Professional Documents

Culture Documents

ETS Connection Requirements-Indirect

Uploaded by

Ahm AnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ETS Connection Requirements-Indirect

Uploaded by

Ahm AnCopyright:

Available Formats

TABREED

ENERGY TRANSER STATIONS (E.T.S)

Indirect connection via heat exchanger

ETS CONNECTION TECHNICAL GUIDE

TABREED Revision 8

INTRODUCTION

PURPOSE

This guide will discuss the scope of work, and technical requirements of connecting to the

Energy Transfer Station(s) (herein referred to as ETS).

ETS CONNECTION TECHNICAL GUIDE Page 2 of 8

TABREED Revision 8

THE ENERGY TRANSFER STATION

GENERAL

1.1.1 District Cooling

A. Cooling is to be provided for the building via the site-wide district cooling system

provided by(Tabreed).Tabreed will deliver chilled water at the design temperatures

specified under “Technical Requirements – General Conditions” to the CUSTOMER

(building ), subject to the scope of work and the district cooling technical

requirements outlined in this document. The piping connection will be discussed in

this document and is as shown on the attached schematic. The place of connection

will be surveyed and approved by Tabreed and is referred to herein as the Energy

Transfer Station

B. The District Cooling Water System (DCWS) will be designed and installed by

Tabreed complete with primary PHE’S and all monitoring and controls associated

with the main (DCWS). The terminal point between the (DCWS) provider and

building system is the PHE’S hot side connection only. Tabreed requirements for

monitoring the building system to be as per attached schematic diagram

C. Tabreed will provide one metering station for each ETS room on tabreed side only.

D. The Energy Transfer Station (ETS) plant space to be as per Tabreed requirements

E. Configuration and arrangements of Tabreed PHE’S and Tabreed piping work will be

designed& constructed &supervised and approved by Tabreed as per Tabreed

requirements and specifications

F. Configuration and arrangements of building side equipments and piping will be

designed by the building designer as per Tabreed requirements and constructed

under the building contract

G. All works associated with the construction of tunnels, ducts, sleeves or trenches to

accommodate District Cooling Water mains between the Energy Transfer Station

and Plot Boundary shall be designed by the building designer as per Tabreed

requirements and constructed under the building contract to the approval of the

DCWS provider (Tabreed).

H. The District cooling pipe work will utilize Pre-insulated carbon-steel

I. Building system maximum working pressures shall be provided by the building

designer to Tabreed: to allow Tabreed to identify the pressure rating for Tabreed

PHE’S

ETS CONNECTION TECHNICAL GUIDE Page 3 of 8

TABREED Revision 8

SCOPE OF WORK

The scope or limit of work of Tabreed and that of our CUSTOMER is defined as per the

attached schematics. Tabreed CUSTOMER are kindly advised to adhere to the following

design requirements to ensure successful implementation of District Cooling.

TABREED SCOPE OF WORK

1- Tabreed will supply & install the heat exchanger and all required piping connection from

Tabreed’s side as per attached schematic.

2- All industrial controls and automation, including programmable logical controller (PLC),

instrumentation and wiring as per this guide and attached schematic.

THE CUSTOMER SCOPE OF WORK (Building Side )

1- To provide 3 phase electric power supply to the ETS. 50A

2- A water supply line of 1 1/4” (32 mm) is required for filling the customer side piping

system and as a make up for the required pressurization / expansion pump set tank.

3- Drain Connection to the nearest external manhole.

4- Modify (if necessary & where applicable) and install all piping, insulation and valves on

the CUSTOMER (building) side of the ETS, as per the attached schematic.

5- Supply and install the variable speed pumps for distribution.

6- Supply and install pressurization / expansion tank pumps sets.

7- To supply and install one or two number differential pressure transmitters usually located

across the far end chilled water pipes of an air handling unit utilizing a 2-way modulating

motorized valve. The customer should wire this transmitter(s) to the plantroom PLC.

8- Supply and install a motor control center (MCC) in the electric room that incorporates:

a) Main Circuit Breaker.

b) Variable Frequency drives for the chilled water pumps.

c) Capacitor banks for power correction.

d) Distribution Board (DB) for ETS room lighting and receptacles.

ETS CONNECTION TECHNICAL GUIDE Page 4 of 8

TABREED Revision 8

9- Supply and install two numbers Temperature Transmitter on the Chilled Water mains as

per attached schematic.

