Professional Documents

Culture Documents

E85 SN B48411001 & Above-401-500

E85 SN B48411001 & Above-401-500

Uploaded by

lssanchez.93Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

E85 SN B48411001 & Above-401-500

E85 SN B48411001 & Above-401-500

Uploaded by

lssanchez.93Copyright:

Available Formats

BLADE CONTROL LEVER (CONT’D) Figure 20-160-20

Disassembly And Assembly (Cont’d)

Figure 20-160-18

1

P-92010

1

Remove the four bolts (Item 1) [Figure 20-160-20].

P-92008

Figure 20-160-21

Route the harness (Item 1) [Figure 20-160-18] through 1

the top of the dust boot.

Figure 20-160-19

Page 401 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

3

2

1 P-92011

Remove the pivot assembly (Item 1), detent lock (Item 2),

and plate (Item 3) [Figure 20-160-21].

P-92006

Loosen the nut (Item 1) [Figure 20-160-19] and remove

the handle and dust boot.

20-160-7 E85 Service Manual

BLADE CONTROL LEVER (CONT’D) Figure 20-160-24

Disassembly And Assembly (Cont’d)

1

Figure 20-160-22

2

P-92018

Remove the lever (Item 1). Remove the shim (Item 2)

P-92021 [Figure 20-160-24] from both sides of the lever.

Figure 20-160-25

Remove the roll pin (Item 1) [Figure 20-160-22].

Figure 20-160-23

2

1 3

Page 402 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

3

2

1 3

P-92011

1

P-92017 Remove the bushings (Item 1) and push rods (Item 2).

Remove the O-rings (Item 3) [Figure 20-160-25] from the

ID and OD of the bushings.

Remove the pivot pin (Item 1) [Figure 20-160-23].

20-160-8 E85 Service Manual

BLADE CONTROL LEVER (CONT’D) Figure 20-160-28

Disassembly And Assembly (Cont’d)

Figure 20-160-26

1 3

1 2 3

P-92015

2 3

Remove the spring (Item 1) and shims (Item 2) from the

P-92013 spool (Item 3) [Figure 20-160-28].

Remove the blade raise spool assembly (Item 1), blade

lower / float spool assembly (Item 2) and springs (Item 3)

[Figure 20-160-26].

NOTE: The spool assemblies must be installed in the

correct bores or the float function of the blade

will not work correctly.

Page 403 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

Figure 20-160-27

1

2

P-32591

Compress the spring (Item 1) and remove the seat (Item

2) [Figure 20-160-27].

20-160-9 E85 Service Manual

20-160-10

E85 Service Manual

Page 404 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

CASE DRAIN FILTER MOUNT

Removal And Installation

Remove the right upperstructure cover. (See Removal

And Installation on Page 40-70-1.)

IMPORTANT

When repairing hydrostatic and hydraulic systems,

clean the work area before disassembly and keep all

parts clean. Always use caps and plugs on hoses,

tubelines and ports to keep dirt out. Dirt can quickly

damage the system.

I-2003-0888

Figure 20-170-1

2 1

Page 405 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

P131646

Remove the two hoses (Item 1) [Figure 20-170-1].

Remove the two bolts (Item 2) [Figure 20-170-1] and

remove the filter mount assembly.

20-170-1 E85 Service Manual

20-170-2

E85 Service Manual

Page 406 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

TRAVEL CONTROL VALVE Figure 20-180-2

Removal And Installation

Remove the travel levers. (See Removal And Installation

on Page 40-90-1.)

1

1

Remove the floor mat and center floorplate. (See

Removal And Installation on Page 40-100-1.)

Figure 20-180-1

1 1

1

P133058

Tip the plate towards the operator’s seat. Mark and

remove the hoses (Item 1) [Figure 20-180-2].

1

If equipped with a sending unit, disconnect the wire

harness.

P133059

IMPORTANT

Remove the bolts (Item 1) [Figure 20-180-1] from the

Page 407 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

When repairing hydrostatic and hydraulic systems,

front floorplate. clean the work area before disassembly and keep all

parts clean. Always use caps and plugs on hoses,

tubelines and ports to keep dirt out. Dirt can quickly

damage the system.

I-2003-0888

Remove the valve / floorplate assembly.

20-180-1 E85 Service Manual

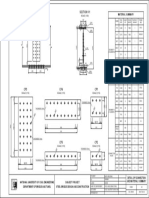

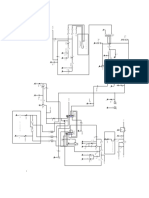

TRAVEL CONTROL VALVE (CONT’D)

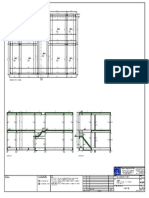

Parts Identification

1. O-ring

2. Bushing 8

3. Plunger

4. Spring Seat

5. Spring

1

6. Shim 9

7. Spool

8. Cable Tie 2

9. Dust Boot

10. Screw

11. Pivot Assembly 1

12. Plate

13. Valve Body 8

14. Plug 3

15. Nut

16. Sending Unit

4

10

5

11

6

Page 408 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

7

12

13 14

1

15

7

7

15

1

1 14

7

15

16 NA2307S

20-180-2 E85 Service Manual

TRAVEL CONTROL VALVE (CONT’D) Figure 20-180-5

Disassembly And Assembly

Figure 20-180-3 1

P-92102

1

Remove the dust boot (Item 1) [Figure 20-180-5].

P-92097

Figure 20-180-6

Remove the bolts (Item 1) [Figure 20-180-3] and nuts.

Remove the valve from the floor pan.

3

Installation: Tighten the bolts to 43 - 47 N•m (32 - 35 ft-

lb) torque.

2

NOTE: The procedure is shown on the left travel side

3

Page 409 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

of the valve. The procedure is the same for

both sides of the valve.

1

Figure 20-180-4

2

1

P-92103

Remove the four screws (Item 1) [Figure 20-180-6] and

remove the pivot assembly.

1

Installation: After installing the pivot assembly loosen

the screws (Item 2). Turn the adjustment screws (Item 3)

[Figure 20-180-6] until there is no end play in the pivot

assembly.

1

Tighten the screws (Item 2) [Figure 20-180-6] after the

P-92101 adjustment is complete.

Cut and remove the cable ties (Item 1) [Figure 20-180-

4].

20-180-3 E85 Service Manual

TRAVEL CONTROL VALVE (CONT’D) Figure 20-180-9

Disassembly And Assembly (Cont’d)

Figure 20-180-7

1

1

P-92106

2

Remove the plunger assemblies (Item 1) [Figure 20-180-

P-92019 9].

Figure 20-180-10

Loosen the screw (Item 1) and remove the pivot pin (Item

2) [Figure 20-180-7].

1

Figure 20-180-8

2

3

Page 410 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

1

P-32587

Remove the O-rings (Item 1) and plunger (Item 2) from

P-92105 the bushing (Item 3) [Figure 20-180-10].

Remove the plate (Item 1) [Figure 20-180-8].

20-180-4 E85 Service Manual

TRAVEL CONTROL VALVE (CONT’D) Figure 20-180-13

Disassembly And Assembly (Cont’d)

3

Figure 20-180-11

2

1

P-32590

1

Remove the spring (Item 1) and shim (Item 2) from the

P-92107 spool (Item 3) [Figure 20-180-13].

Figure 20-180-14

Remove the spool assemblies (Item 1) [Figure 20-180-

11].

Figure 20-180-12

1

1

Page 411 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

P-92108

2 Remove the spring (Item 1) [Figure 20-180-14].

P-32591

Repeat the procedure for the right travel side of the valve.

Compress the spring (Item 1) and remove the seat (Item

2) [Figure 20-180-12].

20-180-5 E85 Service Manual

TRAVEL CONTROL VALVE (CONT’D) Figure 20-180-17

Disassembly And Assembly (Cont’d)

Figure 20-180-15

1 P-95287

1

Remove the O-rings (Item 1) [Figure 20-180-17] from the

P-95286 fittings.

Figure 20-180-18

Remove the fittings (Item 1) [Figure 20-180-15].

Figure 20-180-16

Page 412 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

1

1

P-95288

P-95285 Remove the O-rings (Item 1) [Figure 20-180-18] from the

plugs.

Remove the plugs (Item 1) [Figure 20-180-16].

20-180-6 E85 Service Manual

TRAVEL CONTROL VALVE (CONT’D) Figure 20-180-21

Disassembly And Assembly (Cont’d)

Figure 20-180-19

1 1

2 P-95287

1 2

Remove the O-ring (Item 1) [Figure 20-180-21] from

P-95289 both fittings.

Remove the nut (Item 1) [Figure 20-180-19].

Installation: Tighten the nut to 9,8 N•m (7.2 ft-lb) torque.

Remove the spool (Item 2) [Figure 20-180-19].

Figure 20-180-20

Page 413 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

1

P-95290

Remove the fittings (Item 1) [Figure 20-180-20].

20-180-7 E85 Service Manual

20-180-8

E85 Service Manual

Page 414 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

REMOVING AIR FROM THE HYDRAULIC SYSTEM Start the excavator.

Procedure The excavator piston pump has a minimum displacement

stop, approximately 9,6 L/min (2.4 U.S. gpm) which is

Open the right side cover. (See Opening And Closing on being circulated through the valve even when all

Page 10-60-1.) functions are in neutral.

Figure 20-190-1 If additional air has gotten into some of the circuits

(motors or cylinders), the excavator can be operated with

the bleed tool in place.

1 NOTE: When the excavator is operated with bleed

hose in place, the reservoir cap is removed.

The hydraulic system must be protected from

contamination and spill.

P131648

Install a female quick coupler and hose on the male quick

coupler (Item 1) [Figure 20-190-1].

Figure 20-190-2

Page 415 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

P131647

Remove the fill cap from the reservoir. Route the hose

(Item 1) [Figure 20-190-2] into the reservoir.

NOTE: The hydraulic system must be filled with oil

before starting the excavator to prevent

damage to the system.

20-190-1 E85 Service Manual

20-190-2

E85 Service Manual

Page 416 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

MANIFOLD (PIN GRABBER)

Removal And Installation

IMPORTANT

When repairing hydrostatic and hydraulic systems,

clean the work area before disassembly and keep all

parts clean. Always use caps and plugs on hoses,

tubelines and ports to keep dirt out. Dirt can quickly

damage the system.

I-2003-0888

Lower the work group to the ground.

With the engine off, turn the key to the ON position and

move both hydraulic control levers to relieve hydraulic.

Remove the floor mat and floorplate.

Remove the tool box. (See Removal And Installation on

Page 40-210-1.)

Figure 20-200-1

2

Page 417 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

2

1

P131788

Disconnect the wire harness (Item 1) and hoses (Item 2)

[Figure 20-200-1].

Remove the nuts and bolts (Item 3) [Figure 20-200-1].

Remove the manifold.

20-200-1 E85 Service Manual

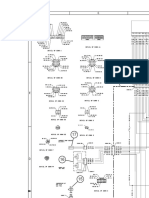

MANIFOLD (PIN GRABBER) (CONT’D)

Parts Identification

1. Nut 1

2. O-ring

3. Coil 2

4. Spool

5. Back-up Ring

6. Body 3

7. Check Valve

8. Plug

9. Orifice

2

5

2

Page 418 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

5

2

5

6

2 5

7

2

8 8

9

NA13737S

20-200-2 E85 Service Manual

MANIFOLD (PIN GRABBER) (CONT’D) Figure 20-200-4

Disassembly And Assembly

Clean the outside of the manifold before disassembly.

1

Figure 20-200-2

P131897

Remove the O-ring (Item 1) [Figure 20-200-4] from the

2 nut.

P131896 Figure 20-200-5

Remove the nut (Item 1) and coil (Item 2) [Figure 20-

200-2] from the spool assembly. 1

Remove the spool from the body.

Page 419 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

Figure 20-200-3

1

1

1 P131899

1

1

Remove the check valve (Item 1) [Figure 20-200-5].

2 2 2

P131898

Remove the O-rings (Item 1) and back-up rings (Item 2)

[Figure 20-200-3] from the spool.

20-200-3 E85 Service Manual

MANIFOLD (PIN GRABBER) (CONT’D) Figure 20-200-8

Disassembly And Assembly (Cont'd)

Figure 20-200-6

P131902

1

Remove the O-rings (Item 1) [Figure 20-200-8] from the

P131900 fittings and plugs.

Figure 20-200-9

Remove the back-up ring (Item 1) and O-rings (Item 2)

[Figure 20-200-6].

Figure 20-200-7 1

2 1

Page 420 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

2

P131904

1

Remove the threaded orifice (Item 1) [Figure 20-200-9]

2 from the P port.

P131901

Clean all parts in solvent and dry with compressed air.

Remove the plugs (Item 1) and fittings (Item 2) [Figure

20-200-7]. Inspect all parts for wear or damage. Replace any worn

or damaged parts.

Always install new back-up rings and O-rings. Lubricate

all O-rings with clean hydraulic fluid before installation.

20-200-4 E85 Service Manual

SECONDARY AUXILIARY VALVE Figure 20-210-2

Removal And Installation

Lower the work group to the ground.

Stop the engine.

With the engine off, turn the start key to the ON position

and move both hydraulic control levers to relieve

hydraulic pressure.

IMPORTANT P128518

When repairing hydrostatic and hydraulic systems,

clean the work area before disassembly and keep all Remove the hoses (Item 1) and tubelines from the top of

parts clean. Always use caps and plugs on hoses, the valve [Figure 20-210-2].

tubelines and ports to keep dirt out. Dirt can quickly

damage the system.

I-2003-0888

Remove the right upperstructure cover. (See Removal

And Installation on Page 40-70-1.)

Remove the battery. (See Removing And Installing The

Battery on Page 50-20-3.)

Page 421 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

Remove the hydraulic reservoir. (See Removal And

Installation on Page 20-140-1.)

Figure 20-210-1

P131589

Disconnect the harness (Item 1) [Figure 20-210-1].

Mark all hoses for proper installation.

20-210-1 E85 Service Manual

SECONDARY AUXILIARY VALVE (CONT’D)

Removal And Installation (Cont'd)

Figure 20-210-3

P131590

Remove the bolts (Item 1) [Figure 20-210-3].

Figure 20-210-4

Page 422 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

1

1

P-95638

Reposition the valve and remove the hoses (Item 1)

[Figure 20-210-4].

Remove the valve.

20-210-2 E85 Service Manual

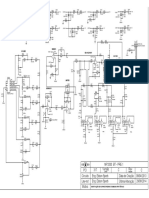

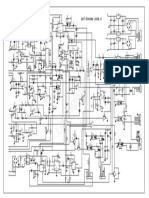

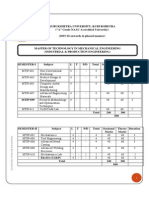

SECONDARY AUXILIARY VALVE (CONT’D)

Parts Identification

1. Nut

2. Coil

3. Solenoid

4. O-ring 6 6

1

5. Back-up Ring

6. Plug

7. Spring

8. Spool 2 4

9. Relief Valve 4

10. Body

7

7

3

8

8

4 4

4

Page 423 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

5

4

5

4

10

4

4

4

6

6

NA10136S

20-210-3 E85 Service Manual

SECONDARY AUXILIARY VALVE (CONT’D) Figure 20-210-7

Disassembly And Assembly

Figure 20-210-5 2 2

1 1 1

2

P122687

Remove the O-rings (Item 1) and back-up rings (Item 2)

P122684 [Figure 20-210-7].

