Professional Documents

Culture Documents

Jis A 5363-2016

Jis A 5363-2016

Uploaded by

HENDRO0 ratings0% found this document useful (0 votes)

131 views29 pagesOriginal Title

JIS A 5363-2016

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

131 views29 pagesJis A 5363-2016

Jis A 5363-2016

Uploaded by

HENDROCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 29

JIS

JAPANESE

INDUSTRIAL

STANDARD

Translated and Published by

Japanese Standards Association

JIS A 5363»

(JPCC/JSA)

Precast concrete products — General

rules for methods of performance test

ICS 91.100.30:93.080.30

Reference number : JIS A 5363 : 2016 (E)

PROTECTED BY COPYRIGHT 15S

A5363 : 2016

Date of Establishment: 2001-12-20

Date of Revision: 2016-04-20

Date of Public Notice in Official Gazette: 2016-04-20

Investigated by: Japanese Industrial Standards Committee

Standards Board for ISO area

Technical Committee on Civil Engineering

JIS A 5363 : 2016, First English edition published in 2017-03,

Translated and published by: Japanese Standards Association

Mita MT Building, 3-13-12, Mita, Minato-ku, Tokyo, 108-0073 JAPAN

In the event of any doubts arising as to the contents,

the original JIS is to be the final authority

© J8A2017

Allright reserved, Unless otherwise specified no par of this publication may be reproduced or ute

in any form or by any means, electronic or mechanical, including photocopying and microfilm, without

permission in writing trom the publisher,

Printed in Japan KK/HIN

PROTECTED BY COPYRIGHT

A5363: 2016

Contents

Page

1 Scope 1

2 Normative references“ a1

3 Terms and definitions ++ 1

4 Classification of performance test methods of products “2

5 Performance of testing machine +++: sssssssescssesssessceeesestssssssseeniins a

6 Performance tests of product “8

6.1 Flexural strength test of product “3

6.2 Shear strength test of product 9

6.3 Compressive strength test of product w

6.4 Internal pressure strength test of product 12

Annex A (informative) Comparison table hetween previous and current edi-

tions of this Standard on technically significant revi-

sions «=== : 15

wo

PROTECTED BY COPYRIGHT.

A5363 : 2016

Foreword

hhis translation has been made based on the original Japanese Industrial

Standard revised by the Minister of Economy, Trade and Industry

through deliberations at the Japanese Industrial Standards Committee

as the result of proposal for revision of Japanese Industrial Standard

submitted by Japan Precast Concrete Standard Committee (JPCC)/Jap

anese Standards Association (SA) with the draft being attached, based

on the provision of Article 12 Clause 1 of the Industrial Standardization

Law applicable to the case of revision by the provision of Article 14.

Consequently JIS A 5363:2010 is replaced with this Standard.

‘This JIS document is protected by the Copyright Law.

Attention is drawn to the possibility that some parts of this Standard

may coniliet with patent rights, applications for a patent after opening to

the public or utility model rights. The relevant Minister and the Japanese

Industrial Standards Committee are not responsible for identifying any of

such patent rights, applications for a patent after opening to the public or

utility model rights.

aid

PROTECTED BY COPYRIGHT

JAPANESE INDUSTRIAL STANDARD JIS A 5363 : 2016

Precast concrete products — General rules for

methods of performance test

1 Scope

This Japanese Industrial Standard specifies the general matters of the performance

test for precast concrete products (hereafter referred to as products), which is one of

the verification methods of the performance of the said products, However, this Stand-

ard is not applicable to concrete products for buildings which are separately specified

in Japanese Industrial Standards.

This Standard does not restrict the use of other suitable test methods, and is appli-

cable to the tests for type inspection (classification of performance test), final inspec

tion and delivery inspection of a product, as appropriate. The comparison table be~

tween previous and current editions of this Standard on technically significant revi-

sions is listed in Annex A.

2 Normative references

The following standards contain provisions which, through reference in this text,

constitute provisions of this Standard. ‘The most recent editions of the standards (in-

cluding amendments) listed below shall be applied.

JIS A0203 Conerete terminology

JIS B 7505-1 Aneroid pressure gauges — Part 1: Bourdon tube pressure gauges

JIS B7721 Tension/compression testing machines — Verification and calibration

of the force-measuring system

3 Terms and definitions

For the purposes of this Standard, the terms and definitions given in JIS A 0203,

and the following apply.

