Professional Documents

Culture Documents

kme_STOL76_C19010_en

Uploaded by

Mattia Terri TerrandoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

kme_STOL76_C19010_en

Uploaded by

Mattia Terri TerrandoCopyright:

Available Formats

C19010

ENGINEERING

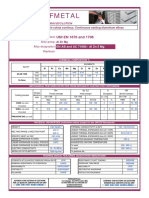

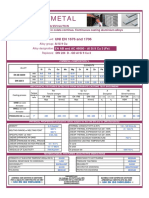

6.2. STOL® 76 - CuNiSi COPPER SOLUTIONS

Alloy Designation STOL® 76 Characteristics

EN CuNiSi STOL® 76 is a CuNiSi alloy that can be hardened by cold forming and by

DIN CEN/TS 13388 precipitation of NiSi-phases during a heat treatment. It has excellent

bendability, excellent hot and cold forming properties, a high strength and

UNS C19010 a good corrosion resistance.

Due to the NiSi-precipitations the relaxation properties, even at

temperatures up to 150 °C are excellent. The electrical and thermal

conductivity is good. Welding, soldering and brazing properties are good

Chemical Composition (Balance) too.

Weight percentage

Cu Rest % Main Applications

Ni 1.3 % Automotive: Switches and Relays, Contacts, Connectors, Terminals.

Electrical: Switches and Relays, Contacts, Connectors, Terminals,

Si 0.25 %

Components for the electrical industry, Stamped parts, Semiconductor

P 0.03 % Components, Junction Boxes.

Mechanical Properties (EN 1652)

Temper Temper Tensile Yield Elongation Hardness Bending

Strength Strength Minimum 90°

Minimum A50mm HV ** gw bw

H.. = Cold worked Rm Rp0.2 rel. Bending Radius R/T

TM = Mill hardened

MPa MPa % HV Strip Thickness ≤ 0.50mm

R360 H01 (¼ hard) 360 .. 430 300 12 14 * 100 .. 130 0 0

R410 H02 (½ hard) 410 .. 470 360 9 11 * 125 .. 155 0 0

R460 H04 (¾ hard) 460 .. 520 410 7 9* 135 .. 165 0.5 1

R520 H06 (extra hard) 520 .. 580 460 5 7* 145 .. 175 1 2

R520 TM06 (XHM) 520 .. 590 440 8 155 .. 180 0.5 0.5

R580 TM08 (SHM) 580 .. 650 520 9 160 .. 210 1 1

* values for stress relieved qualities / ** only for information

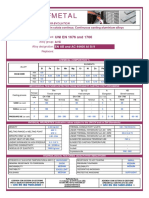

Physical Properties Fabrication Properties *

Typical values in annealed temper at 20 °C Cold Forming Properties Excellent

Density 8.93 g/cm³ Machinability (Rating 20) Less suitable

Electroplating Properties Excellent

Thermal expansion

20 .. 300 °C 16.8 10-6/K

coefficient Hot Tinning Properties Excellent

Specific heat capacity 0.377 J/(g·K) Soft Soldering, Brazing Excellent

Resistance Welding Less suitable

Thermal conductivity 260 W/(m·K)

Gas Shielded Arc Welding Excellent

Electrical conductivity MS/m 35 MS/m Laser Welding Fair

Electrical conductivity IACS 60 % * For more details call our technical service

Thermal coefficient of

(0 .. 100 °C) 2 10-3/K

electrical resistance Due to continuous improvements within our production process, the details given in our

brochure cannot be guaranteed. We reserve the right to update or change our products without

Modulus of elasticity GPa 135 GPa prior notice. We recommend that you seek confirmation of our product details / specifications

before committing to specific alloys.

©KME - www.kme.com Page 35

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Steel PropertiesDocument22 pagesSteel PropertiesMOHD SALMANNo ratings yet

- C95500 ASTM - Nickel Aluminum BronzeDocument2 pagesC95500 ASTM - Nickel Aluminum BronzethuykvNo ratings yet

- Physical Science Quiz 1Document1 pagePhysical Science Quiz 1Alison BarreroNo ratings yet

- A High Performance, Damage Tolerant Fusion Bonded Epoxy CoatingDocument15 pagesA High Performance, Damage Tolerant Fusion Bonded Epoxy CoatingpaimpillyNo ratings yet

- Coal Technology Presentation PDFDocument24 pagesCoal Technology Presentation PDFyondelaNo ratings yet