Figure 20-210-8

Remove the nut (Item 1) and coil (Item 2) [Figure 20-

210-5].

Installation: Tighten the nut to 7 N•m (5 ft-lb) torque.

Figure 20-210-6

1 1

Page 424 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

1

P122686

Remove the relief valves (Item 1) [Figure 20-210-8].

Installation: Tighten the relief valves to 51 - 61 N•m (38 -

P122685 45 ft-lb) torque.

Remove the solenoid (Item 1) [Figure 20-210-6].

Installation: Tighten the solenoid to 24 - 30 N•m (18 - 22

ft-lb) torque.

20-210-4 E85 Service Manual

SECONDARY AUXILIARY VALVE (CONT’D) Figure 20-210-11

Disassembly And Assembly (Cont'd)

Figure 20-210-9

1

P122691

1

Remove the O-ring (Item 1) [Figure 20-210-11].

P122688

Figure 20-210-12

Remove the O-ring (Item 1) [Figure 20-210-9]. 1

Figure 20-210-10

2 2

1 1

Page 425 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

P122695

Remove the springs (Item 1) and spools (Item 2) [Figure

P122689 20-210-12].

Remove the plugs (Item 1) [Figure 20-210-10].

20-210-5 E85 Service Manual

SECONDARY AUXILIARY VALVE (CONT’D)

Disassembly And Assembly (Cont'd)

Figure 20-210-13

1 1

P122692

Remove the plugs (Item 1) [Figure 20-210-13].

Tighten the plugs to 96 - 107 N•m (71 - 79 ft-lb) torque.

Figure 20-210-14

Page 426 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

1

P122693

Remove the O-rings (Item 1) [Figure 20-210-14].

Clean all parts in solvent and dry with compressed air.

Inspect all parts for wear or damage. Replace any worn

or damaged parts.

Always install new O-rings. Lubricate the O-rings with

clean hydraulic fluid before installation.

20-210-6 E85 Service Manual

VALVE (BOOM LOCK) Figure 20-220-2

Removal And Installation

2

Lower the work group to the ground.

With the engine off, turn the key to the ON position and

move both hydraulic control levers to relieve hydraulic

pressure.

Figure 20-220-1 1

1

P133216

1

2 Remove the hose (Item 1) [Figure 20-220-2].

Disconnect the tubeline (Item 2) [Figure 20-220-2].

1

P132112

Remove the four bolts (Item 1) and cover (Item 2) [Figure

Page 427 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

20-220-1].

IMPORTANT

When repairing hydrostatic and hydraulic systems,

clean the work area before disassembly and keep all

parts clean. Always use caps and plugs on hoses,

tubelines and ports to keep dirt out. Dirt can quickly

damage the system.

I-2003-0888

20-220-1 E85 Service Manual

VALVE (BOOM LOCK) (CONT’D)

Removal And Installation (Cont’d)

Figure 20-220-3

P133215

Remove the two hoses (Item 1) [Figure 20-220-3].

Figure 20-220-4

Page 428 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

3

P133213

Remove the nuts (Item 1) and bolts. Remove the valve

(Item 2) [Figure 20-220-4].

The lock valve is not serviceable. If the relief valves (Item

3) [Figure 20-220-4] have been tampered with, the

complete valve assembly must be replaced.

20-220-2 E85 Service Manual

VALVE (ARM LOCK)

Removal And Installation

IMPORTANT

Lower the work equipment to the ground.

When repairing hydrostatic and hydraulic systems,

With the engine off, turn the key to the ON position and clean the work area before disassembly and keep all

move both hydraulic control levers to relieve hydraulic parts clean. Always use caps and plugs on hoses,

pressure. tubelines and ports to keep dirt out. Dirt can quickly

damage the system.

Figure 20-221-1 I-2003-0888

Figure 20-221-3

1

P133184

P133185

Remove the bolts (Item 1) [Figure 20-221-1].

Page 429 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

Figure 20-221-2 Remove the hoses (Item 1) [Figure 20-221-3].

Figure 20-221-4

1

1

1

2

1

P133183

P133186

Remove the bolts (Item 1) and cover (Item 2) [Figure 20-

221-2].

Remove the three hoses (Item 1) [Figure 20-221-4].

20-221-1 E85 Service Manual

VALVE (ARM LOCK) (CONT’D)

Removal And Installation (Cont’d)

Figure 20-221-5

1 1

P133191

Figure 20-221-6

Page 430 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

2 1

P133189A

Loosen the clamps (Item 1) [Figure 20-221-5] and

remove the valve / bracket assembly (Item 1) [Figure 20-

221-6].

The lock valve is not serviceable. If the relief valves (Item

2) [Figure 20-221-6] have been tampered with, the

complete valve assembly must be replaced.

20-221-2 E85 Service Manual

UNDERCARRIAGE

BLADE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-10-1

Removal And Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-10-1

TRACK UNDERCARRIAGE COMPONENTS (RUBBER TRACK) . . . . . . . . . . . . . . . . . 30-20-1

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-20-1

Track Lug Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-20-1

Checking Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-20-2

Adjusting Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-20-3

Track Removal And Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-20-4

Idler Removal And Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-20-6

Idler Parts Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-20-7

Idler Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-20-8

Idler Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-20-11

Track Tensioner Removal And Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-20-16

Track Tensioner Parts Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-20-17

Track Tensioner Disassembly And Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-20-18

Roller Removal And Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-20-19

Lower Roller Parts Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-20-20

Lower Roller Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-20-21

Lower Roller Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-20-24

Upper Roller Parts Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-20-30

Upper Roller Disassembly And Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-20-31

Sprocket Removal And Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-20-34

Page 431 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

TRACK UNDERCARRIAGE COMPONENTS (STEEL TRACK) . . . . . . . . . . . . . . . . . . 30-21-1

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-21-1

Checking Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-21-2

Adjusting Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-21-3

Track Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-21-4

Track Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-21-6

Idler Removal And Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-21-7

Idler Parts Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-21-8

Idler Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-21-9

Idler Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-21-12

Track Tensioner Removal And Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-21-17

Track Tensioner Parts Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-21-18

Track Tensioner Disassembly And Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-21-19

Roller Removal And Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-21-20

Lower Roller Parts Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-21-21

Lower Roller Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-21-22

Lower Roller Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-21-25

Upper Roller Parts Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-21-31

Upper Roller Disassembly And Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-21-32

Sprocket Removal And Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-21-35

Guide Plate Removal And Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-21-35

30-01 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (SEGMENTED TRACK) . . . . . . . . . . . . . 30-22-1

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-22-1

Rubber Pad Removal And Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-22-1

Guide Plate Removal And Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-22-2

TRACK MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-30-1

Track Damage Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-30-1

SWING CIRCLE GEAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-40-1

Swing Bearing Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-40-1

Swing Bearing Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-40-2

Page 432 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

30-02 E85 Service Manual

BLADE

Removal And Installation

Lower the work group and blade to the ground.

Remove the blade cylinder. (See Removal And

Installation on Page 20-24-2.)

Figure 30-10-1

P131518

Remove the nuts (Item 1) [Figure 30-10-1] and bolt from

the blade arm pivot pin (both sides).

Page 433 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

Remove the pivot pin (Item 2) [Figure 30-10-1] (both

sides).

Remove the blade.

30-10-1 E85 Service Manual

30-10-2

E85 Service Manual

Page 434 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

TRACK UNDERCARRIAGE COMPONENTS (RUBBER Track Lug Height

TRACK)

The lug height of a new rubber track is 30 mm (1.18 in).

Description

Figure 30-20-1

The track undercarriage components consist of the front

idler, top roller, bottom rollers, drive motor and track

frame.

Straight Edge

B-14489

To find the percentage of wear on a excavator track,

measure the height of the lug by placing a straight edge

across the top of three lugs and measure the distance

from the base of the track to the bottom of the straight

edge [Figure 30-20-1].

