Professional Documents

Culture Documents

VAL 045 Impact Assessment For Computerised Systems Sample

VAL 045 Impact Assessment For Computerised Systems Sample

Uploaded by

Leyvert De JesusOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VAL 045 Impact Assessment For Computerised Systems Sample

VAL 045 Impact Assessment For Computerised Systems Sample

Uploaded by

Leyvert De JesusCopyright:

Available Formats

Standard Operating Procedure

Title: Impact Assessment for Computerised Systems

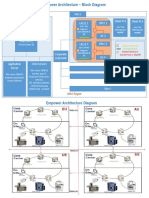

An illustration of the structure of a Computerised System is the following Finishing Line PLC:

Master Packing Line PLC SCADA interface for Line

Item Monitoring.

Operator Panel

Packing Line PLC (internal) Functions:-

Servo Drives Various

1. Control line operation i.e., pad

printing.

Vision System 2. Monitor quality functions, i.e.,

Vision system, Leak testers,

Inspection.

Printers

3. Track rejects and eject using shift

System Related

register.

Boundary Items

Inkjet Printer

4. Calculate reject statistics.

5. Detect alarm conditions.

Leak Testers

3. Criticality Assessment (Quality Impact)

Validation is concerned with assuring that our manufacturing processes, activities and systems

deliver product that reliably meets quality standards. Product Quality attributes are Identity, Safety,

Efficacy, Purity, and Evidence. Examples of quality characteristics are shown in the table in Section

10. Consideration of the significance of electronically records generated may influence the Criticality

Assessment, as outlined in Section 11.

3.1. Direct Impact

Impact Assessments look individually at the Items within Computerised Systems to evaluate the

affect of their Functions on product quality.

The following list of questions assess whether an Item/Function has a “Direct Impact” on the quality

of a product/process or integrity of stored data.

(If the answer to any question is “YES” the Item/Function has Direct Impact.)

The Criteria below should be used to assist in formulating a judgement based on the

comprehensive understanding of the product, process and the nature of the system. They

should NOT be used to replace the exercise of professional judgment by appropriately

qualified personnel.

1. Is the Item used to demonstrate compliance with the registered process?

2. Will the normal operation or control by the Item have a direct effect on the product/process

quality, (including ingredients and product components)?

3. Will failure of the Item or its alarms have a direct effect on product quality or efficacy?

4. Is information from this Item recorded as part of batch record, lot release data, or other GMP

related documentation?

5. Does the Item control critical process functions that may affect product quality (and there is

Copyright©www.gmpsop.com. All rights reserved

Unauthorized copying, publishing, transmission and distribution of any part of the content by electronic

means are strictly prohibited. Page 4 of 19

Standard Operating Procedure

Title: Impact Assessment for Computerised Systems

to lower levels should be assessed on the basis of their GAMP rating however their

interaction with higher levels within the Item must also be considered.

Note that the Data level has no GAMP rating. If this level however, has a GMP role it may

determine the overall Impact of the system (i.e. Direct). Examples of ratings for various

types of records are shown in Section 11. Data layers with GMP Impact require control

measures to preserve their documentation attributes (i.e. accuracy, authenticity, availability

and integrity). These control measures should be recorded on the Impact Assessment form

and included in the Validation Plan.

5. Overall Risk-Profile Classification

Combine the Impact rating and GAMP category to determine a Validation strategy (C number):

Impact Assessment (Criticality)

No Impact Indirect Impact Direct Impact

on GXP Functions on GXP Functions on GXP Functions

No impact on the Items that may affect the Items that have a direct

performance or performance or operation of effect on the

operation of GxP other Items which have performance or

GAMP Category Functions Direct Impact on GxP operation of GxP

(Complexity) Functions Functions

C1 C1 C1

1. Operating

systems Validation: Validation: Validation:

Record Version & Record Version & GEP Record Version & GEP

GEP Functional Functional Functional

C1 C1 C2 Validation:

2. Firmware

(Instruments Validation: Validation:

and controllers) Record Version & Record Version & GEP Record Configuration

GEP Functional Functional and Version No & GEP

Functional

C1 C2 Validation: C3 Validation:

3. Standard

packages Validation:

Record Version & Record Configuration and Minimal Functional

GEP Functional Version No & GEP

Functional

4. Configurable

packages C2 Validation: C3 Validation: C4 Validation:

Record Configuration Minimal Functional Some Functional

and Version No &

GEP Functional Minimal Structural

5. Custom-built

C3 Validation: C4 Validation: C5 Validation:

Minimal Functional Some Functional Extensive

Minimal Structural Functional

Extensive Structural

Copyright©www.gmpsop.com. All rights reserved

Unauthorized copying, publishing, transmission and distribution of any part of the content by electronic

means are strictly prohibited. Page 8 of 19

Standard Operating Procedure

Title: Impact Assessment for Computerised Systems

the site can be reduced. Tests recorded on protocols developed by suppliers do not require

copying to site formats (so long as the content is appropriate). Conversely, where there is

reason to be concerned about the assurance provided by a supplier, additional testing and

input by the site may be necessary. For maximum benefit, any extra involvement from the

site should be provided as early as possible within the Development Lifecycle.

