Professional Documents

Culture Documents

MAN Simplex 25 Oz13749

Uploaded by

jonathanaraujo57Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MAN Simplex 25 Oz13749

Uploaded by

jonathanaraujo57Copyright:

Available Formats

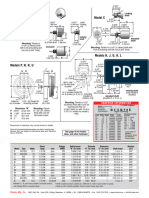

Drill #20 Drill #36

File 1/32 " sq. slot (4 places)

0.500" 0.593"

0.625"

Ø1.063"

0.125" 0.125" 0.125"

Ø1.000"

1.250" 1.250"

0.500"

Ø0.938"

0.594" Ø1.000" 1.250" 0.125" 1.250"

Spot from -2 and -3 0.313"

Drill #44 1/4 " deep

-3 FUEL TANK

Tap 3-48 (8 places)

1-1/4 " sq. Aluminum

Temporary chucking "spud"

Bore Ø0.816" 9/16 " deep (see text)

Thread 28 TPI 1/2 " deep.

Ø0.964"

Drill #38

File flats (4 places)

each 0.344" 1.250"

side 0.125" 1.125" 0.125"

0.031"

1.000" 0.187"

1.098"

1.250"

0.562" 0.250"

Ø0.531" 0.062"

1.250" Ø0.250"

0.001" press

Drill thru -1 Ø1.000" 0.125" 0.125" Ø0.438"

fit on -2

on assrmbly Ø0.500"

Ø0.312" 30°

0.219" Ø1.187"

(Ream)

Ø0.437" 0.062"

Chamfer opening

0.437"

0.025" deep

-1 CRANKCASE -4 VENTURI -2 FRONTPLATE

1-1/4 " sq. Aluminum Aluminum 1-1/4 " sq. Aluminum

MAT'L DO NOT SCALE DRAWING NAME

SCALE FULL SIZE

WORK TO DIMENSIONS

ALL DIMENSIONS

ARE IN INCHES MOTOR MAN SIMPLEX 25

DRAWN Luis Garami 1947 NEXT ASSEMBLY BOYS NUMBER

DATE BY RC 2007-02-03 (INTERNATIONAL)

Sheet 1 - Crankcase

CHANGE CAD

Ø0.172" (Note 1)

0.172" Ø0.980" 45° 0.062"

Drill #19 Port and Passage

1.062"

Tap 10-32 drill #1

Ø0.313"

0.437" Note 2 Ø0.937"

Ø0.250"

0.344"

0.063"

0.187" Ø0.250"

0.063" 0.031" (Note 2)

1.531" 0.125" 60°

Section through inlet port

-1 CRANKSHAFT -2 PROP DRIVER

Steel Steel

Ø0.688"

Ø0.500"

(nom)

Ø0.438" 0.094" 0.031"

0.062" 0.062"

Press fit Cutter:

Ø0.297"

over 1-2 Ø0.375"

0.281"

Housing Drill #3

3/16 " seep

Ø0.161" 0.047"

Note 3 0.188" Ø0.937"

Ø0.812" 0.125"

-7 TIMER MOUNT -5 PISTON BALL SOCKET

0.500"

Aluminum Aluminum Ø0.859"

Screw-cut 28 TPI

Ø0.688"

Ø0.213" 0.062" (typ)

(nom)

0.141"

Ø0.615" 0.062" (typ)

Fin Diameter Table

Ø 0.119" Ø0.438"

Top 1.118 "

5th 1.160 " 0.047" (typ) Ø0.816"

4th 1.187 "

Drill #20 3rd 1.177 " 0.437"

1.375"

2nd 1.142 "

1.328"

1st 1.080 "

Ex. 0.937 "

Ø 0.135" 0.625" 0.578" 0.641"

0.500"

Ø0.172" Notes: 1. Drill for press-fit of Ø 11/64 "

drill rod crankpin Drill #3

(ream) Ø1.187"

2. File 1/32 " deep flat on Ø 1/4 " Tap 1/4-32

Ø0.257" -1 Crankshaft nose. Drill and file

keyed hole in -2 Prop Driver to suit.

