Professional Documents

Culture Documents

Boquilla de Pulverizacion TN Ss 10

Uploaded by

bladimirpineda1998Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Boquilla de Pulverizacion TN Ss 10

Uploaded by

bladimirpineda1998Copyright:

Available Formats

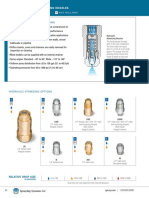

HOLLOW UNIJET ® NOZZLES

CONE S S TA ND ARD ANGL E SPRAY | W W ID E AN GLE S PRAY

OVERVIEW: UNIJET

• Quick-connect nozzles reduce maintenance time – bodies remain

on pipe/header

• Save on nozzle replacement costs – bodies can be reused, only

spray tips are replaced; tips fit on male or female bodies

• Hollow cone spray pattern with a circular impact area

UniJet TX, D and

• Excellent atomization at relatively low pressures TN Nozzles

As the liquid passes through

• Spray angles: Standard – 13° to 114°, Wide – 130° to 140°

the nozzle, it is forced to

• Uniform spray distribution from 3.6 to 4,920 gph (13.2 to 17,760 lph) pass through slots in the

orifice. These slots make

• Operating pressures up to 400 psi (25 bar) the liquid spin in a circle at

a high speed as it exits the

• Orifice inserts, cores and strainers are easily removed for orifice, creating the hollow

inspection or cleaning cone pattern.

• TN versions provide very fine atomized sprays using liquid

pressure alone; compressed air not required

– Spray angles: Standard – 43° to 91°

– Uniform spray distribution from .82 to 184 gph (3.1 to 701 lph)

– Operating pressures up to 2000 psi (140 bar)

UNIJET OPTIONS

S S

S S

W

Tip Tip

Retainer Retainer

TN-SSTC Spray Tip

TN Spray Tip

High-pressure tungsten carbide

D Disc Fine/hollow cone spray tip

orifice tip

TX

Spray Tip

Core

Strainer

Strainer

T Body/Cap TT Body/Cap

1/8" to 1/2" female conn. 1/8" to 1/2" male conn.

Use with TX, D, T-W or TN tips Use with TX, D, T-W or TN tips

T Body TT Body

TX Spray Tip + T Body D Spray Tip + TT Body

1/4" female conn. 1/4" male conn.

Use with screen strainer Disc and core type 11430 High Pressure Body

and tip retainer Use with slotted strainer 1/4" female conn.

and tip retainer Use with TN-SSTC tips

D20 spray.com | 1.800.95.SPRAY

UNIJET ® NOZZLES HOLLOW

S S TAN D ARD A N GL E SPR AY | W W I DE AN GL E SPR AY CONE

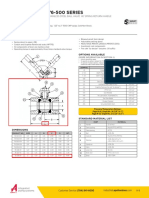

ORDERING INFORMATION

UNIJET

NOZZLE BODY SPRAY TIP Example

Inlet Body Material Tip Material Capacity

Conn. Type – Code + Type – Code Size

1/4 T – SS + TX – SS 1.25

UniJet nozzle assemblies include a pre-sized wire mesh based on orifice diameter. BSPT connections require the addition of a “B” prior to the nozzle body inlet connection.

When ordering just a UniJet spray tip, the mesh is not included.

See Accessories, page F6 for a mesh selection guide and ordering information.

UNIJET – DISC AND CORE TYPE

NOZZLE BODY ORIFICE DISC AND CORE Example

Core

Inlet Body Material Orifice Core

Conn. Type – Code + Disc No. – No.

Material

Code

1/4 TT – SS + D4 – 25 HSS

BSPT connections require the addition of a “B” prior to the nozzle body inlet connection.

DISC ONLY Example CORE ONLY Example

Core

Orifice Core

Disc No.

D4 No. – Material

Code

DC25 – HSS

UNIJET HIGH PRESSURE

NOZZLE BODY SPRAY TIP Example

Strainer

Body Inlet

Type – Conn. – Material

Code –

Screen

Mesh + Tip

Type – Material

Code

Capacity

Size

11430 – 1/4 – SS – 100 + TN – SSTC 10

Size

BSPT connections require the addition of a “B” prior to the nozzle body inlet connection.

