Professional Documents

Culture Documents

Deap Sea 703

Deap Sea 703

Uploaded by

Arif ImronOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Deap Sea 703

Deap Sea 703

Uploaded by

Arif ImronCopyright:

Available Formats

703

DEEP SEA ELECTRONICS PLC Auto Start

Issue 6

VH 28/08/02

DESCRIPTION

The 703 is an engine auto start and Selection of the Configuration Mode is

protection module. It utilises advanced indicated by rapid flashing of the ‘Auto’

surface mount construction techniques to LED.

provide a compact, yet highly specified

module. The module is designed with DSE’s proven

experience and uses modern construction

Operation is via three pushbuttons to provide a high level of reliability and

mounted on the front panel with STOP, suitability for the intended operating

MANUAL and AUTO positions. environment. Issues such as

environmental compliance and EMC have

been carefully engineered into the design.

OPERATION Advanced features such as protected solid

state outputs mean that there are no

Stop mode - This is used to stop the

moving parts or contacts to burn out.

engine when it is running and to cancel

‘Auto’ mode. It is also used to reset any

Shutdown Alarm conditions. FEATURES SPECIFICATION

Ø DC Supply:

Manual mode - This mode is used to 8 to 35 V Continuous.

manually start and run the engine, which Ø Micro-processor based design

can be stopped by pressing the Stop Ø Automatic Engine Starting and Ø Cranking Dropouts:

button. Stopping Able to survive 0 V for 50 mS,

Ø Automatic Shutdown on fault condition providing supply was at least 10 V

Auto mode - This selects the automatic Ø Configurable via front panel before dropout and supply recovers

mode of operation, in which the module Ø Simple pushbutton controlled to 5V. This is achieved without the

will await the remote start signal. Once operation need for internal batteries.

received, the module will initiate its pre- Ø Configurable Digital Inputs Ø Max. Current:

configured Start Sequence, observing Ø Configurable Solid State Outputs Operating 50mA

the start delay timer before starting the Ø Configurable Timer Settings Standby 10mA

engine. When the remote start signal is Ø Solid State Fuel and Crank outputs

Ø Alternator Input Range:

removed, the module will initiate its pre- Ø External Remote Start input

Ø LED Alarm indication 75(ph-N) to 277(ph-N) 3 Phase

configured Stopping Sequence.

Ø Start DelayTimer 4wire AC (+20%)

The module monitors the engine and Ø Stop Delay Timer Ø Alternator Input Frequency:

provides the following functions: Ø Energise to Stop timer 50 - 60 Hz at rated engine speed

Ø Automatic Start with 3 attempts and Ø Pre-heat Timer (Minimum: 75V AC Ph-N) (Crank

Automatic Crank Disconnect - with Ø Over Speed Shutdown Disconnect from 15V Ph-N @ 20 Hz)

adjustable Start and Stop Timers Ø Optional Underspeed Protection Overspeed +14% (+24% overshoot)

and Fail to Start indication. Ø Low Oil Pressure Shutdown Underspeed –20%

Ø Configurable Pre-heat and Energise Ø High Engine Temp Shutdown Ø Start Output:

to Stop functions. Ø Optional Crank Disconnect from Oil 1.2 Amp DC at supply voltage.

Ø Low Oil Pressure and High Engine Pressure

Temperature Shutdown. Ø Fuel Output:

Ø Overspeed and Underspeed 1.2 Amp DC at supply voltage.

(frequency) protection. Ø Auxiliary Outputs:

Ø Charge Fail Alarm 1.2 Amp DC at supply voltage.

Ø Two fully configurable auxiliary The 700 series modules have been Ø Dimensions:

inputs. designed for front panel mounting. The 125 X 165 X 28 mm

All alarms are indicated by high visibility module is fitted into the cut-out, and screw

red LED’s. Ø Charge Fail:

holes are provided for secure fixing.

12V = 8V CF 24V = 16V CF

The module’s microprocessor provides a

comprehensive list of timers and Ø Operating Temperature Range:

configurable functions. Parameter -30 to +70°

settings can be adjusted using the front

panel pushbuttons once in Configuration Ø Compliant with BS EN 60950

Mode. Access to the settings is via a Low Voltage Directive

small ‘Configuration Switch’ on the rear Ø Compliant with BS EN 50081-2

of the module (see figs. 1 and 2), and EMC Directive

enables changes to be made in the field. Ø Compliant with BS EN 50082-2

EMC Directive

Deep Sea Electronics plc reserve the right to change

specification without notice.

