Professional Documents

Culture Documents

IP MS 14 Tiling & Flooring (Walls & Floor)

IP MS 14 Tiling & Flooring (Walls & Floor)

Uploaded by

Zubair Ahmed KhaskheliCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IP MS 14 Tiling & Flooring (Walls & Floor)

IP MS 14 Tiling & Flooring (Walls & Floor)

Uploaded by

Zubair Ahmed KhaskheliCopyright:

Available Formats

Doc No: IP/MS-14

TILING & FLOORING (WALLS & FLOOR) Rev: 01

Page: 1 of 4

METHOD STATEMENT

FOR

TILING & FLOORING (WALLS & FLOOR)

01 Introduction of HSE Instructions 12 Oct, 04 M Ashraf MSC AKK

0 Method Statement for Tiling & Flooring 24 July, 03 M Ashraf MSC AKK

(Walls & Floor)

Do not Duplicate, Controlled Copy If Stamped In Red

Descon Engineering Limited

Doc No: IP/MS-14

TILING & FLOORING (WALLS & FLOOR) Rev: 01

Page: 2 of 4

Rev. No. Details Of Revision Date Prepared by Checked by Approved by

1. OBJECTIVE

The objective of this method statement is to provide general guidelines for all the tiling

work.

2. SCOPE

This method statement covers the activities of laying any type of tiles on walls and floors

at all project sites.

3. REFERENCES

Construction drawings & specifications

4. DEFINITIONS

CAR Corrective Action Request

HSE Health, Safety and Environment

QIP Quality Inspection Plan

Doc. Document

5. RESPONSIBILITIES

Construction Manager shall be responsible for implementation of this method

statement.

6. PROCEDURE

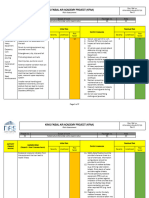

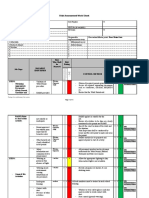

6.1 Quality Inspection Plan (QIP) specific to project requirements shall be made and

inspection activities shall be recorded either on the formats as given under

“Related Documents” or those supplied by customer.

6.2 Get the specified sample of tiles approved from customer/consultant.

6.3 The tiles shall have uniform texture and straight edges.

6.4 The tiles shall be true, even on face and of uniform thickness throughout.

6.5 The floor layout shall be at pattern to permit setting of tile with a minimum of

cutting.

6.6 All the dimensions shall be controlled to avoid setting tile smaller than one half

size.

6.7 The tiles shall be cut with a suitable cutting tool and rough edges shall be rubbed

smooth.

6.8 The edges shall be tooled slightly concave.

6.9 The tiles shall be skillfully laid with ordinary Portland cement and sand mortar as

mentioned in the project specifications.

Do not Duplicate, Controlled Copy If Stamped In Red

Descon Engineering Limited

Doc No: IP/MS-14

TILING & FLOORING (WALLS & FLOOR) Rev: 01

Page: 3 of 4

6.10 All joints shall be properly grouted with white cement or in accordance with the

project specifications.

6.11 All joints shall be straight, level, perpendicular and have even width. Vertical joint

shall be maintained plumb for the entire height of the tile work.

6.12 The tiling work shall be cured as per period mentioned in project specifications or

for at least 10 days.

6.13 In case of non-conformity at any stage of inspection, the segregation shall be

covered by method statement No. QA&QC/MS-02 and Corrective Action Request

(CAR) shall be raised as per standard operating procedure No. QA&QC/SOP-04.

7. TOOLS AND EQUIPMENTS

Tile Cutting Machine, Hand Tools, Plumb Lines, Mortar Mixing Pans.

8. HSE INSTRUCTIONS

8.1 Hand gloves must be used while doing the job.

8.2 Tiles of same size must be separated before start of job.

8.3 While cutting the tiles, the worker must wear the safety glasses.

8.4 Extra material on tiles must be cleared immediately after the fixing of tiles.

8.5 First make the outer boundary of tiles, so that the cutting/wastage can be

minimized.

8.6 No trash, rapes, shopping bags, papers, cans, bottles or any other litter should

be left in the open.

8.7 Any liquid fuel spills and accidental waste disposal should be avoided and

properly cleaned up.