Divide this measurement by the new track height and

Page 435 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

multiply by 100. This will give the percentage of track lug

left.

Example: lug height 23,4 mm (0.92 in)

0.92

1.15 x 100 = 80

80% of the track lug is remaining with 20% wear on the

track lugs.

30-20-1 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (RUBBER

TRACK) (CONT’D)

Checking Tension WARNING

NOTE: The wear of the pins and bushings on the AVOID INJURY

undercarriage vary with the working Keep fingers and hands out of pinch points when

conditions and the different types of soil checking the track tension.

conditions. It is necessary to inspect track W-2142-0903

tension to maintain the correct tension. See

Service Schedule for the correct service Figure 30-20-3

interval. (See SERVICE SCHEDULE on Page

10-70-1.)

Figure 30-20-2

30 – 45 mm

1

(1.2 – 1.6 in)

P131519

P131422 Figure 30-20-4

Page 436 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

Track Frame

1

30 – 45 mm

(1.2 – 1.6 in)

Track

Roller

P131423

Track

Raise one side of the machine (Approximately four

inches) using the boom and arm. B-14067

Raise the blade fully and install jackstands under the

blade and track frame (Item 1) [Figure 30-20-2]. Raise Measure the clearance at the middle track roller. Do not

the boom until all machine weight is on the jackstands. get fingers into pinch points between the track and the

track roller. Use a bolt or a dowel of the appropriate size

Stop the engine. to check the gap between the contact edge of the roller

and the top edge of the track guide [Figure 30-20-3] and

[Figure 30-20-4].

Rubber Track Clearance: 30 – 45 mm (1.2 – 1.6 in).

30-20-2 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (RUBBER Figure 30-20-7

TRACK) (CONT’D)

1

Adjusting Tension

Figure 30-20-5

P131512

The tension removal tool (P/N 7277225) is available and

1 recommended to direct the flow of grease to aid in

cleanup. Always dispose of the grease in an

environmentally friendly manner.

P131514

Use tool 7277225 (Item 1) [Figure 30-20-7] to loosen the

track tension fitting (Item 1) [Figure 30-20-6] to release

Loosen the two bolts on the cover (Item 1) [Figure 30-20- tension from the track.

5]. Pivot the cover downward.

The tool is sized to fit the one piece track tension fitting

(Item 1) [Figure 30-20-6].

WARNING NOTE: Do not loosen the track tension fitting (Item 1)

[Figure 30-20-6] more than 1-1/2 turns.

Page 437 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

HIGH PRESSURE GREASE CAN Installation: Tighten the track tension fitting to 24 – 30

CAUSE SERIOUS INJURY N•m (18 – 22 ft-lb) torque.

• Do not loosen the track tension fitting more than

1 - 1/2 turns. Repeat the procedure for the opposite side.

W-2994-0515

Figure 30-20-6

P131513

Add grease to the track tension fitting (Item 1) [Figure

30-20-6] until the track tension is correct.

30-20-3 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (RUBBER

TRACK) (CONT’D)

Track Removal And Installation WARNING

Lift and block both sides of the machine as follows: Put jackstands under the blade and rear corners of

the undercarriage before working under the machine.

Raise the blade fully. Failure to block up the machine may allow it to move

or fall and result in injury or death.

Figure 30-20-8 W-2218-1195

Stop the engine.

Release track tension. (See Adjusting Tension on Page

30-20-3.)

Start the engine.

Slowly turn the track in the forward direction.

Figure 30-20-10

1 1

P131515

Use the boom and arm to lift the blade end of the

machine up about 75 mm (3.0 in) and install jackstands

(Item 1) [Figure 30-20-8] under the blade.

Page 438 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

Raise the boom.

Figure 30-20-9

P131517

Insert a steel rod or pipe (Approximately 30 mm [1.250 in]

1 in diameter) between the track and the idler wheel

[Figure 30-20-10].

P133064

Swing the upperstructure 180 degrees and use the boom

and arm to slowly lift the opposite end of the

undercarriage and install jackstands (Item 1) [Figure 30-

20-9] under the undercarriage.

Raise the boom until the weight of the machine is

supported by the jackstands.

30-20-4 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (RUBBER Figure 30-20-12

TRACK) (CONT’D)

Track Removal And Installation (Cont’d)

Figure 30-20-11

P131425

Insert a pry bar between the track and the idler wheel

and pry out on the track until the track slides off the idler

P131424 wheel [Figure 30-20-12].

Remove the track.

Insert a second steel rod or pipe, at a distance of two

lugs, between the track and the idler wheel [Figure 30- To install the track:

20-11]. Continue to turn the track until the first pipe

contacts the track frame. Put the track over the rear drive sprocket lugs.

Stop the engine. Put the front of the track onto the front idler wheel.

Page 439 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

Adding grease to the track tensioner. (See Adjusting

Tension on Page 30-20-3.)

30-20-5 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (RUBBER Figure 30-20-14

TRACK) (CONT’D)

Idler Removal And Installation

Remove the track. (See Track Removal And Installation 1

on Page 30-20-4.)

Figure 30-20-13

3

1 2

1

P131592

Remove the four bolts (Item 1) and washers. Remove the

idler (Item 2) [Figure 30-20-14].

DO NOT DISASSEMBLE OR REPAIR THE COIL

SPRING ASSEMBLY (Item 3) [Figure 30-20-14].

P131591

Install a chain (Item 1) [Figure 30-20-13] and hoist to the

idler and slide the idler out the track frame. WARNING

Page 440 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

P-62574

AVOID INJURY OR DEATH

• Spring loaded components under pressure can

cause serious injury or death.

• Do not disassemble the coil spring assembly

W-2617-1004

30-20-6 E85 Service Manual

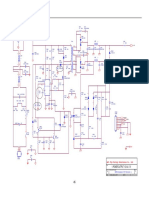

TRACK UNDERCARRIAGE COMPONENTS (RUBBER TRACK) (CONT’D)

Idler Parts Identification

1. Plug

2. Support

3. Roll Pin

4. Seal Assembly

5. O-ring

7

6. Bushing

7. Idler

8. Shaft

4

3

6

5

Page 441 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

2 3

1

5

4

NA14243S

30-20-7 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (RUBBER Figure 30-20-17

TRACK) (CONT’D)

Idler Disassembly

Figure 30-20-15

P-89261

Figure 30-20-18

P-89259

Remove the roll pin (Item 1) [Figure 30-20-15].

Figure 30-20-16 1

Page 442 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

1

P-89263

Remove the floating seal (Item 1) [Figure 30-20-17] and

[Figure 30-20-18] from the support and idler.

P-89260

Pull up on and remove the support (Item 1) [Figure 30-

20-16].

30-20-8 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (RUBBER Figure 30-20-21

TRACK) (CONT’D)

Idler Disassembly (Cont’d)

Figure 30-20-19

P-89267

Figure 30-20-22

P-89264

Remove the O-ring (Item 1) [Figure 30-20-19] from the 1

shaft.

Figure 30-20-20

Page 443 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

P-89268

Remove the floating seal (Item 1) [Figure 30-20-21] and

[Figure 30-20-22] from the support and idler.

P-89266

Tip the idler over and remove the support / shaft

assembly (Item 1) [Figure 30-20-20].

30-20-9 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (RUBBER Figure 30-20-25

TRACK) (CONT’D)

Idler Disassembly (Cont’d)

Figure 30-20-23 1

P-89270

Remove the O-ring (Item 1) [Figure 30-20-25].

P-89262 Figure 30-20-26

Remove the O-ring (Item 1) [Figure 30-20-23] from all

four of the steel seals.

1

Figure 30-20-24

Page 444 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

1

P-89271

Remove the bushings (Item 1) [Figure 30-20-26] from

2 both sides of the idler.

