Professional Documents

Culture Documents

Acar 1

Uploaded by

FAUSTO JAVIER ZAPA PEREZOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Acar 1

Uploaded by

FAUSTO JAVIER ZAPA PEREZCopyright:

Available Formats

ACAR

Aluminum Conductor. Aluminum Alloy Reinforced. Bare.

APPLICATIONS

Used as bare overhead transmission cable and as primary and secondary distribution cable. A good strength-to-weight ratio

makes ACAR applicable where both ampacity and strength are prime considerations in line design; for equal weight, ACAR

offers higher strength and ampacity than ACSR.

SPECIFICATIONS

Southwire's ACAR bare conductor meets or exceeds the following ASTM specifications:

• B230 Aluminum 1350-H19 Wire for Electrical Purposes.

• B398 Aluminum-Alloy 6201-T81 Wire for Electrical Purposes.

• B524 Concentric-Lay-Stranded Aluminum Conductors, Aluminum-Alloy Reinforced (ACAR, 1350/6201).

CONSTRUCTION

Aluminum 1350-H19 wires, concentrically stranded about an aluminum-alloy 6201-T81 core. Although the alloy strands

generally comprise the core of the conductor, in some constructions they are distributed in layers throughout the aluminum

1350-H19 strands.

Tue Sep 10 14:23:31 EDT 2013 Page 1 of 2

ACAR

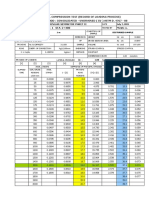

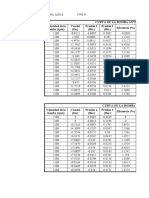

Size Strand- Diameter (ins.) Weight Rated Resistance Allowable

(kcmil) ing Per Strength OHMS/1000 ft. Ampacity+

(EC/6201) 1000 ft. (lbs.) (Amps)

Individual Wires Comp. (lbs.) DC @ AC @

Cable 20°C 75°C

6201 1350

355.0 12/7 0.1367 0.1367 0.683 332.1 8500 .0514 .0624 519

465.9 12/7 0.1566 0.1566 0.783 435.8 11000 .0392 .0477 616

503.6 12/7 0.1628 0.1628 0.814 471.1 11900 .0362 .0441 646

653.1 12/7 0.1854 0.1854 0.927 611.0 15400 .0279 .0342 760

739.8 30/7 0.1414 0.1414 0.990 692.7 15300 .0240 .0296 831

739.8 18/19 0.1414 0.1414 0.990 691.6 18800 .0252 .0308 814

853.7 30/7 0.1519 0.1519 1.063 799.3 17500 .0208 .0257 907

853.7 18/19 0.1519 0.1519 1.063 798.0 21500 .0218 .0268 890

927.2 30/7 0.1583 0.1583 1.108 868.2 19000 .0192 .0238 955

927.2 18/19 0.1583 0.1583 1.108 866.7 23400 .0201 .0247 936

1024.5 30/7 0.1664 0.1664 1.165 959.3 20900 .0173 .0216 1015

1024.5 18/19 0.1664 0.1664 1.165 957.7 25800 .0182 .0225 995

1081.0 30/7 0.1709 0.1709 1.196 1012.1 22100 .0164 .0205 1048

1081.0 18/19 0.1709 0.1709 1.196 1010.5 27200 .0172 .0213 1028

1109.0 30/7 0.1731 0.1731 1.212 1038.4 22700 .0160 .0200 1065

1109.0 18/19 0.1731 0.1731 1.212 1036.6 27900 .0168 .0208 1044

1172.0 30/7 0.1780 0.1780 1.246 1097.3 24000 .0152 .0190 1101

1172.0 18/19 0.1780 0.1780 1.246 1095.5 29500 .0159 .0198 1080

1197.0 30/7 0.1799 0.1799 1.259 1120.8 24500 .0148 .0187 1115

1197.0 18/19 0.1799 0.1799 1.259 1118.9 30200 .0156 .0194 1094

1280.0 30/7 0.1860 0.1860 1.302 1198.5 26200 .0139 .0175 1160

1280.0 18/19 0.1860 0.1860 1.302 1196.5 32200 .0146 .0182 1139

1361.0 42/19 0.1494 0.1494 1.344 1273.6 30300 .0133 .0168 1196

1527.0 42/19 0.1582 0.1582 1.424 1428.8 33600 .0118 .0151 1314

1703.0 42/19 0.1671 0.1671 1.504 1593.5 37500 .0106 .0137 1363

1933.0 42/19 0.1780 0.1780 1.602 1808.8 42500 .00936 .0123 1465

2267.0 42/19 0.1928 0.1928 1.735 2142.0 49900 .00806 .0108 1594

2493.0 72/19 0.1655 0.1655 1.821 2356.9 50400 .00722 .0099 1687

2493.0 54/37 0.1655 0.1655 1.821 2354.5 57600 .00743 .0101 1670

+Ampacity based on 75°C conductor temperature, 25°C ambient temperature,with 2 ft./sec. wind in the sun.