-6 CONROD -4 PISTON SHELL -3 CYLINDER

Steel (case harden) Cast Iron (SG or "Meenhite") 3. Drill #44, tap 3-48 on assembly with Timer. Cast Iron (SG or "Meenhite")

MAT'L DO NOT SCALE DRAWING NAME

SCALE FULL SIZE

WORK TO DIMENSIONS

ALL DIMENSIONS

ARE IN INCHES MOTOR MAN SIMPLEX 25

DRAWN Luis Garami 1947 BOYS NUMBER

DATE BY RC 2007-02-03 (INTERNATIONAL)

Sheet 2 - Shaft and Cylinder

CHANGE CAD

Ø0.203"

Ø0.625"

(stock)

1.750" 0.250"

Drill letter "F" (0.257") Drill #3 (0.213")

Ø0.609"

10° from vertical 10° from vertical

120°

Ø0.257"

0.625" 0.625"

Chamfer 45° to

Ø0.609"

Ø0.375" Saw and file ends back as

2.750"

shown after drilling holes

-1 SOCKET SETTING TOOL

Steel 0.148" 0.060"

Stone or grind top cutting surface

at ends before case hardening

Drill #37

0.750" Drill thru #60

Tap 5-40 Ø0.125 "

0.050"

Thread 5-40

9/16 " 9/16 "

-2 CONROD FORM TOOL

Drill Ø0.063 " to: 3/8 " sq. Steel - case harden ends

3/32 " 1.500" 15/16 " on -8 Needle side

1/14 " 7/16 " on fuel supply side

Drill thru #60

-4 SPRAYBAR NUT -3 SPRAYBAR

1/4 " AF Hex Brass (2 required) 1/8 " Ø Brass Rod

5/16 "

1/8 "

3/32 " 3/4 "

1/16 " Ø Music Wire

3/8 " Ø0.125"

3/8 " R0.094"

Drill thru #54

Drill #37 7/16 "

7/16 " deep R0.156"

Ø 3/16 " 0.875"

Tap 5-40 1/2 " 21/64 "

Ø 3/8 "

(medium straight knurl) -5 NEEDLE VALVE -6 NEEDLE RATCHET

Body: Brass 0.010" Hard Brass Shim

Needle: 1/16 " Ø Music Wire

MAT'L DO NOT SCALE DRAWING NAME

SCALE FULL SIZE

WORK TO DIMENSIONS

ALL DIMENSIONS

ARE IN INCHES MOTOR MAN SIMPLEX 25

DRAWN Luis Garami 1947 BOYS NUMBER

DATE BY RC 2007-02-03 (INTERNATIONAL)

Sheet 3 - Tooling and COTS substitutes

CHANGE CAD

R0.608"

0.049" Ø0.188" 0.020" 0.329"

0.135"

Ø0.147"

0.812"

(flat development) 0.175"

0.014" Drill #36 R0.062"

0.375" 0.030" slight kink

0.465"

0.250"

-4 FIXED CONTACT -5 INSULATOR Ø0.094" 0.140"

Tungsten tipped 3-48 screw (Note 1) Ebonite (2 reqd) (Note 1)

0.250"

Drill #25

6 Spring

0.008" clock spring steel -7 MOVING CONTACT

0.145" Ø0.938"

0.030 " hard brass

Ø0.813"

0.270" Ø0.625"

Notes: 1. Tungsten rivet points, once plentiful, are now

Ø0.437" almost extinct. Use them if you've got them.

