Professional Documents

Culture Documents

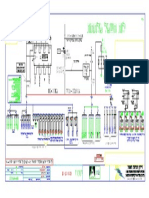

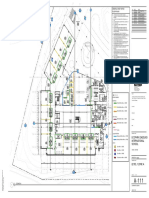

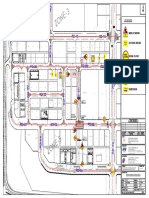

A3-106304-02017-01-A General Arrangement S313

Uploaded by

Chandra KanthOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A3-106304-02017-01-A General Arrangement S313

Uploaded by

Chandra KanthCopyright:

Available Formats

8 7 6 5 4 3 2 1

N-10

N1-2A N1-2B

N-3 N-8 N6-A

N7-A N7-B N-2 N1-3

F F

6000´

N1-1 M-1A N6-B

° N-5

53

.

52

CLIPS SUPPORTS

~9000 MAXIMUM LEVEL

OF PRODUCT

10200

6084

1200

E ECUATOR ECUATOR E

4400

00

~23800

00

23477

R=2

TE

AME

16084

R DI

N

INE

INNER LADDER

4400

STILLING

13380

WELLS

4400

47.1

NAME PLATE

EARTHING LUG

TOG 530.55m VORTEX

3383

1600

3383

FIREPROOFING

1500

2880

SUPPORTS BREAKER

TOC 530.50m N9-A N9-B

D D

N-4

GL 530.0m

(GROUTING)

500

GL 530.0m

50

130

COLUMN CIRCLE = 19550

FOUNDATIONS TIE RODS

ELEVATION

SCHEMATIC VIEW NOTES:

1.- THIS IS AN SCHEMATIC DRAWING AND IT IS NOT INTENDED TO SHOWN ANY ORIENTATION.

FOR ASSEMBLY PARTS AND ORIENTATION, REFER THE DRAWINGS LIST C-106304-02001

2.- ALL PLATES WITH WELDED NOZZLES AT SHOP, SHALL BE SUBMITTED TO THE POST WELD HEAT TREATMENT IN SHOP.

GRAPHIC TEMP. / TIME FOR PWHT

4.- INSPECTION L.R. INSURANCE INC.

5.- TEST WATER TEMPERATURE 25° C MIN.

PLANT TEMP.

6.- ALL DIMENSIONS ARE IN mm. UNLESS NOTED OTHERWISE.

NORTH (°C) 7.- DIMENSIONAL TOLERANCES PER A3-106304-02023-01.

PLANT

TRUE 625° 8.- FOR SPHERE LAYOUT , SEE DRAWING R3-77598

NORTH SOAK TIME

NORTH 610° 9.- ALL ELEMENTS WELDED TO THE VESSEL, SHALL BE SA-516 Gr.70 (N) + S5

0

° 10.- GL = GROUND LEVEL

595°

MA

h

TOC = TOP OF CONCRETE

56 C/

X.

MI

2

.

/h

78

° TOG = TOP OF GROUTING

°

0°

8

N.

9

.

°C

9

15

2

MI .12

11.- FLEXIBLE GRAPHITE WITH SS316L INNER AND C.S. OUTER RING.

55

3°

°C

C/

C C

N.

X

12.- HOP DIP GALVANIZED

1

07

MA

/h

h

28 13.- TO BE DONE AFTER FINAL HYDROSTATIC TEST.

430° 14.- AND INTERNAL COMPONENTS WELDED TO THE VESSEL IN EACH FACE.

PREVAILING

TE NG

° 88 15.- INTERNAL SURFACE OF VESSEL (FROM BOTTOM TO 1m HEIGHT) SHALL BE COATED WITH PHENOLIC EPOXY COATING

8

I

20

CO

° 1

. 67

36

AT

WIND 8 00

AT

3°

. WITH DFT NOT LESS THAN 300 MICRONS.

OL

16 8° 1

.7

20

HE

1

8.

16.- MIN. 2 EARTHING BOSSES SHALL BE PROVIDED ON SUPPORTS DIAMETRICALLY OPPOSITE TO EACH OTHER.