8.8 Keep your environment clean.

9. RELATED DOCUMENTS

9.1 Related Drawings & Customer’s Specifications.

9.2 QA&QC/FRM-161 Soil Compaction Check List

9.3 QA&QC/FRM-163 E//Work , Road Work & Flexible Paving Inspection

Report

Do not Duplicate, Controlled Copy If Stamped In Red

Descon Engineering Limited

Doc No: IP/MS-14

TILING & FLOORING (WALLS & FLOOR) Rev: 01

Page: 4 of 4

9.4 QA&QC/FRM-187 Aggregate Combination Calculation Sheet

9.5 QA&QC/FRM-188 Gradation Chart

9.6 QA&QC/FRM-199 Material Approval Form

9.7 QA&QC/FRM-200 Foundation Inspection Report

9.8 .QA&QC/FRM-203 Concrete Placement Report

9.9 QA&QC/FRM-210 Sewerage & Drainage Piping Installation

9.10 QA&QC/FRM-232 Earthing System Check Report

9.11 QA&QC/FRM-08 Corrective Action Request

Do not Duplicate, Controlled Copy If Stamped In Red

Descon Engineering Limited

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- 1021.000 Street and Road Closure Excavations Reinstatement and Traffic ControlsDocument37 pages1021.000 Street and Road Closure Excavations Reinstatement and Traffic ControlsZubair Ahmed Khaskheli0% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 3-Pre-Lift Checklist Rev A 06302015Document2 pages3-Pre-Lift Checklist Rev A 06302015Zubair Ahmed Khaskheli100% (1)

- False CeilingDocument19 pagesFalse CeilingZubair Ahmed Khaskheli50% (2)

- IP MS 09 GroutingDocument4 pagesIP MS 09 GroutingZubair Ahmed KhaskheliNo ratings yet

- MS (Fin Fan Coolers)Document3 pagesMS (Fin Fan Coolers)Zubair Ahmed KhaskheliNo ratings yet

- Bolt Tightening Procedure (New)Document1 pageBolt Tightening Procedure (New)Zubair Ahmed KhaskheliNo ratings yet

- Erection of TanksDocument9 pagesErection of TanksZubair Ahmed KhaskheliNo ratings yet

- MS (Valves)Document1 pageMS (Valves)Zubair Ahmed KhaskheliNo ratings yet

- MS (Pneumatic Test - Heat Exchanger)Document4 pagesMS (Pneumatic Test - Heat Exchanger)Zubair Ahmed KhaskheliNo ratings yet

- IP MS 06 Concrete WorkDocument9 pagesIP MS 06 Concrete WorkZubair Ahmed KhaskheliNo ratings yet

- MS1 (Painting)Document5 pagesMS1 (Painting)Zubair Ahmed KhaskheliNo ratings yet

- IP MS 07 Cast Insitu PilingDocument5 pagesIP MS 07 Cast Insitu PilingZubair Ahmed KhaskheliNo ratings yet

- Installation of Vaporizers JSADocument6 pagesInstallation of Vaporizers JSAZubair Ahmed KhaskheliNo ratings yet

- IP MS 18 Road PavementDocument12 pagesIP MS 18 Road PavementZubair Ahmed KhaskheliNo ratings yet

- IP MS 19 Embankment ConstructionDocument4 pagesIP MS 19 Embankment ConstructionZubair Ahmed KhaskheliNo ratings yet

- 3.material Lifting & TransportationDocument5 pages3.material Lifting & TransportationZubair Ahmed KhaskheliNo ratings yet

- IP MS 20 Underground PipingDocument7 pagesIP MS 20 Underground PipingZubair Ahmed KhaskheliNo ratings yet

- 18.hot Tapping Preparation & Work.Document11 pages18.hot Tapping Preparation & Work.Zubair Ahmed KhaskheliNo ratings yet

- 045 - KFAA-NAS-JV-RA-45-F07-20 - Substructure Concrete Works (Cast-In-Situ) Rev.0Document7 pages045 - KFAA-NAS-JV-RA-45-F07-20 - Substructure Concrete Works (Cast-In-Situ) Rev.0Zubair Ahmed KhaskheliNo ratings yet

- Excavator ChecklistDocument1 pageExcavator ChecklistZubair Ahmed KhaskheliNo ratings yet

- Air Conditioning Unit SystemDocument11 pagesAir Conditioning Unit SystemZubair Ahmed KhaskheliNo ratings yet