Professional Documents

Culture Documents

PMET 720-420 Stainless

Uploaded by

.x0 ratings0% found this document useful (0 votes)

85 views1 page.

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

85 views1 pagePMET 720-420 Stainless

Uploaded by

.x.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

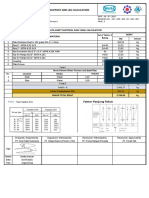

Technical Datasheet

PMET 720 420 Stainless Steel

Nov. 30, 2018

PRODUCT OVERVIEW

PMET 720 is a 420 stainless steel wire, specifically designed for thermal spraying. PMET 720 forms a dense, well bonded coating,

with excellent wear resistance and good corrosion resistance. It is widely used for machine elements repair, dimensional restora-

tion, and wear resistant applications. PMET 720’s low shrink rate characteristics allows for increased coating thickness on parts

requiring heavier coatings.

TYPICAL DEPOSIT CHARACTERISTICS: SURFACE PREPARATION

Abrasion Resistance Excellent

Surface should be clean, white metal, with no oxides (rust), dirt,

Corrosion Resistance Good

grease, or oil on the surface to be coated. Note: It is best not to

Typical Hardness: HRC 35-45

handle surfaces after cleaning.

Bond Strength: 7100 psi

Recommended method of preparation is to grit blast with 24

Deposit Rate: 10 lbs/hr/100A mesh aluminum oxide, rough grind, or rough machine in a

Deposit Efficiency 70% lathe.

Wire Coverage: 0.8 oz/ft2 / mil

Coating Shrink Rate Low

Service Temperature Up to 550C 1022 F

APPLICATION

Paper Rolls

Part Restoration

Corrosion/Wear

NOMINAL CHEMICAL COMPOSITION

(wt%)

Cr Si Mn C Fe

13.0 1.0 1.0 0.3 Bal

RECOMMENDED ARC SPRAY PARAMETERS:

Diameter Air Pressure Voltage Amperage Standoff

1/16” (1.6mm) 50-60 psi 28-30 100-200 4-6 in (10-15 cm)

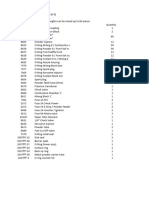

STANDARD SIZES & PACKAGING:

Diameter Packaging Part Number

1/16” (1.6mm) 25# LWS 720062LWS00

1/8” (3.17 mm) 50# Coils 720125COIL00

7397 Union Centre Blvd. West Chester, OH 45014 / Phone: 513-874-3586 / Fax: 513-874-2880

E-mail: sales@polymet.us

You might also like

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- PMET 273 Amorphous Coating DatasheetDocument1 pagePMET 273 Amorphous Coating Datasheet.xNo ratings yet

- PMET 292 Nano AlloyDocument1 pagePMET 292 Nano Alloy.xNo ratings yet

- Polymet PMET 877-MonelDocument1 pagePolymet PMET 877-MonelgersomNo ratings yet

- P♦MET 720 Arc Spray Wire Data SheetDocument1 pageP♦MET 720 Arc Spray Wire Data Sheetelias667No ratings yet

- PMET 542 - BabbittDocument1 pagePMET 542 - Babbitt.xNo ratings yet

- PMET 885 Technical DatasheetDocument1 pagePMET 885 Technical Datasheet.xNo ratings yet

- DATA SHEET - WD-Alloy718Document2 pagesDATA SHEET - WD-Alloy718MTB ENGNo ratings yet

- PRODUCT NUMBER: 0279-0-15-80-47-80-10-0: Data SheetDocument3 pagesPRODUCT NUMBER: 0279-0-15-80-47-80-10-0: Data SheetPista KissNo ratings yet

- Polywear 60 Technical DatasheetDocument1 pagePolywear 60 Technical DatasheetFlori MovNo ratings yet

- Specification: Si MN P S 0.08 0.56 1.02 0.013 0.010Document2 pagesSpecification: Si MN P S 0.08 0.56 1.02 0.013 0.010Jennylyn DañoNo ratings yet

- Polywear 50 Gtaw 1Document1 pagePolywear 50 Gtaw 1Flori MovNo ratings yet

- 304 / 304L Stainless: Technical DatasheetDocument1 page304 / 304L Stainless: Technical DatasheettadilakshmikiranNo ratings yet