CONFIGURATION

Configuration Mode is selected by operation of a small switch on the rear, left-hand edge of the PCB. This is partially hidden to

prevent accidental operation. See figs 1 and 2

Fig. 1 Once Configuration Mode is selected, the ‘Auto’ LED will commence rapid flashing. When in

Configuration Mode all normal operation is suspended.

The ‘Stop’ pushbutton can be used to select the LED ‘code’ that corresponds to the required

Normal function. The 5 left hand LED’s will form the code

The ‘Manual’ pushbutton will allow the user to change the function parameters. The 3 right-hand LED’s

inform the user of the current value for the chosen function.

When the required parameters are displayed, pressing the ‘Auto’ button will save the

Configuration new setting. The process is repeated for each function change.

When configuration is complete, the Configuration Mode Selector Switch should be returned to the

‘Normal’ position.

A key to all configuration options is provided (refer to Installation Instructions supplied with module).

Fig. 2

Diagram of reverse side of 703

Fig. 3

Dimensions (mm)

F 2A TYPICAL CONNECTIONS

21 20

15

Fuel o/p Start o/p Auxiliary Outputs

SSO SSO SSO SSO Auxiliary Alarm

Inputs

1 2 3 4 5 6 7 8 9 10 11 12

+ + + +

F2A F

+ Crank

Starter Charge

Battery Fuel

motor alt

SSO = Solid state outputs

= External 'Automotive' or 'Plug-in' type relays

Deep Sea Electronics plc

Highfield House, Hunmanby Industrial Estate, North Yorkshire, YO14 0PH, England

Tel: +44 (0) 1723 890099 Fax: +44 (0) 1723 893303 E-mail sales@deepseaplc.com

You might also like

- Easytronic Micro II (2012 Revision15) ControllerDocument11 pagesEasytronic Micro II (2012 Revision15) Controllermohammedalathwary56% (9)

- 520 PDFDocument2 pages520 PDFAhmed DiaaNo ratings yet

- DS 720 SDocument2 pagesDS 720 SIvan DumontNo ratings yet

- Datacom 507 - Manual PDFDocument29 pagesDatacom 507 - Manual PDFvasilimertzani100% (1)

- Analog Circuit Design Volume Three: Design Note CollectionFrom EverandAnalog Circuit Design Volume Three: Design Note CollectionRating: 3 out of 5 stars3/5 (2)

- 标准版供电装置hcyd22 Xx Ag2说明书4.70 Tdgk Vr1.1板子英文 单相Document7 pages标准版供电装置hcyd22 Xx Ag2说明书4.70 Tdgk Vr1.1板子英文 单相mohammedalathwary100% (1)

- 标准版供电装置hcyd22 Xx Ag2说明书4.70 Tdgk Vr1.1板子英文 单相Document7 pages标准版供电装置hcyd22 Xx Ag2说明书4.70 Tdgk Vr1.1板子英文 单相mohammedalathwary100% (1)

- Siemens 4200 Gigaset Cordless Phone Manual (4200, 4210, 4215)Document153 pagesSiemens 4200 Gigaset Cordless Phone Manual (4200, 4210, 4215)FB43100% (1)

- AMF PanelDocument2 pagesAMF PanelSudipto MajumderNo ratings yet

- Dse 509Document2 pagesDse 509SOSNo ratings yet

- Automatic Start: DescriptionDocument2 pagesAutomatic Start: DescriptionMasnawiNo ratings yet

- Description: Deep Sea Electronics Auto Mains FailureDocument2 pagesDescription: Deep Sea Electronics Auto Mains Failureabduallah muhammadNo ratings yet

- DSE521 Data Sheet PDFDocument2 pagesDSE521 Data Sheet PDFJohn GarnetNo ratings yet

- Deep Sea 5110 Automatic Engine Control ModuleDocument2 pagesDeep Sea 5110 Automatic Engine Control ModuleÁlvaro 2.0No ratings yet

- DSE520 Data Sheet PDFDocument2 pagesDSE520 Data Sheet PDFDuda CorrêaNo ratings yet

- DSE520Document3 pagesDSE520abuzer1981No ratings yet

- Amf ControllerDocument3 pagesAmf ControllerbisryawayeNo ratings yet

- Description: Deep Sea Electronics PLC Manual StartDocument2 pagesDescription: Deep Sea Electronics PLC Manual StartJoel Khamala KarokiNo ratings yet

- Deep Sea Electronics PLC: Model 520 Automatic Start ModuleDocument2 pagesDeep Sea Electronics PLC: Model 520 Automatic Start ModuleLuis Francisco Calderon EspinozaNo ratings yet

