Pre-Start Up Checklist

Pre Start Up CHECKLIST

TAG-NO : DATE :

ENGINE TYPE : CRAFT :

STATION : CHECKED :

PRESTART ENGINE PROCEDURE CHECKLIST

DESCRIPTION CHECK REMARKS

LUBE OIL SYSTEM

- Main lube oil pump bolts tightened

- Pump suct & disch hose secured

- Return oil line from acc-drive ( tube )

- Return oil line from eng brg # 2 & 3 to tank ( Tube )

- Return oil line from engine brg # 1 to tank ( tube )

- Return oil line from POWER TURBINE to tank ( tube )

- Supply hydraulic oil to IGV in right position ( in and out )

- Supply oil line to engine brg # 1( flex-hose / tube )

- Supply oil line to engine brg # 2 & 3 ( flex-hose ).

- Supply oil line to POWER TURBINE ( flex-hose / tube )

SEAL OIL SYSTEM

- Main seal oil pump bolts tightened .

- Pump suction & discharge supply line ( Tube ).

- Seal oil pump extension shaft installed.

SERVO PUMP SYSTEM

-Pump bolts tightened

-Hydraulic oil line return from servo actuator to tank ( tube )

-Hydraulic oil line supply to servo actuator ( tube )

-Pump suction & discharge tube / hose secured.

AIR SYSTEM

- Bleeder valve flexible duct clamp secured

- Combustor drain valve ( tube ).

- PCD line supply from engine to air & oil tube assy ( tube )

- PCD line supply from engine to FGCV. ( tube )

- PCD line supply from engine to IGV actuator ( tube )

1

� Pre-Start Up Checklist

- PCD line supply from engine to POWER TURBINE ( tube )

AIR INTAKE DUCT

- Air inlet bolts flanges

STARTER SYSTEM

- Motor starter bolt tightened

- Gas source line to motor starter (flex-hose)

- Return gas source line to vent (flex-hose)

INTERCONECTING SHAFT.

- Interconnecting cover secured.

- Straight / proper

FUEL GAS SYSTEM

- Fuel gas supply to torch igniter ( tube )

- Fuel gas supply line to engine manifold (flex-hose)

EXHAUST COLLECTOR

- Exhaust bellows clamp

- Burma sleeve.

2

� Pre-Start Up Checklist

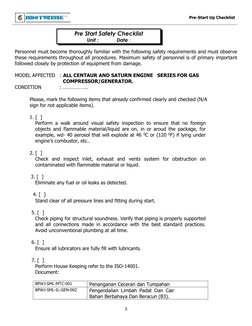

Pre Start Safety Checklist

Unit : Date :

Personnel must become thoroughly familiar with the following safety requirements and must observe

these requirements throughout all procedures. Maximum safety of personnel is of primary important

followed closely by protection of equipment from damage.

MODEL AFFECTED : ALL CENTAUR AND SATURN ENGINE SERIES FOR GAS

COMPRESSOR/GENERATOR.

CONDITION : ……………….

Please, mark the following items that already confirmed clearly and checked (N/A

sign for not applicable items).

1. [ ]

Perform a walk around visual safety inspection to ensure that no foreign

objects and flammable material/liquid are on, in or aroud the package, for

example, wd- 40 aerosol that will explode at 46 0C or (120 0F) if lying under

engine’s combustor, etc..

2. [ ]

Check and inspect inlet, exhaust and vents system for obstruction on

contaminated with flammable material or liquid.

3. [ ]

Eliminate any fuel or oil leaks as detected.

4. [ ]

Stand clear of all pressure lines and fitting during start.

5. [ ]

Check piping for structural soundness. Verify that piping is properly supported

and all connections made in accordance with the best standard practices.

Avoid unconventional plumbing at all time.

6. [ ]

Ensure all lubricators are fully fill with lubricants.

7. [ ]

Perform House Keeping refer to the ISO-14001.

Document:

BPWJ-SML-MTC-001 Penanganan Ceceran dan Tumpahan

BPWJ-SML-IL-GEN-002 Pengendalian Limbah Padat Dan Cair

Bahan Berbahaya Dan Beracun (B3).