Tue Sep 10 14:23:31 EDT 2013 Page 2 of 2

You might also like

- ACAR Nehring USA Data SheetDocument2 pagesACAR Nehring USA Data SheetPM PandianNo ratings yet

- Stranded Overhead Shield Wire (Ground Wire) : Product DescriptionDocument1 pageStranded Overhead Shield Wire (Ground Wire) : Product DescriptionNguyen KhoaNo ratings yet

- The Properties of AirDocument2 pagesThe Properties of AirPeter LuvisNo ratings yet

- Triaxial STA 2+575Document8 pagesTriaxial STA 2+575rismanNo ratings yet

- Triaxial STA 2+300Document8 pagesTriaxial STA 2+300rismanNo ratings yet

- Triaxial STA 2+875Document11 pagesTriaxial STA 2+875rismanNo ratings yet

- StrengthhhhDocument5 pagesStrengthhhh20212846No ratings yet

- Vdocuments - Us - Excel Curvas RemansoDocument12 pagesVdocuments - Us - Excel Curvas RemansoIsa RodriguezNo ratings yet

- Datos de Entrada: Suelo Ang de Fric. ɸ' Cohesion (C ) Kpa P.Espc. Kn/M3 P.Espc. Sat. Kn/M3 TipoDocument2 pagesDatos de Entrada: Suelo Ang de Fric. ɸ' Cohesion (C ) Kpa P.Espc. Kn/M3 P.Espc. Sat. Kn/M3 TipoPatricia Ercilia Chavez AlejandroNo ratings yet

- Size of ConductorDocument1 pageSize of ConductorGie matusNo ratings yet

- Wire Gauge - Gage Conversion ChartDocument4 pagesWire Gauge - Gage Conversion ChartDarkstarRidenow100% (1)

- A.5 Steam and Water Tables: B. G. LiptákDocument8 pagesA.5 Steam and Water Tables: B. G. LiptákjigjigawNo ratings yet

- Lab 5 - BombasDocument12 pagesLab 5 - BombasDavid Paez GonzalezNo ratings yet

- Wires and CableDocument5 pagesWires and Cablewaz zuppNo ratings yet

- Earthquake Load Calculations As Per IS1893-2002.-.: Building Xyz at Mumbai. Rev - Mar2003 HSVDocument11 pagesEarthquake Load Calculations As Per IS1893-2002.-.: Building Xyz at Mumbai. Rev - Mar2003 HSVanirudh modhalavalasaNo ratings yet

- Viaduct - Superstructures: Pc-Box Type, Straight, Double Track L 40m, W 10.6mDocument12 pagesViaduct - Superstructures: Pc-Box Type, Straight, Double Track L 40m, W 10.6mPisey2014No ratings yet

- Seccion Circular Repaso Vapm 6cbDocument19 pagesSeccion Circular Repaso Vapm 6cbserviciosmbalderasNo ratings yet

- StrengthhhDocument5 pagesStrengthhh20212846No ratings yet

- Gauge Vs Current PDFDocument2 pagesGauge Vs Current PDFRnDES1 CML100% (1)

- TSDist03 CabosCapac 2015Document21 pagesTSDist03 CabosCapac 2015Felipe Savieto AcorsiNo ratings yet

- Earthquake Load Calculations As Per IS1893-2002.-: Building Xyz at Mumbai. Rev - Mar2003 HSVDocument9 pagesEarthquake Load Calculations As Per IS1893-2002.-: Building Xyz at Mumbai. Rev - Mar2003 HSVeco protectionNo ratings yet

- Earthquake Load Calculations As Per IS1893-2002.-: Building Xyz at Mumbai. Rev - Mar2003 HSVDocument9 pagesEarthquake Load Calculations As Per IS1893-2002.-: Building Xyz at Mumbai. Rev - Mar2003 HSVEr Rakesh SharmaNo ratings yet

- Calculation Spread SheetDocument9 pagesCalculation Spread SheetHitesh GajeraNo ratings yet

- AAAC - All Aluminum Alloy ConductorDocument5 pagesAAAC - All Aluminum Alloy ConductoralejandraNo ratings yet

- How To Convert AWG To MMDocument3 pagesHow To Convert AWG To MManamulk_1No ratings yet