3.1 flexural strength test of product

test method in which a load is directly applied to a product under the condition where

the bending fracture occurs on the product:

3.2 shear strength test of product

test method in which a load is directly applied to a product under the condition where

the shear fracture occurs on the product

3.3 compressive strength test of product

test method in which a load is directly applied to a product under the condition where

the compressive fracture occurs on the product in its axial direction

3.4 internal pressure strength test of product

PROTECTED BY COPYRIGHT

2

A5363: 2016

test method in which the hollow part of a product is filled with water and is subjected

to an internal pressure, then the internal pressure strength of the product is deter

mined and the leakage of water is examined

3.5 cracking load of product

value of the load by which a product is judged whether it holds the flexural cracking

strength in the product performance test

3.6 ultimate load of product

value of the load by which a product is judged whether it holds the ultimate flexural

strength in the product performance test

4 Classification of performance test methods of products

‘The performance test methods of products shall be classified as shown in Table 1

Table 1 Classification of performance test methods of products

Performance | Shape of Toading method

test method | product,

Flexural Bar product — | Two-position loading on simple beam Method in which a

Strength test | Plate product | component ina simple beam form is supported at both ends,

and load is applied to two positions across the centre of com-

ponent (see Figure 1).

One-position loading on simple beam Method in which a

component in a simple beam form is supported at both ends,

and load is applied to one position on the centre of component

iste Figure 3

Lading on cantilever beam Method in which one end of

component is fixed, and load is applied to the other end (see

Figure 3 and Figure 4),

Cube rigid | Method in which the bottom plate of component of cube rigid

frame product | frame is supported at both ends, and linear load is applied in

the length direction of top plate (see Figure 5).

Cylinder Method in which the cylindrical component is horizontally

product and linearly supported, and linear load is applied in the

length direction of the top part (see Figure 6).

Shear Bar product | Loading on simple beam Method in which a component ina

Strength test | Plate-type | simple beam form is supported at both ends, and load is ap-

product plied to two positions across the centre (see Figure 7).

Loading on beam with one end overhanging Method in

which a component is supported at two positions with one end

overhanging, and load is applied to two positions, one on the

overhanging end and the ather between the supporting posi-

tions (see Figure 8).

Compressive | Oylinder ‘Axial compression loading Method in which a component is

strength test | product, ete. | installed vertically, and the compressive foree is applied in

the axial direction of the component (see Figure 9).

Tntornal Cylinder ‘Mothod in which the hollow part of cylindrical component oF

pressure product cube rigid frame is filled with water, and a test water pres

strength test | Cube rigid | sure is applied (see Figure 10 and Figure 11),

frame product

PROTECTED BY COPYRIGHT

3

A5363 | 2016

5 Performance of testing machine

The testing machine for the performance test of at least Class 1 specified in JIS B

7721, or that having the performance at least equivalent thereto shall be used. For the

measurement of water pressure, the pressure gauge of Grade 1.6 specified in JIS B

7505-1 or superior shall be used.

6 Performance tests of product

6.1 Flexural strength test of product,

6.1.1 Measuring items

Crack width, displacement and curvature may be selected as mi

flexural strength test of products.

6.1.2 Loading and test methods

The loading and test methods shall be as follows.

uring items for the

a) ‘The load shall be applied to the product without an impact, and the flexural erack-

ing strength shall be obtained from the load when cracking starts, The crack width

corresponding to the load shall be measured, if necessary. The flexural cracking

strength, critical cracking width strength, ete. may be obtained after the relation

between the load and the crack width is determined.

b) The ultimate flexural strength shall be obtained in such a way that the load is in-

creased until the cross-sectional fracture occurs or the maximum load is confirmed.

©) When the flexural strength test is carried out on the product only for the purpose of

judging whether the product has the required strength, the load is increased up to

that corresponding to the strength, and cracking, deformation, ete. shall be exam-

ined.

6.1.8 Installation of product and calculation of strength

The loading and test methods according to the shape of product shalll be as follows.

a) Two-position loading on simple beam for bar produet or plate product ‘The product

shall be installed as shown in Figure 1. The product shall be supported at its both

ends, and the load shall be applied on two positions across the centre of span.

In this case, a rubber plate or the like shall be placed on the supporting positions

and the loading positions so that the load is uniformly distributed. When a local

fracture is likely to occur at the loading position or at the supporting position be-

fore the start of the flexural fracture of the product, a preventive action may be

taken. The flexural strength (bending moment) of the product shall be calculated as

follows. The own weight may be ignored depending on its degree of influence.

NOTE: The hardness, thickness and width of rubber plate, ete. should be se-

lected by taking the product and test conditions into consideration.

PROTECTED BY COPYRIGHT

4

A 5363 : 2016

2F(I-b)+ gm(2/-L)

8

where, M: bending moment (kN-m)

Ft load (kN)

acceleration of gravity (use 9.81 m/s?)

m: mass of component (t)

13 length of component (m)

13 span (m)

= length between loading positions (m)

Load F

|

alo

t =

Let,

Span /

:

Figure 1 Two-position loading on simple beam

(bar product or plate product)

1b) One-position loading on simple beam for bar product or plate product The product

shall be installed as shown in Figure 2. The product shall be supported at its both

ends, and the load shall be applied on one position at the centre of span.

In this case, a rubber plate or the like shall be placed on the supporting positions

and the loading position so that the load is uniformly distributed. When a local

fracture is likely to occur at the loading position or at the supporting position be-

fore the start of the flexural fracture of the product, a preventive action may be

taken. The flexural strength (bending moment) of the product shall be calculated as

follows. The own weight may be ignored according to its degree of influence.

