Professional Documents

Culture Documents

Multicomponent Absorption

Multicomponent Absorption

Uploaded by

Abdulrahim Segir0 ratings0% found this document useful (0 votes)

24 views14 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

24 views14 pagesMulticomponent Absorption

Multicomponent Absorption

Uploaded by

Abdulrahim SegirCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 14

Vn Ys

he),

[Say eal

pose [tzcateal

Exiting Entering vapor A | Exiting

Entering vapor liquid (stcipping agent) tiquid

Var. Vine Ly ly Vo. Vo uh

(a) (b)

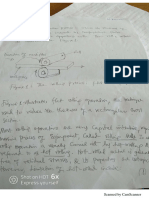

Figure 8.1: Countercurrent cascades of N adiabatic stages:

(a) absorber; (b) stripper

First consider the absorber with the stages numbered from the top.

Component molar flow rates in the vapour and liquid phases are indicated by v, and

1,. In the following derivation the subscript is dropped for clarity reasons only. It is

also assumed that the entering liquid does not contain any of the components of the

gas phase. /, is thus = 0.

‘og’ ge ie a eed

'A component material balance is done over

1 and N-1 for any of the components in the gas phase.

Vath =Vn=¥i thy

‘The total flow rates of the gas and liquid are denoted by: V and L

Thus vey

And’ text

Equilibrium is assumed td be reached in each stage, thus for stage N.

Yu =Ku ky

Combining equations (2), (3) and (4) gives:

‘An absorption factor is defined as. A=

\

‘Thus vant

Ay

1e top of the absorber, including stages

oO)

@

8

“)

©)

(6)

1)

ale

‘Substitute (7) In (1) thus

tievs+h,

fre ee(ratheAe ®

‘A component balance is now done around the top ofthe column including stages 1

and N-2, thus

Niaey, the )

By similar substitution as above it follows that:

Myth 2)An (19)

‘Substitute (10) in (8)

WW) Av¥, Anas tna vA

Thus

hea Bs An tVs (An Ane +n) «ty

‘This calculation is carried on up to the fist stage where /, =», 4, thus

WAV (AAAs Ay tA gy HA Ay toot) (12)

The overall component balance is given by:

Ww=Vuer Ys (13)

A balance between the entering vapour v,., and v, is given by:

(14)

Vs=Vuar ba

‘Where ¢, is the recovery fraction of each component that is given by:

1

WFAGAg Ay PAs Ay tot Ay Ht A)

KAA.

= fraction of species in entering vapour that is not absorbed

‘An effective absorption factor, A, , replaces the separate absorption factors, thus

1

pet 16)

PA ANSASANE tA, ue

Equation (16) is multiplied and divided by (A, -1) to yield

Ay-1 a7)

ara

“eunby oy)

ul umoys ee Sdn ~ yes Yong ~seqlosqe au} 0} pejoXoa! s1 Jey} pINby| UEqOSGe ey)

1p 40 sueddujs ym poydnos Ajuanbey ese siaquosqy

eyereuese1 0} suuimoo uo1

(02) uonenbe 0} seljdde osje jo!d enoge ay

20700) Burdens ee

(oz) TTDI

(en) peddins you si uy pinby Buuayue ul seloads jo uoyoes) = cas. 59

aru

) aon

‘mojag uani6 aie syInsed ou} KUO

———

The recycle liquid is normally not completely free of the components that enter in the

vapour stream to the absorber.

Itis thus possible that the vapour can strip some of these components from the liquid

‘A general absorber equation is obtained by combining equation (14) with a modified

form of equation (18), thus for stages numbered from the top to the bottom:

=o yy

but “Vth (22)

(23)

Thus

The total balance for a component that enters in the entering vapour and entering

liquid is determined by adding (14) and (23) thus:

ner 9a +h (1-5) (24)

Equation (24) is applied to each component entering in the vapour while equation

(21) is used for species that enter only in the entering liquid.

‘The analogous equation of (24) for a stripper is given by:

(25)

Ines +Vo(1- 94)

Example 1")

The heavier components have to be removed from a gas stream by absorption, The

‘column operates at 2 760 kPa. The entering liquid is a high molecular mass oll

Estimate the compositions and flow rates of the exit streams by using the method

given above. It can be assumed that the A and S values can be based on the

entering values of L, V and that the K- values can be determined at the average of

the top and bottom of the absorber, There are six stages in the column, thus N = 6.

Lean gas, V;

il, 32°C

iE —

Feed gas, Vr

40°C

Rich oll, Ls

fy, k mol /h vy, k mol /h

CHa (Cs) ce

CaHe( C2) 370

CaHe( Cs) 240

Cx Hie (Cs) 0.05 25

n-CsHi2(Cs) 078 5

oi 164,17

Le= 165 Vp = 800

The relevant A's and S; 's are calculated with the Kj ‘s determined at the average

temperature of 36°C.

Equations (17 ) and (19) are used to calculate the gx 's and $s:‘s

Equation (14) is used to calculate the v's.

The following equation is used to calculate the /s's:

(de =e +(idy - (Wis (26)

x

03

128

960.

