100% found this document useful (1 vote)

15K views25 pagesThermal Power Plant - Diagram, Layout, Working & Construction

Thermal power plants generate electricity by converting heat energy from the combustion of fuels like coal into mechanical energy using steam to power turbines that drive generators. The key components include a boiler to produce high-pressure steam from water, a steam turbine turned by the steam, and a generator powered by the turbine. Cooling water is used to condense the exhaust steam back into water, which is pumped back into the boiler repeating the process. Thermal power plants are well-suited as baseload power sources since their output can be adjusted to match changing electricity demand.

Uploaded by

ACME NKSTPPCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

15K views25 pagesThermal Power Plant - Diagram, Layout, Working & Construction

Thermal power plants generate electricity by converting heat energy from the combustion of fuels like coal into mechanical energy using steam to power turbines that drive generators. The key components include a boiler to produce high-pressure steam from water, a steam turbine turned by the steam, and a generator powered by the turbine. Cooling water is used to condense the exhaust steam back into water, which is pumped back into the boiler repeating the process. Thermal power plants are well-suited as baseload power sources since their output can be adjusted to match changing electricity demand.

Uploaded by

ACME NKSTPPCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Introduction to Thermal Power Plant: Provides an overview of thermal power plants and their role in modern power generation.

- Components of Thermal Power Plant: Details the components and operating principles of thermal power plants with diagrams for clarity.

- Layout and Working of Thermal Power Plant: Explains the layout including major circuits and describes the working mechanism of a thermal power plant.

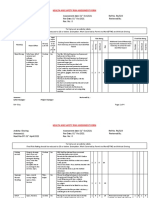

- Factors for Selection of Site for Thermal Power Plant: Lists and explains the key factors involved in selecting a site for thermal power plant construction.

- Materials Required for Thermal Power Plant: Outlines the basic materials required for the construction and operation of thermal power plants.

- Advantages of Thermal Power Plants: Highlights the benefits associated with thermal power plants compared to other power generation methods.

- Types of Fuels Utilized in Thermal Power Plant: Discusses the types of fuels used in thermal power plants, highlighting energy conversion processes.

- Disadvantages of Thermal Power Plants: Outlines the drawbacks and environmental impacts of operating thermal power plants.

- Conclusion: Summarizes the thermal power plant discussions and encourages readers to explore further details.

- Supplementary Information: Provides additional information about the document, author details, and relevant links.