QUICK REFERENCE GUIDE

Connection Page Number

Model Connection Size Materials Performance Dimensions

(in.) Data and Weights

T body F –

1/8 to 1/2 Brass, 303 stainless steel (SS)

TT body M –

11430 body F 1/4 303 stainless steel (SS) –

TX spray tip NA NA Brass, 303 stainless steel (SS) D22

Brass, 303 stainless steel (SS), D26

D spray tip NA NA D23–D24

Hardened stainless steel (HSS)

T-W spray tip NA NA D22

Brass, 303 stainless steel (SS)

TN spray tip NA NA D25

TN-SSTC

NA NA 303 stainless steel with tungsten carbide orifice (SSTC) D25–D26

spray tip

F = female thread; M = male thread; NA = not applicable. There is no material code for brass. Leave material code blank when ordering. Other materials available upon request.

For more dimensions and sizes, contact your sales engineer.

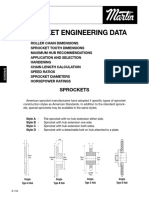

RELATIVE DROP SIZE

IN MICRONS

10 to 100 100 to 500 500 to 1000 1000 to 5000

Drop size will vary based on flow rate and pressure.

spray.com | 1.800.95.SPRAY D21

UNIJET ® NOZZLES HOLLOW

S STAN DARD AN G LE SP R AY CONE

PERFORMANCE DATA:

S

STANDARD ANGLE SPRAY

Body UniJet Tip Type Orifice Flow Rate Capacity (gallons per hour) Spray Angle (°)

Inlet Capacity Dia. Core

Conn. Size Nom. No. 30 40 60 100 200 300 500 700 1000 40 80 300

TN

(in.) (in.) psi psi psi psi psi psi psi psi psi psi psi psi

l .30 .016 106 – – – – – .82 1.1 1.3 1.5 – – 51

l .40 .016 108 – – – – – 1.1 1.4 1.7 2.0 – – 58

l .60 .016 206 – – – .95 1.3 1.6 2.1 2.5 3.0 – 35 65

l 1 .020 210 – 1.0 1.2 1.6 2.2 2.7 3.5 4.2 5.0 45 62 72

l 1.5 .020 216 1.3 1.5 1.8 2.4 3.4 4.1 5.3 6.3 7.5 65 70 72

l 2 .028 216 1.7 2.0 2.4 3.2 4.5 5.5 7.1 8.4 10.0 70 75 77

l 3 .028 220 2.6 3.0 3.7 4.7 6.7 8.2 10.6 12.5 15.0 65 70 73

l 4 .042 220 3.5 4.0 4.9 6.3 8.9 11.0 14.1 16.7 20 72 81 84

1/4

l 6 .042 225 5.2 6.0 7.3 9.5 13.4 16.4 21 25 30 73 79 81

l 8 .060 225 6.9 8.0 9.8 12.6 17.9 22 28 33 40 85 89 91

l 10 .064 420 8.7 10.0 12.2 15.8 22 27 35 42 50 82 84 86

l 12 .076 420 10.4 12.0 14.7 19.0 27 33 42 50 60 78 82 85

l 14 .076 421 12.1 14.0 17.1 22 31 38 49 59 70 85 88 90

l 18 .076 422 15.6 18.0 22 28 40 49 64 75 90 81 84 86

l 22 .076 625 19.1 22 27 35 49 60 78 92 110 70 72 75

l 26 .086 625 23 26 32 41 58 71 92 109 130 73 74 77

Other body types may be available. Contact your sales engineer for more information.

Highlighted column shows the rated pressure.

PERFORMANCE DATA:

S

STANDARD ANGLE SPRAY

Body UniJet Tip Type Orifice Flow Rate Capacity (gallons per hour) Approximate

Inlet Capacity Dia. Spray Pattern Dia.