Otherwise, you can turn them from tungsten Ø0.170"

Drill #36 welding rod. Failing that, drill rod will work, Ø0.106"

(ref) (3-48 thread)

although the use of a transistor switch on the

coil is recommended to reduce the current

and so reduce pitting, making "soft" points

31° practical. 0.039"

0.040"

0.156"

Bend 45-60° to taste

0.125"

0.125"

0.219"

64°

0.106" Ø0.170"

0.395"

1.125" 0.300"

Ø0.125"

-1 TIMER SHELL -2 TIMER ARM -3 CONTACT PIVOT

Aluminum 0.050" Steel Steel

MAT'L As Noted DO NOT SCALE DRAWING NAME

SCALE 2 X SIZE

WORK TO DIMENSIONS

ALL DIMENSIONS

ARE IN INCHES MOTOR MAN SIMPLEX 25

DRAWN Les Stone BOYS NUMBER

DATE CHANGE BY CAD RC 2007-01-05 (INTERNATIONAL)

Sheet 4 - TIMER (O&R 29)

4-4 Fixed Contact 3-6 Ratchet

4-5 Insulator(s)

an 3-48 nuts

3-5 Needle Valve

3-3 Spraybar

4-6 Spring

4-2 Timer Arm 4-3 Contact Pivot

Inlet closes TDC 200°

55° ATDC

Transfer opens

50° BBDC Transfer closes 3-4 Nut(s)

Inlet opens

35° ABDC 130° BTDC 3-48 x 1/4"

screw and nut

100° 4-7 Moving Contact

4-1 Timer Shell

Exhaust opens Exhaust closes

58° BBDC 122° BTDC

V3 Sparkplug

115°

2-5 Piston Ball Socket

Model Airplane News SIMPLEX 25

Designed by Louis Garami. 2-3 Cylinder 2-4 Piston Shell

Published in Model Airplane News (MAN) issues of March, 1947 and April, 1947.

Bore: 0.688 " (17.48 mm)

Stroke: 0.688 " (17.48 mm)

Capacity: 0.256 cu in (4.19 cc) 1-2 Frontplate 2-6 Conrod

Compression Ratio: 8:1 1-4 Venturi

2-2 Prop Drive Disk 3-48 x 1/4" screws (8 off)

10-32 Bolt

2-1 Crankshaft 1-3 Fuel Tank

1-1 Crankcase

2-7 Timer Mount

MAT'L DO NOT SCALE DRAWING NAME

SCALE FULL SIZE

WORK TO DIMENSIONS

ALL DIMENSIONS

ARE IN INCHES MOTOR MAN SIMPLEX 25

DRAWN Luis Garami 1947 BOYS NUMBER

DATE BY RC 2007-02-03 (INTERNATIONAL)

Sheet 5 - General Arrangement

CHANGE CAD

You might also like

- Chunn Chum GasDocument5 pagesChunn Chum GasOlavo PastoreNo ratings yet

- Nalon ViperDocument8 pagesNalon ViperDonJohnsonNo ratings yet

- 1 Crankcase: Motor BoysDocument6 pages1 Crankcase: Motor BoysVitaly BilousNo ratings yet

- Reliant Kitten Lower Ball JointDocument1 pageReliant Kitten Lower Ball Jointbluemouse100No ratings yet

- Dragonfly BB Pistol: C Leslie Proper, October 25, 2016Document9 pagesDragonfly BB Pistol: C Leslie Proper, October 25, 2016Fairuz AliNo ratings yet

- Impulser-X Rocket Motor Nozzle: Material: Mild Steel Chamfer All Sharp Edges 0.010 MinDocument1 pageImpulser-X Rocket Motor Nozzle: Material: Mild Steel Chamfer All Sharp Edges 0.010 MinBERNATE TORRES LUIS ALEJANDRONo ratings yet

- BJ Cicada: Bore: Stroke: Displacement: 0.437" (11.10mm) 0.554" (14.07mm) 0.093 Cuin (1.362cc)Document5 pagesBJ Cicada: Bore: Stroke: Displacement: 0.437" (11.10mm) 0.554" (14.07mm) 0.093 Cuin (1.362cc)antamanNo ratings yet

