Professional Documents

Culture Documents

Suspended Personnel Platform Check List

Suspended Personnel Platform Check List

Uploaded by

Borislav Vulic0 ratings0% found this document useful (0 votes)

3 views1 pageOriginal Title

Suspended-Personnel-Platform-Check-List

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views1 pageSuspended Personnel Platform Check List

Suspended Personnel Platform Check List

Uploaded by

Borislav VulicCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

SUSPENDED PERSONNEL PLATFORM CHECKLIST

Crane Operator Date:

Crane Make: Model:

Equipment Number Crane Capacity:

Crane Type: Hydraulic: Conventional:

1. CRANE REQUIREMENTS

Subcontractors and/or users must ensure that all items in this checklist are satisfied, including compliance with all safety

requirements prior to making a lift. All precautions and instructions on the decals attached to the crane and the platform

must be strictly adhered to. This checklist must be prepared by Site Engineer and approved by Area HSE Manager.

Check Items "Yes" to verify compliance:

No Yes Use of a man-basket is the safest and most practical way to accomplish task.

No Yes All crane inspections are current. Third Party Certificate of inspection valid within six months.

No Yes All hooks have a positive locking type latch.

The correct load chart is with the crane and the operator is thoroughly familiar with all special notes and

No Yes manufacturer recommendations given on the chart.

All operation aids and safety devices on the crane are functioning and the operator is fully versed in their

No Yes operation.

No Yes The load lines have 10:1 safety factor. NOTE: This is achieved by 50 percent de-rating of the crane load chart.

No Yes The crane is on firm footing and the crane outriggers are all the way out, down, and locked as applicable.

The crane is level within 1 percent, (1 foot in 100 feet) and is on the firm surface. NOTE: Stability of the footing

No Yes will be verified during the full cycle of the operation test.

No Yes All load lines are properly reeved and laying properly on the drums

No Yes All drum hoists have full control load lowering. NOTE: Free fall is not to be used.

No Yes The boom angle and radius indicators work.

No Yes The boom length indicator on telescoping booms is fully functional.

2. RIGGING REQUIREMENTS

Each bridle leg is connected to the master link, or shackle in a way that ensures the load is evenly distributed

No Yes between all the bridle legs.

All rigging, wire rope, shackles, rings, master links, and other rigging hardware, have a minimum safety factor of

No Yes 10:1 and must have valid third party inspection certificate within six months.

No Yes All rigging equipment for the man-basket is exclusively for the man-basket use only.

No Yes All lifting accessories have been inspected for kinks or damage of any kind.

No Yes The maximum rated load and maximum capacity is posted on a permanently affixed plate on the man-basket.

3. MANBASKET REQUIREMENTS -

No Yes Body harness anchorage provided.

A trial-lift meeting has been attended by the crane, signal person(s) (if necessary for the lift), employee(s) to be

No Yes lifted, and the employee responsible for the task to be performed.

Precautions have been taken to protect employees from any special hazards in the area where the crane and

No Yes man-basket will be operating; for example, power lines or areas where the man-basket will be out of the

operator's view.

No Yes A post-trial -lift inspection of the crane has been carried out by a designated employee.

No Yes The loading is less than 50 percent of the crane-rating chart for all work locations.

The operator has determined that all systems, controls, and safety devices are activated and functioning

No Yes properly and that no interferences exist.

The operator, and all employees that will be using the plat form, have been advised that no other object may be

No Yes lifted of any of the crane load lines while the plat form is suspended.

All manuals, operating instruct ions, and load charts provided have been read and understood by the operating

No Yes personnel prior to starting the operation.