Conn. Size Nom. 400 750 1000 1500 2000 (at 1 foot distance)

TN-SSTC

(in.) (in.) psi psi psi psi psi (in.)

l .60 .016 1.9 2.6 3.0 3.7 4.2 3

l .80 .014 2.5 3.5 4.0 4.9 5.7 3

l .90 .016 2.8 3.9 4.5 5.5 6.4 3

l 1 .020 3.2 4.3 5.0 6.1 7.1 3-1/2

1/4

l 1.5 .020 4.7 6.5 7.5 9.2 10.6 3-1/2

l 1.8 .025 5.7 7.8 9.0 11.0 12.7 4-1/2

l 2 .028 6.3 8.7 10.0 12.2 14.1 4-1/2

l 3 .028 9.5 13.0 15.0 18.4 21 6

Spray pattern diameter is based on liquid with viscosity of 20 seconds #3 Zahn Cup spraying at 1600 psi (110 bar).

Coverage will vary with viscosities and pressures. Tabulated capacities are based on water.

Other body types may be available. Contact your sales engineer for more information.

Calibration pressure = 40 psi (3 bar).

spray.com | 1.800.95.SPRAY D25

HOLLOW UNIJET ® NOZZLES

CONE S S TA ND ARD ANGL E SPRAY | W W ID E AN GLE S PRAY

PERFORMANCE DATA:

S

STANDARD ANGLE SPRAY

Body UniJet Tip Type Orifice Flow Rate Capacity (gallons per hour) Approximate

Inlet Capacity Dia. Spray Pattern Dia.

Conn. Size Nom. 400 750 1000 1500 2000 (at 1 foot distance)

TN-SSTC

(in.) (in.) psi psi psi psi psi (in.)

l 4 .042 12.6 17.3 20 24 28 8

l 6 .042 19.0 26 30 37 42 10

l 8 .060 25 35 40 49 57 12

l 9 .060 28 39 45 55 64 14

l 10 .064 32 43 50 61 71 16

l 12 .076 38 52 60 73 85 18

l 14 .076 44 61 70 86 99 14

1/4

l 15 .081 47 65 75 92 106 16

l 16 .086 51 69 80 98 113 18

l 18 .076 57 78 90 110 127 16

l 20 .081 63 87 100 122 141 18

l 22 .076 70 95 110 135 156 12

l 24 .081 76 104 120 147 170 13

l 26 .086 82 113 130 159 184 14

Spray pattern diameter is based on liquid with viscosity of 20 seconds #3 Zahn Cup spraying at 1600 psi (110 bar).

Coverage will vary with viscosities and pressures. Tabulated capacities are based on water.

Other body types may be available. Contact your sales engineer for more information.

Calibration pressure = 40 psi (3 bar).

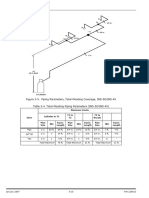

DIMENSIONS AND WEIGHTS

Inlet Net Inlet Net

L Hex. L Hex.

Nozzle Nozzle Type Conn. Weight Nozzle Nozzle Type Conn. Weight

(in.) (in.) (in.) (in.)

(in.) (oz.) (in.) (oz.)

T (F) + TX T (F) + TN

1/4 1.875 13/16 2.5 1/4 1.906 13/16 2.5

TT (M) + TX TT (M) + TN

L LL

T (F) + T-W T (F) + TN-SSTC

1/4 1.875 13/16 2.5 1/4 1.906 13/16 2.5

TT (M) + T-W TT (M) + TN-SSTC

T (F) + D

LL 1/4 1.500 13/16 2.5 L 11430 (F) + TN-SSTC 1/4 1.938 13/16 2.6

TT (M) + D

Based on the largest/heaviest version of each type. Based on the largest/heaviest version of each type.

