Professional Documents

Culture Documents

Longitudinal Stress-Deflection Check

Longitudinal Stress-Deflection Check

Uploaded by

samir bendre0 ratings0% found this document useful (0 votes)

6 views1 pageOriginal Title

longitudinal stress-deflection check

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views1 pageLongitudinal Stress-Deflection Check

Longitudinal Stress-Deflection Check

Uploaded by

samir bendreCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

BRIHANMUMBAI MUNICIPAL CORPORATION

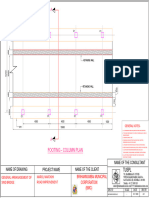

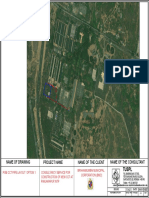

GHATKOPAR PIPELINE SUPPORT

PIPE STRESS CHECK

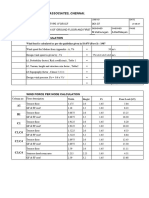

saddle stress

FI = K * p/ * log(r/t)

k a factor obtained from expression (0.02-0.00012(β-90)) Β angle of support

B 120 degree

k 0.0164

P saddle reaction including 10% for continuity

406.45 kg

t =shell thk 0.6 cm

R= radius of pipe 15 cm

R/t 25

log e R/t 4.6

FI 85 kg/cm2

bending stress

Fb = bending moment / modulus of shell plate Where, bending moment, M = W*l*l /8

span 3m W 147.8 kg/m

M 115 kgm

Sectional Modulus= π*R*R *t

Z 424 cm4

fb 27 kg/cm2

hoop stress

Fh = P*d/2/t

P (internal pressure) 2

Fh 50 kg/cm2

Rim stress

Fr=Fh/4

Fr 13 kg/cm2

Longitudinal stress

Max permissible longitudinal stress F’ = fy *0.6*efficiency of circumferential joint = 2500*0.6*0.8

F’ = 1200 kg/cm2

Total actual longitudinal stress, F’= saddle stress +bending stress +rim stress = fI + fb + fr

F' actual 125 kg/cm2 ok

CHECK FOR DEFLECTION

from staad file the vertical deflection for variou loads are as follows

working loads considered as per serviceability limit state

allowable deflection 3 percent

75 mm

dead load(pipe self

wt + lining) 0.693 mm

live load 0.637 mm

water 19.81 mm

total 21.14 mm safe

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 010 - Submission of Drawings Pertaining To Security Gate BuildingDocument1 page010 - Submission of Drawings Pertaining To Security Gate Buildingsamir bendreNo ratings yet

- 1 Load Calculations - Staff WelfareDocument23 pages1 Load Calculations - Staff Welfaresamir bendreNo ratings yet

- Dbr-Iscon Gopal Nagar-Format-12-01-2024Document26 pagesDbr-Iscon Gopal Nagar-Format-12-01-2024samir bendreNo ratings yet

- 009 - Submission of Drawings Pertaining To Admin Building Pile CapDocument1 page009 - Submission of Drawings Pertaining To Admin Building Pile Capsamir bendreNo ratings yet

- 2 Piling Calculations - Staff WelfareDocument73 pages2 Piling Calculations - Staff Welfaresamir bendreNo ratings yet

- 011 - Submission of Drawings Pertaining To Staff Welfare Building Pile CapDocument1 page011 - Submission of Drawings Pertaining To Staff Welfare Building Pile Capsamir bendreNo ratings yet

- Design Basis Report - HNBS - R0-13-12-2023Document20 pagesDesign Basis Report - HNBS - R0-13-12-2023samir bendreNo ratings yet

- Specification For Launching of Steel Girders Over Railway TrackDocument1 pageSpecification For Launching of Steel Girders Over Railway Tracksamir bendreNo ratings yet

- Yahoo Mail - FW - ISCON GOPALNAGAR-STRUCTURAL SUBMISSION SET FOR BLOCK - CDEF - 12-01-2024Document1 pageYahoo Mail - FW - ISCON GOPALNAGAR-STRUCTURAL SUBMISSION SET FOR BLOCK - CDEF - 12-01-2024samir bendreNo ratings yet

- 1-2021462 (G) - 400-0775 (Sheet-1 of 3)Document1 page1-2021462 (G) - 400-0775 (Sheet-1 of 3)samir bendreNo ratings yet

- 01 - Design Comments - 0 - Residential Building Block ED-CF - Ahmedabad - 24.01.24Document2 pages01 - Design Comments - 0 - Residential Building Block ED-CF - Ahmedabad - 24.01.24samir bendreNo ratings yet

- Open Web Girder LaunchingDocument2 pagesOpen Web Girder Launchingsamir bendreNo ratings yet

- Basket Handle Bridge DesignDocument1 pageBasket Handle Bridge Designsamir bendreNo ratings yet

- Neral Arranagement of SWD Bridge - Layout.2Document1 pageNeral Arranagement of SWD Bridge - Layout.2samir bendreNo ratings yet

- Bandra Cycle Track DWGSDocument1 pageBandra Cycle Track DWGSsamir bendreNo ratings yet

- Neral Arranagement of SWD Bridge - Layout 1Document1 pageNeral Arranagement of SWD Bridge - Layout 1samir bendreNo ratings yet

- Underwater WeldingDocument1 pageUnderwater Weldingsamir bendreNo ratings yet

- Precast Box Culvert Segment WeightDocument1 pagePrecast Box Culvert Segment Weightsamir bendreNo ratings yet

- Deonar RWRM Staad ReportDocument5 pagesDeonar RWRM Staad Reportsamir bendreNo ratings yet

- CCT Pipe Layout Option-1Document1 pageCCT Pipe Layout Option-1samir bendreNo ratings yet