Professional Documents

Culture Documents

029934

Uploaded by

Хелфор УкраинаOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

029934

Uploaded by

Хелфор УкраинаCopyright:

Available Formats

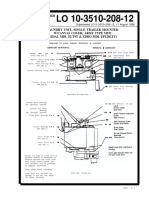

LUBRICATION L05 3805 243 12-2

ORDER

10 APRIL 1968

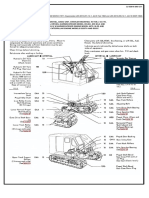

LOADER, SCOOP TYPE, D.E.D., 4 WHEEL DRIVE, PNEUMATIC TIRES,

HINGED FRAME STEER, W/FORKLIFT FRONT MOUNTED,

HYDRAULIC OPERATED, 10,00 LB CAPACITY (EATON

YALE & TOWN, TROJAN MODEL 3000M) W/ENGINE

CUMMINS MODEL C-180-CI

Reference: LO 5-3805-243-12-1 and C9100-IL

Intervals are based on normal hours of operation. Adjust to compensate Clean parts with SOLVENT, dry-cleaning, or with OIL, Fuel, Diesel. Dry

for abnormal operations and severe conditions. During inactive periods, before lubricating.

sufficient lubrication must be performed for adequate preservation.

Lubricate points indicated by dotted arrow shafts on both sides of

Clean fittings before lubricating. equipment.

Relubricate after washing or fording. Drain gearcases when hot. Fill and check level.

FOLD FOLD

(See Note 3.)

(See Note 3.)

FOLD FOLD

-KEY-

LUBRICANTS CAPACITY EXPECTED TEMPERATURES INTERVALS

Above +32°F + 40°F to -10° F 0°F to -65°F

OE -OIL, Engine, Heavy Duty

Oil Can Points

Transmission and Converter 24 qt OE 10 OE 10 OES Intervals

Hydraulic Reservoir 200 qt given are

OES -OIL, Engine, Sub-zero in hours

GO -LUBRICATING OIL, Gear of normal

Front Differential 24 qt GO 90 GO 90 GOS operation.

Rear Differential 24 qt

GOS -LUBRICATING OIL, Gear, Sub-zero

GAA -GREASE, Automotive and Artillery ALL TEMPERATURES

NOTES: 4. LUBRICANTS: The following is a list of lubricants with the Military

1. FOR OPERATION OF EQUIPMENT in PROTRACTED COLD Symbols and the applicable specification numbers.

TEMPERATURES BELOW-10°F. Remove lubricants prescribed in the

key for temperatures above-10°F. Relubricate with lubricants specified OE-MIL-L-2104 OES-MIL-L-10295

in the key for temperatures below-10°F GO-MIL-L-2105 GOS-MIL-L-10324

GAA-MIL-G-10924

2. OIL CAN POINTS. Every 50 hours lubricate handbrake, control lever

linkage, and all exposed adjusting threads with OE. Copy of this Lubrication Order will remain with the equipment at all times;

instructions contained herein are mandatory.

3. HYDRAULIC SYSTEM. Every 100 hours remove breather, wash in

solvent, blow dry and reinstall. Every 250 hours remove steering system BY ORDER OF THE SECRETARY OF THE ARMY:

return filter element, clean housing, and install new element. Every 1000

hours of operation drain and clean hydraulic reservoir, install new HAROLD K. JOHNSON,

element, fill system, operate equip for 5 minutes, check for leaks, check General, United States Army,

oil level and bring to full mark. OFFICIAL: Chief of Staff.

KENNETH G. WICKHAM,

Major General, United States Army,

The Adjutant General.

LO 5-3805-243-12-2 DISTRIBUTION: To de distributed in accordance with DA Form 12-25, Section

II, Organizational Maintenance Requirements for Earth Moving Equipment Leaders.