- Especificaciones Tecnicas Deep Sea 501 - EspañolDocument2 pagesEspecificaciones Tecnicas Deep Sea 501 - EspañolMH..2023No ratings yet

- Dse 703 & Dse 4110 Auto Start Control ModulesDocument2 pagesDse 703 & Dse 4110 Auto Start Control ModulesImam Syarifuddin0% (1)

- Dkg-227 Manual and Remote Start UnitDocument24 pagesDkg-227 Manual and Remote Start UnitabotalebNo ratings yet

- DSE550 Data Sheet PDFDocument4 pagesDSE550 Data Sheet PDFjulNo ratings yet

- DSE520 Data SheetDocument2 pagesDSE520 Data Sheettoa87No ratings yet

- Description: Deep Sea Electronics PLC Manual StartDocument2 pagesDescription: Deep Sea Electronics PLC Manual StartFrank LlavNo ratings yet

- Manual Start Deep Sea Electronics: Features DescriptionDocument2 pagesManual Start Deep Sea Electronics: Features Descriptionabduallah muhammadNo ratings yet

- Ultra: Starting With QualityDocument2 pagesUltra: Starting With QualityVinayak JakkanNo ratings yet

- Warning: Keystart 9620/9621Document4 pagesWarning: Keystart 9620/9621John GarnetNo ratings yet

- Manual and Remote Start Unit: ApplicationsDocument2 pagesManual and Remote Start Unit: ApplicationsAhmed El-AdawyNo ratings yet

- Kg-545 Automatic Mains Failure UnitDocument35 pagesKg-545 Automatic Mains Failure UnitJack GehlotNo ratings yet

- Manual Start Unit: DescriptionDocument2 pagesManual Start Unit: DescriptionHaider HameedNo ratings yet

- DKG 114Document2 pagesDKG 114Vu TuongNo ratings yet

- Controlador de CorrienteDocument12 pagesControlador de Corrientecjaziel66No ratings yet

- EPC Technical Reference ManualDocument19 pagesEPC Technical Reference Manualhibidder7775891No ratings yet

- Description: Deep Sea Electronics Auto StartDocument2 pagesDescription: Deep Sea Electronics Auto StartMaylen RivasNo ratings yet

- DSE501 Data Sheet PDFDocument2 pagesDSE501 Data Sheet PDFChristopher100% (3)

- Deep Sea Electronics PLC: 701 Key Start Module Operating InstructionsDocument11 pagesDeep Sea Electronics PLC: 701 Key Start Module Operating InstructionsosanebiNo ratings yet

- Deep Sea Electronics PLC: Model 606 Comprehensive Amf ModuleDocument4 pagesDeep Sea Electronics PLC: Model 606 Comprehensive Amf ModulemohammedalathwaryNo ratings yet

- X 704 Tech SpecsDocument2 pagesX 704 Tech SpecsWilson Irigoin FernandezNo ratings yet

- Solar VFD Pump Drive: For Customer UseDocument4 pagesSolar VFD Pump Drive: For Customer UseMuhammad TahirNo ratings yet

- Ecu 04 Manual enDocument4 pagesEcu 04 Manual enMahendra PersonnelNo ratings yet

- Bernini OverviewDocument7 pagesBernini Overviewaberardo1No ratings yet

- Newage Mx341 Automatic Voltage RegulatorDocument6 pagesNewage Mx341 Automatic Voltage RegulatoredgarcooNo ratings yet

- s1000 Voltage RegulatorDocument36 pagess1000 Voltage RegulatorAnonymous 7PtTlrNo ratings yet

- DKG 114 User PDFDocument9 pagesDKG 114 User PDFangel aguilarNo ratings yet

- Deep Sea Electronics PLC: 702 Automatic Start Module Operating InstructionsDocument10 pagesDeep Sea Electronics PLC: 702 Automatic Start Module Operating InstructionsAmborsius SitorusNo ratings yet

- Manual de Operación Deepsea DSE702Document21 pagesManual de Operación Deepsea DSE702Carlos Andrés Marín ArcosNo ratings yet

- Gen Auto XMDocument47 pagesGen Auto XMCameron Ledingham100% (1)

- 5110UL EngDocument2 pages5110UL EngAhmed Elsayed Abdel GhanyNo ratings yet

- 701 Key Start Module Operating Instructions: Author:-John RuddockDocument11 pages701 Key Start Module Operating Instructions: Author:-John RuddockAmir MohammedNo ratings yet