NOTE: The hardness, thickness and width of rubber plate, ete. should be se~

lected by taking the product and test conditions into consideration.

ua

7

where, bending moment (kN'm)

+ Toad (kN)

1 span (m)

PROTECTED BY COPYRIGHT

5

A.5363 ! 2016

Pressure plate of al

Rubber plate Main body

- - End face_ End face

End face +e

Figure 2 One-position loading on simple beam

(bar product or plate product)

c) Loading on cantilever beam for bar product or plate product The bar-type product

shall be installed and fixed with cushion material or the like inserted as shown in

Figure 3. The plate-type product shall be installed and fixed with steel beam or the

like inserted as shown in Figure 4. The load shall be applied to the loading position

as perpendicularly as possible to the axis of the component,

In this case, a rubber plate or the like shall be placed on the supporting position

and the loading position so that the load is uniformly distributed. When a local

fracture is likely to occur at the loading position or at the supporting pos

‘ion be-

fore the start of the flexural fracture of the product, a preventive action may be

taken. The flexural strength (bonding moment) of the produet shall be calculated as

follows. The own weight of the cantilever part of the product shall be taken into

consideration, if required.

NOTE: The hardness, thickness and width of rubber plate, ete. should be se~

lected by taking the product and test conditions into consideration,

M=FH

where, M: bending moment (kN-m)

F: load (kN)

H° length from supporting position to loading position (m)

PROTECTED BY COPYRIGHT

6

A563: 2016

Unit: mm.

Jack» Cushion material

Fixing base"

position

Bottom end

Loading,

eater

spor

meee #

250

Load F

Support-

ing posi

tion

Note* The fixing devices in the diagram (fixing bases, cushion materials

and jacks) are examples.

Figure 3 Loading on cantilever beam (bar product)

PROTECTED BY COPYRIGHT

ad

7

A 5363: 2016

a Unit: mm

Load F Pressure plate of Load F

testing machine

Rubber C J c

plate

————

L L

‘Trough 2 2

Rubber (main body) L |

plate

Rubber Testing

plate machine

t ——— Load F C

Stoel beam

= material

SY 7

“Fixed with high strength bolt

Figure 4 Loading on cantilever beam (plate product)

Cube rigid frame product ‘The product shall be installed as shown in Figure 5.

‘The product shall be supported at the centre line of the side wall of the product.

‘The linear load shall be applied to the centre of the top plate.

In this case, a rubber plate or the like shall be placed on the supporting position

and the loading position so that the load is uniformly distributed. When a local

fracture is likely to occur at the loading position or at the supporting position be~

fore the flexural fracture of the product, a preventive action may be taken. The

flexural strength (bending moment) of the product shall be calculated using the

slope deflection method of cube rigid frame.

PROTECTED BY COPYRIGHT

8

A563: 2016

NOTE: ‘The hardness, thickness and width of rubber plate, ete. should be se~

lected by taking the product and test conditions into consideration.

Load F Load F

| Steel beam |

Rubber plate dt/“rop plate

Side wall

~

Bottom plate

if

Rubber plate

Figure 5 Loading on cube rigid frame product

©) Cylinder product The product shall be horizontally installed as shown in Figure 6.

‘The linear load shall be applied to one position of the top of the product.

In this case, a rubber plate or the like shall be placed on the supporting position

and the loading position so that the load is uniformly distributed. The square bar

at the supporting position may he omitted. When a local fracture is likely to occur

at the loading position or at the supporting position before the flexural fracture of

the product, a preventive action may be taken. The flexural cracking strength

(bending moment) of the product shall be calculated as follows.

NOTE: The hardness, thickness and width of rubber plate, ete. should be se~

lected by taking the product and test conditions into consideration.

M =0.318/F +0.239gmr

where, M: ending moment per unit length in length direetion of compo~

nent (kN-m/m)

Fi load per unit length in length direction of component (kNim)

acceleration of gravity (use 9.81 m/s")

m: mass per unit length in length direction of component (t/m)

r+ radius to wall+thickness centre of component (m)

‘The flexural strength (bending moment) of the product after cracking has occurred at

four positions on the internal surfaces of the supporting position and the loading posi-

tion, and the external surfaces of both sides which are perpendicularly located to these

two positions shall be calculated according to the formula shown below.

M =0.25rF +0.165qmr

where, M: bending moment per unit length in length direetion of compo-

nent (N-m/m)

PROTECTED BY COPYRIGHT

9

A5363 | 2016

F* load per unit length in length direction of component (kN/m)

2 acceleration of gravity (use 9.81 mis

mm! mass per unit length in length direction of component (t/m)

radius to wall-thickness centre of component (m)

Load F 4 Load F

z (e+e) Steel beam

“ ~

Square bar “7

- ~

/ Rubber plate”

TISLSIITL IESE Sage bat

Figure 6 Loading on cylinder product

6.2 Shear strength test of product

6.2.1 Measuring items

Shear crack strength, shear fracture strength and crack width may be selected as

measuring items for the shear strength test of products.

