Professional Documents

Culture Documents

MS (Valves)

Uploaded by

Zubair Ahmed KhaskheliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MS (Valves)

Uploaded by

Zubair Ahmed KhaskheliCopyright:

Available Formats

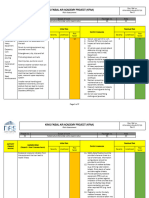

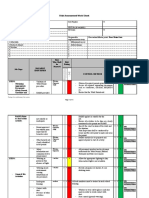

DESCON ENGINEERING

PO BOX 46821, Abu Dhabi, UAE Tel. (971 2) 6440903 Fax.

(971 2) 6446786

METHOD STATEMENT

FOR SAFETY RELIEF VALVES

Provide metallic tags to all Safety Relief Valves.

Obtain Work permit from operations.

It shall be confirmed that the line is depressurized.

Remove safety valve, tag on flanges of vessels and PSV’s for identification and blind

temporarily the line

Transport safety valve to the workshop in standing position and keep in suitable device

(pigeon boxes) for this requirement.

While removing the pigeon box to ground level take special care so that existing setting

of the valve shall not be disturb.

`1

Carry out initial pop test in the presence of DESCON inspector and record setting,

adjustment to bellow setting and pop test.

Dismantle Safety valves, check seat plug clean all parts and re assemble the valves.

Calibrate the safety valves to set point provided by data sheet.

Sealed the set point.

Stencil PSV’s No on inlet / outlet flanges.

Paint PSV’s body with one coat of red oxide primer and two coats of enamel orange

color.

Transport back valves to DESCON premises as per instructions of DESCON inspector.

Paint the set point.

Obtain work permit for reinstallation of the valves and install at exactly the same location

with new gasket of specified rating.

Remove blind flanges after reconfirmation that line is without pressure.

You might also like

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- 3-Pre-Lift Checklist Rev A 06302015Document2 pages3-Pre-Lift Checklist Rev A 06302015Zubair Ahmed Khaskheli100% (1)

- Valvula Doble Cheque DC-4 Bendix Manual de ServicioDocument4 pagesValvula Doble Cheque DC-4 Bendix Manual de Serviciojgomez30No ratings yet

- IP MS 09 GroutingDocument4 pagesIP MS 09 GroutingZubair Ahmed KhaskheliNo ratings yet

- Copper Pipes InstallationDocument6 pagesCopper Pipes InstallationrkssNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 30-Oct-17 MechDocument2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 30-Oct-17 MechJagdishNo ratings yet

- Overhead LinesDocument3 pagesOverhead LinesengrandyNo ratings yet

- MS 220kVLCCPanelBCFDRD07 PDFDocument12 pagesMS 220kVLCCPanelBCFDRD07 PDFSuprodip DasNo ratings yet

- Uic-qp-Ins-011 PSV Rev11Document12 pagesUic-qp-Ins-011 PSV Rev11Iksan Adityo MulyoNo ratings yet

- Method Statement For ChillersDocument8 pagesMethod Statement For ChillersFark Off100% (1)

- Electrical SMDB Check ListDocument2 pagesElectrical SMDB Check ListBabu100% (2)

- Installation, Operation, Maintenance Instructions For Severn Glocon Control & Choke ValvesDocument4 pagesInstallation, Operation, Maintenance Instructions For Severn Glocon Control & Choke ValvesEderson Santos67% (3)

- Installation & Routine Maintenance Manual: FOR Type: 3" Mud Gate Valve (Model I)Document8 pagesInstallation & Routine Maintenance Manual: FOR Type: 3" Mud Gate Valve (Model I)Sergio Fabian VasicekNo ratings yet

- 1021.000 Street and Road Closure Excavations Reinstatement and Traffic ControlsDocument37 pages1021.000 Street and Road Closure Excavations Reinstatement and Traffic ControlsZubair Ahmed Khaskheli0% (1)

- Repairing and Maintenance Work PlanDocument5 pagesRepairing and Maintenance Work PlanMalik RiazNo ratings yet

- PSV TestingDocument26 pagesPSV Testingmanoj thakkar100% (1)

- False CeilingDocument19 pagesFalse CeilingZubair Ahmed Khaskheli50% (2)

- Pneumatic Test ProcedureDocument3 pagesPneumatic Test Procedurevijay padale50% (2)

- Checklist Rev2Document5 pagesChecklist Rev2Min Min SoeNo ratings yet

- SWP For Gas Detection System and TelemetryDocument3 pagesSWP For Gas Detection System and TelemetryvictorNo ratings yet

- Coiled Tubing Operation Safety StandardDocument23 pagesCoiled Tubing Operation Safety Standardahmed elsanhoryNo ratings yet

- Vacume Box Test ProcedureDocument5 pagesVacume Box Test ProcedureFarhan Sheikh100% (3)

- MS-Installation 11Kv Switch Gear at Lusail-CP1Document6 pagesMS-Installation 11Kv Switch Gear at Lusail-CP1Tayab Ansari100% (2)