10- Tabreed CUSTOMER to furnish and install Chilled water treatment system including

manual feed chemicals dozing pot with the necessary rust inhibitors and biocides quantity

necessary for testing, commissioning and operation. A specialized professional company

shall handle the water treatment system.

11- Install industrial grade automatic air vents (1”) at the highest point(s) in the customer’s

(building) piping system.

12- CUSTOMER (building ) will build the E.T.S and all associated civil work with the E.T.S

room, equipment bases and piping trenches

ETS CONNECTION TECHNICAL GUIDE Page 5 of 8

TABREED Revision 8

TECHNICAL REQUIREMENTS

GENERAL CONDITIONS

DISTRICT COOLING REQUIREMENT

(1)Cooling Capacity Requirement: To be confirmed by building

CONSULTANT.

(2)Pipe Connection Size: Depends on load.

(3)Design temperature diagram on Tabreed PHE

(3-1) Temperature diagram on Tabreed side (Tabreed PHE cold side) is

(A) Tabreed Supply chilled water temperature 40OF (4.44 OC)

(B) Tabreed Return chilled water temperature 56OF (13.33OC)

(3-2) Temperature diagram on Building side (Tabreed PHE hot side) is

(A) Building Supply chilled water temperature 42OF (5.56 OC)

(B) Building Return chilled water temperature 58OF (14.44OC)

Chilled water flow depends on load.

Maximum variation in Tabreed supply

Chilled water temperature is + / - 1.8OF (1.0OC)

Minimum acceptable building return chilled

Water temperature is 56OF (13.33OC)

Maximum acceptable building return chilled

Water temperature is 60OF (15.56 OC)

Pressure drop inside Tabreed PHE is 0.7 bar

Design water velocities / Pressure drops

• Pipe size 2” and smaller Min = 1.5 ft/sec, Max 4 ft /sec

• Pipe size 2 1/2” and larger Min = .75 ft / 100 ft, Max 4 ft / 100ft

Particular Requirements: How To Achieve The Above Conditions?

1- Building designer will design building air side equipment and chilled water piping using

the above chilled water temperatures .for building side

2- By designing the control system around variable flow chilled water system using two way

equal percentage control valves for all air handling units and fan coil units. Air Handling

units above 2,000 CFM shall have modulating equal percentage type. Fan Coil units with

capacity equal and smaller than 2,000 CFM can be on/off or modulating type.

3- The Air handling units and fan coil units at the end of the faraway circuits should have

three way control valves to avoid chilled water stagnation and allow for the minimum

ETS CONNECTION TECHNICAL GUIDE Page 6 of 8

TABREED Revision 8

pump flow. The number of air handling units or fan coil units designed for using three way

control valve should correspond to a maximum chilled water flow of 10% of full design

flow. The bypass on the three-way valve should have a double regulating valve to do

proper balancing and shut off of the bypass whenever the system requires that.

4- All Air handling units, Fan coil units and main branches shall have a double regulating

balancing valve with self sealing test point used for chilled water flow measurement

required during balancing and commissioning. During commissioning phase the customer

shall have a digital-measuring instrument furnished by the valve manufacturer to translate

quickly and accurately the valve pressure drop into corresponding chilled water flow.

5- Tabreed CUSTOMER to furnish and install secondary chilled water pumps. Two or

more operating and one standby pumps should be used in order to allow flow control

to vary between 10% and 100%. Pumps motors, and pump seal cooling should be

designed for variable speed operation range of 10 to 50 Hz ( 300 to 1,500 rpm). The

minimum mechanical efficiency of pump is 78% and the electric efficiency of the pump

motor is 94%. The variable speed drive efficiency should be 95% at 50 Hz (1,450 rpm),

90% at 35 Hz (1,000 rpm), 85% at 25 Hz (725 rpm) and 85% 10 Hz (300 rpm).

6- Install strainers on all AHU supply chilled water pipe.

7- Tabreed CUSTOMER are required to perform a complete and thorough flushing of their

chilled water piping network, so that at the time of connection to Tabreed’s ETS, the

client’s piping system is full of clean water and is clear from all unwanted debris.

8- Tabreed CUSTOMER are required to furnish and install VFD drives in the MCC with the

following control requirement in order to monitor them by Tabreed Programmable Logical

Controller PLC installed in the ETS room.

Analog Input 0-10V DC, input impedance 200KΩ

4-20 amps, input impedance 250Ω,

Differentially isolated external potentiometer, 0-10v dc, 1KΩ minimum

Digital Input 6- programmable positive or negative control logic

Auxiliary Supply 24V DC ± 20%, 100 mA

Reference Supply 10V DC (-0% to +3%), 10 mA

Analog Output Programmable: 0-20 mA, impedance 500Ω, resolution 10-bit, ±

3%

Digital Output 2 programmable from C Relays, 250 V AC 2 Amp, or 30V DC 2

Amp resistive. 1 programmable open collector, 48 V DC, 50mA

9- Differential Pressure Transmitter: Electronic, output: 4-20mA dc signal, linear with

differential pressure, into 1000 ohms, isolated.

ETS CONNECTION TECHNICAL GUIDE Page 7 of 8

TABREED Revision 8

10- Temperature Transmitter Output: 4-20mAdc linear with temperature into 1000 ohms,

isolated.

Recommended manufacturers for the VFDs are Allen Bradley, ABB, GE, or similar.

Recommended manufacturers for the Differential Pressure transmitter are Rosemount,

Yokogawa, E+H, Sen Sit, Dieterich, Barton or approved equal.

____________________________

ETS CONNECTION TECHNICAL GUIDE Page 8 of 8

You might also like

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- 03.SOP For Air CompressorDocument4 pages03.SOP For Air CompressorThangella Vijayaramaraju100% (2)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Technical Specification - PumpDocument7 pagesTechnical Specification - PumpBalasundaramSrinivasaRajkumarNo ratings yet

- Air Washer UnitDocument19 pagesAir Washer UnitAnonymous BbZceWkVn100% (1)

- 06-236730-001 - Kidde AEGIS Control Unit Installation Wiring Diagram, Rev AD PDFDocument1 page06-236730-001 - Kidde AEGIS Control Unit Installation Wiring Diagram, Rev AD PDFLUIS FELIPE LIZCANO MARINNo ratings yet

- Design Control Document-MVACDocument48 pagesDesign Control Document-MVACRudivic LumainNo ratings yet

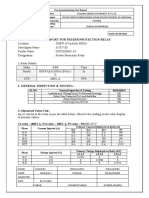

- Test Report For Feeder Protection RelayDocument3 pagesTest Report For Feeder Protection RelayHari haranNo ratings yet

- 15545-Chilled Water SystemDocument5 pages15545-Chilled Water Systemenlightened1718No ratings yet

- HVAC System Design Report Master DocumentDocument7 pagesHVAC System Design Report Master DocumentHisham MustafaNo ratings yet

- Distric Cooling Connection RegulationDocument10 pagesDistric Cooling Connection RegulationJobin JosephNo ratings yet

- ETS Design Guidelines Rev4Document69 pagesETS Design Guidelines Rev4Javed BhattiNo ratings yet

- ETS Design Guidelines - Lusai, QatarDocument30 pagesETS Design Guidelines - Lusai, Qatarpal_stephen100% (1)

- VRV Technical SpecificationDocument7 pagesVRV Technical Specificationdheerajdorlikar100% (2)

- Sample Mechanical Basis of Design For UW - Chiller SystemsDocument4 pagesSample Mechanical Basis of Design For UW - Chiller SystemsdaveleyconsNo ratings yet

- 7-Annexure 21B To TS - Heating Ventilation and Air Conditioning WorksDocument15 pages7-Annexure 21B To TS - Heating Ventilation and Air Conditioning WorkscliffrajjoelNo ratings yet

- Cooling TowersDocument11 pagesCooling Towerszarzoura001No ratings yet

- Comments On Volume 07 - Electrical DBR Rev (1) 0702 (Final) - ADocument188 pagesComments On Volume 07 - Electrical DBR Rev (1) 0702 (Final) - AdipakkupatelNo ratings yet

- Appendix 2CDocument159 pagesAppendix 2Crmm99rmm99No ratings yet

- LP Dosing AgecDocument12 pagesLP Dosing AgecShameer MajeedNo ratings yet

- Novam SeriesDocument35 pagesNovam Serieshidraulica inteligenteNo ratings yet

- Assignment MechanicalDocument5 pagesAssignment MechanicalSoufiane RamdaniNo ratings yet

- Mechanical Specifications For VillasDocument30 pagesMechanical Specifications For VillasdreamagiczNo ratings yet

- Commission HVAC SystemsDocument9 pagesCommission HVAC Systemsizzat555No ratings yet