D26

spray.com | 1.800.95.SPRAY

You might also like

- Pullers & Puller Sets Proto PDFDocument24 pagesPullers & Puller Sets Proto PDFMauricio GarciaNo ratings yet

- Agitation and Mixing PDFDocument83 pagesAgitation and Mixing PDFKuldeep28883100% (1)

- French Revolution Notes - IB Hist ExamDocument12 pagesFrench Revolution Notes - IB Hist ExamAshika I100% (52)

- MAXIMUS - 516 руководство пользователя - 1Document214 pagesMAXIMUS - 516 руководство пользователя - 1MMM-MMM100% (1)

- Kenya Water Design - Manual - 2005 PDFDocument500 pagesKenya Water Design - Manual - 2005 PDFChege KagoNo ratings yet

- HOOOKUP NEW FOR-WPS OfficeDocument2 pagesHOOOKUP NEW FOR-WPS Officeugochukwuibeaja100% (3)

- An Introduction To The Digital Protection of Power Systems - HarbawiDocument163 pagesAn Introduction To The Digital Protection of Power Systems - HarbawiWalber MoraisNo ratings yet

- Dynabolt CatalogDocument3 pagesDynabolt Cataloggirlie fabroNo ratings yet

- Basic 4 PPC ManualDocument1,360 pagesBasic 4 PPC ManualIngwaar Rosenson100% (1)

- Vjet Sprey NozzleDocument9 pagesVjet Sprey Nozzleleosac6No ratings yet

- NZ17DH5N3KW03800 ZR00Document3 pagesNZ17DH5N3KW03800 ZR00DanielEscobarMontecinosNo ratings yet

- cat75HYD Us E4Document1 pagecat75HYD Us E4rudo25No ratings yet

- Cat75b HydDocument3 pagesCat75b HydrichardNo ratings yet

- Nozzle M - Spray SystemDocument4 pagesNozzle M - Spray SystemAry SetiawanNo ratings yet

- Cat75HYD Metric Fine-Spray EDocument12 pagesCat75HYD Metric Fine-Spray Edavide scamardellaNo ratings yet

- Extra Wide Angle Nozzles: Overview: Whirljet Standard, Wide andDocument4 pagesExtra Wide Angle Nozzles: Overview: Whirljet Standard, Wide andAdrian EspinosaNo ratings yet

- Tuf-Lite III Fans 3000K Series Hub: Installation ManualDocument9 pagesTuf-Lite III Fans 3000K Series Hub: Installation ManualVíctor Hugo Morales Curay100% (1)

- cat75HYD Us Hollow-Cone DDocument32 pagescat75HYD Us Hollow-Cone DEmanuelNo ratings yet

- 4000 In-Manual R6Document8 pages4000 In-Manual R6Faiz MiserangNo ratings yet

- Pipetting Challenging Liquids INTL ENDocument1 pagePipetting Challenging Liquids INTL ENXimena Solis TejadaNo ratings yet

- Drilltech Services (USA) Inc: Spiro-TorqDocument10 pagesDrilltech Services (USA) Inc: Spiro-TorqDante Cabrera GuzmanNo ratings yet

- Agricultural-Products-Catalog Impact Sprinklers OnlyDocument19 pagesAgricultural-Products-Catalog Impact Sprinklers OnlyinfocvpjsNo ratings yet

- Fulljet MD WideDocument2 pagesFulljet MD Widechris110No ratings yet

- Hudson Tuflite 5000seriesDocument8 pagesHudson Tuflite 5000seriesGuess VaughnNo ratings yet

- 05 Full Cone NozzlesDocument26 pages05 Full Cone Nozzlesamir ashrafNo ratings yet

- Screw Selector Guide 032906Document1 pageScrew Selector Guide 032906mohitvats916711No ratings yet

- 6000M in Manual - R4Document8 pages6000M in Manual - R4Faiz MiserangNo ratings yet

- Fulljet - SM - Wide - HH-WDocument4 pagesFulljet - SM - Wide - HH-WMilton Jesus Tapia VillarrealNo ratings yet

- Counterbores & CountersinksDocument6 pagesCounterbores & Countersinkscaeiro60No ratings yet

- Description Tungsten Carbide Lined Rubber Jacketed: Short Venturi: TJP, TYP Long Venturi: TSP, TMP, TXPDocument2 pagesDescription Tungsten Carbide Lined Rubber Jacketed: Short Venturi: TJP, TYP Long Venturi: TSP, TMP, TXPGabriel De La FuenteNo ratings yet