- Guidelines For PSV Test Bench & PSV TestingDocument2 pagesGuidelines For PSV Test Bench & PSV Testinghaunted houseNo ratings yet

- MS-E019 Installation of 11KV SwitchgearDocument8 pagesMS-E019 Installation of 11KV Switchgeara wasayNo ratings yet

- Replacement of Lip Seal Gasket For Heat ExchangerDocument10 pagesReplacement of Lip Seal Gasket For Heat ExchangerBESTIN67% (3)

- 13-OM-QC-PL-MS-06 - MS FIXED TUBE TYPE EXCHANGER'S INSPECTION & CLEANING (Rev.00)Document7 pages13-OM-QC-PL-MS-06 - MS FIXED TUBE TYPE EXCHANGER'S INSPECTION & CLEANING (Rev.00)SANDEEP100% (1)

- MS Safety Relief ValvesDocument2 pagesMS Safety Relief ValvesZubair Ahmed KhaskheliNo ratings yet

- Descon Engineering: PO BOX 46821, Abu Dhabi, UAE Tel. (971 2) 6440903 Fax. (971 2) 6446786Document3 pagesDescon Engineering: PO BOX 46821, Abu Dhabi, UAE Tel. (971 2) 6440903 Fax. (971 2) 6446786Mohammad Fazal KhanNo ratings yet

- MS1 (CGC Cleaning)Document3 pagesMS1 (CGC Cleaning)Zubair Ahmed KhaskheliNo ratings yet

- MS (Fin Fan Coolers)Document3 pagesMS (Fin Fan Coolers)Zubair Ahmed KhaskheliNo ratings yet

- 14-OM-QC-PL-MS-06 - MS FLOATING HEAD TYPE EXCHANGER'S INSPECTION & CLEANING (BFW) (Rev.00)Document7 pages14-OM-QC-PL-MS-06 - MS FLOATING HEAD TYPE EXCHANGER'S INSPECTION & CLEANING (BFW) (Rev.00)SANDEEPNo ratings yet

- 08-KU-TWK-50-QA-PRO-2163-Hydrotest and Flushing procedure-REV 0Document12 pages08-KU-TWK-50-QA-PRO-2163-Hydrotest and Flushing procedure-REV 0Avak NishanNo ratings yet

- Bolt Tightening Procedure (New)Document1 pageBolt Tightening Procedure (New)Zubair Ahmed KhaskheliNo ratings yet

- Spc-004-Leak Testing of Vacuum VesselsDocument10 pagesSpc-004-Leak Testing of Vacuum VesselsMuthuraj74No ratings yet

- Worcester Large 3-Piece Cryogenic Valves: Installation, Operating & Maintenance InstructionsDocument14 pagesWorcester Large 3-Piece Cryogenic Valves: Installation, Operating & Maintenance Instructionsافضح الكوارثNo ratings yet

- 16-OM-QC-PL-MS-06 - MS FLOATING HEAD TYPE EXCHANGER'S INSPECTION & CLEANING (IRIS, ECT) (Rev.00)Document7 pages16-OM-QC-PL-MS-06 - MS FLOATING HEAD TYPE EXCHANGER'S INSPECTION & CLEANING (IRIS, ECT) (Rev.00)SANDEEPNo ratings yet

- MS (Hydrotest - Heat Exchanger)Document4 pagesMS (Hydrotest - Heat Exchanger)Zubair Ahmed KhaskheliNo ratings yet

- Prevent MaintenanceDocument15 pagesPrevent Maintenancemecanico_ipnNo ratings yet

- Leak ProofingDocument1 pageLeak ProofingZubair Ahmed KhaskheliNo ratings yet

- MS (Pneumatic Test - Heat Exchanger)Document4 pagesMS (Pneumatic Test - Heat Exchanger)Zubair Ahmed KhaskheliNo ratings yet

- Kaysafe Sight-Flow Glass IOM Rev1-2021Document3 pagesKaysafe Sight-Flow Glass IOM Rev1-2021Steve NewmanNo ratings yet

- King Servo SM292Document5 pagesKing Servo SM292splynNo ratings yet

- Copes Vulcan Valves StorageDocument8 pagesCopes Vulcan Valves StorageAdoBrodNo ratings yet

- FlowCon EVC Instruction 05.2010Document4 pagesFlowCon EVC Instruction 05.2010Jeff Anderson CollinsNo ratings yet

- Sidney Manufacturing: Side Wall Return Drag Conveyor Installation InstructionsDocument13 pagesSidney Manufacturing: Side Wall Return Drag Conveyor Installation InstructionsNuzuliana EnuzNo ratings yet

- OTECO EB003RevBDocument24 pagesOTECO EB003RevBVictor AlcantaraNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 22-Jan-18 MechDocument2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 22-Jan-18 MechaneeshNo ratings yet

- Severn Glocon General IOM Final 09.08.2019Document4 pagesSevern Glocon General IOM Final 09.08.2019Ahmad YaniNo ratings yet

