0% found this document useful (0 votes)

151 views3 pagesStructural Design for Engineers

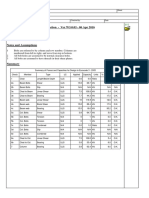

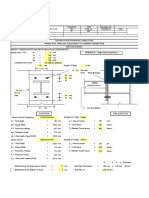

This document provides design calculations for the foundation and access platform for a chemical dosing area. It includes calculations to check for bearing pressure, thickness requirements, weld design, and other structural checks.

Uploaded by

Chandra KanthCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

151 views3 pagesStructural Design for Engineers

This document provides design calculations for the foundation and access platform for a chemical dosing area. It includes calculations to check for bearing pressure, thickness requirements, weld design, and other structural checks.

Uploaded by

Chandra KanthCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd