Professional Documents

Culture Documents

Ramag HT80

Uploaded by

Karima ABOUALICopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ramag HT80

Uploaded by

Karima ABOUALICopyright:

Available Formats

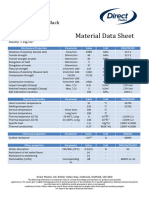

Ramag HT80 Monolithic

TS LFD00409 MX0 MOLD Refractory

Product Information

Revision: B.01 Date: 30 Aug 2007

Hearth ramming material for use in EAF applications.

3

Service Temperature: 1750 °C Material Required: 2500 kg/m

Typical Water Required: -% Maximum Grain Size: 6.0 mm

Bulk Density As Rammed: 2580 kg/m3 Loose Fill Density: 2240 kg/m3

Chemical Analysis

SiO2 Al2O3 Fe2O3 CaO MgO

0.9 0.5 4.0 14.1 80.0

Typical Physical Properties Tested in accordance with International and European Standards

Prefired Bulk Cold Cold Permanent

to Density Crushing Strength Modulus of Rupture Linear Change

3 2 2

(°C) (kg/m ) (N/mm ) (N/mm ) (%)

1600 2850 - - -4.0

Other Physical Properties Tested in accordance with International and European Standards

Prefired Apparent Thermal Hot Permanent

to Porosity Conductivity Modulus of Rupture Volume Change

2

(°C) (%) (W/m.K) (N/mm ) (%)

1600 18.1 - - -

Formerly:

Drying & Firing: N/A Installation Method: N/A Mixing / Installation: N/A

Shotcreting: N/A Pumping: N/A MSDS Reference: LFD00409

The physical and/or chemical properties and specifications of the product set forth above represent typical average results obtained in

accordance with generally accepted standard test methods conducted under controlled conditions, and are subject to normal

manufacturing variations. Vesuvius reserves the right to modify the properties and specifications at any time without prior notice.

NO WARRANTY IS EXPRESSED OR IMPLIED REGARDING THE ACCURACY OF THIS INFORMATION, THE SUITABILITY OF THE

PRODUCT FOR A PARTICULAR PURPOSE, OR THE RESULTS TO BE OBTAINED BY THE USE OF THE PRODUCT. USERS

EXPRESSLY ASSUME ALL RISKS AND LIABILITIES ARISING FROM THE USE OF OR RELIANCE UPON THIS INFORMATION.

You might also like

- Triad HCDocument1 pageTriad HCalexiq05No ratings yet

- ASM Material Data SheetDocument2 pagesASM Material Data Sheetducchinh080No ratings yet

- Ramlox 311Document1 pageRamlox 311rivrsideNo ratings yet

- TDS BluramDocument1 pageTDS BluramRiesky FirdyanNo ratings yet

- Bluram HSDocument1 pageBluram HSAndrew JacksonNo ratings yet

- Pei 0270 RTP 2183Document2 pagesPei 0270 RTP 2183Vincent NguyenNo ratings yet

- Chem-Bonded Castables: Product DataDocument1 pageChem-Bonded Castables: Product DataJavier Hinojosa Garrido LeccaNo ratings yet

- 316 Stainless Steel, Annealed SheetDocument2 pages316 Stainless Steel, Annealed SheetZASSNo ratings yet

- BF Runner Mix 20 MT VesuviusDocument3 pagesBF Runner Mix 20 MT VesuviusSaumit PalNo ratings yet

- 316 Stainless Steel, Anneal...Document3 pages316 Stainless Steel, Anneal...Moisés Vázquez ToledoNo ratings yet

- Criterion 85XLDocument1 pageCriterion 85XLwongpengchiong7205No ratings yet

- Brayco Micronic™ SV/B: DescriptionDocument5 pagesBrayco Micronic™ SV/B: DescriptionAlfonsus W.M.No ratings yet

- 410 Stainless SteelDocument2 pages410 Stainless Steelargo_arjieantoNo ratings yet

- Nominal Composition Standard Inventory SpecificationsDocument2 pagesNominal Composition Standard Inventory SpecificationsPramuda SirodzNo ratings yet

- ALTECH ABS C 2017/500 GF17: Technical Data SheetDocument1 pageALTECH ABS C 2017/500 GF17: Technical Data SheetarmandoNo ratings yet

- Ensinger Tecapeek® CF30 Polyetheretherketone, 30% Carbon Reinforced (PEEK)Document2 pagesEnsinger Tecapeek® CF30 Polyetheretherketone, 30% Carbon Reinforced (PEEK)Arthur EmidioNo ratings yet

- SECCO S2040: Polypropylene, HomopolymerDocument2 pagesSECCO S2040: Polypropylene, HomopolymerManuel LopezNo ratings yet

- RTP 2500 FR ADocument2 pagesRTP 2500 FR ASoopNo ratings yet

- UHMW-PE Tivar 1000Document2 pagesUHMW-PE Tivar 1000centurion2988No ratings yet

- PP Gf30 - Suplen v30 LCDocument2 pagesPP Gf30 - Suplen v30 LCarmandoNo ratings yet

- Heatbrake 508-G: Technical Data SheetDocument1 pageHeatbrake 508-G: Technical Data SheetBernardo HoffmannNo ratings yet

- Comprit 185H 0 6Document1 pageComprit 185H 0 6Ahmed AbdelhamidNo ratings yet

- ASM Material Data Sheet 316Document2 pagesASM Material Data Sheet 316.xNo ratings yet

- r2000 Fr3 Data Sheet - 10-21Document8 pagesr2000 Fr3 Data Sheet - 10-21Dirt FilterNo ratings yet

- RGF33NATURALDocument1 pageRGF33NATURALCassianNo ratings yet

- Blu Ram HSDocument1 pageBlu Ram HSM Roy HaqiqiNo ratings yet

- Productcatalog Eastman Com Tds ProdDatasheet Aspx Product 71097791 PN Turbo Oil 2197 Ga 2 203238289 1466225733 1606728244 1342979021 1606728244Document2 pagesProductcatalog Eastman Com Tds ProdDatasheet Aspx Product 71097791 PN Turbo Oil 2197 Ga 2 203238289 1466225733 1606728244 1342979021 1606728244KostiantynNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetihscribedNo ratings yet

- RTP 102 Polypropylene (PP) Glass Fiber: Product Data Sheet & General Processing ConditionsDocument1 pageRTP 102 Polypropylene (PP) Glass Fiber: Product Data Sheet & General Processing ConditionsarmandoNo ratings yet

- Radiflam A Rv250 Af 375 BK: Product InformationDocument3 pagesRadiflam A Rv250 Af 375 BK: Product InformationLucas Valentim MendesNo ratings yet

- Eastma Turbo Oil 2197 TDSDocument2 pagesEastma Turbo Oil 2197 TDSstoreairkgNo ratings yet

- Nylon 6Document1 pageNylon 6luuiissNo ratings yet

- Radilon A Cp300K 333 BK: Product InformationDocument4 pagesRadilon A Cp300K 333 BK: Product InformationmuthuNo ratings yet

- c95500 Spec SheetDocument2 pagesc95500 Spec SheetOrnella MancinelliNo ratings yet

- Ecopond PBATDocument3 pagesEcopond PBATsoniud14No ratings yet

- 316-SS-annealed Bar and Cold DrawnDocument2 pages316-SS-annealed Bar and Cold DrawnARUNKANNANNo ratings yet

- Data Sheet DS Cast 50AR NM: General InformationsDocument1 pageData Sheet DS Cast 50AR NM: General InformationsJCSNo ratings yet

- SABIC® HDPE - P6006AD - Global - Technical - Data - SheetDocument2 pagesSABIC® HDPE - P6006AD - Global - Technical - Data - SheetThouraya Hbs100% (1)

- Aero HF 585 BDocument2 pagesAero HF 585 Bnauta007No ratings yet

- Hojas TécnicasDocument2 pagesHojas TécnicasalejandrocharlescollNo ratings yet

- Apc-2 Peek 031912-01Document6 pagesApc-2 Peek 031912-01Angel LagrañaNo ratings yet

- TDS - Megalon® 150GHSLDocument1 pageTDS - Megalon® 150GHSLshawnNo ratings yet

- Product Technical Data Sheet: Unit Value MethodDocument2 pagesProduct Technical Data Sheet: Unit Value Methodhamza OUADINo ratings yet

- ALTECH ABS A 2020/100 GF20: Technical Data SheetDocument1 pageALTECH ABS A 2020/100 GF20: Technical Data SheetarmandoNo ratings yet

- Ficha Tecnica Additive 201 BiosphereDocument3 pagesFicha Tecnica Additive 201 BiospherePaola Andrea Miranda RuedaNo ratings yet

- Hyosung Topilene J740 PPDocument2 pagesHyosung Topilene J740 PPEmmylouCasanovaNo ratings yet

- 01ML0030 ES-08009 - C - Especificação de MPDocument2 pages01ML0030 ES-08009 - C - Especificação de MPRafah1212No ratings yet

- General Description: Coupling: Yellow, Yellow, Orange Pipe Body: Yellow, Yellow, OrangeDocument5 pagesGeneral Description: Coupling: Yellow, Yellow, Orange Pipe Body: Yellow, Yellow, OrangesunnyNo ratings yet

- TDS - MT 950 - enDocument2 pagesTDS - MT 950 - enTo RaNo ratings yet

- Styrolution TDS400900250546Document2 pagesStyrolution TDS400900250546prabhat singhNo ratings yet

- Aluminium A380Document1 pageAluminium A380Ashokkumar VelloreNo ratings yet

- ABS Terlux 2802 TR - Fiche Technique enDocument2 pagesABS Terlux 2802 TR - Fiche Technique endamien_roule5728No ratings yet

- Monel 400 / UNS N44000 / DIN 2.4360: Industrial Piping ProductsDocument3 pagesMonel 400 / UNS N44000 / DIN 2.4360: Industrial Piping ProductsSamkitNo ratings yet

- Polimaxx 1102K Product Data Sheet 1 1Document1 pagePolimaxx 1102K Product Data Sheet 1 1Kaleb Rido ManurungNo ratings yet

- Polimaxx 1102K Product Data Sheet 1 1Document1 pagePolimaxx 1102K Product Data Sheet 1 1Kaleb Rido ManurungNo ratings yet

- Aluminum 5052Document6 pagesAluminum 5052lalfredoperezNo ratings yet

- Astm Lupol gp3156f - EngDocument2 pagesAstm Lupol gp3156f - EngYo ANo ratings yet

- Technical Data Sheet - ASTMDocument2 pagesTechnical Data Sheet - ASTMwida acNo ratings yet

- CE222 PREFINAL Exam QuestionnairesDocument3 pagesCE222 PREFINAL Exam QuestionnairesMike Clint John SantaanNo ratings yet

- E680-79 (2011) E1 Standard Test Method For Drop Weight Impact Sensitivity of Solid-Phase Hazardous MaterialsDocument8 pagesE680-79 (2011) E1 Standard Test Method For Drop Weight Impact Sensitivity of Solid-Phase Hazardous MaterialsMohamedNo ratings yet

- Es2c6 15 2020Document6 pagesEs2c6 15 2020Mesafint kassieNo ratings yet

- Math 070838Document13 pagesMath 070838Jeric Boy GarampilNo ratings yet

- Feedback ReviewerDocument5 pagesFeedback ReviewerRafael AclanNo ratings yet

- Wave Optics 2023 New NotesDocument9 pagesWave Optics 2023 New NotesAman PrajapatiNo ratings yet

- 10.wave Optics. Byju'sDocument223 pages10.wave Optics. Byju'sSureka100% (1)

- 6 - Experimental Study On The Determination of Strength of Masonry WallsDocument13 pages6 - Experimental Study On The Determination of Strength of Masonry WallsroccaNo ratings yet

- Autodyn Theory ManualDocument235 pagesAutodyn Theory ManualAndre OliveiraNo ratings yet

- SensMat D3.4 M8 Vfinal PDFDocument29 pagesSensMat D3.4 M8 Vfinal PDFcarlos houngbemeNo ratings yet

- Bearing Pressure & DisplacementsDocument36 pagesBearing Pressure & DisplacementsRajveer SinghNo ratings yet

- Dental BiomaterialsDocument491 pagesDental Biomaterialsaris100% (1)

- Lab ReportDocument3 pagesLab ReportmahiraNo ratings yet

- RTO and Scrubber Set Point and Alarm List (29.07.19)Document5 pagesRTO and Scrubber Set Point and Alarm List (29.07.19)JemeraldNo ratings yet

- Mpi 11 4 19Document1 pageMpi 11 4 19qc_531040655No ratings yet

- Bs 1377 5pdfDocument40 pagesBs 1377 5pdfToihir ben abdou salimNo ratings yet

- AIATS JEE (A) 2023 Test-2A P-1 (Code-A) 30-01-2022 Sol.Document24 pagesAIATS JEE (A) 2023 Test-2A P-1 (Code-A) 30-01-2022 Sol.KESSAVAN.M ECE20No ratings yet

- Strength Lab Report (Exp 2) Update 1Document14 pagesStrength Lab Report (Exp 2) Update 1Syafiq RonaldoNo ratings yet

- 6.1 Homework-Areas Between Curves (Homework) : 11:59 PM PDTDocument20 pages6.1 Homework-Areas Between Curves (Homework) : 11:59 PM PDTJaselle Namuag0% (1)

- UTILITIES Pugeda Quiz 19 Sound WaveDocument3 pagesUTILITIES Pugeda Quiz 19 Sound Waveklikbayt0.1No ratings yet

- Hob SelectionDocument4 pagesHob SelectionVikas ChauhanNo ratings yet

- BA-10A - BA-10AL Bonding Agent 052412Document1 pageBA-10A - BA-10AL Bonding Agent 052412EdgarJimenezNievesNo ratings yet

- UNIT-3 Illumination System: Lecture Videos On YoutubeDocument7 pagesUNIT-3 Illumination System: Lecture Videos On YoutubeLavanya LakshmiNo ratings yet

- Tutorial Letter 101/0/2019: Opto-Electronics IV (Theory)Document19 pagesTutorial Letter 101/0/2019: Opto-Electronics IV (Theory)Vandiksha MaharajNo ratings yet

- Stratocell Brochure D-148 10-2017Document4 pagesStratocell Brochure D-148 10-2017Carlos GamioNo ratings yet

- Bonding MOTDocument51 pagesBonding MOTA. F. M. Mahfuzul KabirNo ratings yet

- 5 Displacement and Force in Two Dimensions: 2 FrictionDocument5 pages5 Displacement and Force in Two Dimensions: 2 Frictionalex murker100% (1)

- Fluid Mechanics Notes by TVK Sir DTU PDFDocument10 pagesFluid Mechanics Notes by TVK Sir DTU PDFBhoopesh JorwalNo ratings yet

- Economy of Pakistan EssayDocument6 pagesEconomy of Pakistan Essayafhbgaohb100% (2)

- Physics Definitions, Laws and PrinciplesDocument22 pagesPhysics Definitions, Laws and Principleskaziba stephen100% (1)