- Manual of Cdig-310220Document22 pagesManual of Cdig-310220trinath mohapatraNo ratings yet

- Dkg-205 Automatic Mains Failure UnitDocument20 pagesDkg-205 Automatic Mains Failure UnitRafatNo ratings yet

- Ys 6235Document2 pagesYs 6235pabloperezmtz1No ratings yet

- Sd.ma英文說明書 E-phaa-esda03 -l M型Document130 pagesSd.ma英文說明書 E-phaa-esda03 -l M型Wikmi IgnacioNo ratings yet

- BerniniDocument13 pagesBerniniPanagiotis KarafillisNo ratings yet

- DSE 6010 DatasheetDocument2 pagesDSE 6010 DatasheetRabih MradNo ratings yet

- AVR341 Generator Automatic Voltage Regulator Operation ManualDocument6 pagesAVR341 Generator Automatic Voltage Regulator Operation ManualEmanuel Arguiñarena100% (1)

- OptimDocument2 pagesOptimGabriel GranadoNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- OTIS 506, 506SL, 510 UNITS: Precision Escalator Products, IncDocument10 pagesOTIS 506, 506SL, 510 UNITS: Precision Escalator Products, IncmohammedalathwaryNo ratings yet

- Page0023 PDFDocument1 pagePage0023 PDFmohammedalathwaryNo ratings yet

- EWD-RL-J2 Elevator Weighing Device Introdtion Manual (V2.0) : DeclarationDocument12 pagesEWD-RL-J2 Elevator Weighing Device Introdtion Manual (V2.0) : Declarationmohammedalathwary100% (4)

- Break Reless Chapter 1 IntroDocument1 pageBreak Reless Chapter 1 IntromohammedalathwaryNo ratings yet

- Car Operating Panels & Landing Push Stations: Lift ComponetsDocument1 pageCar Operating Panels & Landing Push Stations: Lift ComponetsmohammedalathwaryNo ratings yet

- Alhamdany Hospital: Partner Asansör FormDocument1 pageAlhamdany Hospital: Partner Asansör FormmohammedalathwaryNo ratings yet

- Chapt Er2Wi Ri NG: 2. 1termi Naldefi Ni T I OnDocument1 pageChapt Er2Wi Ri NG: 2. 1termi Naldefi Ni T I OnmohammedalathwaryNo ratings yet

- De DP016Document14 pagesDe DP016mohammedalathwaryNo ratings yet

- Sky301-V3 User ManualDocument16 pagesSky301-V3 User Manualمحمدحماد100% (1)

- Sec Electronics: Exchange Safety Circuit 185 With Safety Circuit 186Document1 pageSec Electronics: Exchange Safety Circuit 185 With Safety Circuit 186mohammedalathwaryNo ratings yet

- Warnings: Device Usage and Operation SequenceDocument9 pagesWarnings: Device Usage and Operation Sequencemohammedalathwary100% (1)

- Icsoftware Instructions Procedure Brief1.Get Into The Software 2.add Elevator Data 3.switch Card 4.write Owner CardDocument5 pagesIcsoftware Instructions Procedure Brief1.Get Into The Software 2.add Elevator Data 3.switch Card 4.write Owner CardmohammedalathwaryNo ratings yet

- Manual For EncoderDocument2 pagesManual For EncodermohammedalathwaryNo ratings yet

- HGL10 Operation Service ManualDocument49 pagesHGL10 Operation Service ManualmohammedalathwaryNo ratings yet

- SJT-WVF-V Group Control User Manual (Version 2018) : Shenyang Bluelight 2018.7.9Document16 pagesSJT-WVF-V Group Control User Manual (Version 2018) : Shenyang Bluelight 2018.7.9mohammedalathwary100% (2)

- Main Control Board User ManualDocument15 pagesMain Control Board User Manualmohammedalathwary100% (1)

- Lift Transformer2 1Document1 pageLift Transformer2 1mohammedalathwaryNo ratings yet

- RFID0950 Elevator ID Card Manual: Core Lift Accessories Co.,LtdDocument8 pagesRFID0950 Elevator ID Card Manual: Core Lift Accessories Co.,LtdmohammedalathwaryNo ratings yet

- Genesis Newsletter 13-02Document3 pagesGenesis Newsletter 13-02mohammedalathwaryNo ratings yet

- RECORD Deurautomaat DFA 127 INVERS English - Opeartion InstructionsDocument20 pagesRECORD Deurautomaat DFA 127 INVERS English - Opeartion InstructionsmohammedalathwaryNo ratings yet