AM

I

0

32

NG

RA

EE

°

B.

18 44

FR

FR

8. 00

TE

EE

°

36

MP

18

.

1

8.

1

16

50

.

A 24.11.2023 ISSUED FOR REVIEW DE PM EM

°

18

1h. 53 min. TIME

8.

REV DATE ISSUE, SCOPE OF REVISION PREPARED CHECKED APPROVED

36°

PROJECT TITLE:

NAME PLATE

0

16.

99

DESIGN, SUPPLY AND CONSTRUCTION OF NEW LPG STORAGE B

N 3558010.96 FACILITIES IN FIVE SPHERICAL VESSELS AT

500

E 227909.99

ZARKA REFINERY SITE PROJECT

00

1

44

COMPANY:

0

300

B 2

70°

JORDAN LIQUEFIED PETROLEUM GAS MANUFACTURING

00

9

0 & FILLING COMPANY

12

°

0

19

12

EPC CONTRACTOR:

00

MID CONTRACTING

44

TETCO GROUP

00

CONSULTANT:

12

4

45

AXIS CENTRAL PLATES

ILF CONSULTING ENGINEERS

EXTERNAL LADDER A

SUBCONTRACTOR:

DURO FELGUERA ENERGY STORAGE

Energy Storage

11 SUPPORT COLUMNS

A

DRAWING TITLE :

1

80°

GENERAL ARRANGEMENT

ORIGINAL SHEET SIZE - A3

PLANT VIEW(S-313) (S-313)

PROJECT No. - 15488

"Copying ofthis documentand giving itto others and the use

FI-825 8255 S-313 or communication of the contents thereof are forbidden SCALE: DRAWING NO: SHEET OF REV.

withoutexpress authority.Offenders are liable to the payment

ofdamages.Allrights are reserved in the eventofthe grantof

JOB Nº SERIAL Nº EQUIPMENT a patent or the registration of a utility model of design"

S/E A3-106304-02017-01-A 1 1 A

8 7 6 5 4 3 Printing:06.11.2023 1

You might also like

- A3-106304-02001-01-A General Arrangement S309Document1 pageA3-106304-02001-01-A General Arrangement S309Chandra KanthNo ratings yet

- A3-106304-02005-01-A General Arrangement S310Document1 pageA3-106304-02005-01-A General Arrangement S310Chandra KanthNo ratings yet

- A3-106304-02013-01-A General Arrangement S312Document1 pageA3-106304-02013-01-A General Arrangement S312Chandra KanthNo ratings yet

- A3-106304-02009-01-A General Arrangement S311Document1 pageA3-106304-02009-01-A General Arrangement S311Chandra KanthNo ratings yet

- 2047 1803 Ecv Dla 1001 - CDocument1 page2047 1803 Ecv Dla 1001 - CphanikrishnabNo ratings yet

- Haier 21f9d-tDocument1 pageHaier 21f9d-tadithyanvsNo ratings yet

- MBAA Placa Canal Pw18.0 MBAA-251433Document1 pageMBAA Placa Canal Pw18.0 MBAA-251433Sergio SilvaNo ratings yet

- 5e3 Like ApproachDocument1 page5e3 Like Approachdisse_detiNo ratings yet

- Scamec 2000 S 100129425 #FB214 Grease SystemDocument23 pagesScamec 2000 S 100129425 #FB214 Grease SystemIvan Andres Seguel BristiloNo ratings yet

- Esq Nobreak Sen T08075-00 Manager III 1000 RS232 PDFDocument1 pageEsq Nobreak Sen T08075-00 Manager III 1000 RS232 PDFrenanNo ratings yet

- Option C: 1+2 Way Road: Lake Street Shared TrailDocument1 pageOption C: 1+2 Way Road: Lake Street Shared TrailNeenNo ratings yet

- תוכנית לוח חשמל מלתחות PDFDocument1 pageתוכנית לוח חשמל מלתחות PDFdoriaNo ratings yet

- BELT DRIVE 25 Jan 2024Document1 pageBELT DRIVE 25 Jan 2024bimaditya281No ratings yet