- Pressure Washing Cleaning Rinsing Cooling Coating Washdown Parts Washing Degreasing Moistening Surface Preparation SnowmakingDocument54 pagesPressure Washing Cleaning Rinsing Cooling Coating Washdown Parts Washing Degreasing Moistening Surface Preparation SnowmakingVahid ShalchiNo ratings yet

- Cat75HYD Us Flat-Spray CDocument54 pagesCat75HYD Us Flat-Spray ChendNo ratings yet

- Flat Fan Nozzles - Technology: Correct OverlappingDocument24 pagesFlat Fan Nozzles - Technology: Correct OverlappingZen NazehaNo ratings yet

- 76-500 SERIES: FeaturesDocument5 pages76-500 SERIES: FeaturesHung NguyenNo ratings yet

- SprocketDocument41 pagesSprocketDwijo SuwitoNo ratings yet

- Jumper Cable Here For Circuit Bent Bass (Broken Filter IC) : Cut TheseDocument1 pageJumper Cable Here For Circuit Bent Bass (Broken Filter IC) : Cut ThesebanzNo ratings yet

- 71-73 Dynabolts PDFDocument3 pages71-73 Dynabolts PDFErik HaryantoNo ratings yet

- FlowPak - V725 - ANSI - English Veersion Free For Client PDFDocument12 pagesFlowPak - V725 - ANSI - English Veersion Free For Client PDFMisael Castillo CamachoNo ratings yet

- Mechanical Anchoring Systems SectionDocument42 pagesMechanical Anchoring Systems SectionOmoyemi Oluwaseyi FrancisNo ratings yet

- Dry Chemical DesignDocument1 pageDry Chemical DesignmohamedfahmyengNo ratings yet

- ToolsDocument48 pagesToolsTING LINNo ratings yet

- Ruko Twist DrillsDocument80 pagesRuko Twist DrillsPeter NomikosNo ratings yet

- Bicos Spray SprayingDocument40 pagesBicos Spray SprayingAntônio MiguelNo ratings yet

- Cutting Internal Screw ThreadsDocument5 pagesCutting Internal Screw ThreadsAlfred KuwodzaNo ratings yet

- WJ Hollow Med STDDocument7 pagesWJ Hollow Med STDAli MezaNo ratings yet

- B695P SprayDry Performance DataDocument32 pagesB695P SprayDry Performance DataivanNo ratings yet

- US Units Design Case: Released To The Following CompanyDocument2 pagesUS Units Design Case: Released To The Following CompanyPappu Kishore KumarNo ratings yet

- Push-On Hose FittingsDocument4 pagesPush-On Hose FittingsqmasdaNo ratings yet

- Mechanical Anchoring Systems Section-1-9Document9 pagesMechanical Anchoring Systems Section-1-9Mohamed HalathNo ratings yet

- 423 - Fresa DiscoDocument28 pages423 - Fresa DiscoVinicius Sabrina PedroNo ratings yet

- 1.3 Types of Nozzles. Calculations For Calibration of Sprayers and Chemical Application RatesDocument10 pages1.3 Types of Nozzles. Calculations For Calibration of Sprayers and Chemical Application RatesManish KumarNo ratings yet

- Silide Carbide Drilling (Premium Line) PDFDocument183 pagesSilide Carbide Drilling (Premium Line) PDFNicu PascaNo ratings yet

- Cat75hyd Us ADocument16 pagesCat75hyd Us Aaespinosa_rNo ratings yet

- Serie 600.622Document4 pagesSerie 600.622Bryan STNo ratings yet

- RNDC Cylinder Series - MetalworkDocument5 pagesRNDC Cylinder Series - MetalworkMohab AhmedNo ratings yet

- ANZ Technical Guide Heat Exchanger DesigDocument13 pagesANZ Technical Guide Heat Exchanger DesigvikramNo ratings yet

- Spur Gear Design and Selection Standard Proportions: ObjectivesDocument2 pagesSpur Gear Design and Selection Standard Proportions: Objectivesrak9797No ratings yet

- MD Spur DesignDocument8 pagesMD Spur DesignPrithviraj DagaNo ratings yet

- Orifice Plate Overview Rev5 Jan 2016Document14 pagesOrifice Plate Overview Rev5 Jan 2016Karuppiah VairavanNo ratings yet