- Keysight Chart 5991-4907ENDocument1 pageKeysight Chart 5991-4907ENamitk guptaNo ratings yet

- Cambridge International General Certificate of Secondary EducationDocument48 pagesCambridge International General Certificate of Secondary EducationLiana KiwanNo ratings yet

- Some Topologies of High Quality RectifiersDocument6 pagesSome Topologies of High Quality RectifiersSatya NVNo ratings yet

- smart-anchor-pricelistDocument4 pagessmart-anchor-priceliststudy acienceNo ratings yet

- Signals and Systems by Nagoor KaniDocument5 pagesSignals and Systems by Nagoor KaniBENAZIR BEGAM RNo ratings yet

- Vehicle Grade, Lte-Advanced Pro, Gigabit Wi-Fi: Sierra Wireless Airlink® Mp70 High Performance Vehicle RouterDocument6 pagesVehicle Grade, Lte-Advanced Pro, Gigabit Wi-Fi: Sierra Wireless Airlink® Mp70 High Performance Vehicle Routerjunak72No ratings yet

- Anirban Jun 08 Detailed CVDocument5 pagesAnirban Jun 08 Detailed CVDragonzombie0099No ratings yet

- MFJ-259C Manual Ver5 PDFDocument28 pagesMFJ-259C Manual Ver5 PDFRainier Ledesma AcostaNo ratings yet

- Universal Tester For Electronic Control Units in AutomotivesDocument4 pagesUniversal Tester For Electronic Control Units in AutomotivespbollaganiNo ratings yet

- SY103A eDocument16 pagesSY103A eutilscNo ratings yet

- Growbot QueueDocument133 pagesGrowbot QueueAndika Liga BintangNo ratings yet

- Correction To f16 Pulse Doppler Radar Anapg66 Performance - 1983Document1 pageCorrection To f16 Pulse Doppler Radar Anapg66 Performance - 1983Dhimas AfihandarinNo ratings yet

- A 28Nm Poly/Sion Cmos Technology For Low-Power Soc ApplicationsDocument2 pagesA 28Nm Poly/Sion Cmos Technology For Low-Power Soc ApplicationsOne TzueNo ratings yet

- Vostro 3500: Service ManualDocument83 pagesVostro 3500: Service ManualSpaniardbest SpaniardNo ratings yet

- Protokraft Introduces SMPTE 292M Op To Electronic Transmitters and ReceiversDocument3 pagesProtokraft Introduces SMPTE 292M Op To Electronic Transmitters and ReceiversBob ScharfNo ratings yet

- JupiterSRSRem H52513 201411Document117 pagesJupiterSRSRem H52513 201411reivajjwNo ratings yet

- Manual Behringer Ampli V AmpireDocument20 pagesManual Behringer Ampli V Ampiregoogl3No ratings yet

- Bounce DiagramsDocument13 pagesBounce DiagramsOCZulfikar BariklanaNo ratings yet

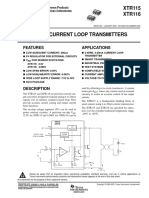

- XTR115 XTR116: Features ApplicationsDocument16 pagesXTR115 XTR116: Features Applications1No ratings yet

- Chris Haslett SecDocument22 pagesChris Haslett SecrittalNo ratings yet

- FM8800S Service Manual B6 1-20-09Document244 pagesFM8800S Service Manual B6 1-20-09jrmartin2k3792% (13)

- Data0305 KX15DTDocument3 pagesData0305 KX15DTAbdelhamid SammoudiNo ratings yet

- Sirius 3 ManualDocument22 pagesSirius 3 Manual'Egemen KayaNo ratings yet

- 02 LF - SS1101 - E01 - 1 Product Description of FDD LTE eNodeBnew PDFDocument53 pages02 LF - SS1101 - E01 - 1 Product Description of FDD LTE eNodeBnew PDFhamzaNo ratings yet

- Service Manual: Conf IdentialDocument17 pagesService Manual: Conf IdentialFrank ElizaldeNo ratings yet

- ECSE 2104 - L1 - Introduction To Microprocessors and Embedded SystemsDocument13 pagesECSE 2104 - L1 - Introduction To Microprocessors and Embedded SystemsWilliam StephensonNo ratings yet

- MOSFET Gate Drive Circuit Design Considerations For Integrated High Switching Frequency Buck ConverterDocument7 pagesMOSFET Gate Drive Circuit Design Considerations For Integrated High Switching Frequency Buck ConverterSergey RosenfeldNo ratings yet