Other Compliance Requirements. Where assurance of software performance is required for

other reasons (e.g. compliance with EHS regulations) additional testing might be

considered. Such testing may utilise the formats and structures of Validation protocols, as

appropriate.

8. Qualification

As shown in Figure 6.1, the overall qualification of the Computerised System would be comprised of

the activities of validation corresponding to the categories of the individual Items, once the criticality

and the complexity of the Items are established (refer to section 5.0).

8.1. Good Engineering Practices

All systems, regardless of their Quality Impact, are to be supplied and developed in

accordance with Good Engineering Practices (GEP). For many systems there will be no

separate requirement for Validation and GEP alone is sufficient. Evidence of GEP includes:

Developments are designed or specified against agreed requirements

Competent personnel (including contractors) are selected for the task

Full consideration is given to EHS, Operating, Maintenance and Standards requirements

Completed works are inspected, tested, commissioned and recorded appropriately.

The “GEP-alone” approach does not imply an absence of documentation; rather there is a

reduced need for review and approval of this documentation by Quality Assurance

personnel.

8.2. Structural Verification

Structural verification involves inspection and assessment of the actual source code by a

suitably qualified person (who is not the programmer). Documentation used to support

verification include logic diagrams, description of modules, definitions of all variables and

specification of all inputs and outputs. Structural verification is used to assess:

1. General application of good programming standards and practices. Some programming

practices are known to be associated with operational failures, or to hamper ongoing

maintenance. Depending on the software being programmed, the following are

examples of issues that might be verified:

code layout is logical and the flow is easy to follow, including adequate comments that

aid understanding by others who may need to maintain it in the future,

dead code and open-loops have been removed or commented out,

variables are sensibly named,

confounding special values are excluded e.g. divide by zero or square root of a negative

number,

operations with invalid or missing data are prevented (e.g. by checking for empty strings,

correct data type, values within limited range),

parameters are initialised to a known value prior to use to prevent unexpected results,

the program operates safely when abnormal (error) conditions occur,

invalid, illegal or adverse conditions such as alarms, alerts, errors and hardware failures,

are identified and highlighted to the user in a way that allows appropriate response,

databases and fields are correctly indexed,

Copyright©www.gmpsop.com. All rights reserved

Unauthorized copying, publishing, transmission and distribution of any part of the content by electronic

means are strictly prohibited. Page 13 of 19

You might also like

- V Model - GampDocument2 pagesV Model - GampNitin KashyapNo ratings yet

- CSV SopDocument1 pageCSV SopjeetNo ratings yet

- Computer System Validation Risk Assessment ToolDocument3 pagesComputer System Validation Risk Assessment Toolcpkakope100% (1)

- MS 21 CFR Part 11 RequirementsDocument8 pagesMS 21 CFR Part 11 RequirementsmagtrolNo ratings yet

- Technical Document Review: Gamp Good Practice Guide: Calibration ManagementDocument6 pagesTechnical Document Review: Gamp Good Practice Guide: Calibration ManagementHassan HoudoudNo ratings yet

- SOP For Computer System Validation in Pharmaceutical IndustryDocument8 pagesSOP For Computer System Validation in Pharmaceutical IndustryDeepakNo ratings yet

- FDA and Industry Collaboration On Computer Software AssuranceDocument56 pagesFDA and Industry Collaboration On Computer Software AssuranceNitin Kashyap100% (5)

- V Model - GampDocument2 pagesV Model - GampNitin KashyapNo ratings yet

- 21 Questions On 21 CFR Part 820Document2 pages21 Questions On 21 CFR Part 820Nitin KashyapNo ratings yet

- Iq/Oq: Iq/Oq For Vaisala Viewlinc Monitoring System Page 1 of 161Document23 pagesIq/Oq: Iq/Oq For Vaisala Viewlinc Monitoring System Page 1 of 161Nitin KashyapNo ratings yet