- Ruger MkI ReceiverDocument1 pageRuger MkI Receiverspartan45No ratings yet

- Page 5 - Tension Arm and SpringDocument1 pagePage 5 - Tension Arm and SpringЄвген ЗаліщукNo ratings yet

- Doppler Gear Techbit: Sprockets: Asme/Ansi B29.1MDocument1 pageDoppler Gear Techbit: Sprockets: Asme/Ansi B29.1Mwilmer_tkNo ratings yet

- Gambar Kerja Rangka BillboardDocument1 pageGambar Kerja Rangka BillboardAhmad ZikriNo ratings yet

- Accurate, Temperature Readings Through Radio or Conduction EnvironmentsDocument2 pagesAccurate, Temperature Readings Through Radio or Conduction EnvironmentsGERMANNo ratings yet

- 700 ML Graphics TemplateDocument1 page700 ML Graphics Template薛泽绵No ratings yet

- 001 39014.breezy - Fuselage.isobomDocument1 page001 39014.breezy - Fuselage.isobomGlenn Bartel100% (1)

- Kommando RCVRDocument1 pageKommando RCVRMike Nichlos100% (1)

- Barra/ Contra Peso, VR 2 150 Bar/ Counte Weight, VR 2 150: Cambios / ChangesDocument1 pageBarra/ Contra Peso, VR 2 150 Bar/ Counte Weight, VR 2 150: Cambios / Changestauasi_1No ratings yet

- 36 RGBDocument5 pages36 RGBCaio AlvarezNo ratings yet

- ER Collet SizesDocument1 pageER Collet SizesRavinder SinghNo ratings yet

- Heavy Copper Magnetics PresentationDocument17 pagesHeavy Copper Magnetics PresentationlancerspatNo ratings yet

- Shaft ToleranceDocument1 pageShaft Tolerancegysebaert95No ratings yet

- U 12 CatDocument1 pageU 12 CatNicolas AguilarNo ratings yet

- Spur Gear PDFDocument1 pageSpur Gear PDFJayaprakashNo ratings yet

- Rheostats WirewoundDocument2 pagesRheostats WirewoundFareed KhanNo ratings yet

- Capabilities 2008Document1 pageCapabilities 2008yasharbixNo ratings yet

- Pub Mtw4 NDocument1 pagePub Mtw4 NTelxinaNo ratings yet

- Hollaender Pipe Size Chart 2017Document1 pageHollaender Pipe Size Chart 2017asad balochNo ratings yet

- Standard I.P.S. Pipe Sizes: - The Hollaender Manufacturing CompanyDocument1 pageStandard I.P.S. Pipe Sizes: - The Hollaender Manufacturing CompanyAnonymous P8Bt46mk5INo ratings yet

- 95105A139 - Steel Heavy-Duty Rivet NutDocument1 page95105A139 - Steel Heavy-Duty Rivet NutBaris YeltekinNo ratings yet

- Page 6 - Tensioner BracketDocument1 pagePage 6 - Tensioner BracketЄвген ЗаліщукNo ratings yet

- Rheostats: (Potentiometers) WirewoundDocument3 pagesRheostats: (Potentiometers) WirewoundJumail SobaNo ratings yet

- Instruction Manual - FL11 LED Flood Light PDFDocument2 pagesInstruction Manual - FL11 LED Flood Light PDFSasikumar SivarajNo ratings yet

- Anillo, VC 6 600 RING, VC 6 600: 1. Premaquinado 1. Pre-MachinedDocument1 pageAnillo, VC 6 600 RING, VC 6 600: 1. Premaquinado 1. Pre-Machinedtauasi_1No ratings yet

- Screen OptionsDocument2 pagesScreen Optionsaraz_1985No ratings yet

- vr3 39011 Patrol Fuselage Sheet1Document1 pagevr3 39011 Patrol Fuselage Sheet1andyroads2No ratings yet

- Sequoia Aircraft Corporation: TitleDocument8 pagesSequoia Aircraft Corporation: TitleMitchell TorpyNo ratings yet