¶ U.S. GOVERNMENT PRINTING OFFICE : 1994 O - 300-721 (329)

PIN: 029934-000

You might also like

- Chevrolet S-10 Blazer 1983-2005Document21 pagesChevrolet S-10 Blazer 1983-2005diaz_almaraz50% (4)

- Odes 800cc1000cc - WorkshopDocument131 pagesOdes 800cc1000cc - WorkshopIvan RochfordNo ratings yet

- Lubrication (2jz-Ge)Document15 pagesLubrication (2jz-Ge)AlexendraNo ratings yet

- Honda cb750fDocument112 pagesHonda cb750fDanyel LeonNo ratings yet

- Audi q7 Electrical SystemDocument6 pagesAudi q7 Electrical Systemmary100% (57)

- Caterpillar MachinesDocument514 pagesCaterpillar Machinesjosmel2100% (1)

- 2012 Nissan Service Maintenance Guide PDFDocument60 pages2012 Nissan Service Maintenance Guide PDFsameermunshi007100% (1)

- Parts bookCASE 580SN PDFDocument539 pagesParts bookCASE 580SN PDFHuda Huda100% (2)

- Oil and LubricantsDocument95 pagesOil and LubricantspopescucvNo ratings yet

- ACCESORIOS PANEL CONTROS - Car CHINOS Gasgoo - Com Whole Brands Hvac ControllerDocument37 pagesACCESORIOS PANEL CONTROS - Car CHINOS Gasgoo - Com Whole Brands Hvac ControllerivanxpeNo ratings yet

- 05 Power Transmission Fluids Southern Asia 2019Document83 pages05 Power Transmission Fluids Southern Asia 2019Jahmia CoralieNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Lo 5-3805-292-13 M1062Document16 pagesLo 5-3805-292-13 M1062AdvocateNo ratings yet

- Lo 10-3930-669-12 Forklift Truck 6K Drexel MDL R60SL-DCDocument22 pagesLo 10-3930-669-12 Forklift Truck 6K Drexel MDL R60SL-DCAdvocateNo ratings yet

- Bremse GsDocument3 pagesBremse GsХелфор УкраинаNo ratings yet

- 029933Document3 pages029933Хелфор УкраинаNo ratings yet

- Total Task-Hr Total Task-Hr: Card 1 of 2Document6 pagesTotal Task-Hr Total Task-Hr: Card 1 of 2SteveNo ratings yet

- Lo 5-3810-206-12-3Document4 pagesLo 5-3810-206-12-3"Rufus"No ratings yet

- 19 July 1984: Total Man-Hours Total Man-Hours Interval Man-Hours Interval Man-HoursDocument6 pages19 July 1984: Total Man-Hours Total Man-Hours Interval Man-Hours Interval Man-HoursХелфор УкраинаNo ratings yet

- Lubrication Order LO 5-1940-221-12Document4 pagesLubrication Order LO 5-1940-221-12SteveNo ratings yet

- 19 July 1994Document8 pages19 July 1994Хелфор УкраинаNo ratings yet

- 01 August 1984Document6 pages01 August 1984Хелфор УкраинаNo ratings yet

- 26 MARCH 1971 (Supersedes LO5-3810-201-12-3, DTD 9 Feb 1968 and LO5-3810-206-12-3, DTD 18 Mar 1968Document5 pages26 MARCH 1971 (Supersedes LO5-3810-201-12-3, DTD 9 Feb 1968 and LO5-3810-206-12-3, DTD 18 Mar 1968SteveNo ratings yet

- 26 MARCH 1971 (Supersedes L05-3810-201-12-1, DTD 9 Feb 1968 and L05-3810-206-12-1, DTD 18 MAR 1968)Document4 pages26 MARCH 1971 (Supersedes L05-3810-201-12-1, DTD 9 Feb 1968 and L05-3810-206-12-1, DTD 18 MAR 1968)SteveNo ratings yet

- 055766Document8 pages055766Хелфор УкраинаNo ratings yet

- 054931Document8 pages054931Хелфор УкраинаNo ratings yet

- 054933Document9 pages054933Хелфор УкраинаNo ratings yet

- 055508Document8 pages055508Хелфор УкраинаNo ratings yet

- Lo 5-6115-440-12Document2 pagesLo 5-6115-440-12AdvocateNo ratings yet

- Lubrication Order L05 4320-258-12 20 JULY 1977 (Supersedes L05-4320-258-12, 30 July 1971)Document5 pagesLubrication Order L05 4320-258-12 20 JULY 1977 (Supersedes L05-4320-258-12, 30 July 1971)SteveNo ratings yet

- 015352Document8 pages015352Хелфор УкраинаNo ratings yet

- TM 5-2410-241-10Document15 pagesTM 5-2410-241-10"Rufus"0% (1)

- Lubrication Order: Total Task-Hr Total Task-Hr Interval Task-Hr Interval Task-Hr 10 0.5 250 0.1 50 0.4 1000 0.5 100 0.5Document6 pagesLubrication Order: Total Task-Hr Total Task-Hr Interval Task-Hr Interval Task-Hr 10 0.5 250 0.1 50 0.4 1000 0.5 100 0.5SteveNo ratings yet

- Lo 5-6115-434-12Document5 pagesLo 5-6115-434-12AdvocateNo ratings yet

- L010-3930-660-12 Lubrication Order 30 MARCH1993Document21 pagesL010-3930-660-12 Lubrication Order 30 MARCH1993Хелфор УкраинаNo ratings yet

- Lo 10-3530-205-12-2Document4 pagesLo 10-3530-205-12-2AdvocateNo ratings yet

- 17 July 1984 (Supersedes LO 10-3930-620-12, 18 NOVEMBER 1972Document7 pages17 July 1984 (Supersedes LO 10-3930-620-12, 18 NOVEMBER 1972Хелфор УкраинаNo ratings yet

- 22 February 84: LO 10-3930-243-12 Card 1 of 4Document10 pages22 February 84: LO 10-3930-243-12 Card 1 of 4Хелфор УкраинаNo ratings yet

- Dge TXT ReducersDocument18 pagesDge TXT ReducersDênis DáyolNo ratings yet

- Dodge TXT6 Conveyor 19 Gear Reducer SpecsDocument18 pagesDodge TXT6 Conveyor 19 Gear Reducer SpecsEmmanuel DiazNo ratings yet

- Oil and FilterDocument22 pagesOil and FilterAdhi NugrohoNo ratings yet

- 054930Document8 pages054930Хелфор УкраинаNo ratings yet

- 055025Document9 pages055025Хелфор УкраинаNo ratings yet

- Lo 10 3930 631 12Document7 pagesLo 10 3930 631 12SteveNo ratings yet

- 2AZ-FE LubricationDocument22 pages2AZ-FE LubricationAdedeji OluwatobilobaNo ratings yet

- Card 1 of 2Document4 pagesCard 1 of 2Хелфор УкраинаNo ratings yet

- 054541Document7 pages054541Хелфор УкраинаNo ratings yet

- Diesel Engine Appraisal-2Document31 pagesDiesel Engine Appraisal-2hendra mmNo ratings yet

- 2GR FE LubricationDocument20 pages2GR FE LubricationNassar Al-EssawiNo ratings yet

- Lubrication Specifications ChartDocument1 pageLubrication Specifications Chartמסגרת רוצחNo ratings yet

- Lubrication Order: WarningDocument29 pagesLubrication Order: WarningSteven HowellNo ratings yet

- Lube Oil SystemDocument3 pagesLube Oil SystemCharan Kumar100% (1)

- Toyota Land Cruiser 1998 2007 Lubrication System Service ManualDocument2 pagesToyota Land Cruiser 1998 2007 Lubrication System Service Manualadrienne100% (45)

- Owner's Handbook Peugeot 505Document97 pagesOwner's Handbook Peugeot 505luki yuspitaNo ratings yet

- Oil and Filter: InspectionDocument36 pagesOil and Filter: Inspectionkywheat3306No ratings yet

- 5vz Fe LubricationDocument21 pages5vz Fe LubricationHenry SilvaNo ratings yet

- Lubrificação 1 WP2300sDocument2 pagesLubrificação 1 WP2300sVinicio HenriqueNo ratings yet

- Laundry Unit, Single Trailer Mounted W/Canvas Cover Army Type M532 (Eidal MDL Elt9T & Edro MDL Ep120Ltu)Document3 pagesLaundry Unit, Single Trailer Mounted W/Canvas Cover Army Type M532 (Eidal MDL Elt9T & Edro MDL Ep120Ltu)pavannnNo ratings yet

