Professional Documents

Culture Documents

Sistemas de Control de Calidad de Polines

Uploaded by

milo ,milo0 ratings0% found this document useful (0 votes)

7 views3 pagesThis document discusses quality control systems for conveyor rollers. It describes various inspection methods for rollers, including testing waterproofness and dust proofness by running rollers in an ash testing device. It also describes testing service life by operating rollers under load for over 600 hours and measuring the damage rate. Additional tests described include measuring rotary resistance, radial runout, and axial displacement. The document also provides background information on TianjinChengke Transmission Mechanical and Electrical Engineering Co., Ltd, the manufacturer of the rollers, noting their experience, facilities, quality control systems, and testing equipment.

Original Description:

sistema control de calidad polines

Original Title

SISTEMAS DE CONTROL DE CALIDAD DE POLINES

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses quality control systems for conveyor rollers. It describes various inspection methods for rollers, including testing waterproofness and dust proofness by running rollers in an ash testing device. It also describes testing service life by operating rollers under load for over 600 hours and measuring the damage rate. Additional tests described include measuring rotary resistance, radial runout, and axial displacement. The document also provides background information on TianjinChengke Transmission Mechanical and Electrical Engineering Co., Ltd, the manufacturer of the rollers, noting their experience, facilities, quality control systems, and testing equipment.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views3 pagesSistemas de Control de Calidad de Polines

Uploaded by

milo ,miloThis document discusses quality control systems for conveyor rollers. It describes various inspection methods for rollers, including testing waterproofness and dust proofness by running rollers in an ash testing device. It also describes testing service life by operating rollers under load for over 600 hours and measuring the damage rate. Additional tests described include measuring rotary resistance, radial runout, and axial displacement. The document also provides background information on TianjinChengke Transmission Mechanical and Electrical Engineering Co., Ltd, the manufacturer of the rollers, noting their experience, facilities, quality control systems, and testing equipment.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

SISTEMAS DE CONTROL DE CALIDAD DE POLINES

http://www.roller.com.tw/about_quality.asp?gclid=CM_qiKiso84CFQwEkQodp-AINw

http://www.roller.com.tw/about_quality.asp

SISTEMAS DE DISEÑO DE POLINES

http://www.roller.com.tw/rd.asp

NUEVAS TECNOLOGIAS EN POLINES (SOLDADURA EN POLINES; SISTEMAS DE TRACCION EN

POLINES)

http://www.roller.com.tw/products_list.asp?seq=17

SISTEMAS DE INSPECCION EN POLINES

http://chengke-transmission.en.made-in-china.com/product/JKNQeBaybnpv/China-Conveyor-

Roller-Conveyor-Pulley-Roller-Conveyor.html

inspections devices

Way of shop inspection

Name of inspection Way of inspection Necessary performance

After 200h operation of ash device

the ahs inflow in the grease should

not exceed 0.5%(0.8% in

Put the roller in the testing device MT/T665-1997; after 200

of coal ash and raining and run by operation of raining device, water

Waterproof and dust proof

motor at the speed of 1450r/min inflow should not exceed

100g( 120g in MT/T665-1997)

Apply the imported roller

strengthened service life platform; The normal service life of a roller

install the roller in a sealed is 30000-50000h, damage rate

container with a 2.25 times of

actual operational load. Run the within effective period should not

roller by motor at a 3 times of exceed 8%( In GB/T10595-2009,

actual operational speed. Suspend the service should be not less than

Service life 1h after operating for 5h, the total 30000h and the damage rate shoul

operation time should not be less not be less than 10%)

than 600h.

Run the roller on the testing

platform at the speed of 1450r/min

Shop inspection<=0.010

continuously for 15minutes. And

In operation<=0.020

put it in the environment of 20-

Comply with GB990-91,MT821-

25ºC for 2h, and test the rotary

2006,

Rotary resistance resistance in accordance with the

GB/T10595-2009

normal speed and load.

<= 0.5mm( roller

length<=550mm)

Rotate the roller for one circle on <=0.6mm(roller length>550-

the radial runout platform, measure 950mm)

the runout value in three axial <=1.0mm( roller length>950-

Radial runout position and consider the max. 1600mm)

<=1.3mm(roller length>1600-

2400mm)

Measured value<0.4mm,

After installation, put 500N axial

In national standard, the value

Axial displacement load on the shaft end of the roller

is <=0.7mm

About TianjinChengke Transmission Mechanical and Electrical Engineering

Co., Ltd

Chengke was established in 2000, 15 years of designing and manufacturing

experiences in material handling industry. Now we have 100 - 200 full time

employees, Registered Capital: RMB 30,000,000, we have 3 subsidiaries: one

is specialized in providing dust removal solutions to customers and the

other is dedicated in supplying conveyor maintenance tools and the third is

specialized in developing status and temperature monitoring products. We

have more that 30 engineers. We have passed ISO9001:2008 certification in

2012 and obtained CE certificate for belt conveyor system. It takes only 1

hour from our company to Tianjin port and 30min to Beijing.

