Professional Documents

Culture Documents

Interior Sig Continuous

Uploaded by

Zuhair AliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Interior Sig Continuous

Uploaded by

Zuhair AliCopyright:

Available Formats

SIG Conti.

Interior

INTERIOR SIG CONTINUOUS

A. GENERAL BACK TO MENU

A1. BRIDGE DESCRIPTION

Bridge Location REGION VII

Bridge Name SIG Conti. Interior

Bridge Simple or Continuous C Steel I-Girder Bridge

Type Number of Span 2

Bridge Width (curb to curb) (m) 24.00

Number of Lanes 6

Bridge Length (m) 27.000 27.000 =54.000m

Year Built 1967

Nos. of Girder 13 Multiple Girder composite for live load

Structure Girder Spacing (m) 2.020 on centers

Substructure Wall Type RC Pier and RC Cantilever Abutments

Wearing thickness (mm) 50

Course material Asphalt

fc= 8.3 Mpa fs= 137.9 Mpa

Material Properties

f'c= 20.7 Mpa fy= 248.2 Mpa

Weight of barrier rail Wbr = 3.600 KN/m

Concrete Unit Weight Wu = 24.0 KN/m3

Assumption

Steel Girder Unit Weight Ws = 77.0 KN/m3

Asphalt Unit Weight Wa = 22.0 KN/m3

Others Rating Live Load is AASHTO MS18 (HS20-44)

NEXT

Year of fc or fs

Material

Construction

f'c or fy

Inventory Operating Posting

Prior to 1905 179.3 96.5 134.4 96.5

Structural

1905 to 1936 206.8 110.3 155.1 110.3

Steel

1936 to 1963 227.5 124.1 168.9 124.1

Bending

after 1963 248.2 137.9 186.2 137.9

Structural Prior to 1905 179.3 58.6 79.3 58.6

Steel 1905 to 1936 206.8 65.5 93.1 65.5

Web 1936 to 1963 227.5 75.8 103.4 75.8

Shear after 1963 248.2 82.7 110.3 82.7

Prior to 1954 227.5 124.1 172.4 124.1

after 1954 275.8 137.9 193.1 137.9

Rebar

Grade 50 344.7 189.8 224.1 137.9 *pc

Grade 60 413.7 227.5 248.2 165.5 *pc

Prior to 1959 17.2 6.9 10.3 6.9

after 1959 20.7 8.3 13.1 8.3

Concrete

1977 to 1981 27.6 11.0 16.5 11.0 *pc

after 1981 31.0 12.4 18.6 12.4 *pc

INTERIOR SIG CONTINUOUS.xls

Sheet 1: GENERAL

SIG Conti. Interior

A2. BRIDGE LAYOUT AND SECTION

24.0m

GIRDER SECTION

SECTION SECTION A (At Pier) SECTION B (Dummy) SECTION C (At Midspan)

Location

(m) 0.010 1.000 13.500

Dimension b (m) h (m) b (m) h (m) b (m) h (m)

thickness = 0.170 m

Slab

0.202 0.170 0.202 0.170 0.202 0.170 *10 (Modular Ratio)

0.300 0.062 0.300 0.029 0.300 0.022

Uflg

0.000 0.000 0.000 0.000 0.000 0.000

0.010 0.810 0.010 0.810 0.010 0.810

Web

0.000 0.000 0.000 0.000 0.000 0.000

0.300 0.062 0.300 0.032 0.300 0.051

Lflg

0.000 0.000 0.000 0.000 0.000 0.000

Length 2.700 2.700 16.200

NEXT

INTERIOR SIG CONTINUOUS.xls

Sheet 2: LAYOUT

SIG Conti. Interior

B. DEMAND FORCES

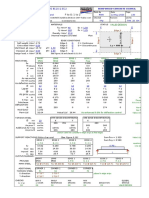

B.1 INPUT AND SECTION PROPERTIES

B0. INPUT

Slab thickness ts (m) 0.170

Slab width ws (m) 2.020

Span Length L(m) 27.000

B1. PROPERTIES OF STEEL GIRDER SECTIONS

(1) UNDER DEAD LOAD (NON-COMPOSIE GIRDER)

SECTION Total Area Web Area Iz (m4) Yb (m) Yt (m) Sxb (m3) Sxt (m3)