- Inventobox InstructionsDocument3 pagesInventobox InstructionsAsep JamaludinNo ratings yet

- Val 045Document7 pagesVal 045drs_mdu48No ratings yet

- Computersystemsvalidation BlogspotDocument7 pagesComputersystemsvalidation BlogspotNitin KashyapNo ratings yet

- Process Control Systems GAMP 5 Software CategoriesDocument4 pagesProcess Control Systems GAMP 5 Software CategoriesApoloTrevinoNo ratings yet

- Sequence of Activities Status Timelines/Key Challenges Computer System Validation For SAP S/4 HANADocument5 pagesSequence of Activities Status Timelines/Key Challenges Computer System Validation For SAP S/4 HANASourav Ghosh DastidarNo ratings yet

- Presentation Track Trace Jan 2017Document24 pagesPresentation Track Trace Jan 2017OdunlamiNo ratings yet

- 21CFRPart11Compliance PDFDocument36 pages21CFRPart11Compliance PDFFachrurroziAs100% (1)

- GAMP 5 A Risk Based Approach To A Risk BDocument29 pagesGAMP 5 A Risk Based Approach To A Risk BLia LiawatiNo ratings yet

- Risk Profile of The SystemDocument7 pagesRisk Profile of The SystemAbhijeetNo ratings yet

- ECA Computerised System Validation GAMP 5 ApproachDocument6 pagesECA Computerised System Validation GAMP 5 ApproachHanan NoussaNo ratings yet

- Computer Validation StandardsDocument21 pagesComputer Validation Standardssaidvaret100% (1)

- CO - CSA - AgilentDocument19 pagesCO - CSA - AgilentAK Agarwal100% (1)

- GMPAnnex 11 ChecklistDocument11 pagesGMPAnnex 11 Checklistosamakamel1No ratings yet

- SOP of URS 1657011596Document5 pagesSOP of URS 1657011596Huỳnh Ngọc SángNo ratings yet

- 1.GxP Assessment Document of SCADA System FormDocument9 pages1.GxP Assessment Document of SCADA System FormFurquan KhanNo ratings yet

- 21CFR11 Assessment FAQ Metler Toledo STAREDocument51 pages21CFR11 Assessment FAQ Metler Toledo STAREfurqan.malikNo ratings yet

- Urs For Erp Ex 2Document37 pagesUrs For Erp Ex 2AbhijeetNo ratings yet

- Validation - DataPro 3 FullDocument642 pagesValidation - DataPro 3 FullroooyyNo ratings yet

- Gamp5 For Basic Training PDFDocument47 pagesGamp5 For Basic Training PDFVimlesh Kumar PandeyNo ratings yet

- Computer System Validation: Embedding Quality Into Automated ProcessesDocument29 pagesComputer System Validation: Embedding Quality Into Automated ProcessesMohamed KamalNo ratings yet

- Applying GAMP 5 To Validate An ERP System: by Stephen R. FerrellDocument7 pagesApplying GAMP 5 To Validate An ERP System: by Stephen R. FerrellRahmat DennyNo ratings yet

- GS002-T02 Computer System Validation Checklist v4.0Document2 pagesGS002-T02 Computer System Validation Checklist v4.0prakashNo ratings yet

- FORM-000249181 DI Equipment Software Pre-Assessment QuestionnaireDocument3 pagesFORM-000249181 DI Equipment Software Pre-Assessment QuestionnaireSebastian LopezNo ratings yet

- Gamp 5Document5 pagesGamp 5vignan50No ratings yet

- Electronic Batch Recording: Kevin Walls Senior Solutions ConsultantDocument68 pagesElectronic Batch Recording: Kevin Walls Senior Solutions ConsultantFaress RabiNo ratings yet

- VAL 135 Risk Assessment For Computer Validation Systems Sample - SandraDocument3 pagesVAL 135 Risk Assessment For Computer Validation Systems Sample - SandraSandra Silva100% (1)

- Data Integrity Checklist: S. No. Question Response (Yes, No, N/A) Impact Mitigation PlanDocument2 pagesData Integrity Checklist: S. No. Question Response (Yes, No, N/A) Impact Mitigation PlanCarolina TarifNo ratings yet

- Vision and Validation White Paper PDFDocument47 pagesVision and Validation White Paper PDFQC SriprasitNo ratings yet

- Wayahead System ValidationDocument41 pagesWayahead System Validationpate malabananNo ratings yet

