0% found this document useful (0 votes)

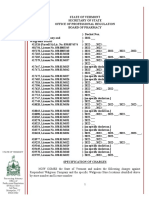

416 views1 pageCobalt Alloy L605: Specifications AMS: 5537, 5759 UNS: R30605 Chemical Composition, %

L605 is a cobalt-chromium-tungsten-nickel alloy that displays excellent high-temperature strength and oxidation resistance up to 2000°F. It also has good sulfidation resistance and resistance to wear and galling. The alloy has applications in aircraft engine components, combustion liners, industrial furnace muffles, valves, bearings, and springs due to its high strength, fabricability, and resistance to corrosion at high temperatures. The alloy retains tensile strength down to 1200°F but strength decreases significantly above 1500°F.

Uploaded by

Dedika MulyanaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

416 views1 pageCobalt Alloy L605: Specifications AMS: 5537, 5759 UNS: R30605 Chemical Composition, %

L605 is a cobalt-chromium-tungsten-nickel alloy that displays excellent high-temperature strength and oxidation resistance up to 2000°F. It also has good sulfidation resistance and resistance to wear and galling. The alloy has applications in aircraft engine components, combustion liners, industrial furnace muffles, valves, bearings, and springs due to its high strength, fabricability, and resistance to corrosion at high temperatures. The alloy retains tensile strength down to 1200°F but strength decreases significantly above 1500°F.

Uploaded by

Dedika MulyanaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Features and Applications

- Chemical Composition

- Physical Properties

- Cobalt Alloy L605 Overview

- Mechanical Properties