Professional Documents

Culture Documents

Escaner Manual Valvula de Recirculacion

Escaner Manual Valvula de Recirculacion

Uploaded by

.x0 ratings0% found this document useful (0 votes)

10 views12 pages.

Original Title

ESCANER MANUAL VALVULA DE RECIRCULACION

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views12 pagesEscaner Manual Valvula de Recirculacion

Escaner Manual Valvula de Recirculacion

Uploaded by

.x.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 12

ABE ixonranc

HBE/SCHROEDAHL AUTOMATIC RECIRCULATION VALVE

INSTALLATION/MAINTENANCE MANUAL WITH DRAWING

SCHROEDAHL ARV MODEL: TDL 113 UVW SS

LANCASTER STEEL PURCHASE ORDER NO: @® 2812966

HBE REFERENCE NO: 35-1630/A

205 Porage Ave, PO. ee Rivers, Mi 49098 US.A

Phone (65 8

‘SCHROEDANL AUTOMATIC RECIRCULATING VALVE

ABE sxoncranon INSTALLATION AND MAINTENANCE MANUAL

GENERAL, INFORMATION.

‘TYPICAL INSTALLATION. .

INSTALLATION. .

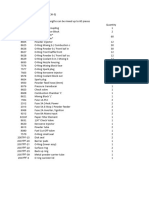

BYPASS ASSEMBLY PARTS LIST.

QUICK HINTS FOR INSTALLATION. ....

‘ASSEMBLY/DISASSEMBLY INSTRUCTIONS...

DRAWING,

205 Forage Ave PO Box 578, Thee River, Ml 45088 US.A

The Schroedahl Automatic Recirculation

Valve series offers the highest state

of the art for centrifugel pump recircu-

lation control systems. with 25 years

experience, i.e., from the original

patent of the self-contained unit to

the latest product improvements, the

Schroedahl series continue to provide

the customer's system with the proper

equipment.

APPLICATION:

Minimum Flow Recirculation for pump

protection.

During critical low-load operating

periods, centrifugal pumps require a

dependable minima flow recirculation

system to prevent overheating and

unstable operation. Previously, these

systems have been comprised of multiple

components including flow or pressure

sensing devices, signal controllers,

check valves, pressure dissipating

devices and diverting control valves.

This resulted in systems that were

both complex and costly, requiring

sizable expenditures for design, in-

stallation, and maintenance, while

Providing marginal performance.

The Schroedahl ARV series offers an

economic alternative to the above out-

lined recirculation system. The ARV

series is a self-contained, automatic

flow regulating device encompassing

all the components of the conventional,

minimum flow system in a single valve.

FEATURES:

The ARV is a compact design offering

several features nonmally associated

only with separate components. ‘The

main body is comprised of a lifting

disc check valve to prevent reverse

flow through the pump. Motion of the

check valve regulates directly the

flow to the bypass section. Selection

of the correct bypass depends on the

flow and pressure requirements of the

pump and process. Bypass options are

detailed on page two (2). Pulsation

dampening device is mounted on top of

the main check valve to eliminate

pulsation.

Use of the ARV reduces power costs,

saves on system engineering and mainte-

nance costs, and reduces down time,

as well as the primary function of

purp protection.

PRINCIPLE OF OPERATI

‘The ARV, just as a check valve, is

installed in the pump main discharge

line. As pump output decreases, flow

across valve also decreases, resulting

in a reduction of dynamic forces

acting on the spring loaded disc. when

these dynamic forces become less than

the spring forces, the disc or check

valve portion begins to seat. It is

important to note that the seating

begins while there is still a positive

flow, thus protecting against reverse

flow.

‘SPECIFICATIONS:

The ARV is available in carbon, alloy,

or stainless steel, and rated by ANSI

pressure classes up to 4500f. Material:

are of the highest quality and selected

to minimize the effects of erosion

and corrosion.

215 Forage Ave, P.O. Box 37S, Thee Rivers, MI 49093 US.A

Phone: (616) 9.2085. Fax (66) TOPS

TOIMAM

The TD and MAM valves basically have the same hou:

sing, with a spring loaded checkvalve.

The checkvalye move upwards when the mainflow in.

Creases.(and downwithadecreasein low). The stem

of the checkvalve transmits the stem motion to-a te

vet. This lever, in turn, opens or closes the bypass

system,

BYPASS - K

Max AP —:2000psi.- 200 BAR.

Minflow [30% of main flow.

BYPASS - L

MODULATING

‘Max. OP 600 psi. 40 BAR,

Minilow ‘as required,

BYPASS - M

MODULATING

Max. AP :2000psi,-200 BAR

Minitow sas required,

BYPASS- MRM

MODULATING

Max.aP—:asrequired

Minjlow Fas required

‘TYPICAL INSTALLATION

HBE sxonmmncne

Bypass to (a) Deaerator

‘Automatic (b) Feedwater

Recirculating (c) Condensor

Valve 7 I

Pump

A

Pump Suction

208 rage Ave, 2.0. Bo

Phone 616 2

Three River, M4908 US.A

ne (19) 706745

INSTALLATION:

‘The pump recirculation control valve,

‘TD series, is best mounted on the

discharge connection of the pump, in

a vertical position with the flow

direction upward.

NOTE: The vertical installation is

considered standard. Horizontal

installation is acceptable but the

valve must be ordered as such. These

valves are fitted with a hard liner

in the check valve area to prevent

excessive wear due to the weight of

the check valve.

If not mounted directly to the pump

flange, the distance between the valve

inlet and pump outlet should not exceed

five (5) feet. This is important so

that low frequency pulsations due to

the elasticity of the fluid are prevented.

The outlet should be connected to

piping such that a minimum of 14" clearance

is available to allow lifting of the

upper housing after the flange bolts

have been removed. This allows access

to the valve internals without dismount-

ing the lower housing.

BYPASS CONNECTION:

The bypass Line should be connected to

the side flange. Provide a 12" spool

piece to facilitate the removal of

the bypass section. The bypass internals

can then be inspected or removed.

NOTE: Be careful to install the

correct valve for each application.

Fach valve is sized for a specific

set of operating conditions. Valves,

even of the sane size, are usually

not interchangeable. Contact HBE

Engineering, Inc. at (616) 279-2035

if any field conditions should change.

On each valve body a special nutber

starting with the letter "K" is

hammered into the body. Please check

this number before contacting HBE

Engineering, Inc.

‘START UP:

Prior to start up, the valve should be

inspected for mechanical damage.

Observe proper operation of the valve

by closing the discharge valve on the

outlet of the pump. A flow should be

noticed through the bypass piping.

Open the discharge valve again to

establish a no-flow condition in the

bypass.

NOTE: The shut off valve in the bypass

should always be opened first during

start up and closed last during shut

down.

‘MAINTENANCE:

Periodically check the correct opera-

tion of the valve. Proceed as de-

scribed in the above section.

INSPECTION:

Disassemble and inspect the valve,

depending on the condition, at least onde

a year. Due to the fact that fluids are

of different natures, we recommend that

the bypass valve be inspected after the

start up procedure. After this, clean

fluids once per year, contaminated fluids

depending on the contamination, every 345

months.

SPARE PARTS:

A parts list is enclosed. It is

reconmended to stock a set of spare

parts (see list) and an extra set of

seals.

208 Porage Ave, P.O. Box 375, Thee Rives, Ml 47098 USA

Phone: 615 29.2088 Fax (66) 2784745,

Install Schrocdahl ARV on pump outlet if possible, but not further

than 5' away from pump outlet. In case installation is further

away than 5*, call HBE Engineering, Inc. for installation instruc-

tions (616) 279-2035.

In case bypass orifice plates are supplied, install these on the

inlet of the bypass line entrance to the feed tank.

In case start up orifices were not part of the supply, renove

bypass valve during cleaning of the systems.

CONTROL VALVES CAN BE DAMAGED BY CONTAMINATED LIQUID.

CLEAN SYSTEM WELL BEFORE OPERATING THE AUTOMATIC

RECIRCULATING VALVE.

In case isolation valves are installed to isolate the pump and

recirculating valve, the following start up and shut down

Procedures should be used:

START UP: a. Open bypass line isolation valve.

b. Open suction side and outlet side

isolation valves.

Close suction side and outlet side

isolation valves.

Close bypass line isolation valve.

208 Forage Ave, P.O Box

hone (66) 2

Thee River, Ml 49098 USA.

18 O-AS

ABE moneranc

ASSEMBLY AND DISASSEMBLY

‘The automatic recirculating valve Model TDM (called hereafter TDM) is usually

installed vertically, with the mainflow upward, and directly on the pump

discharge flange. The bypass housing is connected to the bypass piping (and

the piping consequently to the feedwater tank) so that a recirculation flow

will be possible. Other installation positions of the valve (horizontal,

upside-down) are possible, if so ordered only.

No special tools are required for the installation, assembly or disassembly

of the valve.

INSTALLATION AT THE JOBSITE

In order to prevent damage to the flange finish and/or the bolts, the complete

valve should be installed in the piping, free of tension/stress.

DISASSEMBLY OF THE ‘TIM

Remove the TON fram the piping system. Disassemble bypass housing Pos. 09.