- Kaiser Aluminum Soft Alloy Extrusions Product AvailabilityDocument1 pageKaiser Aluminum Soft Alloy Extrusions Product AvailabilityMichaelKubaNo ratings yet

- Data Sheet Deca Switchlab Me040-508762Document1 pageData Sheet Deca Switchlab Me040-508762Engla ZikrillahNo ratings yet

- Data Sheet DECA SWITCHLAB ME040-508762Document1 pageData Sheet DECA SWITCHLAB ME040-508762Engla ZikrillahNo ratings yet

- Series OFC Flow Type Orifice PlatesDocument2 pagesSeries OFC Flow Type Orifice PlatesEnrique AssmannNo ratings yet

- Guideline For Shaft and BoreDocument1 pageGuideline For Shaft and BorePitipong SunkhongNo ratings yet

- Hammer Union 8-0.5 - 4 AcmeDocument1 pageHammer Union 8-0.5 - 4 AcmeQC RegianNo ratings yet

- Sheet Steel Gauge Conversion Chart: Product Search (WEB - Search - Asp)Document2 pagesSheet Steel Gauge Conversion Chart: Product Search (WEB - Search - Asp)waqas_a_shaikh4348No ratings yet

- Ward Office 6 DrawingDocument1 pageWard Office 6 DrawingPrabhat BaralNo ratings yet

- Bend: 1 Left/1 Right: Support 02/02/18 A1061 11/09/96 SupportDocument1 pageBend: 1 Left/1 Right: Support 02/02/18 A1061 11/09/96 SupportHenry delavariNo ratings yet

- Bend: 1 Left/1 Right: Support 02/02/18 A1061 11/09/96 SupportDocument1 pageBend: 1 Left/1 Right: Support 02/02/18 A1061 11/09/96 SupportHenry delavariNo ratings yet

- Flow Tubebtop Wireline Catalog PDFDocument2 pagesFlow Tubebtop Wireline Catalog PDFfelipeNo ratings yet

- ADL - Torque Spec Sheet3Document5 pagesADL - Torque Spec Sheet3docashishmittalNo ratings yet

- Blind BoxDocument1 pageBlind BoxDragonNo ratings yet

- Crimp Ring Recommended Mounting Hole Pin Chuck SocketDocument1 pageCrimp Ring Recommended Mounting Hole Pin Chuck SocketMarcos ZanelliNo ratings yet

- 91032A101 - Bowed External Retaining RingsDocument1 page91032A101 - Bowed External Retaining RingsBaris YeltekinNo ratings yet

- A4 1 of 2 Dimensional Datasheet For Rom-1 100715: Scale Sheet No Doc Number Title Date Ver NoDocument2 pagesA4 1 of 2 Dimensional Datasheet For Rom-1 100715: Scale Sheet No Doc Number Title Date Ver NoNduP78No ratings yet

- Copper Tubes - CHUAN KOKDocument8 pagesCopper Tubes - CHUAN KOKyw_oulalaNo ratings yet

- PriveinventoryDocument3 pagesPriveinventoryapi-256451389No ratings yet

- Technical Data Master: GrippersDocument1 pageTechnical Data Master: Grippersnumber_25No ratings yet

- Streetlight Post DetailsDocument1 pageStreetlight Post DetailsMaRkZzz081No ratings yet

- SCH 80Document9 pagesSCH 80Ahmad AnthonyNo ratings yet

- Chap 3 ADocument16 pagesChap 3 AMike BelayNo ratings yet

- 4aa5 6674eewDocument4 pages4aa5 6674eewAlejandro Casal LagoNo ratings yet

- Ficha Tecnica Dioxido de Titano Rutilo R93Document1 pageFicha Tecnica Dioxido de Titano Rutilo R93Carlos SiuNo ratings yet

- WPS PresentationDocument27 pagesWPS PresentationSenthil Kumar50% (2)