‘O.8Ta.

sa

‘0.185 | 1.08 [O46 [0.1 68

‘o.0713 [2.88 x 0g

‘0.0007 i 995. | 0.0

oie

ee oy Gian ca wal ie autre ee

oe

1194 =160%0,9691=155,056

oll

S = 4,85 K= 4,85 x 0,0001 = 4,86 x 10-*

4 85x10"

(45x10

9085

ae

= =164,17 «0.9995 =164088

G

A= 0,206/K = 0,206/6,65 = 0,0309

A,-1_ 00305

1 A,-1 903097

1

09681

Vyesiba =160x0.9691=155 056

85% 10-*

4,85 K= 4,85 x 0,000

S.-1__495x10-*~

0.9995

1 (485x10")

os

5 =16417 x0.9995-164088

Table 4 shows the mole fraction of gas and oil components that are fed into an absorber

‘operated at 32°C and 10 bar (abs) with six theoretical plate. Given that the molar ratio of gas

to oil entering the absorber is 1.0.

Table 4: Mole fraction of gas and oil

‘Components [Gas mole fraction [Oil mole fraction __[K values ah

CH 0.70 Fe [6s al

He 0.10, : 34

GHs 0.10 1.16 fa

n= City 0.06 (0.03 rf 035

CH 0.04 0.01 0.12 ral

« 0.96 0.0001

1.00 fi 1.00 |

Estimate the compositions and flow rates of the exiting streams. The initial A’s and $s can

be based on the given feed rates but the calculated flow rates must be used when the next

values of the A’s and S's are calculated, Perform two iterations

2 a

@

8)

@

V, = VussGa + lo(1 ~ bs) = Voda + lo(1 ~ 5) ©)

Vy + lo = Vit Ios = de = fy + Vy ~V ©

From equations 1-6

Components[V> [lo [Ki [Ai__[ 6a os TH Ibe

CHy 0.70. 16.5 0.0606 } 0.939. 4.6x10* | 0.657_| 0.042

CoH, 0.10 34 0.294 | 0.706 0.00046 _| 0.071 _| 0.029

C3Hy 0.10 1.16 0.862 _| 0.213 0.0876 0.021_| 0.0786

n-CyHio 0.06 [0.03 | 0.35 2.857 _| 0.0012 0.6504 0.0105 | 0.0794

n-CsHir 0.04 70.01 [0.12 8.333_ | 2.610" 0.880 0.001_| 0.0488

Oil 0.96 | 0.0001 | 10000 | 0 0.9999 0 0.9599

Total 1.00 | 1.00 0.7605 | 1.237

V;__|lo | K; AL Si 4 os Vi Ts

0.70, 16.5 {0.0986 | 10.1475 [0.9014 [8.85107 [0.631] 0.06

0.10 34 [0.4785 [2.091 [0.5245 [0.00627 | 0.052 | 0.0475

0.10, 116 {1.4026 [0.7134 [0.0416 | 0.3164 [0.00416 | 0.0958

0.06 {0.03 [0.35 | 4.6486 [0.2153 [7.7107 [0.7847 | 0.0065 | 0.0835

0.04 [0.01 {0.12 | 13.5583 | 0.0738 |1.49*107 | 0.9262 [0.001 | 0.0492

0:96 [0.0001 [16270 [6.15107 [0 0.9999 | 5.910 | 0.9599

1.00 | 1.00 0.6948 [1.3057

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ASimple Procedurefor Designofa Spray DryerDocument6 pagesASimple Procedurefor Designofa Spray DryerAbdulrahim SegirNo ratings yet

- SAG2019 Doll Simonian-BondWiDocument13 pagesSAG2019 Doll Simonian-BondWiAbdulrahim SegirNo ratings yet

- Review of Sacred Luxuries Fragrance AromDocument3 pagesReview of Sacred Luxuries Fragrance AromAbdulrahim SegirNo ratings yet

- 314 Tutorial Questions 9th EditionDocument12 pages314 Tutorial Questions 9th EditionAbdulrahim SegirNo ratings yet

- PollutionDocument31 pagesPollutionAbdulrahim SegirNo ratings yet

- 300 Level Past QuestionsDocument30 pages300 Level Past QuestionsAbdulrahim SegirNo ratings yet

- Manu TechDocument12 pagesManu TechAbdulrahim SegirNo ratings yet

- Water PollutionDocument15 pagesWater PollutionAbdulrahim SegirNo ratings yet

- Line Integral & Double Integral NoteDocument16 pagesLine Integral & Double Integral NoteAbdulrahim SegirNo ratings yet

- 326 Last Part (God No Go Shame Us O)Document15 pages326 Last Part (God No Go Shame Us O)Abdulrahim SegirNo ratings yet

- Thermo Steam CycleDocument11 pagesThermo Steam CycleAbdulrahim SegirNo ratings yet

- Manufacturing TechnologyDocument6 pagesManufacturing TechnologyAbdulrahim SegirNo ratings yet

- Comparative Studies of Natural and Synthetic RubberDocument8 pagesComparative Studies of Natural and Synthetic RubberAbdulrahim SegirNo ratings yet

- Process Optimizationcorrect1without Addendum 1Document55 pagesProcess Optimizationcorrect1without Addendum 1Abdulrahim SegirNo ratings yet

- Seperation 2Document6 pagesSeperation 2Abdulrahim SegirNo ratings yet