- PDS Top Tec 6200 0W-20Document1 pagePDS Top Tec 6200 0W-20Akbar SaputroNo ratings yet

- Product Specification - Apcoshield Py905sg Grey Ral 7016 20kgDocument1 pageProduct Specification - Apcoshield Py905sg Grey Ral 7016 20kgVenkatraman SubramaniamNo ratings yet

- BABBITT P-Met-542SPR-1Document1 pageBABBITT P-Met-542SPR-1jpolancosNo ratings yet

- Aisi 9254 - Spring SteelDocument2 pagesAisi 9254 - Spring SteelSergio100% (1)

- Self-shielded electrode for heavy component repairDocument1 pageSelf-shielded electrode for heavy component repairAravind rajNo ratings yet

- Technical Datasheet: Engineering SteelDocument1 pageTechnical Datasheet: Engineering SteelKarimulla ShaikNo ratings yet

- Knock OUT: IntroducingDocument10 pagesKnock OUT: IntroducingMuhammad QusyairiNo ratings yet

- Namson laser portable welding machineDocument5 pagesNamson laser portable welding machineChitMoeNo ratings yet

- 420 SS/BronZE 3D PRINTDocument2 pages420 SS/BronZE 3D PRINTNicola MerzagoraNo ratings yet

- En 8Document1 pageEn 8Devendera TripathiNo ratings yet

- CuZn20-convertedDocument2 pagesCuZn20-convertedwjjt6chgtmNo ratings yet

- Sikasil - 728 NsDocument4 pagesSikasil - 728 NsMichael A FarinNo ratings yet

- 321Document4 pages321saeedmahboob05No ratings yet

- CJ-9 MettalicDocument1 pageCJ-9 MettalicTFM comprasNo ratings yet

- LIQUI MOLY P004096-Motorbike-4T-Synth-10W-40-Street-Race-26-en - GBDocument1 pageLIQUI MOLY P004096-Motorbike-4T-Synth-10W-40-Street-Race-26-en - GBHicham BenNo ratings yet

- RR's Energy Efficient Extruder Offers Low Power Sheet ProductionDocument14 pagesRR's Energy Efficient Extruder Offers Low Power Sheet ProductionSwabir NalbandNo ratings yet

- Electrode Booklet F Web 100Document1 pageElectrode Booklet F Web 100satnamNo ratings yet

- PETg Data SheetDocument4 pagesPETg Data SheetVikram BorkhediyaNo ratings yet

- ABS EDGEBANDS Technical SpecificationsDocument3 pagesABS EDGEBANDS Technical SpecificationsBurak KececiNo ratings yet

- Pro Dec PlateDocument9 pagesPro Dec PlateAbe VoigNo ratings yet

- Oil Field: Main CatalogueDocument176 pagesOil Field: Main CatalogueM. Aguiar100% (1)

- T 754 PG 203-206 PDFDocument4 pagesT 754 PG 203-206 PDFJossimar PerezNo ratings yet

- Cutting oil drilling tapping technical sheetDocument1 pageCutting oil drilling tapping technical sheetgopalakrishna100% (1)

- Aluminium Casting Alloy (AL - Si12) : Home About Us Processes Design Quality Products Technical ContactDocument3 pagesAluminium Casting Alloy (AL - Si12) : Home About Us Processes Design Quality Products Technical Contactrafdinal.sNo ratings yet

- Sikasil 728 SLDocument5 pagesSikasil 728 SLJesusFloresRodriguezNo ratings yet

- Strenx 700 MC: Advanced High Strength SteelDocument2 pagesStrenx 700 MC: Advanced High Strength SteeldbaNo ratings yet

- Mill-Max Pin Receptacle Spec SheetDocument3 pagesMill-Max Pin Receptacle Spec SheetPista KissNo ratings yet

- TDS 351do enDocument1 pageTDS 351do enMumkoNo ratings yet

- Chronifer M-4108Document3 pagesChronifer M-4108IltefatNo ratings yet

- HMG Epozinc1000Document2 pagesHMG Epozinc1000ben.ledwidgeNo ratings yet

- CuZn15-convertedDocument2 pagesCuZn15-convertedwjjt6chgtmNo ratings yet

- SB 870800 R6 HPR260XDDocument2 pagesSB 870800 R6 HPR260XDIlian AvramovNo ratings yet

