Professional Documents

Culture Documents

Range Guard Manual

Uploaded by

Kus MadiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Range Guard Manual

Uploaded by

Kus MadiCopyright:

Available Formats

Your Owner’s How Your Automatic Fire

Protection System Works

What You Should Do

In The Event Of A Fire

Guide To... 1. Quickly and

carefully, EXIT

evacuate

others from

the premises.

2

3

1 2. If the system has not operated

® automatically...

IN CASE OF FIRE

PULL PIN,

PULL

HANDLE

HARD

FIRE SUPPRESSION SYSTEM

FIRST...WITH THE BEST

...Manually activate the system. (Which type

This guide helps you understand your responsibilities As illustrated above: of manual operation do you have?)

in fire protection. It covers system operation, ➀ A fire starts...

maintenance precautions, and emergency 3. Call the Fire Department.

➁ A fusible link melts, or an electric probe detects

procedures.

fire temperatures...

Number:___________________

This guide is not a Design, Installation, Operation, and ➂ An actuating device automatically opens the cylin- EXIT

Maintenance Manual. Only factory trained and der valve, allowing Karbaloy®, a liquid chemical

certified companies and individuals are permitted to solution, to discharge through pipe and nozzles,

install and maintain the Range Guard system. For all suppressing fire through a patented process.

maintenance, recharge, service, or repair, contact your ➃ Gas valves and electrical switches, where in-

authorized distributor. stalled, will operate to shut off your sources of fuel.

Request that the installer provide you with a statement 4. Stand by with

which specifies the equipment provided and the

a fire extin-

appliances protected.

guisher if it is

safe to do so.

UL EX 2458 UL EX 2458

BADGER FIRE PROTECTION 2 3

Before Resuming Your Role In Fire Monthly

Operations Protection Inspection

1. Call a factory-trained and approved Range Guard 1. Keep hoods, ducts, filters, appliances, and fans MONTHLY INSPECTIONS SHALL BE CONDUCTED

Distributor to restore your system. clean. Approximately 90% of major restaurant BY THE OWNER OF THE SYSTEM PER NFPA 17A,

fires occur in these areas. AND ARE REQUIRED BY BADGER.

2. Have a fire department and your Range Guard 2. Have your Range Guard Distributor completely The owner is to conduct the following “quick check” inspection

Distributor determine the cause of system service the system at minimum 6-month intervals. of the Range Guard system to verify the following:

operation. The fire may have originated in an area (Required by NFPA 17A.) 1. Inspect all system components, agent distribution pipe, and

where it was not visible (plenum/duct). conduit runs for physical damage and/or displacement.

3. Never tamper with any of the parts or mechanisms 2. Inspect all nozzles to see if foil seal caps (if applicable) are in

of the system. place. Check for possible obstructions to the discharge of the

3. Promptly clean up the discharge area with damp

wet chemical.

rags and sponges. (Never use flammable cleaning 4. In between complete service calls, periodically

fluids.) check the gauge(s) for full pressure in the 3. Inspect all detectors (Fusible-links and Thermo-bulbs) for con-

tamination. If contamination is found, contact an authorized

cylinder(s).

Badger Distributor for service.

4. Correct the conditions which caused the fire. 5. Advise your Range Guard Distributor of any 4. Inspect each Cylinder and Valve Assembly. The pointer on the

alterations or changes in your appliances or hood pressure gauge should be in the “green” range. The cylinder

5. Start exhaust fans. (Always ensure fans are and duct system. Such changes could severely should not show evidence of corrosion or damage.

running before turning appliances on. Failure to do affect the system’s ability to extinguish fire. 5. Inspect manual pull stations are unobstructed and in clear view

so could result in unwanted discharge.) 6. Inform your employees on fire emergency

and labeled for intended use.

6. Inspect all tamper seals are intact and the system is in a ready

procedure.

6. Bring all your employees together. Analyze what condition.

just happened and why. Review everyone’s 7. Verify the inspection tag or certificate is in place and current.

For all maintenance, recharge, service, or repair,

actions. (There’s no better time than now.) 8. A record of the monthly inspection is to be kept reflecting the

contact your authorized distributor. date inspected, initials of the person performing the inspection,

This system is made up of units tested within and any corrections required.

___________________________________________ limitations contained in the detailed installation 9. If wall mounted, the UCH Control System must be tightly

NAME OF AUTHORIZED DISTRIBUTOR manual. (The system designer must be consulted secured to the wall. If cylinder mounted, the UCH Control

System must be tightly bolted to the SVA. The Cam/Flag on the

whenever changes are planned for the system or

UCH Control System indicator should point to the ‘Set’ position.