6.2.2 Installation of product and calculation of strength

The loading and test methods according to the shape of product shalll be as follows,

a) Loading on simple beam for bar product or plate product ‘The product shall be in-

stalled as shown in Figure 7. The product shall be supported at its both ends, and

the load shall be applied on two positions across the centre of span,

In this case, a rubber plate or the like shall be placed on the supporting position

and the loading position so that the load is uniformly distributed. When a local

fracture is likely to occur at the loading position or at the supporting position be-

fore the shear fracture of the product, a preventive action may be taken.

In some products, if the shear span ratio (= bending moment/shear force x heam

height) is larger than 1.0, the bending fracture instead of the shear fracture may

oceur. It is recommended to examine beforehand the range of shear span ratio in

which the shear fracture occurs. The shear strength (shear force) of the product

shalll be calculated as follows.

NOTE: The hardness, thickness and width of rubber plate, ete. should be se-

lected by taking the product and test conditions into consideration.

PROTECTED BY COPYRIGHT

10

A563: 2016

where, Q shear force (kN)

F load (kN)

Figure 7 Loading on simple beam

b) Loading on beam with one end overhanging for bar product or plate product The

product shall be installed as shown in Figure 8. The product shall be supported at

two supporting positions and the load shall be applied on two positions, one of

between the supporting positions.

ch is on one overhanging end and the other

wh

In this case, a rubber plate or the like shall be placed on the supporting position

and the loading position so that the load is uniformly distributed. When a local

fracture is likely to occur at the loading position or at the supporting position be-

fore the shear fracture of the product, a preventive action may be taken. The shear

strength (shear force) of the product shall be calculated as follows.

NOTE: The hardness, thickness and width of rubber plate, ete. should be se-

lected by taking the product and test conditions into consideration.

Fb

a+b

where, Q: shear force (kN)

F load (kN)

a2 shear span (length from central supporting position to loading

position, and length from loading position to central distribu:

tion loading position) (m)

length from supporting position of component end to central

distribution loading position, and length from central sup-

porting position to overhanging end distribution loading posi

tion (m)

A shear crack occurs in the neighbourhood of the oblique line connecting the sup

porting position and the loading position within the range of the shear span 2a of the

centre part, in parallel with the oblique line, A crack that occurs perpendicularly to the

PROTECTED BY COPYRIGHT

ul

A5363 | 2016

axis of the component in the neighbourhood directly under the central distribution

loading position or directly above the central supporting position is a flexural crack,

and this shall not be taken as a shear crack.

Load F

{SSS

7

b 2a 6

D+ height of beam

@? shear span

Figure 8 Loading on beam with one end overhanging

6.3 Compressive strength test of product

6.3.1 Measuring items

Crack strength and ultimate strength against the compression in axial direction of

the product may be selected as measuring items for the compressive strength test of

products. When components are assembled in the axial direction, the examination of

the introduction of the compression force in axial direction at the joint or the like may

be added.

6.3.2 Installation of product

The product shall be installed as shown in Figure 9. The axial lower end of the prod-

uct shall be supported by a plane, and the load shall be applied over the upper end.

When the load is applied directly on a cover, for example of the assembled manhole,

recommended to use the packing material which fits the shape of the cover.

PROTECTED BY COPYRIGHT

12.

A563: 2016

Packing

material

Packing

“material

Figure 9 Compressive strength test of product

6.4 Internal pressure strength test of product

6.4.1 Measuring items

Crack strength against the inner water pressure of the product, ultimate strength,

and presence/absence of leakage due to the test water pressure may be selected as

measuring items for the internal pressure strength test of products.

In the test of a joint, the pull-out amount of joint and the like may be selected as

measuring items. In this case, whether to apply an inner water pressure after pulling

out the joint, or whether to measure the pull-out amount after applying an inner water

pressure shall be selected as agreed between the parties concerned with delivery.

6.4.2 Installation of product

The loading and test method shalll he as follows.

a) Examination of water-tightness of cylinder product or cube rigid frame product

‘The product shall be installed as shown in Figure 10. The test water pressure shall

be applied after the hollow part of produet is filled with water, The pressure shall

be maintained for the predetermined duration, and the leakage of water shall be

examined. Spots or drops of water which exuded onto the surface of product. are not

deemed as leakage of water.

PROTECTED BY COPYRIGHT

13.

A5363 | 2016

Air ventf

Water pressure

testing machine ‘=—__4 Water pressure

(spigod _Aesting machine

Goeket)

Pressure gauge

Water

injection _©

Pump]

~_| Sealing material

for joint

Figure 10 Internal pressure strength test of hollow cross section

b) Examination of water-tightness of product including joint ‘Two products connect~

ed in series by joint work shall be installed as shown in Figure 11, The test water

pressure shall be applied after the hollow part of product is filled with water. The

pressure shall be maintained for the predetermined duration, and the leakage of

water shall be examined, Spots or drops of water which exuded onto the surface of

product are not deemed as leakage of water,

SDLP

q SY [Bo Air vent.