- Lo 5 2350 262 12Document29 pagesLo 5 2350 262 12SteveNo ratings yet

- Lo 5 2350 262 12Document29 pagesLo 5 2350 262 12SteveNo ratings yet

- Cap. 91Document16 pagesCap. 91Marcos ValdezNo ratings yet

- Oil Chart - ShellDocument8 pagesOil Chart - ShellviktorNo ratings yet

- Engine Oil (Checking The Level) : WarningDocument4 pagesEngine Oil (Checking The Level) : WarningPhạm Hoài MinhNo ratings yet

- C6 - 1 HXI HPU Minimum Required Operating Parts 12V2000Document17 pagesC6 - 1 HXI HPU Minimum Required Operating Parts 12V2000Anggi KurniawanNo ratings yet

- CLCentrifugal Pumps CL-100DDocument46 pagesCLCentrifugal Pumps CL-100DMara GonzálezNo ratings yet

- C5000SL инструкция по ремонту-01Document33 pagesC5000SL инструкция по ремонту-01Евгений ГубаревNo ratings yet

- MANUAL LUBGICACION NORD b1100 - Us - 1010Document10 pagesMANUAL LUBGICACION NORD b1100 - Us - 1010Walter JimenezNo ratings yet

- 812 - Turning Gear For Diesel Engines YRTG 18-23Document14 pages812 - Turning Gear For Diesel Engines YRTG 18-23diego19absNo ratings yet

- 028336Document93 pages028336Хелфор УкраинаNo ratings yet

- 051956Document392 pages051956Хелфор УкраинаNo ratings yet

- 028324Document118 pages028324Хелфор УкраинаNo ratings yet

- 028321Document176 pages028321Хелфор УкраинаNo ratings yet

- Operating Instructions Parts List: FH1025-SMS-001 - ENDocument9 pagesOperating Instructions Parts List: FH1025-SMS-001 - ENХелфор УкраинаNo ratings yet

- 028342Document153 pages028342Хелфор УкраинаNo ratings yet

- 028295Document59 pages028295Хелфор УкраинаNo ratings yet

- 028311Document137 pages028311Хелфор УкраинаNo ratings yet

- CLE M UserManualDocument16 pagesCLE M UserManualХелфор УкраинаNo ratings yet

- 015452Document134 pages015452Хелфор УкраинаNo ratings yet

- Nomenclature NSN EIC Nomenclature NSN EICDocument11 pagesNomenclature NSN EIC Nomenclature NSN EICХелфор УкраинаNo ratings yet

- 055508Document8 pages055508Хелфор УкраинаNo ratings yet

- Warranty Program: Department of The Army Technical BulletinDocument8 pagesWarranty Program: Department of The Army Technical BulletinХелфор УкраинаNo ratings yet

- 069858Document248 pages069858Хелфор УкраинаNo ratings yet

- 054930Document8 pages054930Хелфор УкраинаNo ratings yet

- 17 July 1984 (Supersedes LO 10-3930-620-12, 18 NOVEMBER 1972Document7 pages17 July 1984 (Supersedes LO 10-3930-620-12, 18 NOVEMBER 1972Хелфор УкраинаNo ratings yet

- This Copy Is A Reprint Which Includes Current Pages From Change 1Document44 pagesThis Copy Is A Reprint Which Includes Current Pages From Change 1Хелфор УкраинаNo ratings yet

- Operator'S Manual: Pneumatic-Tired WheelsDocument30 pagesOperator'S Manual: Pneumatic-Tired WheelsХелфор УкраинаNo ratings yet

- 028496Document29 pages028496Хелфор УкраинаNo ratings yet

- Army TM 10-3930-253-20PDocument40 pagesArmy TM 10-3930-253-20PХелфор УкраинаNo ratings yet

- 012093Document3 pages012093Хелфор УкраинаNo ratings yet

- Us Terex pt-100 Forestry Mstr-Parts 1-10Document37 pagesUs Terex pt-100 Forestry Mstr-Parts 1-10Хелфор УкраинаNo ratings yet