P-89269

Remove the roll pin (Item 1). Remove the shaft (Item 2)

[Figure 30-20-24] from the support.

30-20-10 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (RUBBER NOTE: Inspect the seal ring for damage before

TRACK) (CONT’D) installing the O-ring. Make sure that the O-ring

is not twisted when installing it. To remove

Idler Assembly any twists, gently pull a section of the O-ring

and let it snap back.

Clean all parts in solvent and dry with compressed air.

Figure 30-20-29

The seal assemblies are a matched set and must be

replaced in pairs.

1

Figure 30-20-27

P-40754

Place the seal assembly in the installation tool (Item 1)

P-89271 [Figure 30-20-29].

The O-ring and seal ring assembly have to be lubricated

Install the bushings (Item 1) [Figure 30-20-27] on both with alcohol, so that the O-ring will slip past the housing

sides of the idler.

Page 445 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

retaining ring and seal uniformly in the housing radius.

Figure 30-20-28 Dip the seal assembly in a pan of alcohol.

Figure 30-20-30

1

1

P-89262

P-89276

Install the O-ring (Item 1) [Figure 30-20-28] on the seal

ring. Repeat this procedure on all four seal assemblies.

Shake off the excess alcohol and install the seal

The O-ring and seal ring must be clean and free of any assembly (Item 1) [Figure 30-20-30] in the idler.

dust, oil film, and foreign matter.

Use firm, even pressure on the installation tool to pop the

O-ring into the housing.

Remove the installation tool.

30-20-11 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (RUBBER Figure 30-20-33

TRACK) (CONT’D)

Idler Assembly (Cont’d) 1

Figure 30-20-31 2

P-89269

Install the shaft (Item 1) in the support. Install the roll pin

(Item 2) [Figure 30-20-33] through the shaft and support

P-89277 assembly.

Figure 30-20-34

The seal assembly stand off height must be equal and

the O-ring must not be twisted [Figure 30-20-31].

1

Figure 30-20-32

Page 446 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

1

P-40754

Place the seal assembly (Item 1) [Figure 30-20-34] in

P-89270 the installation tool.

The O-ring and seal ring assembly have to be lubricated

Install the O-ring (Item 1) [Figure 30-20-32] onto the with alcohol, so that the O-ring will slip past the housing

shaft. retaining ring and seal uniformly in the housing radius.

Dip the seal assembly in a pan of alcohol.

30-20-12 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (RUBBER Figure 30-20-37

TRACK) (CONT’D)

Idler Assembly (Cont’d)

Figure 30-20-35 1

P-89264

Install the idler (Item 1) [Figure 30-20-37] on the shaft /

support assembly.

P-89274

Figure 30-20-38

Shake off the excess alcohol and install the seal

assembly (Item 1) [Figure 30-20-35] in the support. 1

Use firm, even pressure on the installation tool to pop the

O-ring into the housing.

Figure 30-20-36

Page 447 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

P-40754

Place the seal assembly (Item 1) [Figure 30-20-38] in

the installation tool.

The O-ring and seal ring assembly have to be lubricated

with alcohol, so that the O-ring will slip past the housing

P-89275 retaining ring and seal uniformly in the housing radius.

Dip the seal assembly in a pan of alcohol.

The seal assembly stand off height must be equal and

the O-ring must not be twisted [Figure 30-20-36].

Apply a light film of oil to both metal seal rings.

NOTE: Do not get any oil on the rubber O-rings.

30-20-13 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (RUBBER Figure 30-20-41

TRACK) (CONT’D)

Idler Assembly (Cont’d)

Figure 30-20-39

1

P-89280

Install the O-ring (Item 1) [Figure 30-20-41] on the shaft.

P-89278 Figure 30-20-42

Shake off the excess alcohol and install the seal 1

assembly (Item 1) [Figure 30-20-39] in the idler.

Use firm, even pressure on the installation tool to pop the

O-ring into the housing.

Remove the installation tool.

Page 448 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

Figure 30-20-40

P-40754

Place the seal assembly (Item 1) [Figure 30-20-42] in

the installation tool.

The O-ring and seal ring assembly have to be lubricated

with alcohol, so that the O-ring will slip past the housing

1 retaining ring and seal uniformly in the housing radius.

Dip the seal assembly in a pan of alcohol.

P-89279

The seal assembly stand off height must be equal and

the O-ring (Item 1) [Figure 30-20-40] must not be

twisted.

30-20-14 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (RUBBER Figure 30-20-45

TRACK) (CONT’D)

Idler Assembly (Cont’d)

Figure 30-20-43 1

P-89283

Install the support (Item 1) on the shaft. Press down on

the support and install the roll pin (Item 2) [Figure 30-20-

P-89281 45].

Figure 30-20-46

Shake off the excess alcohol and install the seal

assembly (Item 1) [Figure 30-20-43] in the idler.

Use firm, even pressure on the installation tool to pop the

O-ring into the housing.

Remove the installation tool.

Page 449 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

1

Figure 30-20-44

89324

Remove the plug (Item 1) [Figure 30-20-46].

Add 0,101 – 0,139 L (3.4 – 4.7 U.S. fl oz) 30W oil to the

1

idler. Install the plug (Item 1) [Figure 30-20-46].

P-89282

The seal stand off height must be equal and the O-ring

(Item 1) [Figure 30-20-44] must not be twisted.

Apply a light film of oil to both metal seal rings.

NOTE: Do not get any oil on the rubber O-rings.

30-20-15 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (RUBBER Figure 30-20-49

TRACK) (CONT’D)

Track Tensioner Removal And Installation

DO NOT DISASSEMBLE OR REPAIR THE COIL

SPRING ASSEMBLY.

Figure 30-20-47

P131596

1

Figure 30-20-50

P131593

Remove the shaft (Item 1) [Figure 30-20-47] from the

tube.

NOTE: Add grease to the track tension fitting to push

Page 450 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

the shaft out of the tube. 1

Figure 30-20-48

P131597

The flat sides (Item 1) [Figure 30-20-49] of the recoil

spring grease cylinder must engage the mount (Item 1)

[Figure 30-20-50] of the track frame.

1

P131594

Lower the tube (Item 1) [Figure 30-20-48] out the bottom

of the track frame.

30-20-16 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (RUBBER TRACK) (CONT’D)

Track Tensioner Parts Identification

1. Coil Spring Assembly

2. Shaft

3. Wiper seal

4. Wear Ring

5. O-ring

6. Seal

7. Tube

8. Bleed / Grease Fitting

1

Page 451 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

NA14241S

30-20-17 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (RUBBER

TRACK) (CONT’D)

Track Tensioner Disassembly And Assembly WARNING

Figure 30-20-51

P-62574

1

AVOID INJURY OR DEATH

• Spring loaded components under pressure can

cause serious injury or death.

• Do not disassemble the coil spring assembly

W-2617-1004

P131600

DO NOT DISASSEMBLE OR REPAIR THE COIL

Remove the O-ring (Item 1) [Figure 30-20-51] from the SPRING ASSEMBLY.

cylinder.

Installation: Apply oil to the O-ring before installation.

Figure 30-20-52

Page 452 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

2

3 4

1

P131595

Remove the wiper seal (Item 1), wear ring (Item 2), seal

(Item 3) and O-ring (Item 4) [Figure 30-20-52].

30-20-18 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (RUBBER Figure 30-20-55

TRACK) (CONT’D)

Roller Removal And Installation

Figure 30-20-53

2

1

P-89286

Remove the bottom roller (Item 1) [Figure 30-20-55].

P-98302 NOTE: The procedure is shown on a lower roller used

with the steel track. The photos may appear

different, the procedure is the same.

Loosen the bolt (Item 1) and nut. Remove the top roller

(Item 2) [Figure 30-20-53].