‘Tension 4 \ “fF Water

material bse <— injection

fo Pressure gauge

= Water pressure

fF pump

co Aa

Bolt

Water stop (reinforced “|

with grid rib to main

tain rigidity)

\ Supporting base

(steel section or

square bar)

Figure 11 Internal pressure strength test of product including joint

PROTECTED BY COPYRIGHT

14

A5363: 2016

Bibliography

JIS A 6361

JIS A 5364

JIS A 5365

JIS A 5371

JIS A 5372

JIS A 5373

Precast concrete products — General rules for classification, designa-

tion and marking

Precast concrete products — General rules of materials and product

methods

Precast concrete products — General rules for method of inspection

Precast unreinforced concrete products

Precast reinforced concrete products

Precast prestressed concrete products

PROTECTED BY COPYRIGHT

15,

A5363 | 2016

Bi

sssup9 ate yonpoxt yo sisay sow

T9092 &

SLEW: paytoods soni9q 40 9° s8uI9 Jo anv

‘pan 0q qs 0149

<8 20 1.9091 4 SLE Ut pay}oads 9'T apary Jo

afines amssadd ay

gard 29}0 Jo qu9Ut

‘urvoq, ojdunts Jo poxour

shurpnoy ayy se pawrasoyap par

poptatp oze uupeoy uorstsod. omy

pu Suypvo| uorysod.oug,

urpooy wsa0p 0

unay putes odsy.aqng,

UDTOMAOS ywouy

FUHTOTUT od 9

sranpoud yo spo4)

359 sousutsOHIOd Jo UONEDITSSE|D ToT

syonpoxd

Je spoyyour

389} gout

Ta oa to Bape COST ANG

tavoq a[duns uo Zupwoy TROT,

[RPM omy pists oqny,

PUPAE sopuyisy

[papoRTTay

swonpoud yo spoyyour

380) oomeurs0pF0d Jo LONEOITESEID LTE,

3804 souvun40

=paujap aan

sr qyuans qm paqemosse peor

‘piuarys #1380} 043 UE

‘pouryygo souvmuopsod oy verte

-9q wortpe snoqsaud ay jo awvu

spnposd w yo3s0 aznssaud yeusopur pe

spnpoud v 30 450) uorseorduto9 ge

sonpoud u so wo, aweys ¢e

PUPA POISE

380 PAUSE aunssaad pousoquy pe

rd jo 3801 RUSH axrssordwioo gg

onpoxd jo san WERTONS aways gg

TTS

uo(stial 10) woseayy

auanuog,

1 puv “ON

auoqu09, 0

(Wide oes VBI) wonTPA SHORT

(OTOZ= ORV SIF) WORTpA TwARING

SUOTSTAAT JUBOYTUBIS ATBOTTYDA} UO PABPUEIg S1q} Jo SuOTITpa aL puw snorAard USaMIaq o[qe} UOStTEdUION

(@AHeuLoyuy) y xeuuy

PROTECTED BY COPYRIGHT

16

2016

A5363

‘pnpoud jo 1501 qaiiuans pemnxo

nd a

‘yySuons jwinsoy SuUNEAGO

40} poyrowt ay “poyow SurpLoy

110) oUt ez23yuU yy MOUS

opso ut paptaoad st agnepamng

poue

-30 2g [1eYs 989 ‘LoNFUL}EP FuPpELD

uu “yssuacys oy 01 Suupuodsaao> ywyp oy

dn poswasour st peo] ayy ‘yyauanns post

ai ou) sey jonpoud og Aayjoys IUBIpNE

40 osoddanel aq 205 Sto yoapard 9x7 wo 7N0

S389) Guus [eINXay OM UOHAL ©

pouy,

51 peoy ay geys Kem ¥ yons ur pauTErgo

9q TeYs (HauaNs pemMxay oreUI 9, (4

auseiep St

ogy aoa

‘ypu Furyooso wor9 “yyFusye RuryoRAD

Temxoyy oy, rmssoont 3 pamsvant

oq Te PHOT oR OF FerpLdsoxs09 pI

youd ou, *H1e}8 Burjaaso oy peo oy

suouy pattngo 09 yous qasacis SuPyoUD

wansog uy pu pedant we yoy

2npord ayy oy parle oq MENS PROT LLP

spoypant

so pure

Sumpeor e1'9

sampoxd 30 9894

Suanys [eaMxoy 9

Suymsvow [w10UEA aM MOY

(03 s9pao ut papiaoad st asnepqng

BRAT

puw Suowasedeyp “(USMOU SUT IIT SAT

SSRNESP) pooy Supqearq “pH uD Tape

-03 "qppta ¥ous9 ‘0

pro} Sursom0 oy

ou, npaNTE FO LET

“HUTpU yy HuxutTx9 yo asodand ay} 205

ano ponte

yposd & Jo 9804 Suypusg au,

pod » Jo 380),

Buypuag 1

‘sionpoad jo 3801 ypBuanys jeanxoyy

Supmsvou se payaojae ag seu

anseoW TT

sonpord jo

as HURTS

remxoy 9

pn

-paxd jo sysay

9 pur qwameoeydstp “yspya youn | eouEUUOHEA 9

Uuotstiat 10) woseay

jyuot09) 3091

pun “ont

suo.)