- Earthquake Load Calculations As Per IS1893-2002.-: Building Xyz at Mumbai. Rev - Mar2003 HSVDocument8 pagesEarthquake Load Calculations As Per IS1893-2002.-: Building Xyz at Mumbai. Rev - Mar2003 HSVNAYAN RANPURANo ratings yet

- ch9t8 PDFDocument1 pagech9t8 PDFReimart H BornilloNo ratings yet

- Earthquake Load Calculations As Per IS1893-2002.-: Building Xyz at Mumbai. Rev - Mar2003 HSVDocument8 pagesEarthquake Load Calculations As Per IS1893-2002.-: Building Xyz at Mumbai. Rev - Mar2003 HSVJobert CajayonNo ratings yet

- How To Convert AWG To MM: Wire Diameter CalculationDocument2 pagesHow To Convert AWG To MM: Wire Diameter CalculationYousif_Abdalhalim0% (1)

- Plastic Moment Capacity - RevisedDocument19 pagesPlastic Moment Capacity - RevisedVishal NalwarNo ratings yet

- AAAC 6201 Type A3 IEC61089Document1 pageAAAC 6201 Type A3 IEC61089Proteksitrans1 p3bsNo ratings yet

- Earthquake Load Calculations As Per IS1893-2002.-: Building Xyz at Mumbai. Rev - Mar2003 HSVDocument8 pagesEarthquake Load Calculations As Per IS1893-2002.-: Building Xyz at Mumbai. Rev - Mar2003 HSVanirudh modhalavalasaNo ratings yet

- AERO3000 Equation ListDocument19 pagesAERO3000 Equation ListlalalallkjdlfjlkNo ratings yet

- A.5 Steam and Water Tables: © 2003 by Béla LiptákDocument8 pagesA.5 Steam and Water Tables: © 2003 by Béla LiptákMazarel AurelNo ratings yet

- Copper Cable Tech. DetailsDocument8 pagesCopper Cable Tech. DetailsDaya CheluvaNo ratings yet

- Sistema Estructural de Tres Capas (Jones)Document4 pagesSistema Estructural de Tres Capas (Jones)Andrés VacaNo ratings yet

- U1 Seccion CircularDocument31 pagesU1 Seccion CircularserviciosmbalderasNo ratings yet

- Steel Gauge ThicknessDocument4 pagesSteel Gauge ThicknessLaplaceFourierNo ratings yet

- AWG To Mmmm2 ConversionDocument2 pagesAWG To Mmmm2 ConversionTanvir ChowdhuryNo ratings yet

- American Wire GaugeDocument3 pagesAmerican Wire Gaugeعلي القحطانيNo ratings yet

- EQ Base ShearDocument9 pagesEQ Base Shearnazeer_mohdNo ratings yet

- Fractional Inches To MM - BWDocument2 pagesFractional Inches To MM - BWHenrique MarquesNo ratings yet

- Round Tubes Irrigation and Rectangular TubesDocument4 pagesRound Tubes Irrigation and Rectangular TubesSushilkumarNo ratings yet

- The Relative NMR Sensitivity of Nucleus at Constant Magnetic FieldDocument4 pagesThe Relative NMR Sensitivity of Nucleus at Constant Magnetic FieldSaurav PaulNo ratings yet

- 148 Size Reduction Comp SimulationDocument34 pages148 Size Reduction Comp SimulationJoyce VicenteNo ratings yet

- A.5 Steam and Water Tables: © 2002 by Béla G. LiptákDocument8 pagesA.5 Steam and Water Tables: © 2002 by Béla G. LiptákramkrishnaNo ratings yet

- Earthquake Load Calculations As Per IS1893-2002.-: Building Xyz at Mumbai. Rev - Mar2003 HSVDocument9 pagesEarthquake Load Calculations As Per IS1893-2002.-: Building Xyz at Mumbai. Rev - Mar2003 HSV4geniecivilNo ratings yet

- Aluminum Conductor CharacteristicsDocument7 pagesAluminum Conductor CharacteristicsHew LetNo ratings yet

- Al Wire DataDocument1 pageAl Wire DataBhushan KalgaonkarNo ratings yet

- Steel ShapesDocument25 pagesSteel ShapesAly Arquillano JrNo ratings yet

- Metodo Euler Mejorado G2Document11 pagesMetodo Euler Mejorado G2Pavel CayojaNo ratings yet

- Babcock & Wilcox Steam TablesDocument5 pagesBabcock & Wilcox Steam Tablesnum0067No ratings yet

- Triaxal MutikDocument114 pagesTriaxal MutikMuhammad RaflyNo ratings yet

- Compressible Flow TableDocument9 pagesCompressible Flow TableLp SaiNo ratings yet