Chengke has been dedicated in designing, manufacturing and supplying belt

conveyors for 15 years for hundreds of domestic and overseas clients since

2000. There are two roller and pulley production lines in our workshop, we

have two steel structure manufacture factory in Tangshan and Foshan.

Quality is the life of our company and products, we have a series of roller

inspection devices to ensure roller quality, such as rotating resistance, radial

runout, axial movement, dust-proof &water-proof tests etc.

You might also like

- Purificacion de Aceite de Transformador ZYDDocument34 pagesPurificacion de Aceite de Transformador ZYDTonny Laulate MelgarejoNo ratings yet

- Payment Lot w1-5 PDFDocument1 pagePayment Lot w1-5 PDFIfin Eebbaa TaatooNo ratings yet

- ISO Standard Vibration Severity ChartsDocument4 pagesISO Standard Vibration Severity ChartsSUNIL TV100% (1)

- Chapter 3Document22 pagesChapter 3Fatiaa Nffz100% (1)

- 660III ImprovementsDocument20 pages660III Improvementsaugusto100% (1)

- Manual MCD 500 DanffossDocument13 pagesManual MCD 500 DanffossCristian QuinteroNo ratings yet

- How To Change The WorldDocument106 pagesHow To Change The Worldalejo.gaviriaNo ratings yet

- VG Power Turbo Rotor BalancingDocument6 pagesVG Power Turbo Rotor BalancingmersiumNo ratings yet

- Design of Roller Contact BearingDocument60 pagesDesign of Roller Contact BearingJatin ChaudhariNo ratings yet

- 001305012941Document3 pages001305012941RAJEEV MAHESHWARINo ratings yet

- UTM CatalogDocument6 pagesUTM CatalogAsmita AcharyaNo ratings yet

- TM-ZT1004H: ModelDocument5 pagesTM-ZT1004H: ModelKormandi KDANo ratings yet

- 6HI Reversible Cold Rolling 1350 MM, 550 MPM: Client: PLASTOCHEM India Pvt. LTDDocument58 pages6HI Reversible Cold Rolling 1350 MM, 550 MPM: Client: PLASTOCHEM India Pvt. LTDSANTOSH TIWARINo ratings yet

- Chinese Centrifuge LW450x1000 Centrifuge ManualDocument34 pagesChinese Centrifuge LW450x1000 Centrifuge ManualNurlan Valiyev100% (1)

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- SAC2500S: SANY All Terrain Crane 250 Tons Lifting CapacityDocument16 pagesSAC2500S: SANY All Terrain Crane 250 Tons Lifting CapacityRohit GhuseNo ratings yet

- TM-ZT1005H S G PDFDocument5 pagesTM-ZT1005H S G PDFEdwardhutaurukNo ratings yet

- PU LPH 80540 80553 Esite GBDocument7 pagesPU LPH 80540 80553 Esite GBAl-Alamiya TradeNo ratings yet

- JnbncjcerbjerbDocument1 pageJnbncjcerbjerbFedericoNo ratings yet

- Fokleradio 1Document1 pageFokleradio 1FedericoNo ratings yet

- Applicable Standards & Test Methods Dynamic Test Brake Life Static Load Test Impact Test Brake EffectivenessDocument1 pageApplicable Standards & Test Methods Dynamic Test Brake Life Static Load Test Impact Test Brake EffectivenessFedericoNo ratings yet

- Balancing and Overspeed Facilities: Man Turbo AgDocument8 pagesBalancing and Overspeed Facilities: Man Turbo AgSaptarshi BasuNo ratings yet

- Series 100 Flange Mounted Hydraulic Dynamometers For Load Testing Aerospace EnginesDocument2 pagesSeries 100 Flange Mounted Hydraulic Dynamometers For Load Testing Aerospace Engines唐波No ratings yet

- AMAWELD Catalogue NEWDocument8 pagesAMAWELD Catalogue NEWJoshita YoNo ratings yet

- NMRVDocument13 pagesNMRVherpadianaNo ratings yet

- Turbine O&M ManualDocument83 pagesTurbine O&M ManualMohammed MuzzamilNo ratings yet

- Proact™ Itb: Integrated Actuator and Throttle Body For Large Bores (85 MM To 180 MM)Document4 pagesProact™ Itb: Integrated Actuator and Throttle Body For Large Bores (85 MM To 180 MM)JerNo ratings yet