Name: ID#: Designation: Signature:

Prepared by:

Approved by:

You might also like

- Datasheet COW LOTO Nov 2022Document2 pagesDatasheet COW LOTO Nov 2022Borislav VulicNo ratings yet

- 67081.d Original de 21202Document4 pages67081.d Original de 21202Borislav VulicNo ratings yet

- TransactionDocument1 pageTransactionBorislav VulicNo ratings yet

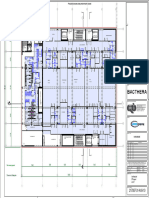

- Bacthera-ACR-Layout - Level 1 - Rev1 21-08-06Document1 pageBacthera-ACR-Layout - Level 1 - Rev1 21-08-06Borislav VulicNo ratings yet

- Faq enDocument2 pagesFaq enBorislav VulicNo ratings yet

- Premium Statements Borislav Vulic 2023-05!13!001813127090Document1 pagePremium Statements Borislav Vulic 2023-05!13!001813127090Borislav VulicNo ratings yet

- Policy Borislav Vulic 20230301 10014241154Document5 pagesPolicy Borislav Vulic 20230301 10014241154Borislav VulicNo ratings yet

- Fieldwork Leader's Health and Safety Checklist: Fieldwork Course Dates Name of Fieldwork Leader Signature DateDocument5 pagesFieldwork Leader's Health and Safety Checklist: Fieldwork Course Dates Name of Fieldwork Leader Signature DateBorislav VulicNo ratings yet

- (00 41 01) - Steuerbescheinigung - Deklaration - 21916278 - 319137 - 25Document3 pages(00 41 01) - Steuerbescheinigung - Deklaration - 21916278 - 319137 - 25Borislav VulicNo ratings yet

- Dvprogram State Gov Application AspxDocument1 pageDvprogram State Gov Application AspxBorislav VulicNo ratings yet

- Streetsweeper Main TCH KLSTDocument1 pageStreetsweeper Main TCH KLSTBorislav VulicNo ratings yet

- Job Safety Analysis FormDocument1 pageJob Safety Analysis FormBorislav VulicNo ratings yet

- Job Hazard Analysis Elevator Mechanic and Lead 7 2017Document6 pagesJob Hazard Analysis Elevator Mechanic and Lead 7 2017Borislav VulicNo ratings yet

- Kundan KumarDocument2 pagesKundan KumarBorislav VulicNo ratings yet

- MHW Pid-740-Vu221-Mec-001Document1 pageMHW Pid-740-Vu221-Mec-001Borislav VulicNo ratings yet

- Power Cable FundamentalsDocument1 pagePower Cable FundamentalsBorislav VulicNo ratings yet

- Policy or Procedure For Rules & Regulation Register For ISO 1Document2 pagesPolicy or Procedure For Rules & Regulation Register For ISO 1Borislav VulicNo ratings yet

- 001 HSE Induction (Rev.02-Final)Document26 pages001 HSE Induction (Rev.02-Final)Borislav VulicNo ratings yet

- Questions - AnswersDocument19 pagesQuestions - AnswersBorislav VulicNo ratings yet

- JobDocument42 pagesJobBorislav VulicNo ratings yet

- Auto Updated HSSE DASH BOARDDocument132 pagesAuto Updated HSSE DASH BOARDBorislav VulicNo ratings yet

- 01 July 2022 Gulf Job Vacancies NewspaperDocument113 pages01 July 2022 Gulf Job Vacancies NewspaperBorislav VulicNo ratings yet

- Chemical Safety Sheets ChemicalDocument1,064 pagesChemical Safety Sheets ChemicalBorislav VulicNo ratings yet

- Chemicals Hazard - Basics AwarnessDocument53 pagesChemicals Hazard - Basics AwarnessBorislav VulicNo ratings yet

- 4 Post Lift MaintenanceDocument4 pages4 Post Lift MaintenanceBorislav VulicNo ratings yet

- ChemicalsafetyDocument12 pagesChemicalsafetyBorislav VulicNo ratings yet

- Chemical StorageDocument38 pagesChemical StorageBorislav VulicNo ratings yet

- Harness Inspection Checklist: CommentsDocument1 pageHarness Inspection Checklist: CommentsBorislav VulicNo ratings yet

- Chemical Handling 1Document25 pagesChemical Handling 1Borislav VulicNo ratings yet

- Developing A Landscaping Lawn Maintenance Safety ProgramDocument134 pagesDeveloping A Landscaping Lawn Maintenance Safety ProgramBorislav VulicNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)