Professional Documents

Culture Documents

Oreja de Izaje Conectada en El Ala Superior

Oreja de Izaje Conectada en El Ala Superior

Uploaded by

Sleyda MunozOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Oreja de Izaje Conectada en El Ala Superior

Oreja de Izaje Conectada en El Ala Superior

Uploaded by

Sleyda MunozCopyright:

Available Formats

"LIFTING_LUG.

xls" Program

Version 1.4

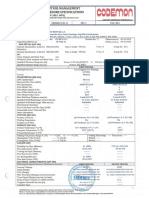

LIFTING LUG ANALYSIS

Per AISC 13th Edition ASD Manual, ASME BTH-1-2008, and

"Design and Construction of Lifting Beams" by David T. Ricker

Project Name: Oreja de Izaje Plataforma Limeslaker Client: Barrick

Project No.: PV-21016 Prep. By: JCPR Date: 3/17/2023

Input:

Design Parameters:

Lug Yield Strength, Fy = 36 ksi

Lug Ult. Strength, Fu = 58 ksi

Edge Dist., a = 2.000 in.

Edge Dist., e = 2.750 in.

Lug Width, b = 5.500 in.

Rounded Edge? = No

Will Pin Rotate Under Load? = Yes

Hole Diameter, dh = 1.500 in.

Pin Diameter, dpin = 1.000 in.

Lug Thickness, t = 1.000 in.

AISC Factor of Safety, F.S.1 = 5.0

AISC Factor of Safety, F.S.2 = 3.1 F.S.2 = max{3, Fy/(Fu/F.S.1)} ASME Notation

ASME Factor of Safety, F.S.3 = 3.0 Assuming Category B lifters

AISC Preferred Geometry AISC Alternate Geometry

Results:

Check Geometry:

Check 1: O.K. dh - dpin > 0, Pin fits in hole, O.K.

Check 2: O.K. a >= max(0.5*dh,2*t), Plate Proportions are O.K.

Check 3: O.K. e >= 0.67*dh, Plate Proportions are O.K.

Check 4: O.K. e >= 1.33*a, Use full value of a for design

a,eff = 2.00 in. a controls

a,max = 2.63 in. a,max = 2*t+.625

a,use = 2.00 in. Use a,eff in design

(continued)

3/17/2023 C:\Users\j.perezrodriguez\Downloads\ Page 1

4:07 PM LIFTING_LUG_analysis (1) of 2

"LIFTING_LUG.xls" Program

Version 1.4

Tensile Strength of Lifting Lug (AISC Eqn. D5-1):

P1 = 46.40 kips P1 = (2*a,use*t*Fu) / F.S.1

Bearing Capacity of Lifting Lug (AISC Eqn. J7-1):

P2 = N/A kips P2 = (1.8*Fy*t*dpin) / F.S.2

Per Ricker, only check bearing capacity if pin is "snug" in hole

Tearing Tension Capacity of Lifting Lug (Ricker pg 152):

P3 = 97.67 kips P3 = {(1.67*Fy*t*e^2)/dh} / F.S.2

Per Ricker pg. 152, Fb is used instead of Fy, but Fb = Fy/F.S.2

Shear Capacity (Shear Rupture) of Lifting Lug (AISC Eqn D5-2):

P4 = 38.28 kips P4 = (0.6*Fu*2*t*e) / F.S.1

Per AISC Eqn. D5-2, Asf = 2*t*(e+dh/2), cons. to assume dh/2=0)

Gross Section Yielding of Lifting Lug (AISC Eqn D2-1):

P5 = 63.80 kips P5 = (Fy*t*b) / F.S.2

Tensile Strength of Lifting Lug (ASME Eqn. 3-45):

Cr = 0.795 Cr = 1 - 0.275*sqrt{1 - (dpin^2 / dh^2)}

a,eff = 1.67 in. a, eff = min(a, 4*t, 0.6*a*(Fu/Fy)*sqrt(dh / a)

P6 = 42.89 kips P6 = (Cr*Fu*2*t*a,eff) / (1.2*F.S.3)

Single Plane Fracture Strength of Lifting Lug (ASME Eqn. 3-49):

R= 3.500 in. R = e+(dh/2)

P7 = 49.13 kips P7 = [(Cr*Fu)/(1.2*F.S.3)] *

[1.13*(R-.5*dh)+(0.92*a,eff)/(1+a,eff/dh)] * t

Double Plane Fracture Strength of Lifting Lug (ASME Eqn. 3-50):

f= 36.67 deg. f = 55*(dpin / dh)