Pull the bypass trim "M” out of the assambly carefully. Apply a screwdriver

between the collar of the control head (Pos. 11) and the valve body (Pos. 1).

Remove the upper body (Pos. 2) from the lower body (Pos. 1) by loosening the

hexagon nuts (Pos. 28).

The check valve (Pos. 7) and spring (Pos. 6) can now be removed from the

ower body (Pos. 28).

Clean all parts and check for any damages. In case of damaged seats (check

valve seat or bypass seat), this should be repaired by lapping the respective

parts on the seats.

Replace ring (Pos. 30) as required.

ASSEMBLY OF THE TDM

Replace the check valve (Pos. 5/7) with the spring (Pos. 6) in the lower body

(Pos. 1).

Now the upper body (Pos. 2) is placed on the lower body (Pos. 1) and the

hexagon nuts (Pos. 28) are tightened.

Carefully insert the bypass section "M" in the valve body and ascertain that

lever (Pos. 13) fits (slides) in the slot in the check valve (Pos. 5/7).

‘The bypass housing (pos. 9) with the bypass orifice (Pos. 23) is now carefully

replaced and tightened to the housing (Pos. 1) with the hexagon nuts (Pos. 29).

onage Ave. PO. Box 875, Thee Rive, Ml 45085 USA

Prone: 61 279.2085 Fax (616) 78745,

HBE/SCHROEDAHL AUTOMATIC RECIRCULATION VALVE

INSTALLATION/MAINTENANCE MANUAL WITH DRAWING

SCHROEDAHL ARV MODEL: TDM 116 UVW CS

LANCASTER STEEL PURCHASE ORDER NO: q-058/2966

TAG: ITEM 24 B/M

HBE REFERENCE NO: 31-1444/A

205 Page Ave, PO. Box 25, Tee River, Ml 45098 US.A

Phone: (616) 279.2085 Fax (16) TE-7HS

DATASHEET

SAS Wa uu

Sx Sey

7 Ww

| MS \ \

Dao

odes canara

| its Fes 00

AND MATERIALS

Ls i:

He 6-1/8"

s= 0-1/2"

DNp x = In. PL

We ne Ea

fest:__988 PSIG

es: _1285 PSIG

25 PSIG

25 PSIG

d Water Weight in Lbs, = __ 277

erst

ATIONS

Hee || SCHROEDAHL ARV SERIES TDM 116 UVW CS

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Met Jet 4L 500 Hour Spares ListDocument1 pageMet Jet 4L 500 Hour Spares List.xNo ratings yet

- 20KG Ip54Document1 page20KG Ip54.xNo ratings yet

- PS-10-17 en AqDocument16 pagesPS-10-17 en Aq.xNo ratings yet

- Detalle de EstriadosDocument10 pagesDetalle de Estriados.xNo ratings yet

- Despiece Bomba Fybroc 2x3x6 Fybroc Serie 1500Document1 pageDespiece Bomba Fybroc 2x3x6 Fybroc Serie 1500.xNo ratings yet

- Eficiencias TurbinasDocument2 pagesEficiencias Turbinas.xNo ratings yet

- Recommendation 01Document53 pagesRecommendation 01.xNo ratings yet

- Manual BrazingDocument10 pagesManual Brazing.xNo ratings yet

- Actividad RBIDocument28 pagesActividad RBI.xNo ratings yet

- Dynamic Balancing MachineDocument4 pagesDynamic Balancing Machine.x100% (1)

- Tabla de TorquesDocument2 pagesTabla de Torques.xNo ratings yet

- List PTC AsmeDocument2 pagesList PTC Asme.x100% (1)

- Presentacion FERRESOLDADocument9 pagesPresentacion FERRESOLDA.xNo ratings yet

- Taller Variables Hidro Plantas Hidraulicas 0Document47 pagesTaller Variables Hidro Plantas Hidraulicas 0.xNo ratings yet

- PMET 720-420 StainlessDocument1 pagePMET 720-420 Stainless.xNo ratings yet

- Polymet Full Product CatalogueDocument2 pagesPolymet Full Product Catalogue.xNo ratings yet

- Camara de AspersionDocument1 pageCamara de Aspersion.x100% (1)

- PMET 542 - BabbittDocument1 pagePMET 542 - Babbitt.xNo ratings yet

- PMET 292 Nano AlloyDocument1 pagePMET 292 Nano Alloy.xNo ratings yet

- PMET 885 - Nickel 5 AluminumDocument1 pagePMET 885 - Nickel 5 Aluminum.xNo ratings yet

- ASM Material Data Sheet 304Document2 pagesASM Material Data Sheet 304.xNo ratings yet

- ASM Material Data Sheet 316Document2 pagesASM Material Data Sheet 316.xNo ratings yet