- Hx10e 540 NiveauDocument11 pagesHx10e 540 NiveauХелфор УкраинаNo ratings yet

- hx10m 2008 540Document6 pageshx10m 2008 540Хелфор УкраинаNo ratings yet

- JLC Trucking Sept 24 2011Document2 pagesJLC Trucking Sept 24 2011asdf_00001No ratings yet

- FLYER E-Bikes Rearshok Table MY21 enDocument6 pagesFLYER E-Bikes Rearshok Table MY21 enHitNo ratings yet

- Build Your Own1Document8 pagesBuild Your Own1niaou gatoulaNo ratings yet

- July-Duty-Sheet-2017.. For Car Import - BangladeshDocument21 pagesJuly-Duty-Sheet-2017.. For Car Import - Bangladeshomar_faruq_669% (13)

- Turbo CatDocument9 pagesTurbo Catali4299No ratings yet

- EFG 213/215/216k/216/218k/218/220: Electric Three-Wheel Truck (1,300/1,500/1,600/1,800/2,000 KG)Document4 pagesEFG 213/215/216k/216/218k/218/220: Electric Three-Wheel Truck (1,300/1,500/1,600/1,800/2,000 KG)MA TotalforkliftNo ratings yet

- Alliance Clutch CatalogDocument4 pagesAlliance Clutch CatalogGustavo MosqueraNo ratings yet

- DicarDocument154 pagesDicarGallo0% (1)

- ETACS ECU Conectores VistaDocument3 pagesETACS ECU Conectores VistaSAUL MASATOSHINo ratings yet

- TRANSMISSION CASE (2 - 2) - Wheel Loader Komatsu WA120-1 - TORQUE CONVERTER AND TRANSMISSION 777partsDocument2 pagesTRANSMISSION CASE (2 - 2) - Wheel Loader Komatsu WA120-1 - TORQUE CONVERTER AND TRANSMISSION 777partsashraf elsayedNo ratings yet

- Suzuki Genuine Parts/2 Wheels/Domestics/Arashi/Body/Fig.30 FrameDocument51 pagesSuzuki Genuine Parts/2 Wheels/Domestics/Arashi/Body/Fig.30 FrameDewa NataNo ratings yet

- DFMEA of A Bicycle: Sno. Item / Function Requirements Potential Failure Mode Potential Effect of FailureDocument8 pagesDFMEA of A Bicycle: Sno. Item / Function Requirements Potential Failure Mode Potential Effect of FailureThomas TamangNo ratings yet

- Difference Between Mountain Bike and BMXDocument3 pagesDifference Between Mountain Bike and BMXShakirNo ratings yet

- Painting OilingDocument4 pagesPainting Oilingprsureshbabu7230No ratings yet

- Jta S. Cruz LP B. InjDocument7 pagesJta S. Cruz LP B. InjRoberto Azevedo da SilvaNo ratings yet

- Leads 7859530e3a083Document70 pagesLeads 7859530e3a083scoop otiblackNo ratings yet

- Electrical Equipment-Circuit DiagramDocument2 pagesElectrical Equipment-Circuit DiagramatitntNo ratings yet

- Webasto Folder Sunroof 2006 AMDocument7 pagesWebasto Folder Sunroof 2006 AMPhilip van AstNo ratings yet

- Smart KeyDocument9 pagesSmart KeyDarkz CruelNo ratings yet

- Paus-1 MincaDocument32 pagesPaus-1 MincaJesus Alejandro Ibarra HernandezNo ratings yet

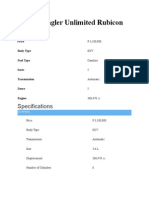

- Jeep Wrangler Unlimited RubiconDocument4 pagesJeep Wrangler Unlimited RubiconlycheemelonNo ratings yet

- C5 Gearbox Gear RatioDocument3 pagesC5 Gearbox Gear Ratiov.d.terzNo ratings yet

- Glass ReferenceDocument26 pagesGlass ReferenceArbey GonzalezNo ratings yet