- JJX140 Drop Box Operation ManualDocument12 pagesJJX140 Drop Box Operation ManualMohammed MostafaNo ratings yet

- NSK Product Guide - BearingsDocument5 pagesNSK Product Guide - BearingsAndiniPermanaNo ratings yet

- Boiler Coal FeederDocument9 pagesBoiler Coal FeederGilang NurdiansyahNo ratings yet

- Otary Ctuators: Sudhir 100926005 M.Tech Manufacturing TechnologyDocument34 pagesOtary Ctuators: Sudhir 100926005 M.Tech Manufacturing TechnologySudhir BhatNo ratings yet

- Combo Screen PDFDocument4 pagesCombo Screen PDFAksha NabviNo ratings yet

- Brochure Re-Refinery Thermopac PDFDocument3 pagesBrochure Re-Refinery Thermopac PDFPan Jun KimNo ratings yet

- Portable Dynamometers For Testing Aerospace Turbines: Kahn SeriesDocument4 pagesPortable Dynamometers For Testing Aerospace Turbines: Kahn SeriesEsteban Alejandro Méndez WebarNo ratings yet

- Wiz-Ec SeriesDocument13 pagesWiz-Ec SeriesJohan SneiderNo ratings yet

- A 837 eDocument2 pagesA 837 eKhalida MuddasserNo ratings yet

- Annex I-1 Process Technical and Production Capacity-Rev01Document29 pagesAnnex I-1 Process Technical and Production Capacity-Rev01jackhuguesNo ratings yet

- Samiflex CatDocument7 pagesSamiflex CatJuan Bernardo NietoNo ratings yet

- Amarinth Technical Bulletin Considerations When Installing Centrifugal Pumps To Minimise Vibration and Ensure Reliable Operation MP2616 100 RevADocument5 pagesAmarinth Technical Bulletin Considerations When Installing Centrifugal Pumps To Minimise Vibration and Ensure Reliable Operation MP2616 100 RevAAhmed mazaly100% (1)

- Spin Test: Fluxi 2000/TZDocument5 pagesSpin Test: Fluxi 2000/TZdilor19No ratings yet

- Boiler Coal FeederDocument11 pagesBoiler Coal FeederUrej BandiolaNo ratings yet

- VTM-3000-WB at Cadia Procemin PresentationDocument23 pagesVTM-3000-WB at Cadia Procemin PresentationJD FCNo ratings yet

- 85,000 Barrels Every Day!: 8L-912Y Series Standard Product SpecificationsDocument6 pages85,000 Barrels Every Day!: 8L-912Y Series Standard Product SpecificationsManuel GimenezNo ratings yet

- Ir Turbo-Air-6000 A4Document6 pagesIr Turbo-Air-6000 A4Aris Fitama ZeinauraNo ratings yet

- Twin Disc 7600 Transmission SpecsDocument16 pagesTwin Disc 7600 Transmission SpecsQM EQUIPMENTNo ratings yet

- Top Drive 750 Product SheetDocument2 pagesTop Drive 750 Product SheetMehdi SoltaniNo ratings yet

- Boiler Coal FeederDocument11 pagesBoiler Coal FeederIndra PratamaNo ratings yet

- GP180-120 Suplemental InstructionsDocument20 pagesGP180-120 Suplemental InstructionsyenivNo ratings yet

- Vibration Pen TV200/220/260: Technical SpecificationsDocument1 pageVibration Pen TV200/220/260: Technical SpecificationsDeepakNo ratings yet

- Lotte M7100Document1 pageLotte M7100Chu ChuNo ratings yet

- QHD Service ManualDocument8 pagesQHD Service ManualMaximus MaxisNo ratings yet

- MS50095 - 08E ScheduleDocument33 pagesMS50095 - 08E Scheduletrainingcenter eurasiancmNo ratings yet

- YKK Series of High-Voltage Three-Phase Induction Motors Products CatalogDocument17 pagesYKK Series of High-Voltage Three-Phase Induction Motors Products CatalogAgustinus Bayu Dewanto100% (1)

- Self Blocking Rail ClampsDocument18 pagesSelf Blocking Rail ClampsGogyNo ratings yet

- Details Preventive Maintenance Schedule For Electric MotorDocument8 pagesDetails Preventive Maintenance Schedule For Electric Motoralnaggar.amroNo ratings yet

- Sany Crane-Brochure SAC2200SDocument52 pagesSany Crane-Brochure SAC2200SRexNo ratings yet