- GAMP Overview Presentation 04-03-2012 FINALDocument59 pagesGAMP Overview Presentation 04-03-2012 FINALhigunjNo ratings yet

- Caliber Ilims Features Flipbook PDF - CompressDocument34 pagesCaliber Ilims Features Flipbook PDF - CompressTanaspohorn KaokaewNo ratings yet

- SAP CFR Part11Document62 pagesSAP CFR Part11Seha Gulbaba0% (1)

- A Study of Computerized System ValidationDocument12 pagesA Study of Computerized System ValidationTenzin Tashi100% (1)

- EMA Work Instruction For Trackwise PDFDocument8 pagesEMA Work Instruction For Trackwise PDFantonygamalpharmaNo ratings yet

- Gamp StandardsDocument6 pagesGamp Standardszaman_rafiqNo ratings yet

- 02 Validation PlanDocument14 pages02 Validation PlanQcNo ratings yet

- Empower ArchitectureDocument2 pagesEmpower ArchitecturePinaki ChakrabortyNo ratings yet

- ISPE Paper On Glass - Robert HarrisonDocument5 pagesISPE Paper On Glass - Robert HarrisonrobertharrisonNo ratings yet

- FastVal User Requirement Template PDFDocument6 pagesFastVal User Requirement Template PDFViệt ThắngNo ratings yet

- Audit Computer SystemsDocument11 pagesAudit Computer SystemsROJI LINANo ratings yet

- PQE - General Principles of CVSDocument30 pagesPQE - General Principles of CVSDra CupuNo ratings yet

- 05 Risk AssessmentDocument12 pages05 Risk AssessmentQcNo ratings yet

- LIMS For Lasers 2015 User ManualDocument188 pagesLIMS For Lasers 2015 User Manualcharles_0814No ratings yet

- Lims Vs Elns: Arch Enemies or Best of Friends?Document5 pagesLims Vs Elns: Arch Enemies or Best of Friends?rajramarv007No ratings yet

- Overview of Validation Documents and ProjectsDocument5 pagesOverview of Validation Documents and ProjectsMD Fahad MiajiNo ratings yet

- Standard Operating Procedure: Restricted Circulation (Draft)Document4 pagesStandard Operating Procedure: Restricted Circulation (Draft)mkm969No ratings yet

- SAP System Validation and Compliance Methodologies For Pharma CompaniesDocument2 pagesSAP System Validation and Compliance Methodologies For Pharma Companiestahirzzia0% (1)

- Computerized Systems Periodic Review: QA Manager - IT ValidationsDocument4 pagesComputerized Systems Periodic Review: QA Manager - IT ValidationsMaruf RasselNo ratings yet

- Computer System Validation in The Perspective of TDocument7 pagesComputer System Validation in The Perspective of Tttugce29No ratings yet

- Data Integrity and Compliance: A Primer for Medical Product ManufacturersFrom EverandData Integrity and Compliance: A Primer for Medical Product ManufacturersNo ratings yet

- Final 9 (51 To 56)Document54 pagesFinal 9 (51 To 56)Ali HamzaNo ratings yet

- Computer - System - Validation - An - Integral - Part - For - Effective - Laboratory - Automation - Service 2Document12 pagesComputer - System - Validation - An - Integral - Part - For - Effective - Laboratory - Automation - Service 2Nitin KashyapNo ratings yet

- Thinking Cap 21 CFR AssessmentDocument5 pagesThinking Cap 21 CFR AssessmentNitin KashyapNo ratings yet

- Validation of COTS Using Single Life Cycle Approach - RD McDowallDocument15 pagesValidation of COTS Using Single Life Cycle Approach - RD McDowallNitin KashyapNo ratings yet

- 4541 PDFDocument372 pages4541 PDFNitin Kashyap100% (2)

- 21 CFR 11 Compliance - WatersDocument12 pages21 CFR 11 Compliance - WatersNitin KashyapNo ratings yet

- Gap Analysis & Risk AssessmentDocument47 pagesGap Analysis & Risk AssessmentKevin Thomas100% (2)

- A Road Map To: Computer System ValidationDocument29 pagesA Road Map To: Computer System ValidationNitin KashyapNo ratings yet

- Guide To CFR Part 11Document8 pagesGuide To CFR Part 11Nitin KashyapNo ratings yet

- ECA Annex11 CompSysDocument6 pagesECA Annex11 CompSysNitin KashyapNo ratings yet

- Ranbaxy Case StudyDocument12 pagesRanbaxy Case StudyNitin KashyapNo ratings yet