10 9118 pe “oN

(OTE = BOER V SIF) UoTTPS enor

(B10z | BOT V SIF) WOTTpS THAIN

PROTECTED BY COPYRIGHT

17

A.6363 : 2016

apie pure ssounyarip ‘ssoupanty jo

‘wor}29J96 a4) Jo MoRVZOpIstO> OU,

wuss

vg uruyongo 204s 0 pow

dw pooj ayy Buyuyeygo yoy wosy

avon st oynutaoy woREHoTED aM,

“pamquaystp spuaogtun

de fuspeoy yutod.owy 0 ponaaqns pe

‘pun yyog 4v euunaopay ays au poyioddne

9q [foys JuIKOdWIO wy amNY ar WAOyS

sy quouodaio9 uieoq 2 uo Supeoy

uuioy ureag ayduris arp Jo ase> an

you

pod » Jo 180),

Auypuag Cee

‘uton[sat Jo aaAap S11

4 Sew yyfroM UNO

upBuans

youon

-vmnoqea pu

yonpoid yo wor,

MOWstAat 209 Hosva

jyuoyn0g yo

1 pte “ON

guano

(Oia = CORT SIN) HTTPS eTOTAAIT

(O02 | 8988 V SIF) WoRTpS WHITING

PROTECTED BY COPYRIGHT

18

2016

A5363

‘saupray JO

“womaafas aq Jo MoRRZApIstO9 On,

dv peor ayy Surureyqo yup) waxy

itr ody.aqno e jo ase oxp,

"ods amp Jo aria ax o1to paydae

“pony 30 aap si 0) Raxpionoe poset

-3 9q Soe 1B HHO a, SHOTS EPO

-anoqs> aq os romp

oa) UA

ag] a3 08 woREsod Fuypuoy ayy

-asod fiarpzoddns aro paowd 0

rv sur,

a

291 aq) 20 ape soqqna “oseo seep Uy

‘uvds Jo oxjua0 amp 18 tonteod ou0 to

vontddy on nous pr ona pun pu arog

(8 yonposd am, 2

pn aq reqs 190

sy qusuoTuOy=Esy aU] Jo Aupwo posi v Jo 3809

‘pnpoad aque IO PApoxe THY

mnoqeo pa

yonpord yo wor,

unoj uivag apduuis ax go ovo ou uy @| Surpuog 11'g | soy uwaq a[dunys uo suspeo] TORE commas €°1°9

aR aa

jyuot09) Joop pum oN, jwuor09 10 9118 pe “oN

Uuotstiat 10) woseay

Wie BORE VSI CONTTS TORO

Teeee VSI Tone aR

PROTECTED BY COPYRIGHT

19

A.6363 : 2016

‘qprordoxd

aq Avan zanpoad v Jo Suvysa.0

‘9 Jo juaurour oxv au, “¢peO] UBEap)

peo] paypoads axp eaxpvax puoy [wIU07

quouod ued yp jo 21x

uw spmoqs pore oq

oy ¥ uiod Buy

tarvag yams # qi pas

[reqs TrOTOeTAOS w FATTY ay Umoqs sy

FUDUOMUIOS BIAT-OUTM v Jo woy urweq

luv somo Jo typi ou, INST AUIS

pun auetcoduron 942 J0 #18 942 0

[S80 a APUPMOTPUNAT ER pn

a=W

RESP RTO OTA

UOMO FET PUT TOT TTT

ULE Aq paIDB|AS || PNOYS

panda 9q 1roys PRO]

Ou, FANT UT UNOYS Fe poxtosur 0

ay} 40 wavoq Jo9¥s YaEe pasty pure PI|TETE (ponun

SU og ((eys NPN ATT ou, TAM — | os) yrsuans

wpsuans | —noqd supped sq poss pus poreastt iy aoYs sv parrosur oxy aq JO peioqCME youon

ayy Surungo yey; oy por | oq yroys TaMOMUTES w TAMA ur ways — | (Ponuques) yon | worysno ypEs poxty PUY PITTEBTT og [eye -opnoqea pu