A (At Pier) 0.04490 0.00770 0.00750 0.46700 0.46700 0.01607 0.01607

B (Dummy) 0.02600 0.00770 0.00365 0.42192 0.44908 0.00865 0.00813

C (At Midspan) 0.02960 0.00770 0.00390 0.32621 0.55679 0.01197 0.00701

(2) UNDER SUPERIMPOSED DEAD LOAD AND LIVE LOAD (COMPOSIE GIRDER)

A (At Pier) 0.07924 0.00770 0.01352 0.70623 0.22777 0.01914 0.05934

B (Dummy) 0.06034 0.00770 0.00795 0.72590 0.14510 0.01095 0.05480

C (At Midspan) 0.06394 0.00770 0.01053 0.67092 0.21208 0.01570 0.04967

Standard Section Area of "SECTION A"

Original Section Area (m2) 0.0449

B.2 LOAD DEMAND CALCULATIONS

B2.1 DEAD LOAD CALCULATIONS

Section A (At Pier) 0.691

Section B (Dummy) 0.400

Self-weight of Girder

Section C (At Midspan) 1.367

Stiffener and Bracing 0.307

Slab Weight Continuous 8.242

Uniform Load per meter of Girder (KN/m)

Barrier Rail 0.554

Asphalt Overlay 2.222

Total Load 13.784

Total DeadLoad 11.008

Total Superimposed Dead Load 2.776

B2.2 LOAD DEMAND MIDSPAN AND SUPPORT OF STEEL GIRDER

Conducting a Structural Analysis, the load demands for the SPG should be obtained

separately and input the necessary load demands in the Table below.

At Midspan At Pier Support

Description

10.8 m 27.0 m

Dead load moments, KN-m 546.52 -1016.85

Dead load shears, KN -4.24 -184.41

Additional Dead load moments, KN-m 27.65 -51.45

Additional Dead load shears, KN -0.21 -9.93

MS18 max. positive moment, KN-m 1060.52 0.00

MS18 max. negative moment, KN-m -273.15 -957.00

MS18 max. positive shear force, KN 83.28 0.00

MS18 max. negative shear force, KN -84.40 -198.35

NEXT

INTERIOR SIG CONTINUOUS.xls

Sheet 3: DFDLLL

SIG Conti. Interior

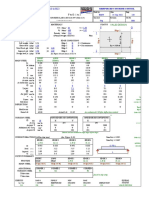

B3. LOAD STRESS CALCULATIONS

B1. PROPERTIES OF STEEL GIRDER SECTIONS

(1) At Midspan

Total Area Web Area Iz (m4) Yb (m) Yt (m) Sxb (m3) Sxt (m3)