- CuNiSi AlloyDocument6 pagesCuNiSi AlloyJdjoNo ratings yet

- Cusn8 Industrial RolledDocument4 pagesCusn8 Industrial RolledPrakash MakadiaNo ratings yet

- CuZn40 01 2019 PDFDocument7 pagesCuZn40 01 2019 PDFMisaelNo ratings yet

- C2700Document6 pagesC2700Andrew TanNo ratings yet

- CuZn33 CatalogueDocument9 pagesCuZn33 CataloguefedericoNo ratings yet

- Cu DHPDocument3 pagesCu DHPLUIGINo ratings yet

- Cuzn37 Industrial RolledDocument6 pagesCuzn37 Industrial RolledcvgfgNo ratings yet

- Cu-HCP: C10300 Industrial RolledDocument7 pagesCu-HCP: C10300 Industrial RolledpierocarnelociNo ratings yet

- EN71000 From ReinferdenDocument2 pagesEN71000 From ReinferdenJason WuNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Martin DuarteNo ratings yet

- Cu-ETP: C11000 Industrial RolledDocument4 pagesCu-ETP: C11000 Industrial Rolledsrsivaraman81No ratings yet

- RAFFMETAL: THE ALUMINIUM EVOLUTIONDocument2 pagesRAFFMETAL: THE ALUMINIUM EVOLUTIONAmandeep SinghNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Hareth MRAIDINo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document1 pageRaffmetal: UNI EN 1676 and 1706swaroop NalamNo ratings yet

- kme_CuSn6_enDocument1 pagekme_CuSn6_enMattia Terri TerrandoNo ratings yet

- The Aluminium Evolution: Continuous Casting Aluminium AlloysDocument2 pagesThe Aluminium Evolution: Continuous Casting Aluminium AlloysHareth MRAIDINo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Raj RajeshNo ratings yet

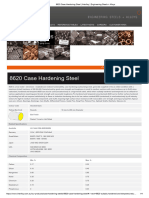

- Interlloy Grade 8620 Case Hardening SteelDocument3 pagesInterlloy Grade 8620 Case Hardening Steelajitchavan2150No ratings yet

- CuZn30 Brass Sheet: Properties and Applications of 70/30 Copper Zinc AlloyDocument2 pagesCuZn30 Brass Sheet: Properties and Applications of 70/30 Copper Zinc Alloyavinashchauhan2695No ratings yet

- AmuDocument2 pagesAmuavinashchauhan2695No ratings yet

- High Tensile: Voestalpine High Performance Metals (Australia) Pty LTDDocument5 pagesHigh Tensile: Voestalpine High Performance Metals (Australia) Pty LTDSinan YıldızNo ratings yet

- Copper Cu-Dhp / Sf-Cu: Page 1/2Document2 pagesCopper Cu-Dhp / Sf-Cu: Page 1/2gemilanglpNo ratings yet

- Data Sheet CuZn20Al2AsDocument1 pageData Sheet CuZn20Al2AsJean Carlos Reyna PascualNo ratings yet

- Alloy 410S Spec SheetDocument2 pagesAlloy 410S Spec SheetPrakash SundharamNo ratings yet

- Niclafor® 1000: Wear and Fatigue Resistant, Recyclable, High Performance Beryllium-Free Spinodal AlloyDocument6 pagesNiclafor® 1000: Wear and Fatigue Resistant, Recyclable, High Performance Beryllium-Free Spinodal AlloyvikrantathavaleNo ratings yet

- EN47100Document2 pagesEN47100tsonjayaNo ratings yet

- Material Datasheet Cuzn30Document2 pagesMaterial Datasheet Cuzn30alex94kgNo ratings yet

- CuZn38Pb2_CW608N_ENDocument4 pagesCuZn38Pb2_CW608N_ENTaner DemirelNo ratings yet

- Material Datasheet Cu-OFDocument2 pagesMaterial Datasheet Cu-OFmohsen_267No ratings yet

- CuZn10-PNA 222 - ENDocument2 pagesCuZn10-PNA 222 - ENYulwido AdiNo ratings yet

- Cu Zn 15 alloy properties and applicationsDocument2 pagesCu Zn 15 alloy properties and applicationsPetrus UngureanuNo ratings yet

- Cu Ofe c10100 Pna 203 - enDocument2 pagesCu Ofe c10100 Pna 203 - enNitin KumarNo ratings yet