- Extrusion of Blown Film: Josip MauričDocument47 pagesExtrusion of Blown Film: Josip MauričlinchonNo ratings yet

- Combustion Training SummaryDocument58 pagesCombustion Training SummarySearch45No ratings yet

- Spec Automotive CustomerDocument2 pagesSpec Automotive CustomeryantoniNo ratings yet

- Floor Wall PaintDocument6 pagesFloor Wall PaintdenisNo ratings yet

- Beijing BF SeminarDocument36 pagesBeijing BF SeminarAnaruzzaman Sheikh100% (2)

- MTC Er70s 2Document1 pageMTC Er70s 2Mirza BaigNo ratings yet

- (Danny Proulx) Build Your Own Home Office Furnitu PDFDocument130 pages(Danny Proulx) Build Your Own Home Office Furnitu PDFLeila MoghadasNo ratings yet

- Diff Between Soldring and BrazingDocument2 pagesDiff Between Soldring and BrazingEr Gurdeep SinghNo ratings yet

- P MTL Pro 240 39456 CDocument18 pagesP MTL Pro 240 39456 Ccsc EXPERTISENo ratings yet

- BS En-12952-2-2021Document46 pagesBS En-12952-2-2021TANK INSPECTNo ratings yet

- Fire SafetyDocument36 pagesFire SafetyDembelo DagimNo ratings yet

- 031-Itp For Piping Fabrication Ag and Ug PDFDocument11 pages031-Itp For Piping Fabrication Ag and Ug PDFKöksal Patan100% (5)

- Jiangsu Senolo Medical Technology Co., LTD.: NO.88 4 Road, Private Venture Park, Jianhu Contry JiangsuDocument2 pagesJiangsu Senolo Medical Technology Co., LTD.: NO.88 4 Road, Private Venture Park, Jianhu Contry JiangsuPedro Ant. Núñez UlloaNo ratings yet

- Densit WearCast 2000 11-17 1515493405Document2 pagesDensit WearCast 2000 11-17 1515493405Cioz NguyenNo ratings yet

- Final Draft - Specification - ISEJ65 - 22 - 02 - 2021Document2 pagesFinal Draft - Specification - ISEJ65 - 22 - 02 - 2021Uday KumarNo ratings yet

- Coating System Guide For Chemical and Petrochemical PlantsDocument12 pagesCoating System Guide For Chemical and Petrochemical Plantsarun3kumar00_7691821No ratings yet

- Astm A108-3Document8 pagesAstm A108-3Shahid RehmanNo ratings yet

- Jasperson Et Al. - 2010 - Comparison of Micro-Pin-Fin and Microchannel HeatDocument13 pagesJasperson Et Al. - 2010 - Comparison of Micro-Pin-Fin and Microchannel Heatmosab.backkupNo ratings yet

- Sub Marc WeldDocument4 pagesSub Marc WeldzhangjlNo ratings yet

- Coating Presentation TP Bangkok 23 Jan 2014Document54 pagesCoating Presentation TP Bangkok 23 Jan 2014Zadeh NormanNo ratings yet

- TR2000 - Get DatasheetDocument1 pageTR2000 - Get DatasheetwendeltrentoNo ratings yet

- Aluminium Section BR Product CatalogueDocument42 pagesAluminium Section BR Product CataloguePrabhakar PothunuriNo ratings yet

- Green University of Bangladesh Man-Made Fiber 00001 YEANDocument12 pagesGreen University of Bangladesh Man-Made Fiber 00001 YEANAbrar RomanNo ratings yet

- ER2594Document2 pagesER2594Zain Ali KidwaiNo ratings yet

- Purification of Solids by RecrystallizationDocument2 pagesPurification of Solids by RecrystallizationAgus Al ImamNo ratings yet

- Product Data Sheet: Transozinc Silicate Solventborne 1.52Document2 pagesProduct Data Sheet: Transozinc Silicate Solventborne 1.52Sachin NambiarNo ratings yet