___________________________________________ area of protection.) An authorized installer or The safety pin and seal wire on the local manual release

PHONE NUMBER system designer must be consulted after the handle should be in place. If no Remote Manual Release is

system has been discharged. installed, the path to the local manual release on the cylinder

should be clear and unobstructed and within reach.

You have invested a significant sum of money in

10. If any discrepancies are noted while making this inspection,

your fire protection system. We thank you for DO NOT CONTINUE OPERATING HAZARDOUS

selecting Badger Fire Protection. We know that PROCESSES OR TURN ON PROTECTED EQUIPMENT.

BADGER FIRE PROTECTION fires can occur, but by exercising your individual Immediately contact an authorized Badger Distributor for

responsibilities, you can strive for a fire-safe service and/or repair.

Charlottesville, VA 22911 operation of your business. 11. The hood, duct, and protected cooking appliances have not

Telephone: (434) 964-3200 been replaced, modified, or relocated.

Fax: (434) 964-3203

UL EX 2458 P/N 60-9100025-000 REV. BA UL EX 2458 UL EX 2458

4 5 6

You might also like

- Risk Assessment Supaww1Document5 pagesRisk Assessment Supaww1Jemina OsallaNo ratings yet

- Fire Safety Tips: Smoke AlarmsDocument7 pagesFire Safety Tips: Smoke AlarmsOmar Lorenzo CalvoNo ratings yet

- FG250B Manual EnglishDocument5 pagesFG250B Manual EnglishAngelina JunioNo ratings yet

- Tool Box Talks: Introduction To Fire ExtinguishersDocument2 pagesTool Box Talks: Introduction To Fire ExtinguishersJiwim Ali BelloNo ratings yet

- Ul STD 217: Recommended Locations For Smoke Alarms, Continued About Smoke Alarms, ContinuedDocument2 pagesUl STD 217: Recommended Locations For Smoke Alarms, Continued About Smoke Alarms, ContinuedOmarNo ratings yet

- Hazard Indentificaction and Risk Assessment: Name of Project:-Documents NoDocument4 pagesHazard Indentificaction and Risk Assessment: Name of Project:-Documents Noaman anand100% (2)

- 81 e 5 UxjhrblDocument7 pages81 e 5 UxjhrblZia GhiasiNo ratings yet

- Frtbgcboqawn PDFDocument32 pagesFrtbgcboqawn PDFKyriacosNo ratings yet

- Fire SafetyDocument8 pagesFire SafetyPriya ShrivastavaNo ratings yet

- Folleto InglesDocument2 pagesFolleto InglesAlejandra GutierrezNo ratings yet

- Risk Assessment Fire HazardDocument3 pagesRisk Assessment Fire HazardSathi sh100% (1)

- Job Hazard Analysis (Drilling)Document2 pagesJob Hazard Analysis (Drilling)jay RNo ratings yet

- Brandalarm Brandmelder GuidDocument10 pagesBrandalarm Brandmelder GuidgghghgfhfghNo ratings yet

- Tissue Solutions: Pdf-Version Adjusted From The BrochureDocument9 pagesTissue Solutions: Pdf-Version Adjusted From The BrochureBambang WibisonoNo ratings yet

- Fire Safety-1Document21 pagesFire Safety-1Anne hazel MacogayNo ratings yet

- Tube Furnace ManualDocument32 pagesTube Furnace ManualSiddharth Vijayaraghavan100% (1)

- FirDocument1 pageFirProsun SarkarNo ratings yet

- Portable Fire Extinguishers A Chain of Survival: Fire Department Is Called Make Sure Everyone Is SafeDocument2 pagesPortable Fire Extinguishers A Chain of Survival: Fire Department Is Called Make Sure Everyone Is SafeJose Luis CastilloNo ratings yet

- Amt 234 - Fire Detection SystemDocument2 pagesAmt 234 - Fire Detection SystemJaypee AmpoNo ratings yet

- SF-2001-SureFire II High Energy Igniter (English) 2020-12-17Document24 pagesSF-2001-SureFire II High Energy Igniter (English) 2020-12-17akash kurheNo ratings yet

- MS 5.0 (1) Risk Assessment ProjectDocument6 pagesMS 5.0 (1) Risk Assessment ProjectEngr. Imran Hasan PathanNo ratings yet

- MS 5.0 (1) Risk Assessment ProjectDocument6 pagesMS 5.0 (1) Risk Assessment ProjectEngr. Imran Hasan PathanNo ratings yet

- Owner Manual - MonarchDocument4 pagesOwner Manual - MonarchYoyon HaryonoNo ratings yet

- A320 Fire and Protection SystemDocument7 pagesA320 Fire and Protection SystemRaj PandyaNo ratings yet

- Using Fire Extinguisher.Document1 pageUsing Fire Extinguisher.madjid bobNo ratings yet