For Dead Load 0.02960 0.00770 0.00390 0.32621 0.55679 0.01197 0.00701

For Add.DL

0.06394 0.00770 0.01053 0.67092 0.21208 0.01570 0.04967

and Live Load

(2) At Pier Support

For Dead Load 0.04490 0.00770 0.00750 0.46700 0.46700 0.01607 0.01607

For Add.DL

0.07924 0.00770 0.01352 0.70623 0.22777 0.01914 0.05934

and Live Load

ESTIMATED STRESS DEMANDS AT GIRDER SECTIONS

Loading Location At Midspan At Pier Support

Top 77.95 -63.28

DL moment

Bottom -45.67 63.28

Top 0.56 -0.87

SDL moment

Bottom -1.76 2.69

LL+I moment, σ LL+I

t Top

Bottom

21.35

-67.55

-16.13

50.01

DL shear, v DL 0.55 23.96

SDL shear, v SDL 0.03 1.29

LL+I shear, v LL+I 10.82 25.78

NEXT

INTERIOR SIG CONTINUOUS.xls

Sheet 4: DSDLLL

SIG Conti. Interior

C. LOAD RATING BY ALLOWABLE STRESS METHOD

C1. ALLOWABLE STRESS CALCULATIONS

C.1.1 ALLOWABLE STRESSES FOR CONCRETE AND STEEL

Allowable Stress fc 8.3

Concrete

Material Properties Strength f'c = fc/0.4 20.7

(Mpa) Allowable Stress fs 137.9

Rebar

Strength fy = fs/0.55 248.2

C.1.2 COMPRESSION AND TENSILE STRESSES

Inventory 137.9

Allowable compressive stress

Operating 186.2

Allowable tensile stress Inventory 137.9

C.1.3 ALLOWABLE SHEAR STRESS

Inventory fy/3 82.7

Allowable Shear Stress

Operating 0.45fy 110.3

C2. LOAD RATING CALCULATIONS

C2.1 RATING FACTOR CALCULATIONS USING ASM

Section Description Inventory Operating

Stress at Top Fiber 2.78 5.04

At

Stress at Bottom Fiber 1.34 2.05

Midspan

Shear 7.59 10.14

At Stress at Top Fiber 4.57 7.57

Pier Stress at Bottom Fiber 1.44 2.40

Support Shear 2.23 3.30

C2.2 LOAD RATING CALCULATIONS

Rating Live Load (Metric Tons) 33.0

Section Description

Inventory Operating

At Moment 1.34 44.2 2.05 67.8

Midspan Shear 7.59 250.4 10.14 334.6

At Moment 1.44 47.5 2.40 79.3

Pier

Support Shear 2.23 73.5 3.30 108.9

Depend on the minimum value of Rating Factor > 1 or <1 ,

instruction is automatically shown below

Return to GENERAL

Click following the above instruction

Return to GENERAL

Load Posting

INTERIOR SIG CONTINUOUS.xls

Sheet 5: LRASM

SIG Conti. Interior

D. LOAD POSTING BY LOAD FACTOR METHOD (LFM)

D1. DEMAND FORCES FOR LOAD POSTING VEHICLES

D1.2 POSTING VEHICLE DEMAND FORCES

Conducting a Structural Analysis, the load demands for the SPG should be obtained

separately and input the necessary load demands in the Table below.

Posting Vehicle Demand Forces At Midspan At Pier Support

Moment 657.5 -593.3

Type 1-1

Shear 45.8 -109.1

Moment 869.3 -784.7

Type 1-2

Shear 65.0 -154.7

Moment 859.0 -775.2

Type 12-2

Shear 64.1 -152.7

D1.3 POSTING VEHICLE DEMAND STRESSES

Posting Vehicle Demand Forces At Midspan At Pier Support

Top Fiber 13.24 -10.00

Type 1-1 Bottom Fiber -41.88 31.00

Shear 5.95 14.18

Top Fiber 17.50 -13.22

Type 1-2 Bottom Fiber -55.37 41.00

Shear 8.45 20.10

Top Fiber 17.29 -13.06

Type 12-2 Bottom Fiber -54.71 40.51

Shear 8.33 19.84

NEXT

INTERIOR SIG CONTINUOUS.xls

Sheet 6: POSTASM

SIG Conti. Interior

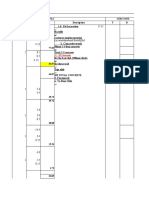

E. LOAD POSTING RATING FACTOR CALCULATIONS

E1. LOAD POSTING RATING FACTOR CALCULATIONS (1)

At Midspan At Pier Support

Posting Vehicle

Inventory Operating Inventory Operating

Top Fiber 4.49 8.13 7.38 12.21

Type 1-1 Bottom Fiber 2.16 3.31 2.32 3.88

Shear 13.80 18.43 4.05 6.00

Top Fiber 3.39 6.15 5.58 9.23

Type 1-2 Bottom Fiber 1.63 2.51 1.75 2.93

Shear 9.72 12.99 2.86 4.23

Top Fiber 3.43 6.23 5.65 9.34

Type 12-2 Bottom Fiber 1.65 2.54 1.78 2.97

Shear 9.86 13.17 2.89 4.29

E2. LOAD POSTING RATING FACTOR CALCULATIONS (2)

Vehicle Inventory Operating

Posting

Vehicle Weight

Moment Shear Moment Shear (Metric

Type (Metric

Tons)