Installation: Tighten the bolt to 115 – 127 N•m (85 – 95

ft-lb) torque.

Figure 30-20-54

Page 453 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

2 2

P-89285

Loosen the bolts (Item 1) [Figure 30-20-54] on the track

roller on both sides of the track frame.

Installation: Tighten the bolts to 160 – 180 N•m (118 –

133 ft-lb) torque.

30-20-19 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (RUBBER TRACK) (CONT’D)

Lower Roller Parts Identification

1. Collar

2. Plug

3. Roll Pin

4. Seal Assembly

5. O-ring

6. Bushing

7. Roller

8. Shaft

7

6

1

5

Page 454 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

4

2

2

3

5

6 4

NA14244S

30-20-20 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (RUBBER Figure 30-20-58

TRACK) (CONT’D)

Lower Roller Disassembly

1

NOTE: The procedure is shown on a lower roller used

with the steel track. The photos may appear

different, the procedure is the same.

Figure 30-20-56

1

P-89289

2

Remove the seal assembly (Item 1) [Figure 30-20-58].

Figure 30-20-59

P-89287

Drive the pin (Item 1) towards the top of the collar (Item

2) [Figure 30-20-56].

Page 455 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

NOTE: The pin bore in the collar is stepped. 2

Figure 30-20-57 1

P-89290

1

Remove the seal assembly (Item 1). Remove the O-ring

(Item 2) [Figure 30-20-59].

P-89288

Remove the collar (Item 1) [Figure 30-20-57].

30-20-21 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (RUBBER Figure 30-20-62

TRACK) (CONT’D)

Lower Roller Disassembly (Cont’d)

Figure 30-20-60

P-89293

1

Remove the seal assembly (Item 1) [Figure 30-20-62]

from the collar.

P-89291

Figure 30-20-63

Remove the shaft assembly (Item 1) [Figure 30-20-60]

from the roller.

Figure 30-20-61 1

Page 456 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

1

P-89262

Remove the O-ring (Item 1) [Figure 30-20-63] from all

four seal rings.

P-89292

Remove the seal assembly (Item 1) [Figure 30-20-61]

from the roller.

30-20-22 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (RUBBER Figure 30-20-66

TRACK) (CONT’D)

Lower Roller Disassembly (Cont’d)

1

Figure 30-20-64

P-89296

1

Remove the O-ring (Item 1) [Figure 30-20-66].

P-87924 Figure 30-20-67

Remove the pin (Item 1) [Figure 30-20-64].

Figure 30-20-65

1

Page 457 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

1

P-89297

Remove the bushing (Item 1) [Figure 30-20-67] from

both sides of the roller.

P-87925

Remove the shaft (Item 1) [Figure 30-20-65].

30-20-23 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (RUBBER Figure 30-20-70

TRACK) (CONT’D)

Lower Roller Assembly

1

Clean all parts in solvent and dry with compressed air.

The seal assemblies are a matched set and must be

replaced in pairs.

Figure 30-20-68

1

P-89295

Install the shaft (Item 1) [Figure 30-20-70] in the collar.

Figure 30-20-71

P-89297

Install the bushing (Item 1) [Figure 30-20-68] on both

sides of the roller.

Page 458 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

Figure 30-20-69

P-89294

Install the pin (Item 1) [Figure 30-20-71] in the collar and

through the shaft.

P-89296

Install the O-ring (Item 1) [Figure 30-20-69] on the shaft.

30-20-24 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (RUBBER Dip the seal assembly in a pan of alcohol.

TRACK) (CONT’D)

Figure 30-20-74

Lower Roller Assembly (Cont’d)

Figure 30-20-72

1

P-89298

P-89262 Shake off the excess alcohol and install the seal

assembly (Item 1) [Figure 30-20-74] in the collar.

Install the O-ring (Item 1) [Figure 30-20-72] on the seal Use firm, even pressure on the installation tool to pop the

ring. Repeat this procedure on all four seal assemblies. O-ring in to the collar.

The O-ring and seal ring must be clean and free of any Remove the installation tool.

dust, oil film and foreign matter.

Figure 30-20-75

NOTE: Inspect the seal ring for damage before

Page 459 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

installing the O-ring. Make sure that the O-ring

is not twisted when installing it. To remove

any twists, gently pull a section of the O-ring

and let it snap back.

Figure 30-20-73

P-89299

The seal assembly stand off height must be equal and

the O-ring must not be twisted [Figure 30-20-75].

P-40754

Place the seal assembly in the installation tool (Item 1)

[Figure 30-20-73].

The O-ring and seal ring assembly have to be lubricated

with alcohol, so that the O-ring will slip past the housing

retaining ring and seal uniformly in the housing radius.

30-20-25 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (RUBBER Figure 30-20-78

TRACK) (CONT’D)

Lower Roller Assembly (Cont’d)

Figure 30-20-76

P-89301

The seal assembly stand off height must be equal and

the O-ring must not be twisted [Figure 30-20-78].

P-40754

Apply a light film of oil to both metal seal rings.

Place the seal assembly (Item 1) [Figure 30-20-76] in NOTE: Do not get any oil on the rubber O-rings.

the installation tool.

Figure 30-20-79

The O-ring and seal ring assembly have to be lubricated

with alcohol, so that the O-ring will slip past the housing

retaining ring and seal uniformly in the housing radius.

1

Page 460 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

Dip the O-ring and seal assembly in a pan of alcohol.

Figure 30-20-77

P-89302

Install the roller (Item 1) [Figure 30-20-79] on the shaft.

P-89300

Shake off the excess alcohol and install the seal

assembly (Item 1) [Figure 30-20-77] in the roller.

Use firm, even pressure on the installation tool to pop the

O-ring in to the collar.

Remove the installation tool.

30-20-26 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (RUBBER Figure 30-20-82

TRACK) (CONT’D)

Lower Roller Assembly (Cont’d)

Figure 30-20-80

P-89304

The seal assembly stand off height must be equal and

the O-ring must not be twisted [Figure 30-20-82].

P-40754

Figure 30-20-83

Place the seal assembly in the installation tool (Item 1)

[Figure 30-20-80].

The O-ring and seal ring assembly have to be lubricated

with alcohol, so that the O-ring will slip past the housing

1

retaining ring and seal uniformly in the housing radius.

Page 461 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

Dip the O-ring and seal ring assembly in a pan of alcohol.

Figure 30-20-81

P-89305

Install the O-ring (Item 1) [Figure 30-20-83].

P-89303

Shake off the excess alcohol and install the seal

assembly (Item 1) [Figure 30-20-81] in the roller.

Use firm, even pressure on the installation tool to pop the

O-ring in to the collar.

Remove the installation tool.

30-20-27 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (RUBBER Figure 30-20-86

TRACK) (CONT’D)

Lower Roller Assembly (Cont’d)

Figure 30-20-84

P-89307

The seal assembly stand off height must be equal and

the O-ring must not be twisted [Figure 30-20-86].

P-40754

Apply a light film of oil to both metal seal rings.

Place the seal assembly in the installation tool (Item 1) NOTE: Do not get any oil on the rubber O-rings.

[Figure 30-20-84].

Figure 30-20-87

The O-ring and seal ring assembly have to be lubricated

with alcohol, so that the O-ring will slip past the housing

retaining ring and seal uniformly in the housing radius. 1

Page 462 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

Dip the O-ring and seal ring assembly in a pan of alcohol.

Figure 30-20-85

P-89308

Install the collar (Item 1) on the shaft. Install the pin (Item

1 2) [Figure 30-20-87] in the collar.

P-89306

Shake off the excess alcohol and install the seal

assembly (Item 1) [Figure 30-20-85] in the roller.

Use firm, even pressure on the installation tool to pop the

O-ring in to the collar.

Remove the installation tool.