- ZXSpectrum Multi IODocument1 pageZXSpectrum Multi IOMihaiNo ratings yet

- G90 Ssigbd 2.0.6 Gai03Document1 pageG90 Ssigbd 2.0.6 Gai03my_scribd_20100607No ratings yet

- Shaft Guide 2. Rubberpad 3. Plate Guide A 4. Plate Guide B 5. Hub GuideDocument3 pagesShaft Guide 2. Rubberpad 3. Plate Guide A 4. Plate Guide B 5. Hub GuidePramudya Sperow SajaNo ratings yet

- POSICIONAMIENTODocument1 pagePOSICIONAMIENTODEYBER LUISEDUARDO ROSAS ALCALDENo ratings yet

- FL3B-434-M-2070-0.0 (434T007) EOP Filtrate TankDocument1 pageFL3B-434-M-2070-0.0 (434T007) EOP Filtrate TanknyaptoNo ratings yet

- Option A: One Way Road: Lake Street Shared TrailDocument1 pageOption A: One Way Road: Lake Street Shared TrailNeenNo ratings yet

- Veri. 0: CO T Ic DiDocument4 pagesVeri. 0: CO T Ic Dicfrias_13No ratings yet

- Chasis CY8873CDocument4 pagesChasis CY8873Cpolancos05No ratings yet

- Chasis TMPA8873CSCNG6V11 PDFDocument4 pagesChasis TMPA8873CSCNG6V11 PDFMax Fredi Quispe AguilarNo ratings yet

- Chasis AssemblyDocument1 pageChasis Assemblyravi cdacNo ratings yet

- Thermocouple Position - Miniatur Microsite Rev.17Document1 pageThermocouple Position - Miniatur Microsite Rev.17tam amiNo ratings yet

- Plamen Plamen - Pale I MenekaDocument1 pagePlamen Plamen - Pale I MenekaLuka DzogovicNo ratings yet

- General Sheet Notes - Floor Plans: Ecopark Daesung International SchoolDocument1 pageGeneral Sheet Notes - Floor Plans: Ecopark Daesung International SchoolVũ Việt DũngNo ratings yet

- The Secrete Life of Plants Bob Ber 83Document8 pagesThe Secrete Life of Plants Bob Ber 83Rodolfo VaraniNo ratings yet

- Rabello Sete CordasDocument4 pagesRabello Sete CordasRafael SouzaNo ratings yet

- ARCH راشد المزروعي PDFDocument4 pagesARCH راشد المزروعي PDFIvanna GlonNo ratings yet

- FL3B-434-M-2073-0.0 (434T010) D1 Filtrate TankDocument1 pageFL3B-434-M-2073-0.0 (434T010) D1 Filtrate TanknyaptoNo ratings yet

- 5wiring DiagramDocument12 pages5wiring DiagramBurgart JassahelNo ratings yet

- Sonata in B Minor K27 L449 by Domenico ScarlattiDocument5 pagesSonata in B Minor K27 L449 by Domenico ScarlattiAxel MaturanoNo ratings yet

- SBVT - Rnav Kigok 1b Mikem 1b Rwy 06 - Star - 20230323Document1 pageSBVT - Rnav Kigok 1b Mikem 1b Rwy 06 - Star - 20230323Valiense FilmesNo ratings yet

- Choro Nº 01 - Heitor Villa-LobosDocument4 pagesChoro Nº 01 - Heitor Villa-LoboslimaNo ratings yet

- Project Oxygas (15687558)Document2 pagesProject Oxygas (15687558)Mario Alberto Pineda CastilloNo ratings yet

- 11 181000 4800000121 RGF SRV DRG 100212 - 02Document1 page11 181000 4800000121 RGF SRV DRG 100212 - 02ahmad.suliman.saeedNo ratings yet

- Silent night holy night 기본Document2 pagesSilent night holy night 기본obedientcrimeNo ratings yet

- Fender Rumble 40 v3 SCHDocument7 pagesFender Rumble 40 v3 SCHCarlos ZaninNo ratings yet