Tons) RF LR RF LR RF LR RF LR

(1) SECTION A

MS18 33.0 1.34 44.2 7.59 250.4 2.05 67.8 10.14 334.6 33

Type 1-1 17.0 2.16 36.7 13.80 234.6 3.31 56.3 18.43 313.4 17

Type 1-2 27.0 1.63 44.1 9.72 262.5 2.51 67.7 12.99 350.7 27

Type 12-2 38.0 1.65 62.8 9.86 374.6 2.54 96.4 13.17 500.5 38

(2) SECTION B

MS18 33.0 1.44 47.5 2.23 73.5 2.40 79.3 3.30 108.9 33

Type 1-1 17.0 2.32 39.4 4.05 68.9 3.88 65.9 6.00 102.0 17

Type 1-2 27.0 1.75 47.4 2.86 77.1 2.93 79.2 4.23 114.2 27

Type 12-2 38.0 1.78 67.5 2.89 110.0 2.97 112.8 4.29 162.9 38

Load Posting

MS18 33T

Type 1-1 17T

Type 1-2 27T

Type 12-2 38T

LOAD

17T

27T

38T

END AND GO TO DECK SLAB

INTERIOR SIG CONTINUOUS.xls

Sheet 7: POSTSUM

You might also like

- Exterior Sig ContinuousDocument9 pagesExterior Sig ContinuousZuhair AliNo ratings yet

- Interior Sig SimpleDocument8 pagesInterior Sig SimpleZuhair AliNo ratings yet

- Interior RCDG SimpleDocument11 pagesInterior RCDG SimpleZuhair AliNo ratings yet

- Exterior Sig SimpleDocument10 pagesExterior Sig SimpleZuhair AliNo ratings yet

- Calculation Report - C01Document29 pagesCalculation Report - C01francis0511No ratings yet

- Rcfs SimpleDocument11 pagesRcfs SimpleZuhair AliNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document4 pagesRCC94 Two-Way Slabs (Tables)HAFEELNo ratings yet

- I. Partial Safety Factors: II. Section PropertiesDocument150 pagesI. Partial Safety Factors: II. Section Propertiespinakin nikash100% (1)

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document3 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2மாறன் செங்கேணிNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document3 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Cioabla BogdanNo ratings yet

- Design TemplateDocument19 pagesDesign TemplatePaul AlcantaraNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document4 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2JigarNo ratings yet

- Under Pass-Eric Take OffDocument20 pagesUnder Pass-Eric Take Offkhraieric16No ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document4 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2christi SNo ratings yet

- Two-Way Slab DesignDocument4 pagesTwo-Way Slab DesignRaghNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document4 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Felicia Ghica100% (1)

- Assignment 3Document3 pagesAssignment 3clinton D'SouzaNo ratings yet

- Prestressed Concrete Deck Girder Girder LengthDocument44 pagesPrestressed Concrete Deck Girder Girder LengthDaniel Laurence Salazar ItableNo ratings yet

- Two-Way Slab V2Document4 pagesTwo-Way Slab V2Eric AbedaniaNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document4 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2ery achjariNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document1 pageF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Ujol PraNo ratings yet

- RCC94 Two-Way Slabs TablesDocument3 pagesRCC94 Two-Way Slabs TablesjohnyNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document5 pagesRCC94 Two-Way Slabs (Tables)adelalwailyNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document3 pagesRCC94 Two-Way Slabs (Tables)Mohammad Twaha JaumbocusNo ratings yet

- Rcfs ContinuousDocument11 pagesRcfs ContinuousZuhair AliNo ratings yet

- 1.structure Report - HOmeDocument23 pages1.structure Report - HOmeBibek WagleNo ratings yet

- Spreader Beam CalDocument98 pagesSpreader Beam CalHa HoangNo ratings yet

- Two Way Continuous and Simply Supported CompletedDocument18 pagesTwo Way Continuous and Simply Supported CompletedSuraj GurungNo ratings yet

- Column & FootingDocument32 pagesColumn & FootingAmol potdarNo ratings yet

- Sebeta Prieced Boq Final Edited OneDocument57 pagesSebeta Prieced Boq Final Edited OneHailuGelanHubenaNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document4 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Mohammed ElemamNo ratings yet

- RCC92 Ribbed Slabs (Tables)Document9 pagesRCC92 Ribbed Slabs (Tables)christi SNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document5 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Murthy GunaNo ratings yet

- BBS-T.19 KeDocument4 pagesBBS-T.19 Keislah ksbNo ratings yet

- Design of Deckslab IRC 112Document24 pagesDesign of Deckslab IRC 112Structural SpreadsheetsNo ratings yet

- Geometry of MS Pipe Staging For PSC GirderDocument5 pagesGeometry of MS Pipe Staging For PSC Girderqs.saidurrahmanNo ratings yet

- 1st Floor 2 Way SlabDocument4 pages1st Floor 2 Way SlabOyelade MuyiwaNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document5 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC298675No ratings yet

- Septic Tank BOQDocument9 pagesSeptic Tank BOQelias worku75% (4)