30-20-28 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (RUBBER

TRACK) (CONT’D)

Lower Roller Assembly (Cont’d)

Figure 30-20-88

P-89309

Push down on the collar until the pin bore of the collar is

aligned with the pin bore of the shaft. Fully seat the pin

(Item 1) [Figure 30-20-88].

Remove the plug (Item 2) [Figure 30-20-88]. Add 0,121

– 0,160 L (4.1 – 5.4 U.S. fl oz) of 30W oil to the roller.

Page 463 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

Install the plug.

30-20-29 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (RUBBER TRACK) (CONT’D)

Upper Roller Parts Identification

1. Snap Ring

2. Pipe Plug

3. Cover

4. O-ring

5. Bearing

6. Roller

7. Seal

8. Shaft

4 1

Page 464 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

2

NA14245S

30-20-30 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (RUBBER Figure 30-20-91

TRACK) (CONT’D)

Upper Roller Disassembly And Assembly

Figure 30-20-89

1

P-87918

Install a 50,8 mm (2.0 in) long 3,175 mm (1/8 in) NPT

pipe (Item 1) into the cover. Pull up on the pipe to remove

P-87915 the cover (Item 2) [Figure 30-20-91].

Figure 30-20-92

Remove the snap ring (Item 1) [Figure 30-20-89].

Figure 30-20-90

Page 465 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

1

1

P-87919

P-87916 Remove the O-ring (Item 1) [Figure 30-20-92].

Remove the pipe plug (Item 1) [Figure 30-20-90].

30-20-31 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (RUBBER Figure 30-20-95

TRACK) (CONT’D)

Upper Roller Disassembly And Assembly (Cont’d)

1

Figure 30-20-93

1 P-87922

Remove the seal (Item 1) [Figure 30-20-95] from the

shaft.

P-87920

Figure 30-20-96

Remove the snap ring (Item 1) [Figure 30-20-93].

Turn the roller over and drain the oil.

1

Assembly: Add 0,133 – 0,169 L (4.5 – 5.7 U.S. fl oz) of

30W oil to the roller before installing the cover.

Page 466 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

Figure 30-20-94

P-87923

1

Remove the seal (Item 1) [Figure 30-20-96] from the

roller.

P-87921

Remove the shaft (Item 1) [Figure 30-20-94] from the

roller.

30-20-32 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (RUBBER

TRACK) (CONT’D)

Upper Roller Disassembly And Assembly (Cont’d)

Figure 30-20-97

P-87924

Remove the snap ring (Item 1) [Figure 30-20-97].

Figure 30-20-98

Page 467 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

P-87925

Remove the bearings (Item 1) [Figure 30-20-98] from

both ends of the roller.

30-20-33 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (RUBBER

TRACK) (CONT’D)

Sprocket Removal And Installation

Figure 30-20-99

P131427

Remove the drive sprocket bolts [Figure 30-20-99].

Installation: Put thread adhesive (Loctite® 242) on the

bolts and tighten to 245 N•m (181 ft-lb) torque.

Remove the drive sprocket from the travel motor.

Page 468 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

30-20-34 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (STEEL

TRACK)

Description

The track undercarriage components consist of the front

idler, top roller, bottom rollers, drive motor sprocket,

tension cylinder and track frame.

Page 469 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

30-21-1 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (STEEL

TRACK) (CONT’D)

Checking Tension WARNING

NOTE: The wear of the pins and bushings on the AVOID INJURY

undercarriage vary with the working Keep fingers and hands out of pinch points when

conditions and the different types of soil checking the track tension.

conditions. It is necessary to inspect track W-2142-0903

tension to maintain the correct tension. See

Service Schedule for the correct service Figure 30-21-2

interval. (See SERVICE SCHEDULE on Page

10-70-1.)

Track Frame

Figure 30-21-1

Track

40 - 60 mm

1 (1.6 – 2.4 in)

B-15022

P131422 Measure the clearance at the middle track roller. Do not

Page 470 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

get fingers into pinch points between the track and the

track roller. Use a bolt or a dowel of the appropriate size

to check the gap between the contact edge of the roller

and the top edge of the track guide [Figure 30-21-2].

Steel Track Clearance: 40 – 60 mm (1.6 – 2.4 in).

P131423

Raise the side of the machine (approximately 102 mm [4

in]) using the boom and arm.

Raise the blade fully and install jackstands (Item 1)

[Figure 30-21-1] and [Figure 30-21-2] under the blade

and track frame. Raise the boom until all machine weight

is on the jackstands.

Stop the engine.

30-21-2 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (STEEL Figure 30-21-5

TRACK) (CONT’D)

Adjusting Tension

Figure 30-21-3

1

P131512

The tension removal tool (P/N 7277225) is available and

recommended to direct the flow of grease to aid in

1 cleanup. Always dispose of the grease in an

environmentally friendly manner.

P131511

Use tool 7277225 (Item 1) [Figure 30-21-5] to loosen the

track tension fitting (Item 1) [Figure 30-21-4] to release

Loosen the two bolts on the cover (Item 1) [Figure 30-21- tension from the track.

3]. Pivot the cover downward.

The tool is sized to fit the one piece track tension fitting

(Item 1) [Figure 30-21-4].

WARNING NOTE: Do not loosen the track tension fitting (Item 1)

[Figure 30-21-4] more than 1-1/2 turns.

Page 471 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

HIGH PRESSURE GREASE CAN Installation: Tighten the track tension fitting to 24 – 30

CAUSE SERIOUS INJURY N•m (18 – 22 ft-lb) torque.

• Do not loosen the track tension fitting more than

1 - 1/2 turns. Repeat the procedure for the opposite side.

W-2994-0515

Figure 30-21-4

P131513

Add grease to the track tension fitting (Item 1) [Figure

30-21-4] until the track tension is correct.

30-21-3 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (STEEL

TRACK) (CONT’D)

Track Removal WARNING

Lift and block both sides of the machine as follows: Put jackstands under the blade and rear corners of

the undercarriage before working under the machine.

Raise the blade fully. Failure to block up the machine may allow it to move

or fall and result in injury or death.

Figure 30-21-6 W-2218-1195

Stop the engine.

Release track tension. (See Adjusting Tension on Page

30-21-3.)

With the excavator raised and the bleed fitting loosened,

start the excavator. (See Adjusting Tension on Page 30-

21-3.)

Slowly turn the track. This will force more grease out of

1 the grease spring.

1 Stop the engine.

P131515

Use the boom and arm to lift the blade end of the

machine up about 75 mm (3.0 in) and install jackstands WARNING

(Item 1) [Figure 30-21-6] under the blade.

Page 472 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

AVOID INJURY OR DEATH

Raise the boom. Keep fingers and hands out of pinch points when

removing the track.

Figure 30-21-7 W-2173-0195

P133064

Swing the upperstructure 180 degrees and use the boom

and arm to slowly lift the opposite end of the

undercarriage and install jackstands under the

undercarriage (Item 1) [Figure 30-21-7].

Raise the boom until the weight of the machine is

supported by the jackstands.

30-21-4 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (STEEL Figure 30-21-10

TRACK) (CONT’D)

Track Removal (Cont’d)

Figure 30-21-8

1

1

P-87906

Remove the pin (Item 1) [Figure 30-21-10] and any

washers (if equipped).

P-87904

Figure 30-21-11

Rotate the track until the master link and cotter pin (Item

1) [Figure 30-21-8] are at the bottom of the track frame,

between the drive motor and rear lower roller.

Stop the engine.

Remove the cotter pin (Item 1) [Figure 30-21-8].

Page 473 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

Figure 30-21-9

P-87907

Start the excavator and run it at low idle. Slowly engage

the travel motor in the reverse direction. Continue to

engage the travel motor in the reverse direction until the

track has been driven off the track frame [Figure 30-21-

1 11].

Stop the engine.