- Fender Rumble 100 V3 TDA8950-88534Document7 pagesFender Rumble 100 V3 TDA8950-88534Claudio Ariel Vera trussy100% (1)

- Rumble 200 V3 Schematics-DiagramsDocument4 pagesRumble 200 V3 Schematics-DiagramsOrlandd Sanchezz100% (1)

- J26 Axis-1 Abutment Segment Cd-Layout2Document1 pageJ26 Axis-1 Abutment Segment Cd-Layout2ahmed fathyNo ratings yet

- Ground Floor Plan: Scale 1:100Document2 pagesGround Floor Plan: Scale 1:100CSEC Uganda Ltd.No ratings yet

- Schematic - KIM M50 EDITED - 2023-07-05Document1 pageSchematic - KIM M50 EDITED - 2023-07-05Estang Da VieNo ratings yet

- Road Diversion2 Layout2Document1 pageRoad Diversion2 Layout2duraiNo ratings yet

- Bigtreetech SKR 3-SCHDocument1 pageBigtreetech SKR 3-SCHAdelino PenedoNo ratings yet

- A A A A A A: Tank Testing Plan With Sounding TablesDocument1 pageA A A A A A: Tank Testing Plan With Sounding TablesMD shawonNo ratings yet

- E-02-02 - Power Coming & Substation System-E-02-02Document1 pageE-02-02 - Power Coming & Substation System-E-02-02Duong Thai BinhNo ratings yet

- 01 Pe371c5 PWCDocument3 pages01 Pe371c5 PWCبوند بوندNo ratings yet

- 2047 1803 Ecv Dla 1003 - CDocument1 page2047 1803 Ecv Dla 1003 - CphanikrishnabNo ratings yet

- Estab-Hexus 500 V.2 - Biv - Rev03Document1 pageEstab-Hexus 500 V.2 - Biv - Rev03Fernando SilvaNo ratings yet

- Esquematico 512-812-12v Lite v1 PDFDocument1 pageEsquematico 512-812-12v Lite v1 PDFIsidro TavaresNo ratings yet

- Grundig-Beko Delta dps-174bp PsuDocument3 pagesGrundig-Beko Delta dps-174bp PsuMy USERNAME100% (1)

- Typical Supply 3Document1 pageTypical Supply 3Mohamed MagdyNo ratings yet

- Tin Tin Plaza Structural Roof Slab LayoutDocument1 pageTin Tin Plaza Structural Roof Slab LayoutPEng. Tech. Alvince KoreroNo ratings yet

- Vendor:: Column Cell No.1 Column Cell Feed DistributorDocument1 pageVendor:: Column Cell No.1 Column Cell Feed DistributorJoseph Junior Jahuira TaparaNo ratings yet

- February Monthly Collection, Grade 5From EverandFebruary Monthly Collection, Grade 5Rating: 3 out of 5 stars3/5 (1)

- 30 June 2022 - Journey of Hajj - 01 Dhul Hijjah 1443Document11 pages30 June 2022 - Journey of Hajj - 01 Dhul Hijjah 1443Chandra KanthNo ratings yet

- Base Plate - Anchor Bolt and Shear Key Design - P1Document3 pagesBase Plate - Anchor Bolt and Shear Key Design - P1Chandra Kanth100% (1)

- 0188PF N DG DG05 ST Dte 1032 001 A01Document2 pages0188PF N DG DG05 ST Dte 1032 001 A01Chandra KanthNo ratings yet

- For Construction: PetrofacDocument1 pageFor Construction: PetrofacChandra Kanth100% (1)

- For Review: PetrofacDocument1 pageFor Review: PetrofacChandra KanthNo ratings yet

- ADR219 CMDocument133 pagesADR219 CMRajiv ChandranNo ratings yet

- C6 Wiper Diagnostics and SchematicsDocument8 pagesC6 Wiper Diagnostics and Schematicsel_frNo ratings yet

- McMurry-Chapter 1Document36 pagesMcMurry-Chapter 1Jeanne Rmlt-KrlNo ratings yet