- COPA Demostration PlanDocument452 pagesCOPA Demostration PlananishlazrusNo ratings yet

- SITXWHS002 Identify Hazards, Assess and Control Safety Risks - Emergency Evacuation ProceduresDocument1 pageSITXWHS002 Identify Hazards, Assess and Control Safety Risks - Emergency Evacuation ProceduresNasir Uddin0% (1)

- JOB Safety AnalysisDocument2 pagesJOB Safety Analysisanon_266837576No ratings yet

- How To Use: The Fire TriangleDocument2 pagesHow To Use: The Fire TriangleMiaochiiNo ratings yet

- Sop 722Document8 pagesSop 722sarwan balochNo ratings yet

- Ul STD 217: Conforms ToDocument2 pagesUl STD 217: Conforms Toandy hsiehNo ratings yet

- Active SystemDocument84 pagesActive SystemS.Norhanisah SNo ratings yet

- Smoke Alarm User's GuideDocument9 pagesSmoke Alarm User's GuideThanh DuyNo ratings yet

- Instructions de SécuritéDocument106 pagesInstructions de SécuritéMonjolNo ratings yet

- Fire Alarm Interface of Smoke Dampers: Jason Lupa, PE Siemens Industry May 2018 Philadelphia, PennsylvaniaDocument44 pagesFire Alarm Interface of Smoke Dampers: Jason Lupa, PE Siemens Industry May 2018 Philadelphia, Pennsylvaniaenlightened1718No ratings yet

- MX Foam Fire Extinguisher Permanen Pressure DWL 6n DWL 9n PDFDocument2 pagesMX Foam Fire Extinguisher Permanen Pressure DWL 6n DWL 9n PDFNarendra Reddy BhumaNo ratings yet

- FDAS GuideDocument1 pageFDAS GuideSilver Villota Magday Jr.No ratings yet

- Fire & Evacuation Safety: Tfs Supplier Academy - Fact Sheet #2Document6 pagesFire & Evacuation Safety: Tfs Supplier Academy - Fact Sheet #2fireguard estanciaNo ratings yet

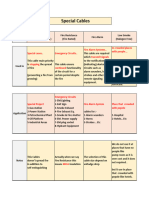

- Special CablesDocument11 pagesSpecial CablesSantosh SwainNo ratings yet

- Module 3 Cuf - T TC3 CLSDocument34 pagesModule 3 Cuf - T TC3 CLSLee SmithNo ratings yet

- Safety and Infection Control 07/29/2021: Fire Safety Electrical SafetyDocument7 pagesSafety and Infection Control 07/29/2021: Fire Safety Electrical SafetyNathalie KerrNo ratings yet

- Task Risk Assessment Engineering Kinetics (PVT.) LTD: Risk Evaluation (Refer To Evaluation Form)Document2 pagesTask Risk Assessment Engineering Kinetics (PVT.) LTD: Risk Evaluation (Refer To Evaluation Form)andreNo ratings yet

- Operation Manual: Duct Air Leakage Tester Model DALT 6900Document27 pagesOperation Manual: Duct Air Leakage Tester Model DALT 6900karimakkiNo ratings yet

- Fire Watcher: Roles & DuetsDocument12 pagesFire Watcher: Roles & DuetsAbdul Hameed Omar100% (2)

- Fire BrigadeDocument16 pagesFire Brigadejovy.gagabuan001No ratings yet

- Kidde DeugraDocument6 pagesKidde DeugraWalid RzigNo ratings yet

- 10 Year Life: Smoke AlarmDocument24 pages10 Year Life: Smoke AlarmAlex WongNo ratings yet

- Instruction Manual: Light Meter SeriesDocument1 pageInstruction Manual: Light Meter SeriesEdy WijayaNo ratings yet

- 1.operation & Maintenance For FM-200Document8 pages1.operation & Maintenance For FM-200MOHAMMED HADINo ratings yet

- Om FC Duo-Cel User 0Document6 pagesOm FC Duo-Cel User 0axwellNo ratings yet

- Guideline 5. Classes-Of-FireDocument5 pagesGuideline 5. Classes-Of-FireMohamed RameesNo ratings yet

- Downloaded From Manuals Search Engine: Conforms ToDocument2 pagesDownloaded From Manuals Search Engine: Conforms ToQuyền Đỗ NgọcNo ratings yet

- Iosh-Risk-Assessment-Project - (MUSTAFA ADNAN SHABAN)Document5 pagesIosh-Risk-Assessment-Project - (MUSTAFA ADNAN SHABAN)MustafaAdnan100% (9)

- I. Chapter 7 - Fire, Egress and 1st AidDocument76 pagesI. Chapter 7 - Fire, Egress and 1st AidMohamed MahgoubNo ratings yet

