa KowkNo ratings yet

- Vynesys - Product Bro Fx20ex EngDocument2 pagesVynesys - Product Bro Fx20ex EngGokul KoreNo ratings yet

- Aiche 36 012problematic Low Temperature ShiftDocument10 pagesAiche 36 012problematic Low Temperature ShiftHsein WangNo ratings yet

- Oil Centrifuge TrainingDocument65 pagesOil Centrifuge Trainingsayed2allNo ratings yet

- BB-4-18/23 Quick Guide: Warnings and Safety PrecautionsDocument4 pagesBB-4-18/23 Quick Guide: Warnings and Safety PrecautionsWalter Dario LopezNo ratings yet

- Tutorial-1 Module 8Document18 pagesTutorial-1 Module 8salkr30720No ratings yet

- Schneider Recloser, Load Break Switch, Sectionaliser 2902134 PDFDocument10 pagesSchneider Recloser, Load Break Switch, Sectionaliser 2902134 PDFSanjay BhattNo ratings yet

- ImPow E4840-I Embedded Power System Data Sheet-20190421Document2 pagesImPow E4840-I Embedded Power System Data Sheet-20190421Charmer JiaNo ratings yet

- TIC Project 8DN9 3 Days Online Training Toachi PilatonDocument2 pagesTIC Project 8DN9 3 Days Online Training Toachi PilatonGastón GuamánNo ratings yet

- Anaerobic FormDocument1 pageAnaerobic FormSohailNo ratings yet

- KTG & Thermodynamics - Practice SheetDocument7 pagesKTG & Thermodynamics - Practice SheetAbcdNo ratings yet

- Bio Nanogenerators: Presented By: Hira Rasab (022) Yusra FarooqDocument23 pagesBio Nanogenerators: Presented By: Hira Rasab (022) Yusra FarooqHira RasabNo ratings yet

- Bravo Trittico ExecutiveDocument22 pagesBravo Trittico ExecutiveAhmed BouticheNo ratings yet

- JKM570 590N 72HL4 BDV F7 enDocument2 pagesJKM570 590N 72HL4 BDV F7 enViệt Trung HồNo ratings yet

- Torques de Motor ISX15 - Búsqueda de Google 2Document1 pageTorques de Motor ISX15 - Búsqueda de Google 2Leonardo NordelosNo ratings yet

- Single Phase TransformerDocument53 pagesSingle Phase TransformerGurpreet Singh100% (2)

- Auweld Welding Machines Accessories Catalogue(s)Document28 pagesAuweld Welding Machines Accessories Catalogue(s)nyaungzinNo ratings yet

- BrochureDocument13 pagesBrochure13421301508No ratings yet

- Manuales de Servicio Serie FB-VIIIDocument540 pagesManuales de Servicio Serie FB-VIIIJose Roca100% (1)

- Cummins M11 High Soot Test: Standard Test Method ForDocument31 pagesCummins M11 High Soot Test: Standard Test Method ForNguyễn Bằng NộiNo ratings yet

- Ian's Backyard Brake Calculator (Enter Blacks Calculates) : BluesDocument5 pagesIan's Backyard Brake Calculator (Enter Blacks Calculates) : Bluesabhijit.ghotaneNo ratings yet

- Case Studies in Construction MaterialsDocument11 pagesCase Studies in Construction MaterialsAmin ZuraiqiNo ratings yet

- Main ShaftDocument7 pagesMain Shaftcosta59dac9242No ratings yet

- Operating-Instruction-Clutch-Brake-14.105 U. 14.115 13231689 en 11 2007Document24 pagesOperating-Instruction-Clutch-Brake-14.105 U. 14.115 13231689 en 11 2007Mihai SpireaNo ratings yet

- Insulators and Circuit BreakersDocument29 pagesInsulators and Circuit Breakersdilja aravindanNo ratings yet

- Energy ResourcesDocument11 pagesEnergy ResourcesMUHAMMAD DANIYAL KANDANo ratings yet

- Alkylation Reactor Material BalanceDocument4 pagesAlkylation Reactor Material BalanceKrizzia Anne ShengNo ratings yet

- Deutz 0312 1936 2011Document554 pagesDeutz 0312 1936 2011caiocunhaconquistaNo ratings yet

- CHH009CA-13B CHH012CA-13B 66129903140 CHH012CD-13B: Downloaded From Manuals Search EngineDocument31 pagesCHH009CA-13B CHH012CA-13B 66129903140 CHH012CD-13B: Downloaded From Manuals Search EngineMARTIN PURIZACA VILCHEZNo ratings yet

- Literture Review Stone CrusherDocument5 pagesLiterture Review Stone CrusherD.n.G StudiosNo ratings yet

- Chap 13Document16 pagesChap 13nelson escuderoNo ratings yet

- RDSS L2 Pert Chart - PKG-04 - Joynagar.... 21082023Document5 pagesRDSS L2 Pert Chart - PKG-04 - Joynagar.... 21082023sourish69No ratings yet