- 2way Slab Output by RCCDocument4 pages2way Slab Output by RCCSherwin PonsNo ratings yet

- Design of Elastomeric Bearing Based On IRC 083-2-1987Document4 pagesDesign of Elastomeric Bearing Based On IRC 083-2-1987Babita SharmaNo ratings yet

- Ks VesicDocument2 pagesKs VesicandreashendiNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document1 pageF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Yasiri LucNo ratings yet

- Prestressed Concrete Deck Girder Girder LengthDocument15 pagesPrestressed Concrete Deck Girder Girder LengthDaniel Laurence Salazar ItableNo ratings yet

- Steel DesignDocument29 pagesSteel DesignAyman Sobhy100% (1)

- 2-Way Spanning Insitu Concrete Slabs To Bs 81101997 (Table 3.14)Document4 pages2-Way Spanning Insitu Concrete Slabs To Bs 81101997 (Table 3.14)alialiNo ratings yet

- RCC92 Ribbed Slabs (Tables)Document7 pagesRCC92 Ribbed Slabs (Tables)Cioabla BogdanNo ratings yet

- Excel Sheet 2007Document20 pagesExcel Sheet 2007Muhammad ImranNo ratings yet

- Highway Steel Composite Bridge Design Using LimitDocument9 pagesHighway Steel Composite Bridge Design Using LimitDiya lizbeth joseNo ratings yet

- Assessment 1 (12200099)Document90 pagesAssessment 1 (12200099)Er SanjivNo ratings yet

- I. Input Data 1.section of Joist: W W F, Top F, Top F, Bot F, BotDocument22 pagesI. Input Data 1.section of Joist: W W F, Top F, Top F, Bot F, BotAnh KyNo ratings yet

- Document 1Document4 pagesDocument 1pejakm1No ratings yet

- RCC95 Continuous Beams (Tables)Document8 pagesRCC95 Continuous Beams (Tables)Felicia GhicaNo ratings yet

- Toaz - Info Septic Tank Boq PRDocument14 pagesToaz - Info Septic Tank Boq PRKunal SeeboruthNo ratings yet

- Elevated Water Tank FinalDocument185 pagesElevated Water Tank FinalMark Ruby OpawonNo ratings yet

- 1.202 (Bending) : Tramo E-FDocument2 pages1.202 (Bending) : Tramo E-FDaniel Alva PretelNo ratings yet

- Copy-Proposed Fence WorkDocument12 pagesCopy-Proposed Fence WorkdillonperrymarieNo ratings yet

- WallcalcDocument31 pagesWallcalcSubhekshya ShresthaNo ratings yet

- Strproject Rishita 510419136Document58 pagesStrproject Rishita 510419136WAJAHAT AKHTERNo ratings yet

- Footing RSB Cutting ListDocument6 pagesFooting RSB Cutting ListZuhair AliNo ratings yet

- Classified2019 3 3395637Document12 pagesClassified2019 3 3395637Zuhair AliNo ratings yet

- Underground Tank Cutting ListDocument1 pageUnderground Tank Cutting ListZuhair AliNo ratings yet

- Classified Advertising: WWW Gulf-Times ComDocument9 pagesClassified Advertising: WWW Gulf-Times ComZuhair AliNo ratings yet

- Board of Civil Engineering Exam ScopeDocument8 pagesBoard of Civil Engineering Exam ScopeMANDARAW93% (14)

- HW1 Solution PDFDocument6 pagesHW1 Solution PDFZuhair AliNo ratings yet

- Do 041 S2012 PDFDocument16 pagesDo 041 S2012 PDFJahRed FronterasNo ratings yet

- Curie Prob PDFDocument52 pagesCurie Prob PDFLissa HannahNo ratings yet

- Gravity PacketDocument1 pageGravity PacketZuhair AliNo ratings yet

- Structural ExDocument14 pagesStructural ExSheryll de Guzman0% (1)

- CE Refresher 2 Nov 2017 Econ 1 SolDocument1 pageCE Refresher 2 Nov 2017 Econ 1 SolZuhair AliNo ratings yet

- Depth Measuring Techniques PDFDocument46 pagesDepth Measuring Techniques PDFImran RazzaqNo ratings yet