- Manual Aer Conditionat GalanzDocument23 pagesManual Aer Conditionat GalanzDaniel DropNo ratings yet

- Moose Z900 ENDocument26 pagesMoose Z900 ENRichard RoperNo ratings yet

- Fire Risk Assessment 2Document14 pagesFire Risk Assessment 2collins ogudoNo ratings yet

- Hot Work Permit New FormDocument3 pagesHot Work Permit New FormMohammed HamzaNo ratings yet

- 2017 - Janjuhah Et Al., - Carbonates and Evaporites1Document19 pages2017 - Janjuhah Et Al., - Carbonates and Evaporites1Waleed HassanNo ratings yet

- Flight International 13 November 2018Document52 pagesFlight International 13 November 2018Adrian BistreanuNo ratings yet

- Outpatient Appointment Systems in Healthcare - A Review of Optimization StudiesDocument32 pagesOutpatient Appointment Systems in Healthcare - A Review of Optimization Studiesgabrieelcrazy100% (1)

- Crimes Commited by Public OfficersDocument51 pagesCrimes Commited by Public OfficersJaime M. Palattao Jr.100% (1)

- Sixnet Training - OSI ModelDocument16 pagesSixnet Training - OSI ModelBiswajit MohantyNo ratings yet

- New A4v Sample 1Document2 pagesNew A4v Sample 1thegocp100% (58)

- Lifefitness Produktkatalog 2020Document43 pagesLifefitness Produktkatalog 2020Gabriel SilvaNo ratings yet

- Dynamic Replication in Data-Centers Connected Over IPFSDocument3 pagesDynamic Replication in Data-Centers Connected Over IPFSNilesh RathiNo ratings yet

- Slack Operations Management 6e Chapter1Document7 pagesSlack Operations Management 6e Chapter1dorislianNo ratings yet

- Final Project Presentation: Designers NameDocument19 pagesFinal Project Presentation: Designers NameKyla Andrea AguirreNo ratings yet

- Testbank: Chapter 1 The Concept of Strategy: True/False QuestionsDocument8 pagesTestbank: Chapter 1 The Concept of Strategy: True/False QuestionsSanket Sourav BalNo ratings yet

- Assign 1Document4 pagesAssign 1Harry PatelNo ratings yet

- Hydrogen Power Handbook (3206)Document34 pagesHydrogen Power Handbook (3206)cesar baranda100% (2)

- SQL Engine ReferenceDocument608 pagesSQL Engine ReferenceIndra AnggaraNo ratings yet

- Mukesh Surana CaseDocument6 pagesMukesh Surana CaseSURANA1973No ratings yet

- Case Study Humanized RobotsDocument3 pagesCase Study Humanized RobotsAakash YadavNo ratings yet

- Report Project ManagementDocument36 pagesReport Project ManagementVarun Mathur100% (1)

- Car ValuationDocument1 pageCar ValuationShiraz VijNo ratings yet

- Tutorial 2 Aspen Plus Vinyl Chloride Monomer Production ProcessDocument15 pagesTutorial 2 Aspen Plus Vinyl Chloride Monomer Production ProcessMinSoo Tom Kim100% (1)

- Taking Battery ChargerDocument6 pagesTaking Battery ChargerChris GreenNo ratings yet

- Ambrosio L., Gigli N. - A User's Guide To Optimal Transport-Web Draft (2009)Document128 pagesAmbrosio L., Gigli N. - A User's Guide To Optimal Transport-Web Draft (2009)Ruigang WangNo ratings yet

- Shashwatchaudhary - Synopsis - Master - CalculaterDocument6 pagesShashwatchaudhary - Synopsis - Master - CalculaterShashwat ChaudharyNo ratings yet

- MSSCV PDFDocument15 pagesMSSCV PDFudayNo ratings yet

- 250613DLDLD2234 Exab00 01Document1 page250613DLDLD2234 Exab00 01Mohammed HijaziNo ratings yet

- Persuasive Speech Outline Draft 4Document4 pagesPersuasive Speech Outline Draft 4AlexisNo ratings yet

- Due Date Telephone Number Amount Payable: Summary of Charges Usage History (6 Months)Document5 pagesDue Date Telephone Number Amount Payable: Summary of Charges Usage History (6 Months)GEO MERINNo ratings yet

- YEF Final ReportDocument12 pagesYEF Final ReportNidhi SharmaNo ratings yet

- Finishing and Polishing ProceduresDocument45 pagesFinishing and Polishing ProceduresDyuti SikdarNo ratings yet

- Catalogo Level OneDocument80 pagesCatalogo Level Onemedo amgdNo ratings yet

- Alberta Transportation Integral AbutmentDocument13 pagesAlberta Transportation Integral AbutmentMehdi.MostNo ratings yet