- LSM 80 (Lamella Settler Module 80 MM) : DesignDocument2 pagesLSM 80 (Lamella Settler Module 80 MM) : DesignJulio TovarNo ratings yet

- Electrode Booklet F Web 97Document1 pageElectrode Booklet F Web 97satnamNo ratings yet

- Circular Saw - Technical DescriptionDocument17 pagesCircular Saw - Technical DescriptionPuneeth KumarNo ratings yet

- Top Tec 6200 0W-20: Product InformationDocument1 pageTop Tec 6200 0W-20: Product Informationهيوا گورانNo ratings yet

- Bisalloy's PlatesDocument16 pagesBisalloy's PlatesMarcoNo ratings yet

- Ac-700 SpecificationDocument10 pagesAc-700 SpecificationTarek Abuzene100% (1)

- Uk 754 - Anel DPDocument3 pagesUk 754 - Anel DPAlessandro OliveiraNo ratings yet

- En1a PDFDocument1 pageEn1a PDFRavindra ErabattiNo ratings yet

- Metal X: 85 School ST, Watertown, MA 02472 All Specifications Approximate and Subject To Change Without NoticeDocument4 pagesMetal X: 85 School ST, Watertown, MA 02472 All Specifications Approximate and Subject To Change Without NoticeslobamsNo ratings yet

- Metal System Datasheets PDFDocument4 pagesMetal System Datasheets PDFEduardo Mateo ArdilNo ratings yet

- Stoody 100HDDocument1 pageStoody 100HDKevin Quispe MarínNo ratings yet

- PRODUCT NUMBER: 0327-0-15-80-34-80-10-0: Data SheetDocument3 pagesPRODUCT NUMBER: 0327-0-15-80-34-80-10-0: Data SheetCADTDDNo ratings yet

- Miginox 316lsi: Aws A/Sfa 5.9 EN ISO 14343-ADocument1 pageMiginox 316lsi: Aws A/Sfa 5.9 EN ISO 14343-AJagannath SahuNo ratings yet

- High Pressure Triplex Pump CatalogueDocument3 pagesHigh Pressure Triplex Pump CatalogueIlyas Rangga RamadhanNo ratings yet

- ADPL718 Catalog Page 25 - Yellow B AckDocument1 pageADPL718 Catalog Page 25 - Yellow B AckSugeng DarmintoNo ratings yet

- Kennametal Stellite - Jet Kote BrochureDocument16 pagesKennametal Stellite - Jet Kote BrochureAnders GrimbarkNo ratings yet

- Met Jet 4L 500 Hour Spares ListDocument1 pageMet Jet 4L 500 Hour Spares List.xNo ratings yet

- Thermal Spray Powders - March 2019 - 2438HOGDocument36 pagesThermal Spray Powders - March 2019 - 2438HOGRavi ViswanadhaNo ratings yet

- Presentacion FERRESOLDADocument9 pagesPresentacion FERRESOLDA.xNo ratings yet

- Fybro Series1500 - UPDATED - 4 - 20 - 12 PDFDocument16 pagesFybro Series1500 - UPDATED - 4 - 20 - 12 PDFRydel CuachonNo ratings yet

- Cuerpo ScrubberDocument1 pageCuerpo Scrubber.xNo ratings yet

- Met-Pro: Fybroc Series 1500 Horizontal PumpsDocument30 pagesMet-Pro: Fybroc Series 1500 Horizontal PumpsAnonymous r3MoX2ZMTNo ratings yet

- PS-10-17 en AqDocument16 pagesPS-10-17 en Aq.xNo ratings yet

- PORTICO FinalDocument1 pagePORTICO Final.xNo ratings yet

- Dynamic Balancing MachineDocument4 pagesDynamic Balancing Machine.x100% (1)

- List PTC AsmeDocument2 pagesList PTC Asme.x100% (1)

- ASM Material Data Sheet 316Document2 pagesASM Material Data Sheet 316.xNo ratings yet

- Portico PR 1Document1 pagePortico PR 1.xNo ratings yet

- PMET 710 - 304 StainlessDocument1 pagePMET 710 - 304 Stainless.xNo ratings yet

- PMET 885 Technical DatasheetDocument1 pagePMET 885 Technical Datasheet.xNo ratings yet