- 1958 Dec 751-756Document6 pages1958 Dec 751-756Zuhair AliNo ratings yet

- Unit No 1Document64 pagesUnit No 1Aadil VahoraNo ratings yet

- Ijtmsr201919 PDFDocument5 pagesIjtmsr201919 PDFPrakash InturiNo ratings yet

- 2.8 Weight 2023Document13 pages2.8 Weight 2023Xinpei ShimNo ratings yet

- Ultra Filtration Manual and Line Diagram (Kanin)Document6 pagesUltra Filtration Manual and Line Diagram (Kanin)marksion exchangeNo ratings yet

- Holographic Optical Data StorageDocument25 pagesHolographic Optical Data StorageShiva GlennNo ratings yet

- Jawaharlal Nehru Technological University Anantapur B.Tech. I - I Sem. L C 4 2 Part-A LABDocument2 pagesJawaharlal Nehru Technological University Anantapur B.Tech. I - I Sem. L C 4 2 Part-A LABHappa1No ratings yet

- Question Report - 11Document17 pagesQuestion Report - 11Suryakant AgrawalNo ratings yet

- Time-Domain Analysis of The Linear SystemsDocument32 pagesTime-Domain Analysis of The Linear SystemskamalNo ratings yet

- Desaireador GKMOSS - Tray - Deaerator - Brochure PDFDocument6 pagesDesaireador GKMOSS - Tray - Deaerator - Brochure PDFCdMoraSNo ratings yet

- User ManualDocument91 pagesUser ManualJorge Luis SoriaNo ratings yet

- Particle Tracing Module Users GuideDocument306 pagesParticle Tracing Module Users GuideAlfonso BarbozaNo ratings yet

- Isothermal Heat Treatment PDFDocument6 pagesIsothermal Heat Treatment PDFsmani170No ratings yet

- AutoCAD - Modify ToolbarDocument18 pagesAutoCAD - Modify ToolbarMarcusNo ratings yet

- Combined Gas Law Lab Report HJM ResearchDocument5 pagesCombined Gas Law Lab Report HJM ResearchHelen100% (4)

- Geotextiles and Geomembranes: E.C. Lee, R.S. DouglasDocument8 pagesGeotextiles and Geomembranes: E.C. Lee, R.S. DouglasPaula T. LimaNo ratings yet

- PugalenthiDocument7 pagesPugalenthiTHANI ORUVANNo ratings yet

- Random Sampling - QuizizzDocument7 pagesRandom Sampling - Quizizzmacjoven101No ratings yet

- AQUATOOL A Generalized Decision Support System For Water Resources Planning and Operational Management 1996 Journal of HydrologyDocument23 pagesAQUATOOL A Generalized Decision Support System For Water Resources Planning and Operational Management 1996 Journal of Hydrologyhoc_kinowNo ratings yet

- Eaton Fuller - Autoshift 16 Service Manual (T20891)Document81 pagesEaton Fuller - Autoshift 16 Service Manual (T20891)Miller Andres ArocaNo ratings yet

- Anthony Hans HL Biology Ia Database WM PDFDocument12 pagesAnthony Hans HL Biology Ia Database WM PDFYadhira IbañezNo ratings yet

- TP3000WC ProWeatherStation User GuideDocument40 pagesTP3000WC ProWeatherStation User GuideRANDY SANTIAGONo ratings yet

- DistilationDocument29 pagesDistilationkindenewNo ratings yet

- 235practice Exam 2 AnswerDocument9 pages235practice Exam 2 Answernbobs7No ratings yet

- Beckman Coulter GenomeLab TroubleshootDocument56 pagesBeckman Coulter GenomeLab TroubleshootChrisNo ratings yet

- Quality For WeldsDocument9 pagesQuality For WeldsArturs StangainisNo ratings yet

- 2200SRM1266 (06 2006) Uk enDocument28 pages2200SRM1266 (06 2006) Uk enEbied Yousif Aly100% (9)

- SSC Scientific Assistant Answer Key For Electronics & Telecommunication 2017Document14 pagesSSC Scientific Assistant Answer Key For Electronics & Telecommunication 2017Shrishanti Kale100% (1)

- Bacterial ClassificationDocument2 pagesBacterial ClassificationAndrew JavierNo ratings yet

- Supply Installation Commissioning of Worlld Largest MillDocument12 pagesSupply Installation Commissioning of Worlld Largest MillAbe ArdiNo ratings yet

- Highwall Miner HWM 300Document20 pagesHighwall Miner HWM 300Amit100% (1)