- Mechanical and Electrical Technical Specification: For TheDocument117 pagesMechanical and Electrical Technical Specification: For TheKo Pauk100% (1)

- AED Design Requirements - Water Tanks and System Distribution - Sep09 PDFDocument23 pagesAED Design Requirements - Water Tanks and System Distribution - Sep09 PDFAvonodOiratulcNo ratings yet

- Combine Cycle Power Plant Design InformationDocument47 pagesCombine Cycle Power Plant Design Informationkalasivan0% (1)

- DFW Airport Design Criteria Manual HVAC SystemsDocument16 pagesDFW Airport Design Criteria Manual HVAC SystemsambuenaflorNo ratings yet

- Technical GuideDocument6 pagesTechnical Guidesajay2010No ratings yet

- Dubai SouthDocument2 pagesDubai SouthMarzook100% (1)

- Chilled Water Dist I But I OnDocument44 pagesChilled Water Dist I But I OnVineeth MuraleedharanNo ratings yet

- Chilled Water Distribution SystemDocument5 pagesChilled Water Distribution SystemThiru AnanthNo ratings yet

- A-ACMV SpecDocument50 pagesA-ACMV Specchong khengNo ratings yet

- Technical Specification for Air Cooled CondenserDocument7 pagesTechnical Specification for Air Cooled CondenserRajendran SrnNo ratings yet

- Installation checklist and commissioning requestDocument2 pagesInstallation checklist and commissioning requestarifzakirNo ratings yet

- TECHNICAL REQUIREMENTS FOR DHCS OPERATIONDocument12 pagesTECHNICAL REQUIREMENTS FOR DHCS OPERATIONameeri143No ratings yet

- ECBC BEE-Hotel CapitolDocument31 pagesECBC BEE-Hotel CapitolrsahayNo ratings yet

- Dartmouth College Design November 15, 2007 & Construction GuidelinesDocument4 pagesDartmouth College Design November 15, 2007 & Construction GuidelinesIndira SharanNo ratings yet

- Letter of AssociationDocument25 pagesLetter of AssociationluluNo ratings yet

- K0101 Thermal Control Design General Description and Volume ListDocument6 pagesK0101 Thermal Control Design General Description and Volume ListtrungNo ratings yet

- Power TransformerDocument17 pagesPower TransformerANANDNo ratings yet

- FINAL Salient Tech Features - DGP - 2x20 MWDocument11 pagesFINAL Salient Tech Features - DGP - 2x20 MWNaresh BalujaNo ratings yet

- Chilled Water System: Part 1: GeneralDocument3 pagesChilled Water System: Part 1: GeneralNoushad P HamsaNo ratings yet

- FF Mew Construction Specs FinalDocument250 pagesFF Mew Construction Specs FinalmaheseeeNo ratings yet

- 3149 Vol 2B-PACDocument12 pages3149 Vol 2B-PACvcasadoayesaNo ratings yet

- 3472 Vol 2b-Pac Tech.-Spec.Document123 pages3472 Vol 2b-Pac Tech.-Spec.Satadal LahiriNo ratings yet

- SpecificationDocument51 pagesSpecificationArjun VinayakumarNo ratings yet

- HVAC system for hospital and collegeDocument17 pagesHVAC system for hospital and collegeAnkush NayarNo ratings yet

- WHZ 2005 PDFDocument8 pagesWHZ 2005 PDFΓεώργιος ΠαπαδόπουλοςNo ratings yet

- AC-310 - Cooling TowerDocument5 pagesAC-310 - Cooling Towerjames_chan2178No ratings yet

- CH 11 - IrrigationDocument13 pagesCH 11 - IrrigationRohit BaliNo ratings yet

- Common Points To Blue StarDocument2 pagesCommon Points To Blue Starvenka07No ratings yet

- Va 22 33 00Document9 pagesVa 22 33 00RicardoNo ratings yet

- R011. TAEevoTech PDFDocument40 pagesR011. TAEevoTech PDFphukaifrNo ratings yet

- Scienfdgfdce Seawater SgfdgdfcientistDocument8 pagesScienfdgfdce Seawater SgfdgdfcientistAhmed MagdyNo ratings yet

- Specification No.: Heep/test-Bed/800/cws, Rev.01Document31 pagesSpecification No.: Heep/test-Bed/800/cws, Rev.01mohan babuNo ratings yet