- Carbon Steels - Data Sheet Grade: U1004: Chemical Composition (% by Weight)Document7 pagesCarbon Steels - Data Sheet Grade: U1004: Chemical Composition (% by Weight)alvida pramudiantiNo ratings yet

- Cu-ETP Material DatasheetDocument2 pagesCu-ETP Material Datasheetwhoam iNo ratings yet

- CuZn15-convertedDocument2 pagesCuZn15-convertedwjjt6chgtmNo ratings yet

- 1.4006 en PDFDocument2 pages1.4006 en PDFutkuNo ratings yet

- Hussey Copper Electrolytic Tough Pitch CDA Copper C 110 00Document1 pageHussey Copper Electrolytic Tough Pitch CDA Copper C 110 00Michael DoyleNo ratings yet

- Material Data Sheet: Manganese Bronze (High Strength Yellow Brass)Document1 pageMaterial Data Sheet: Manganese Bronze (High Strength Yellow Brass)Fred Duarte CaldeiraNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706satheeskumar VikramasingarajNo ratings yet

- CuZn10-PNA 222 - ENDocument2 pagesCuZn10-PNA 222 - ENjurreijndersNo ratings yet

- Arsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!Document2 pagesArsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!David LluguinNo ratings yet

- 02 Asae 101892Document1 page02 Asae 101892raviteja036No ratings yet

- SAE 1018 - Data Sheet PDFDocument1 pageSAE 1018 - Data Sheet PDFHari SuthanNo ratings yet

- P P P P: Alloy 416 Specifications: UNS S41600Document2 pagesP P P P: Alloy 416 Specifications: UNS S41600AVINASHRAJNo ratings yet

- Aalco Metals LTD Aluminium Alloy 6060 T5 Extrusions 144Document2 pagesAalco Metals LTD Aluminium Alloy 6060 T5 Extrusions 144anilbabu4No ratings yet

- Cusn10-Pna 292 enDocument2 pagesCusn10-Pna 292 enRissi CHNo ratings yet

- AW - Datasheet - ALLOY 20 CB 3Document2 pagesAW - Datasheet - ALLOY 20 CB 3.xNo ratings yet

- Alloy 410s Spec SheetDocument2 pagesAlloy 410s Spec SheetALONSO GOMEZNo ratings yet

- Precipitation Hardening Stainless Steel: Voestalpine High Performance Metals (Australia) Pty LTDDocument3 pagesPrecipitation Hardening Stainless Steel: Voestalpine High Performance Metals (Australia) Pty LTDAtlantic Heat Treat ShopNo ratings yet

- 8620 Case Hardening Steel - Interlloy - Engineering Steels + AlloysDocument4 pages8620 Case Hardening Steel - Interlloy - Engineering Steels + Alloysankit7588No ratings yet

- Cucrzr c18160 Pna 372 - enDocument2 pagesCucrzr c18160 Pna 372 - enSulistyo widiatmokoNo ratings yet

- Bronze C86300 SpecificationsDocument2 pagesBronze C86300 SpecificationsDoss MartinNo ratings yet

- Raffmetal aluminium alloy guideDocument2 pagesRaffmetal aluminium alloy guideDhamodaran RNo ratings yet

- Analytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryFrom EverandAnalytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryNo ratings yet

- kme_CuSn6_enDocument1 pagekme_CuSn6_enMattia Terri TerrandoNo ratings yet

- THESIS_FINAL_Akcan-ISTIF_Jan22-2019Document207 pagesTHESIS_FINAL_Akcan-ISTIF_Jan22-2019Mattia Terri TerrandoNo ratings yet

- Adjust focal length and IPD on Eachine EV100 gogglesDocument1 pageAdjust focal length and IPD on Eachine EV100 gogglesMattia Terri TerrandoNo ratings yet

- U Boot V15Document4 pagesU Boot V15Mattia Terri TerrandoNo ratings yet

- Advanced Implicit Numerical MethodsDocument28 pagesAdvanced Implicit Numerical MethodsMattia Terri TerrandoNo ratings yet

- Catalogo Ventose SchmalzDocument716 pagesCatalogo Ventose SchmalzMattia Terri TerrandoNo ratings yet

- Advanz 6F E170 DataSheetDocument1 pageAdvanz 6F E170 DataSheetMattia Terri TerrandoNo ratings yet

- 986 3798 1 PBDocument15 pages986 3798 1 PBMattia Terri TerrandoNo ratings yet

- MSK StarWarsVII Origami A4 PDFDocument1 pageMSK StarWarsVII Origami A4 PDFMattia Terri TerrandoNo ratings yet