- ACCC Conductor List 2019 v1.6Document6 pagesACCC Conductor List 2019 v1.6Mauricio MoralesNo ratings yet

- LevitationDocument5 pagesLevitationcdsiegertNo ratings yet

- Tablas Distri ELT3751 PDFDocument7 pagesTablas Distri ELT3751 PDFFreddy Lopez GonzalesNo ratings yet

- H-Pile Design 1518Document22 pagesH-Pile Design 1518Danny LamNo ratings yet

- United States Census Figures Back to 1630From EverandUnited States Census Figures Back to 1630No ratings yet

- Technical Tables for Schools and Colleges: The Commonwealth and International Library Mathematics DivisionFrom EverandTechnical Tables for Schools and Colleges: The Commonwealth and International Library Mathematics DivisionNo ratings yet

- 2 C 64Document5 pages2 C 64Joglo SoloNo ratings yet

- Quality Assurance Plan For Battery ChargerDocument3 pagesQuality Assurance Plan For Battery ChargerGnanavel GNo ratings yet

- Exp 7 - Induction Motors PDFDocument3 pagesExp 7 - Induction Motors PDFgnathblNo ratings yet

- MC34063ADocument7 pagesMC34063AnhthucdtvtNo ratings yet

- 3a SCR TRIACDocument46 pages3a SCR TRIACFAZRI RENDI KURNIAWANNo ratings yet

- SSL 4K Capacitors BOM 1.1bDocument1 pageSSL 4K Capacitors BOM 1.1bpiretto77No ratings yet

- Tech. Specification For Battery ChargerDocument22 pagesTech. Specification For Battery ChargerPramod B.Wankhade100% (1)

- Case Study - How Maintenance Team Saved A Power TransformerDocument4 pagesCase Study - How Maintenance Team Saved A Power Transformerravi singhNo ratings yet

- EarthDocument2 pagesEarthxs1zameenNo ratings yet

- 2500 CryptoDocument14 pages2500 CryptoinsulatedNo ratings yet

- Earthing and TestingDocument5 pagesEarthing and TestingdestawNo ratings yet

- Motorbook Chapter4 PDFDocument36 pagesMotorbook Chapter4 PDFKraponis TylnessNo ratings yet

- Powerpoint ELK-3 - 420 - ApparatusDocument39 pagesPowerpoint ELK-3 - 420 - ApparatusMahmoud MoezNo ratings yet

- ZESA Nov-2020-Tariff-LeafletDocument1 pageZESA Nov-2020-Tariff-LeafletSimon SamNo ratings yet

- Unit2l1s PDFDocument20 pagesUnit2l1s PDFJack CardiagNo ratings yet

- GuitarDocument3 pagesGuitarMauroFariasNo ratings yet

- Equipment Interconnection SCF & Cantilever Strength Analysis For Rigid BusDocument16 pagesEquipment Interconnection SCF & Cantilever Strength Analysis For Rigid BusSamant SauravNo ratings yet

- EEC 233 TheoryDocument75 pagesEEC 233 TheoryAdeniji Olusegun100% (8)

- Distributed GenerationDocument293 pagesDistributed GenerationReza Foroozan100% (4)

- S11 Electric ComponentsDocument72 pagesS11 Electric ComponentsLiliana Rebeca Santos santosNo ratings yet

- High Voltage EngineeringDocument27 pagesHigh Voltage EngineeringPrakash ParajuliNo ratings yet

- SC4541 Rev.2.1Document19 pagesSC4541 Rev.2.1Akhil GargNo ratings yet

- HCCM System Technical Specification v1Document12 pagesHCCM System Technical Specification v1Ankita ChowdhuryNo ratings yet

- SPE Transformer Inrush Presentation 1 PDFDocument14 pagesSPE Transformer Inrush Presentation 1 PDFgilbertomjcNo ratings yet

- Rg510a Manual ServiceDocument68 pagesRg510a Manual Servicelalocisco4209No ratings yet

- Equivalencing The Collector System of A Large Wind Power Plant (1-4244-0493-206 ©2006 IEEE)Document9 pagesEquivalencing The Collector System of A Large Wind Power Plant (1-4244-0493-206 ©2006 IEEE)Nico StroiliNo ratings yet

- D3200 Barrier ManualDocument14 pagesD3200 Barrier Manualspaceman1972No ratings yet

- Sigurante Ultrarapide SIEMENS - TehnicDocument90 pagesSigurante Ultrarapide SIEMENS - TehnicHapa MaricicaNo ratings yet

- 01 Luzon-Committed 0Document4 pages01 Luzon-Committed 0mokop18924No ratings yet

- Sensor Magnetico MWDocument1 pageSensor Magnetico MWCharlesNo ratings yet