- EQube ECBC BEE-hotel Capitol PresentationDocument31 pagesEQube ECBC BEE-hotel Capitol PresentationrsahayNo ratings yet

- 3 General DescriptionDocument6 pages3 General DescriptionAnonymous n9vKMnNo ratings yet

- 3 General DescriptionDocument6 pages3 General DescriptionAnonymous DLgalmvsxNo ratings yet

- AES Vol 2 P15007 Split AC UnitsDocument5 pagesAES Vol 2 P15007 Split AC UnitsShreejith PanickerNo ratings yet

- SECTION 23 72 00 Air-To-Air Energy Recovery EquipmentDocument9 pagesSECTION 23 72 00 Air-To-Air Energy Recovery EquipmentMoriyasuNguyenNo ratings yet

- Medidor Murphy EGS21 P y TDocument5 pagesMedidor Murphy EGS21 P y TmemocritoNo ratings yet

- Manual GrassoDocument78 pagesManual Grassolider ArancibiaNo ratings yet

- GST IFP8 Prezentare 2015 1Document111 pagesGST IFP8 Prezentare 2015 1Mohamed Abou El hassan100% (2)

- CB-334E & CB-335E Electrical System Vibratory Compactor: Machine Harness Connector and Component LocationsDocument2 pagesCB-334E & CB-335E Electrical System Vibratory Compactor: Machine Harness Connector and Component Locationsjulian guerraNo ratings yet

- Modern Power Transformer Practice2Document3 pagesModern Power Transformer Practice2amulya sNo ratings yet

- Portable Cabin Pressure Tester Under 40 CharactersDocument1 pagePortable Cabin Pressure Tester Under 40 CharactersGenaire LimitedNo ratings yet

- Types of SphygmomanometerDocument2 pagesTypes of SphygmomanometerBea AbesamisNo ratings yet

- Manual Receptor Universal 2 CanalesDocument2 pagesManual Receptor Universal 2 CanalesJabier Tres ENo ratings yet

- Quarterly Hammermill InspectionDocument3 pagesQuarterly Hammermill InspectionWilfred AlexanderNo ratings yet

- DS720i Long Range: AB CD EDocument6 pagesDS720i Long Range: AB CD EJoseph WilczekNo ratings yet

- 520l0541 PDFDocument36 pages520l0541 PDFdozer_kamilNo ratings yet

- Forged - Pipe - Fittings - ANSI - B-16.11 PDFDocument1 pageForged - Pipe - Fittings - ANSI - B-16.11 PDFImran KamalNo ratings yet

- Каталог T105Document307 pagesКаталог T105REMZONANo ratings yet

- KW903-SP: World Leaders in Marine NavigationDocument2 pagesKW903-SP: World Leaders in Marine NavigationBeneDict Ben DNo ratings yet

- Fire Panel Req.Document1 pageFire Panel Req.Amit SharmaNo ratings yet

- TestBlock - ETB-14Document8 pagesTestBlock - ETB-14rudyplNo ratings yet

- Acti9 ApplicationsGuide 2013Document68 pagesActi9 ApplicationsGuide 2013figo lordNo ratings yet

- Model 6300 M4 DatasheetDocument2 pagesModel 6300 M4 DatasheetCARLOS GUILLERMO ORNELAS MACIASNo ratings yet

- History of Electric FanDocument1 pageHistory of Electric FanAaron BautistaNo ratings yet

- BBC Assembly Instructions PDFDocument2 pagesBBC Assembly Instructions PDFdigglesMcgeeNo ratings yet

- Motor ControlDocument10 pagesMotor ControlJAE LOUISE DE ROXASNo ratings yet

- PM Schedule 2022Document109 pagesPM Schedule 2022Praveen BathulaNo ratings yet

- Electrical Work OddisaDocument45 pagesElectrical Work OddisaYusuf HungundNo ratings yet

- Fuzhou Tianyu Electric Co., LTD.: KYN31-12 Armored Metal-Enclosed Switch CabinetDocument26 pagesFuzhou Tianyu Electric Co., LTD.: KYN31-12 Armored Metal-Enclosed Switch CabinetRusman LumbantoruanNo ratings yet

- UntitledDocument210 pagesUntitledAlan Rizki HimawanNo ratings yet

- Saura Keiki Magnetic Compass Sr-165Document51 pagesSaura Keiki Magnetic Compass Sr-165leticia walkerNo ratings yet