- MSK StarWarsVII Origami A4Document1 pageMSK StarWarsVII Origami A4Mattia Terri TerrandoNo ratings yet

- Optimal BIOS HPC Dell 12G.v1.0Document32 pagesOptimal BIOS HPC Dell 12G.v1.0Mattia Terri TerrandoNo ratings yet

- Oznake Auto ReleaDocument4 pagesOznake Auto ReleapagapagaNo ratings yet

- HKDSE Physics Part - 2 MechanicsDocument17 pagesHKDSE Physics Part - 2 MechanicsdexterNo ratings yet

- Selection of Materials For Prototype Fast Breeder Reactor S.L.Mannan, S.C.Chetal, Baldev Raj and S.B.BhojeDocument35 pagesSelection of Materials For Prototype Fast Breeder Reactor S.L.Mannan, S.C.Chetal, Baldev Raj and S.B.BhojeSatish Kumar GautamNo ratings yet

- The Comparison of Three Isomers of ButanolDocument5 pagesThe Comparison of Three Isomers of ButanolLilly0% (2)

- Making Salts: Neutralisation ReactionsDocument4 pagesMaking Salts: Neutralisation ReactionsPedro Moreno de SouzaNo ratings yet

- Flow and Heat Transfer of Ostwald-De Waele Fluid Over A Variable Thickness Rotating Disk With Index DecreasingDocument11 pagesFlow and Heat Transfer of Ostwald-De Waele Fluid Over A Variable Thickness Rotating Disk With Index DecreasingNoveel SheikhNo ratings yet

- Heat Release RateDocument24 pagesHeat Release Rateh4harish100% (1)

- TCW3101200904 HydraulicsDocument3 pagesTCW3101200904 HydraulicsTinashe Mazokera100% (1)

- 1.10 Material Balance Calculations 1Document14 pages1.10 Material Balance Calculations 1Josch DenilaNo ratings yet

- Journal 1210.5589 PDFDocument4 pagesJournal 1210.5589 PDFUdhamNo ratings yet

- Chem Lab ReportDocument24 pagesChem Lab ReportEmman Cortes San JoseNo ratings yet

- Astm D1160 - 18Document20 pagesAstm D1160 - 18Metrologia Piedecuesta Solumed Ingenieria Ltda100% (2)

- Influence of Test Time On The Mechanical Behaviour of Acrylonitrile Butadiene Styrene "ABS"Document4 pagesInfluence of Test Time On The Mechanical Behaviour of Acrylonitrile Butadiene Styrene "ABS"International Journal of Innovative Science and Research TechnologyNo ratings yet

- Janusz S Laskowski PDFDocument178 pagesJanusz S Laskowski PDFjoseph ayronNo ratings yet

- Chapter 16 - SaltsDocument3 pagesChapter 16 - SaltsschlemielzNo ratings yet

- CH 01Document83 pagesCH 01samantha oroNo ratings yet

- Photoelastic stress analysisDocument50 pagesPhotoelastic stress analysisSunder Veera KarthikeyanNo ratings yet

- Weberdry Protect 01Document2 pagesWeberdry Protect 01adelsaqqaNo ratings yet

- Science Form1 Chapter 7Document27 pagesScience Form1 Chapter 7Sue Suraya Naza100% (1)

- Phenol Vs Alcohol PDFDocument18 pagesPhenol Vs Alcohol PDFSonNo ratings yet

- SolutionsDocument33 pagesSolutionsMircea PanteaNo ratings yet

- HumiK Bio WSG FunctionsDocument5 pagesHumiK Bio WSG FunctionsEvelyn Fierro PinoNo ratings yet

- BS 3882 Soil AnalysisDocument3 pagesBS 3882 Soil AnalysisHansika JayathilakaNo ratings yet

- 1032 1st Exam 1040325 A PDFDocument8 pages1032 1st Exam 1040325 A PDFTrung TranNo ratings yet

- 421 821 Chapter 11 20Document51 pages421 821 Chapter 11 20shaikriyaz4965No ratings yet

- Chapter 7 33Document9 pagesChapter 7 33ayushNo ratings yet

- 7697A HeadspaceSamplers Site Preparation GuideDocument28 pages7697A HeadspaceSamplers Site Preparation GuidedriveNo ratings yet

- Density Pepsi Vs Diet PepsiDocument6 pagesDensity Pepsi Vs Diet PepsiMarcel VerstraeteNo ratings yet