- Manuals Inline y Body Valve Lunkenheimer en en 5198206Document6 pagesManuals Inline y Body Valve Lunkenheimer en en 5198206Arman MominNo ratings yet

- FlowCon EVS Instruction 04 2012Document8 pagesFlowCon EVS Instruction 04 2012Jeff Anderson CollinsNo ratings yet

- CN-230F (1) Dtq-21u4ss PDFDocument64 pagesCN-230F (1) Dtq-21u4ss PDFPedroNo ratings yet

- Blinding & Isolation Guideline 2024Document13 pagesBlinding & Isolation Guideline 2024Syd StewartNo ratings yet

- Az1-L Service ManualDocument68 pagesAz1-L Service Manualdra6anNo ratings yet

- In PV 1691 enDocument4 pagesIn PV 1691 enpopyNo ratings yet

- 3890137e Tech Spec Data Sheets 1556604052Document14 pages3890137e Tech Spec Data Sheets 1556604052Prakash AnnamalaiNo ratings yet

- Pioneer Dv59avi Dv868 Dv668 Service ManualDocument170 pagesPioneer Dv59avi Dv868 Dv668 Service Manualjon_scribd2372No ratings yet

- Overcoming Pipeline Access ConstraintsDocument12 pagesOvercoming Pipeline Access ConstraintsDheeraj Chowdary DhanekulaNo ratings yet

- Manual and Istallation Ps55ra R.06 Feb 2016 enDocument29 pagesManual and Istallation Ps55ra R.06 Feb 2016 enItalo Vasconcelos Gulart SilvaNo ratings yet

- Febco DCD and DC 850 856 870 and 876Document12 pagesFebco DCD and DC 850 856 870 and 876Brandon TrocNo ratings yet

- MJR For 30M Maintenance Check of Check ValvesDocument9 pagesMJR For 30M Maintenance Check of Check Valvesxtremewhiz100% (1)

- Check ValveDocument10 pagesCheck ValvekutecoolNo ratings yet

- PM Text As Per Bcel-009Document2 pagesPM Text As Per Bcel-009Jay Rameshbhai ParikhNo ratings yet

- CUS-122 STEM II - III v1.0Document2 pagesCUS-122 STEM II - III v1.0Jorge GarciaNo ratings yet

- MS (Fin Fan Coolers)Document3 pagesMS (Fin Fan Coolers)Zubair Ahmed KhaskheliNo ratings yet

- Bolt Tightening Procedure (New)Document1 pageBolt Tightening Procedure (New)Zubair Ahmed KhaskheliNo ratings yet

- Erection of TanksDocument9 pagesErection of TanksZubair Ahmed KhaskheliNo ratings yet

- Installation of Vaporizers JSADocument6 pagesInstallation of Vaporizers JSAZubair Ahmed KhaskheliNo ratings yet

- MS1 (Painting)Document5 pagesMS1 (Painting)Zubair Ahmed KhaskheliNo ratings yet

- MS (Pneumatic Test - Heat Exchanger)Document4 pagesMS (Pneumatic Test - Heat Exchanger)Zubair Ahmed KhaskheliNo ratings yet

- IP MS 19 Embankment ConstructionDocument4 pagesIP MS 19 Embankment ConstructionZubair Ahmed KhaskheliNo ratings yet

- IP MS 07 Cast Insitu PilingDocument5 pagesIP MS 07 Cast Insitu PilingZubair Ahmed KhaskheliNo ratings yet

- IP MS 14 Tiling & Flooring (Walls & Floor)Document4 pagesIP MS 14 Tiling & Flooring (Walls & Floor)Zubair Ahmed KhaskheliNo ratings yet

- IP MS 06 Concrete WorkDocument9 pagesIP MS 06 Concrete WorkZubair Ahmed KhaskheliNo ratings yet

- IP MS 20 Underground PipingDocument7 pagesIP MS 20 Underground PipingZubair Ahmed KhaskheliNo ratings yet

- IP MS 18 Road PavementDocument12 pagesIP MS 18 Road PavementZubair Ahmed KhaskheliNo ratings yet

- 3.material Lifting & TransportationDocument5 pages3.material Lifting & TransportationZubair Ahmed KhaskheliNo ratings yet

- 045 - KFAA-NAS-JV-RA-45-F07-20 - Substructure Concrete Works (Cast-In-Situ) Rev.0Document7 pages045 - KFAA-NAS-JV-RA-45-F07-20 - Substructure Concrete Works (Cast-In-Situ) Rev.0Zubair Ahmed KhaskheliNo ratings yet

- 18.hot Tapping Preparation & Work.Document11 pages18.hot Tapping Preparation & Work.Zubair Ahmed KhaskheliNo ratings yet

- Air Conditioning Unit SystemDocument11 pagesAir Conditioning Unit SystemZubair Ahmed KhaskheliNo ratings yet

- Excavator ChecklistDocument1 pageExcavator ChecklistZubair Ahmed KhaskheliNo ratings yet