- Trans1 2019 12 PDFDocument135 pagesTrans1 2019 12 PDFkumarNo ratings yet

- Summative Test 9Document2 pagesSummative Test 9Ginalyn B. Entea50% (2)

- Human Resource ManagementDocument23 pagesHuman Resource Managementsanjuktaroy1986No ratings yet

- How To Troubleshoot Ecu Controlled Systems: Repair Manual SystemDocument17 pagesHow To Troubleshoot Ecu Controlled Systems: Repair Manual SystemOscar AcevedoNo ratings yet

- Form 1325Document7 pagesForm 1325Alex HateganNo ratings yet

- Dry Quenched Coke - Enabler To Enhance BF PerformanceDocument26 pagesDry Quenched Coke - Enabler To Enhance BF PerformanceSatyamKumarNo ratings yet

- CH 4 Electrical Design of CIGRE Green Book - Overhead Lines PDFDocument144 pagesCH 4 Electrical Design of CIGRE Green Book - Overhead Lines PDFeeng8124No ratings yet

- 019 022 EyvazovDocument4 pages019 022 EyvazovCeyhun MahmudovNo ratings yet

- Focus 4 A-F Thermodynamic The First LawDocument81 pagesFocus 4 A-F Thermodynamic The First LawSamuelYudhaSinambelaNo ratings yet

- CHM-2045 Exam 1 Sample QuestionsDocument7 pagesCHM-2045 Exam 1 Sample QuestionsFrankNo ratings yet

- Sparepart Turbocharger PDFDocument9 pagesSparepart Turbocharger PDFDandy MartinNo ratings yet

- JEE Class Companion Physics: Module-2Document7 pagesJEE Class Companion Physics: Module-2neoisonlyoneNo ratings yet

- Review of Bioclimatic Architecture Strategies For Achieving Thermal ComfortDocument21 pagesReview of Bioclimatic Architecture Strategies For Achieving Thermal ComfortJayshree RokdeNo ratings yet

- AE1201Document2 pagesAE1201hacker17No ratings yet

- Shear - Torsion - HandoutDocument10 pagesShear - Torsion - HandoutDirajen PMNo ratings yet

- Chemistry PDFDocument113 pagesChemistry PDFShubham YadavNo ratings yet

- QUEDocument2 pagesQUEHitesh VariyaNo ratings yet

- 50 HZ SelectionDocument6 pages50 HZ Selectionzaeem_sidd5291No ratings yet

- Question BankDocument6 pagesQuestion BankHarini KarthikeyanNo ratings yet

- Allis Chalmers 840 840b Articulated Wheel Loader Forklift Parts CatalogDocument20 pagesAllis Chalmers 840 840b Articulated Wheel Loader Forklift Parts CatalogCarl100% (45)

- Datasheet PSV PDPDEDocument8 pagesDatasheet PSV PDPDERicardo NapitupuluNo ratings yet

- Peng Dong Optimized Shift Control in Automatic Transmissions With Respect To Spontaneity, Comfort, and Shift Loads PDFDocument309 pagesPeng Dong Optimized Shift Control in Automatic Transmissions With Respect To Spontaneity, Comfort, and Shift Loads PDFMehdi AlizadehNo ratings yet

- Chapter 4 Practice Test 4u1Document4 pagesChapter 4 Practice Test 4u1helloblargNo ratings yet

- VRNM Nickel-Cadmium Battery: Ultimate Ultra-Low Maintenance SolutionDocument7 pagesVRNM Nickel-Cadmium Battery: Ultimate Ultra-Low Maintenance SolutionchetanNo ratings yet

- Ficha Tecnica Cable de FibraDocument1 pageFicha Tecnica Cable de FibraAnonymous 4kYNmixNo ratings yet

- Catalyzed KNSU Propellant (PP)Document6 pagesCatalyzed KNSU Propellant (PP)Chingyg100% (1)

- 02H-T13-G65-20JI-MA-008 REV 0 Monorail CranesDocument8 pages02H-T13-G65-20JI-MA-008 REV 0 Monorail CranesShubhamYadavNo ratings yet