-dlw peo] ou dunuergo 34 wos sy quouodwoo wieeq ¥ yo Supwo, | -pord vo yson | FONPONTTER oy, youpoad yo wor,

parore sf vmnuzog uoRUTHoTw on | MIAO} OST TIOTTTS axp jo 9ewo om wy (a | Supuog re | -PORCTUY soy evo ToxopyUVS uo SuPUOT E| -MMTeISUT ETS

aD a

yu uoy yon pun oN, quou0y oop paw ox

Mo¥stAa 10) HoseaRT

(07 GOES VIA) WORTH SHOTAOAT

(OTO7 B9ESV SIF) WORTPS WED

PROTECTED BY COPYRIGHT

20

2016

A5363

step UT

“poupoud 24s yo doy ayy yo WOTTEOI

2g (reys MPM aT, FUPOAT reps

wan

40s) uans

youon

-vmnoqea pu

onpoid jo won,

ERT

1 pute “ON

uo yo

juou0g

MOWstAat 209 Hosva

(Oia = CORE VSIA) HoTTpS HOTS

DiOz: CES V SIF) WORTpS IMD

PROTECTED BY COPYRIGHT

2016

A5363

22

z

576

“Xqpwotedoxd “uOREEpSuOF OR

‘suoRTpUED YSo-pUE I>Npore

te

pps pre

syariojran porngesy

THRE TT,» pernqeeisyp Squojran st

‘puo] ay yuy) = UoRESod Sumpeo} oy) puE

wor sod Suraroddns ayy wo posw(d 9g [6ys

aqua oq. ast] ou 40 aypyd aogqna v “oswo sus uy

ayy jo “weds Jo azyt99 anf SSO150 st0N,

de Burpeoy quod.omy 0} payrak 80d om 0 ps uyiuans

‘proj 3804 wo yituans Suyvoys | epua qaog av suunsoqny ays av pousoddns ‘spue yr04 81 48 pas ouon

140 yey? OF ooU05 awoys WOK | 94 [Uys ToUOdUIOD v +g aun (ponurquas) you au, TART Uy umoys #0 -vmnoyeo pt

Pro] 209 ony BureEAgo FOE Oss pod jo yea | oq eqs TMPATT oxy, yanposd oywyd 20 | ompoud jo w

paiaype et pjnutagy uormnoyes ayy] utay ureaq aydusis axp jo aevo axp Ul rwayg ee | sanpoad TH 19) ureag ayduats wo Sumpeoy ce} -wyrewsuy 22"

‘wont Sur

9) ANSwON LO

uSuans aways 2yy q sure Sr gon | -po.d jo a9) TAU aways ayy x0j swat Sur] — yompord yo

NseoUt [e10Uad 9tf1 MOYS 03 Lop THUNTERT TOM STT TOF TNS | -pord v jo sei | -ansvow se PSPIPFOT ATT yipim oxo pu | aso yasuans

papaocd st asnegns aq, | PRE aq 1reys ionpard y jo weramays ay, | ways Te | THURTRAMTETTERE ‘yuiuans yoo sways | swoys <9

aU DERI IO

umn 300198 pue on yonoy opn puw “on

uorstraL 10y wostoy (ida BORO SIN

SHOT (O10E BOTW SIF) HOTS TATA

PROTECTED BY COPYRIGHT

23

A.6363 : 2016

Sqqworesd wmoys

81 your9 avoys jo oruMS aout

-mopo ayy Syous9 [BaNsoU tp

worsnyoa agp juaraad o1 s9p.s0

load

do a803 Bumpeoy ou MNO UI09 0

Ap

Suvasaoau st “aa

yf aaqqna jo

apis puw ssouroryp ‘ssaupzey jo

uoro2}oe ayy Jo woryusapista> aq,

wot

380) wo ySuaNs svoys SuTUTT

qo wy 0} 9010} AwaKS LHOAy P

3807 04] Suan go gwyr WHOS pore

Jv Sf UIMUUIOS LOREPLOTEO OM,

‘yoeuo Sutavays w ypta pasnztian aq

fy pu “ype Slumpuiog w st wms9yny yea

a0 4 B40qU ATDONTP 40 quod FuNpeoy

uoRINqUNstp jesqUs9 ay) zpUN spat

pooymogysiiow ayy wt ‘weds Sutavauys

p UREN quouoduieD o¥p Jo SCW 94

jompuardiad payereuas youI9 y

0q Hod v sf roquouT put sien

‘a Jo puta ayy st ou ‘eyutod om 0

udev 04 [Toys pLEr] ugFuYZAS0 epue

‘si1Jo ovo TH syuTod oma

oxp Jo MonDomp op jotonomaress oy onsen ere ayy | onpord o 3809 tplluanys sd urs ansvaut [es0u98 a1} ous 03 19p Tee oy aH SoU Suzvoq PHOT oy OE ut porqunoseu ate sxuouodu09 uayAy “sionpoad 10 us paptaosd st asneyoqns au, | aq 1reys sonpoud v Jo 4803 oyssacdwuod ay, ssoxdwog ¢°9 aR IO yuou0g yuoi909 opp pur “oN uotstiaa 10) woseay Tide + BOBS W SIP) WOTTpS STOTATI OU0G = BOER V SIN) woRTpS WHEN PROTECTED BY COPYRIGHT Errata for JIS (English edition) are printed in Standardization and Quality Control, published monthly by the Japanese Standards Association, and also provided to subscribers of JIS (English edition) in Monthly Information, Errata will be provided upon request, please contact Publishing Group, Japanese Standards Association Miia MT Bailing $-16-12, Mite, Minato Tolyo, 1060018 JAPAN TEL PAX, O24201-8665 PROTECTED BY COPYRIGHT