- Centrifugal Pumps Horizontal FpsDocument2 pagesCentrifugal Pumps Horizontal FpsMiloradRadnovicNo ratings yet

- Drawoff SumpDocument1 pageDrawoff SumpmabtesoreroNo ratings yet

- Valtek FlowpakDocument12 pagesValtek FlowpakRaphael AndradeNo ratings yet

- Crosby Hoist RingDocument1 pageCrosby Hoist RingtecanasioNo ratings yet

- Opnav 4855 1aDocument8 pagesOpnav 4855 1aRobert ValeNo ratings yet

- CBSE Class 12 Informatics Practices Syllabus 2013Document8 pagesCBSE Class 12 Informatics Practices Syllabus 2013meritutorNo ratings yet

- HCIP-LTE-RNP - RNO V1.0 Exam OutlineDocument6 pagesHCIP-LTE-RNP - RNO V1.0 Exam OutlineSemirNo ratings yet

- Danielle Cuomo Updated ResumeDocument1 pageDanielle Cuomo Updated Resumeapi-261843379No ratings yet

- T6 - Huang & Rust 2021Document12 pagesT6 - Huang & Rust 2021Артем СлипченкоNo ratings yet

- Roff Master Fix Adhesive Mfa Tds DownloadDocument5 pagesRoff Master Fix Adhesive Mfa Tds DownloadsanjayNo ratings yet

- Pineapple Extract For Skin Care: FacialsDocument2 pagesPineapple Extract For Skin Care: Facialsrobustauger1567No ratings yet

- While LoopDocument2 pagesWhile LoopNisha PoudelNo ratings yet

- PACER US Vs Adam Hageman Complaint - Nov 12 2020Document5 pagesPACER US Vs Adam Hageman Complaint - Nov 12 2020jpeppardNo ratings yet

- CA. AJAY JAIN, 9310167881: Time Allowed - 3 Hours Maximum Marks - 100Document14 pagesCA. AJAY JAIN, 9310167881: Time Allowed - 3 Hours Maximum Marks - 100RishabNo ratings yet

- x4640 Server ArchitectureDocument44 pagesx4640 Server ArchitecturesandeepkoppisettigmaNo ratings yet

- A Review Bus Run-Off-Road CrashesDocument12 pagesA Review Bus Run-Off-Road CrashesNabeelSaleemNo ratings yet

- File Formats AssignmentDocument16 pagesFile Formats AssignmentmoregauravNo ratings yet

- 2 International Conference On Innovative Trends in Information Technology (ICITIIT'21)Document2 pages2 International Conference On Innovative Trends in Information Technology (ICITIIT'21)sidhushellyNo ratings yet

- Chest Tubes Nursing CareDocument2 pagesChest Tubes Nursing CareYousef KhalifaNo ratings yet

- First Division (G.R. No. 229440. July 14, 2021)Document27 pagesFirst Division (G.R. No. 229440. July 14, 2021)Christopher ArellanoNo ratings yet

- Chandigarh - The City BeautifulDocument14 pagesChandigarh - The City BeautifulAmit GurjarNo ratings yet

- Hot Mix Asphalt: Section 1: IdentificationDocument11 pagesHot Mix Asphalt: Section 1: Identificationfathul syaafNo ratings yet

- Chapter - 5 Organic MaterialsDocument36 pagesChapter - 5 Organic MaterialsJayvin PrajapatiNo ratings yet

- TW LifecycleDocument7 pagesTW LifecycleSiddhi PisalNo ratings yet

- Kalb 15329 PDFDocument65 pagesKalb 15329 PDFRecordTrac - City of OaklandNo ratings yet

- Mangayar Malar Recipes - 01-09-2013 - Tamil MagazinesDocument4 pagesMangayar Malar Recipes - 01-09-2013 - Tamil MagazinesiyappangokulNo ratings yet

- 17CS754 San Notes Svit Module 3Document30 pages17CS754 San Notes Svit Module 3Jacob DragonetteNo ratings yet

- 2017 Merus Installation ManualDocument1 page2017 Merus Installation ManualLipshaNo ratings yet