P-87905

Drive the master pin (Item 1) [Figure 30-21-9] towards

the inside of the track frame.

30-21-5 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (STEEL Figure 30-21-13

TRACK) (CONT’D)

Track Installation

Figure 30-21-12

3

2 2

1

1

P-87906

1 Rotate the track until the track links (Item 1) are located

on the bottom of the track frame, between the drive motor

P-87907 and rear lower roller. Install the master pin (Item 2)

[Figure 30-21-13] from the inside of the track frame.

Place the steel track (Item 1) under the track frame and in Figure 30-21-14

line with the travel motor. Place the opposite end of the

track (Item 2) [Figure 30-21-12] over the drive sprocket.

WARNING

Page 474 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

AVOID INJURY OR DEATH

Drive motor must be operated slowly to avoid any

sudden movements that could cause injury or death.

W-2174-0195

1

With the help of a second person, start the excavator.

Use the travel lever (on the side of the excavator the track

P-87904

in being installed) to slowly turn the drive motor in the

forward direction. Guide the track over the upper roller

(Item 3) [Figure 30-21-12] and on to the front idler. Install the cotter pin (Item 1) [Figure 30-21-14].

30-21-6 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (STEEL Figure 30-21-16

TRACK) (CONT’D)

Idler Removal And Installation

Remove the track. (See Track Removal on Page 30-21- 1

4.)

Figure 30-21-15

3

2

1 1

P131592

Remove the four bolts (Item 1) and washers. Remove the

idler (Item 2) [Figure 30-21-16].

DO NOT DISASSEMBLE OR REPAIR THE COIL

2 SPRING ASSEMBLY (Item 3) [Figure 30-21-16].

P131591

Install a chain (Item 1) [Figure 30-21-15] and hoist to the

idler. WARNING

Slide the idler (Item 2) [Figure 30-21-15] out of the track

Page 475 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

frame.

P-62574

AVOID INJURY OR DEATH

• Spring loaded components under pressure can

cause serious injury or death.

• Do not disassemble the coil spring assembly

W-2617-1004

30-21-7 E85 Service Manual

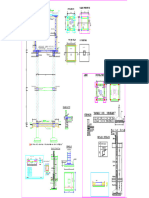

TRACK UNDERCARRIAGE COMPONENTS (STEEL TRACK) (CONT’D)

Idler Parts Identification

1. Plug

2. Support

3. Roll Pin

4. Seal Assembly

5. O-ring

6. Bushing 7

7. Idler

8. Shaft

3

6

5

Page 476 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

3

2

1

4

5

NA14243S

30-21-8 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (STEEL Figure 30-21-19

TRACK) (CONT’D)

Idler Disassembly

Figure 30-21-17

P-89261

Figure 30-21-20

P-89259

Remove the roll pin (Item 1) [Figure 30-21-17].

Figure 30-21-18 1

Page 477 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

P-89263

Remove the floating seal (Item 1) [Figure 30-21-19] and

[Figure 30-21-20] from the support and idler.

P-89260

Pull up on and remove the support (Item 1) [Figure 30-

21-18].

30-21-9 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (STEEL Figure 30-21-23

TRACK) (CONT’D)

Idler Disassembly (Cont’d)

Figure 30-21-21

P-89267

Figure 30-21-24

P-89264

Remove the O-ring (Item 1) [Figure 30-21-21] from the 1

shaft.

Figure 30-21-22

Page 478 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

1

P-89268

Remove the floating seal (Item 1) [Figure 30-21-23] and

[Figure 30-21-24] from the support and idler.

P-89266

Tip the idler over and remove the support / shaft

assembly (Item 1) [Figure 30-21-22].

30-21-10 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (STEEL Figure 30-21-27

TRACK) (CONT’D)

Idler Disassembly (Cont’d)

Figure 30-21-25 1

P-89270

Remove the O-ring (Item 1) [Figure 30-21-27].

P-89262 Figure 30-21-28

Remove the O-ring (Item 1) [Figure 30-21-25] from all

four of the steel seals.

1

Figure 30-21-26

Page 479 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

P-89271

Remove the bushings (Item 1) [Figure 30-21-28] from

2 both sides of the idler.

P-89269

Remove the roll pin (Item 1). Remove the shaft (Item 2)

[Figure 30-21-26] from the support.

30-21-11 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (STEEL NOTE: Inspect the seal ring for damage before

TRACK) (CONT’D) installing the O-ring. Make sure that the O-ring

is not twisted when installing it. To remove

Idler Assembly any twists, gently pull a section of the O-ring

and let it snap back.

Clean all parts in solvent and dry with compressed air.

Figure 30-21-31

The seal assemblies are a matched set and must be

replaced in pairs.

1

Figure 30-21-29

P-40754

Place the seal assembly in the installation tool (Item 1)

P-89271 [Figure 30-21-31].

The O-ring and seal ring assembly have to be lubricated

Install the bushings (Item 1) [Figure 30-21-29] on both with alcohol, so that the O-ring will slip past the housing

sides of the idler.

Page 480 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

retaining ring and seal uniformly in the housing radius.

Figure 30-21-30 Dip the seal assembly in a pan of alcohol.

Figure 30-21-32

1

1

P-89262

P-89276

Install the O-ring (Item 1) [Figure 30-21-30] on the seal

ring. Repeat this procedure on all four seal assemblies.

Shake off the excess alcohol and install the seal

The O-ring and seal ring must be clean and free of any assembly (Item 1) [Figure 30-21-32] in the idler.

dust, oil film and foreign matter.

Use firm, even pressure on the installation tool to pop the

O-ring into the housing.

Remove the installation tool.

30-21-12 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (STEEL Figure 30-21-35

TRACK) (CONT’D)

Idler Assembly (Cont’d) 1

Figure 30-21-33 2

P-89269

Install the shaft (Item 1) in the support. Install the roll pin

(Item 2) [Figure 30-21-35] through the shaft and support

P-89277 assembly.

Figure 30-21-36

The seal assembly stand off height must be equal and

the O-ring must not be twisted [Figure 30-21-33].

1

Figure 30-21-34

Page 481 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

1

P-40754

Place the seal assembly (Item 1) [Figure 30-21-36] in

P-89270 the installation tool.

The O-ring and seal ring assembly have to be lubricated

Install the O-ring (Item 1) [Figure 30-21-34] onto the with alcohol, so that the O-ring will slip past the housing

shaft. retaining ring and seal uniformly in the housing radius.

Dip the seal assembly in a pan of alcohol.

30-21-13 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (STEEL Figure 30-21-39

TRACK) (CONT’D)

Idler Assembly (Cont’d)

Figure 30-21-37 1

P-89264

Install the idler (Item 1) [Figure 30-21-39] on the shaft /

support assembly.

P-89274

Figure 30-21-40

Shake off the excess alcohol and install the seal

assembly (Item 1) [Figure 30-21-37] in the support. 1

Use firm, even pressure on the installation tool to pop the

O-ring into the housing.

Figure 30-21-38

Page 482 - OSS# 6300732522 - All rights reserved by Bobcat Company - 01/20/2022 - 15:50:17 - Produced by Ken Cook Co. with media1off

P-40754

Place the seal assembly (Item 1) [Figure 30-21-40] in

the installation tool.

The O-ring and seal ring assembly have to be lubricated

with alcohol, so that the O-ring will slip past the housing

P-89275 retaining ring and seal uniformly in the housing radius.

Dip the seal assembly in a pan of alcohol.

The seal assembly stand off height must be equal and

the O-ring must not be twisted [Figure 30-21-38].

Apply a light film of oil to both metal seal rings.

NOTE: Do not get any oil on the rubber O-rings.

30-21-14 E85 Service Manual

TRACK UNDERCARRIAGE COMPONENTS (STEEL Figure 30-21-43

TRACK) (CONT’D)