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Flyer Webinar LMK 2023 - SERIES 3 Rev1Document1 pageFlyer Webinar LMK 2023 - SERIES 3 Rev1HENDRONo ratings yet

- TB 10621-2014 Code For Design of High-Speed Railway ChinaDocument193 pagesTB 10621-2014 Code For Design of High-Speed Railway ChinaHENDRONo ratings yet

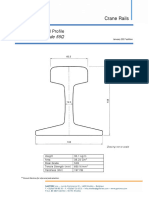

- Gantrex Rail JIS30 Grade 55QDocument1 pageGantrex Rail JIS30 Grade 55QHENDRONo ratings yet

- Perubahan SK Libnas Dan Cuti Bersama 2023Document3 pagesPerubahan SK Libnas Dan Cuti Bersama 2023HENDRONo ratings yet

- Akselerasi: Jurnal Ilmiah Teknik Sipil: I. PendahuluanDocument1 pageAkselerasi: Jurnal Ilmiah Teknik Sipil: I. PendahuluanHENDRONo ratings yet

- Akselerasi: Jurnal Ilmiah Teknik Sipil: Volume 3, No. 1, Agustus 2021 E-ISSN: 2715-7296Document1 pageAkselerasi: Jurnal Ilmiah Teknik Sipil: Volume 3, No. 1, Agustus 2021 E-ISSN: 2715-7296HENDRONo ratings yet

- Akselerasi: Jurnal Ilmiah Teknik Sipil: Probolinggo (C) .Document1 pageAkselerasi: Jurnal Ilmiah Teknik Sipil: Probolinggo (C) .HENDRONo ratings yet

- PDF Aashto M 170m 04 Reinforced Concrete Culvert Storm Drain and Sewer Pipe PDF - CompressDocument23 pagesPDF Aashto M 170m 04 Reinforced Concrete Culvert Storm Drain and Sewer Pipe PDF - CompressHENDRONo ratings yet

- Volume 3, No. 1, Agustus 2021 E-ISSN: 2715-7296: Akselerasi: Jurnal Ilmiah Teknik SipilDocument1 pageVolume 3, No. 1, Agustus 2021 E-ISSN: 2715-7296: Akselerasi: Jurnal Ilmiah Teknik SipilHENDRONo ratings yet

- Infographic Style: Portfolio DesignedDocument1 pageInfographic Style: Portfolio DesignedHENDRONo ratings yet

- Perencanaan Struktur Baja Pada Gedung 5 Lantai Kantor Kesehatan Pelabuhan Probolinggo RaissaDocument2 pagesPerencanaan Struktur Baja Pada Gedung 5 Lantai Kantor Kesehatan Pelabuhan Probolinggo RaissaHENDRONo ratings yet

- Infographic Style: Computer Repair & SupportDocument1 pageInfographic Style: Computer Repair & SupportHENDRONo ratings yet

- Form Harmonis 1 - Penilaian Perilaku AKHLAKDocument1 pageForm Harmonis 1 - Penilaian Perilaku AKHLAKHENDRONo ratings yet

- Analisis Stabilitas Bendung (Studi Kasus: Bendung Tamiang) Afrian Firnanda Manyuk Fauzi SiswantoDocument11 pagesAnalisis Stabilitas Bendung (Studi Kasus: Bendung Tamiang) Afrian Firnanda Manyuk Fauzi SiswantoHENDRONo ratings yet

- GBT 50080-2002 普通混凝土拌合物性能试验方法标准 附条文说明Document61 pagesGBT 50080-2002 普通混凝土拌合物性能试验方法标准 附条文说明HENDRONo ratings yet

- China Peru FTA PDFDocument794 pagesChina Peru FTA PDFHENDRONo ratings yet

- Metode Kerja CBM Soil StabilizerDocument3 pagesMetode Kerja CBM Soil StabilizerHENDRONo ratings yet

- 614 2081 1 PBDocument9 pages614 2081 1 PBHENDRONo ratings yet

- Analysis of Strain State and Cracking of Cocnrete Sleepers: Aidas Jokūbaitis, Juozas Valivonis, Gediminas MarčiukaitisDocument9 pagesAnalysis of Strain State and Cracking of Cocnrete Sleepers: Aidas Jokūbaitis, Juozas Valivonis, Gediminas MarčiukaitisHENDRONo ratings yet