- ASM Material Data Sheet 304Document2 pagesASM Material Data Sheet 304.xNo ratings yet

- Polymet Full Product CatalogueDocument2 pagesPolymet Full Product Catalogue.xNo ratings yet

- Structure Material Details & WeightDocument2 pagesStructure Material Details & WeightRahul SahaNo ratings yet

- BHT & VHTDocument8 pagesBHT & VHTMoHammadNashatSabbahNo ratings yet

- ELEMENT 10 Fire1Document13 pagesELEMENT 10 Fire1Aaquil RaziNo ratings yet

- Quality Plan Outline for Bridge ProjectDocument51 pagesQuality Plan Outline for Bridge ProjectcarlorbeNo ratings yet

- Thermal Properties of ConcreteDocument8 pagesThermal Properties of ConcreteS Praveenkumar100% (1)

- Nature of The Project: TH THDocument4 pagesNature of The Project: TH THSyed YousufuddinNo ratings yet

- Blocking Calc - 3x2x2Document3 pagesBlocking Calc - 3x2x2RUBEN BARTOLOME GARCIANo ratings yet

- Floor QAP Audit FormDocument48 pagesFloor QAP Audit FormSasidharan RajendranNo ratings yet

- Industrial Training: Construction of Flyover From Jagdeo Path To Sheikhpura ModeDocument15 pagesIndustrial Training: Construction of Flyover From Jagdeo Path To Sheikhpura ModeBibek BhattaraiNo ratings yet

- Materials Selection For Subsea ApplicationsDocument47 pagesMaterials Selection For Subsea Applicationstang weng waiNo ratings yet

- SpeedHeat EzeeStat II Instructions Rev 04Document4 pagesSpeedHeat EzeeStat II Instructions Rev 04Lefa Doctormann RalethohlaneNo ratings yet

- Applications of Polymers PDFDocument3 pagesApplications of Polymers PDFProf C.S.Purushothaman57% (7)

- 212-Chpt 7Document6 pages212-Chpt 7zainabcomNo ratings yet

- Cross Regulator EstimateDocument6 pagesCross Regulator EstimateIrfan ShaNo ratings yet

- Bathnagar Et Al 2016Document13 pagesBathnagar Et Al 2016Marcelo CifuentesNo ratings yet

- March Samsung VRF Seminar PDFDocument129 pagesMarch Samsung VRF Seminar PDFSTANDARD EDUCATION ACADEMY M.E.P CENTERNo ratings yet

- Mini ProjectDocument58 pagesMini ProjectDeepak Varma50% (2)

- Marylebone Construction UpdateDocument2 pagesMarylebone Construction UpdatePedro SousaNo ratings yet

- Support and Leg Calculation: Data Sheet Material Dan Tabel CalculationDocument3 pagesSupport and Leg Calculation: Data Sheet Material Dan Tabel CalculationliusNo ratings yet

- Piping Class B2Document5 pagesPiping Class B2Yousab JacobNo ratings yet

- Design of Bridges Question Bank for III SemesterDocument14 pagesDesign of Bridges Question Bank for III SemesterNarayanan MoorthyNo ratings yet

- SikaSwell - Hydrophilic Profiles and SealantsDocument12 pagesSikaSwell - Hydrophilic Profiles and Sealantskhx2No ratings yet

- Concrete Casting - Pump Station ADocument13 pagesConcrete Casting - Pump Station ABright MuzaNo ratings yet

- Is 12727 PDFDocument14 pagesIs 12727 PDFJanardhana ReddiNo ratings yet

- CIVL 222 AXIAL MEMBERSDocument27 pagesCIVL 222 AXIAL MEMBERSskhan247100% (1)

- Roads Elemental CostingDocument47 pagesRoads Elemental Costingsarathirv6100% (2)

- Recommended Erection Instructions For Steel FramesDocument32 pagesRecommended Erection Instructions For Steel FramesYel DGNo ratings yet

- MONOSLOPE Roof Open Building TERRACE Wind LoadsDocument2 pagesMONOSLOPE Roof Open Building TERRACE Wind LoadsAnkita Pal100% (1)

- Junction Box Product ListDocument1 pageJunction Box Product ListtxagusNo ratings yet

- Case Against Balancing ValvesDocument4 pagesCase Against Balancing Valvesa_salehiNo ratings yet