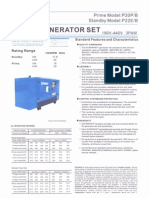

- Diesel GensetDocument4 pagesDiesel GensetErwin GunawanNo ratings yet

- Supermax 841Document8 pagesSupermax 841Fairus AdzhaNo ratings yet

- Rotex SpecDocument30 pagesRotex SpecspringkimNo ratings yet

- Corlift Hydraulic Rod Pump System Flyer EnglishDocument1 pageCorlift Hydraulic Rod Pump System Flyer EnglishFaroukNo ratings yet

- Catalog Máy Ép Phun NH ADocument5 pagesCatalog Máy Ép Phun NH ALehoang Huy100% (1)

- Cp1200hoists ManualDocument3 pagesCp1200hoists Manualabdul0% (1)

- Market StructureDocument3 pagesMarket StructurePranjal TiwariNo ratings yet

- GOOD Local Government Elections 2021 ManifestoDocument8 pagesGOOD Local Government Elections 2021 ManifestoHerald LIVENo ratings yet

- Class 12 Eco Unit Test 2 2021-22Document13 pagesClass 12 Eco Unit Test 2 2021-22Ayush MishraNo ratings yet

- Digital Banking and Alternative SystemsDocument31 pagesDigital Banking and Alternative SystemsRameen ZafarNo ratings yet

- Laporan Cit Harian 2021-2022Document198 pagesLaporan Cit Harian 2021-2022mas sudarsonoNo ratings yet

- 4 Classical Theory of The Interest RateDocument28 pages4 Classical Theory of The Interest RateAYUSHI PATELNo ratings yet

- Swot Analysis of AssetsDocument8 pagesSwot Analysis of Assetsshinjan bhattacharyaNo ratings yet

- External Commercial BorrowingDocument19 pagesExternal Commercial BorrowingparthNo ratings yet

- Topics Covered: Does Debt Policy Matter ?Document11 pagesTopics Covered: Does Debt Policy Matter ?Tam DoNo ratings yet

- Kristen Case SolutionDocument3 pagesKristen Case SolutionMayank JoshiNo ratings yet

- Telenor Pakistan Annual ReportDocument116 pagesTelenor Pakistan Annual ReportHusnain Rasheed0% (2)

- Goolsbee Micro CH15Document4 pagesGoolsbee Micro CH15Carlos García SandovalNo ratings yet

- Ertman, Thomas. Birth of The Leviathan Building States and Regimes in Medieval and Early Modern Europe. Cambridge Cambridge University Press, 1997.Document7 pagesErtman, Thomas. Birth of The Leviathan Building States and Regimes in Medieval and Early Modern Europe. Cambridge Cambridge University Press, 1997.HippiasNo ratings yet

- HS1340Document2 pagesHS1340Prarabdha SharmaNo ratings yet

- Bba Sem Iv All AssignmentDocument5 pagesBba Sem Iv All AssignmentYogeshNo ratings yet

- NeuroShell Forex SystemDocument8 pagesNeuroShell Forex SystemNuha IslamNo ratings yet

- Bachelor in Business Administration (Hons) FINANCE (BA242) : Future Trading Plan (FTP)Document26 pagesBachelor in Business Administration (Hons) FINANCE (BA242) : Future Trading Plan (FTP)Muhammad FaizNo ratings yet

- Aeromexico AMXEES 2022 11 07 HUX-YVR ALLDocument4 pagesAeromexico AMXEES 2022 11 07 HUX-YVR ALLlina perezNo ratings yet

- Dubai-Based Flowershop - Ae Launches Bitcoin PaymentsDocument3 pagesDubai-Based Flowershop - Ae Launches Bitcoin PaymentsPR.comNo ratings yet

- Maximum Social AdvantageDocument18 pagesMaximum Social AdvantageMehak KaushikkNo ratings yet

- Market Microstructure and Strategies: Financial Markets and Institutions, 7e, Jeff MaduraDocument41 pagesMarket Microstructure and Strategies: Financial Markets and Institutions, 7e, Jeff MaduraMaulanaNo ratings yet

- Jane JacobsDocument1 pageJane JacobsTaty Cerrato de JorqueraNo ratings yet

- FVE, InV, 03 NOV, Philippe RobertDocument1 pageFVE, InV, 03 NOV, Philippe RobertLife As Poor ArtistsNo ratings yet

- Metal Mining (19121066)Document7 pagesMetal Mining (19121066)Shivani ChoudharyNo ratings yet

- NCR NegoSale Batch 15157 032023Document30 pagesNCR NegoSale Batch 15157 032023DV ShopNo ratings yet

- Resolution-1-Barangay OrdinanceDocument1 pageResolution-1-Barangay OrdinanceMarlyn PadongNo ratings yet