Z' = 0.000 in. Z' = R - sqrt{R^2 - [(dpin/2)*sin(f)]^2}, only applicable for rounded edges

Av = 5.698 in.^2 Av = 2*{e+0.8*dpin*[1-cos(f)]-Z'}*t

P8 = 64.26 kips P8 = (0.7*Fu*Av) / (1.2*F.S.3)

Bearing Capacity of Lifting Lug (ASME Eqn. 3-54):

P9 = 7.56 kips P9 = (0.63*Fy*dpin*t) / F.S.3 <============= Controls

Summary:

Pallow = 7.56 kips Pallow = min(P1, P2, P3, P4, P5, P6, P7, P8, P9)

Required Weld Strength for Vertical Load:

Pdesign = 11.34 kips Assuming fillet weld and F.S. = 5.0 against Fexx. Use Pdesign

to design welds using 0.3*Fexx*0.707*weld size. Could also use

Pallow, but need to use 0.2*Fexx*0.707*weld size for F.S. = 5.0.

Comments:

3/17/2023 C:\Users\j.perezrodriguez\Downloads\ Page 2

4:07 PM LIFTING_LUG_analysis (1) of 2

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5811)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- D1.1 D1.1M 2020 Errata 2qDocument19 pagesD1.1 D1.1M 2020 Errata 2qSleyda Munoz100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Electrical Installation - SP-0000-60-0030-1Document20 pagesElectrical Installation - SP-0000-60-0030-1Sleyda MunozNo ratings yet

- FMR 004 Materiales para Pararrayos Expansion - InselDocument1 pageFMR 004 Materiales para Pararrayos Expansion - InselSleyda MunozNo ratings yet

- PVDC-5150-17-0022-0 - Ewrick Michel CorcinDocument1 pagePVDC-5150-17-0022-0 - Ewrick Michel CorcinSleyda MunozNo ratings yet

- Carbon Reactivation Kilns - SP 0000-16-0007 2Document21 pagesCarbon Reactivation Kilns - SP 0000-16-0007 2Sleyda MunozNo ratings yet

- Circuit Breakers 230 KV - SP-0000-60-0001-3Document32 pagesCircuit Breakers 230 KV - SP-0000-60-0001-3Sleyda MunozNo ratings yet

- PV-F-80677-4 Purchasing-Card Form Rev.4 - Autocad PlantDocument1 pagePV-F-80677-4 Purchasing-Card Form Rev.4 - Autocad PlantSleyda MunozNo ratings yet

- SP0793 M043.00 G18 0220 Sub01 Construction Work Pack Activator Collector - Pdf.zipDocument532 pagesSP0793 M043.00 G18 0220 Sub01 Construction Work Pack Activator Collector - Pdf.zipSleyda MunozNo ratings yet

- IndustrialDocument9 pagesIndustrialSleyda MunozNo ratings yet

- Manual de Manejo de Cercas Vivas de Piñón: September 2010Document7 pagesManual de Manejo de Cercas Vivas de Piñón: September 2010Sleyda MunozNo ratings yet

- Installation, Operation and Maintenance Manual: Severe Service Knife Gate ValveDocument11 pagesInstallation, Operation and Maintenance Manual: Severe Service Knife Gate ValveSleyda MunozNo ratings yet

- DrenajeDocument1 pageDrenajeSleyda MunozNo ratings yet

- Cod WPS PQR 16 Codemon 2021-04-13Document13 pagesCod WPS PQR 16 Codemon 2021-04-13Sleyda MunozNo ratings yet

- Series 2, 3, 4, & 5 Aluminum - : Straight Section Part NumberingDocument2 pagesSeries 2, 3, 4, & 5 Aluminum - : Straight Section Part NumberingSleyda MunozNo ratings yet

- 5 MLDocument1 page5 MLSleyda MunozNo ratings yet

- OLT02B PLANNER MASTER SHEET Rev.Document92 pagesOLT02B PLANNER MASTER SHEET Rev.Sleyda MunozNo ratings yet

- C1bu 04Document1 pageC1bu 04Sleyda MunozNo ratings yet

- Cod WPS PQR 08 Codemon 2021-04-13Document5 pagesCod WPS PQR 08 Codemon 2021-04-13Sleyda MunozNo ratings yet

- Unit Converter SpreadSheetDocument12 pagesUnit Converter SpreadSheetSleyda MunozNo ratings yet

- PROCEDIMIENTO AWS WPS SRL FILETE D1.1 Gr2 ComentadoDocument2 pagesPROCEDIMIENTO AWS WPS SRL FILETE D1.1 Gr2 ComentadoSleyda MunozNo ratings yet