- Article Ejbps Volume 2 June Issue 3 1433741132Document25 pagesArticle Ejbps Volume 2 June Issue 3 1433741132Nitin KashyapNo ratings yet

- Praxis CSV BasicsDocument17 pagesPraxis CSV BasicsNitin KashyapNo ratings yet

- GSM Based Patient Health Monitoring SystemDocument16 pagesGSM Based Patient Health Monitoring SystemNazmeen BanuNo ratings yet

- Explain Plan Document 1616894.1Document17 pagesExplain Plan Document 1616894.1terry.woganNo ratings yet

- ASAM XCP Part3 Transport Layer Specification XCPonFlexRay V1 1 0Document44 pagesASAM XCP Part3 Transport Layer Specification XCPonFlexRay V1 1 0张敏健No ratings yet

- BIORITMODocument4 pagesBIORITMO159357456No ratings yet

- Defining Custom Rules For Use in Sap WorkflowDocument3 pagesDefining Custom Rules For Use in Sap WorkflowdbedadaNo ratings yet

- Kali Linux Windows Penetration Testing Free Ebooks PDF - pdf-1Document4 pagesKali Linux Windows Penetration Testing Free Ebooks PDF - pdf-1Andrés Quishpe CastroNo ratings yet

- Kotlin For Android DevelopmentDocument61 pagesKotlin For Android DevelopmentFrancois LagrangeNo ratings yet

- Dell Inspiron 13 7373 2-In-1Document3 pagesDell Inspiron 13 7373 2-In-1Jason CandelariaNo ratings yet

- Lab 2aDocument17 pagesLab 2aDhananjay ThakurNo ratings yet

- User Manual c3 AM0047Document38 pagesUser Manual c3 AM0047Jeff WuNo ratings yet

- Secu5101 Computer Forensics & Cybercrime 08-09Document11 pagesSecu5101 Computer Forensics & Cybercrime 08-09David MusokeNo ratings yet

- Sick Station A 22112017Document41 pagesSick Station A 22112017jorgeNo ratings yet

- Fndprog Part 12Document27 pagesFndprog Part 12Jm CruzNo ratings yet

- REL 350 Instruction ManualDocument234 pagesREL 350 Instruction ManualYrene De Jesus Alvarez VasquezNo ratings yet

- Bear Hug V2 1Document4 pagesBear Hug V2 1Elias AlvanNo ratings yet

- Data Storage Tech and Networks Bits PilaniDocument20 pagesData Storage Tech and Networks Bits PilaniflibionacciNo ratings yet

- ABB 800xa Minerals Library GuideDocument95 pagesABB 800xa Minerals Library Guideman_y2k100% (1)

- Overture v25 Installation Instructions On A Ubuntu 14.04Document15 pagesOverture v25 Installation Instructions On A Ubuntu 14.04SangeetSouravSunderroyNo ratings yet

- History of Computers MCQDocument2 pagesHistory of Computers MCQSuresh Khanal100% (2)

- Hands-On Radio - Power Supply Analysis - N0AXDocument2 pagesHands-On Radio - Power Supply Analysis - N0AXAnonymous Kti5jq5EJINo ratings yet

- Omnikey 5025 CL Reader Ds enDocument2 pagesOmnikey 5025 CL Reader Ds engroovey9040No ratings yet

- OpenStack PDFDocument323 pagesOpenStack PDFMalena Silva Lorenzo100% (1)

- CM530 CENSE™ Module Fault and Trend Log Maintenance and Settings For High Horsepower Lean-Burn Gas (HHP LBNG) EnginesDocument11 pagesCM530 CENSE™ Module Fault and Trend Log Maintenance and Settings For High Horsepower Lean-Burn Gas (HHP LBNG) EnginesMuhammad SohailNo ratings yet

- Smart Mirror-Digital Magazine For University Implemented Using Raspberry PiDocument4 pagesSmart Mirror-Digital Magazine For University Implemented Using Raspberry PiNiroshma RajNo ratings yet

- 3056100Document13 pages3056100Grigoriy YefimovichNo ratings yet

- A Bibliography On Blind Methods For IdenDocument11 pagesA Bibliography On Blind Methods For IdenSrilakshmi VNo ratings yet

- Asc Ts SP 300 AtsDocument12 pagesAsc Ts SP 300 AtsSutarjo9No ratings yet

- Plano Elec LetorneauDocument80 pagesPlano Elec LetorneauJonathan Zavala EsparzaNo ratings yet

- CSC 201-Lecture 7Document21 pagesCSC 201-Lecture 7pavanilNo ratings yet