Professional Documents

Culture Documents

Product Specification - Apcoshield Py905sg Grey Ral 7016 20kg

Uploaded by

Venkatraman SubramaniamCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Product Specification - Apcoshield Py905sg Grey Ral 7016 20kg

Uploaded by

Venkatraman SubramaniamCopyright:

Available Formats

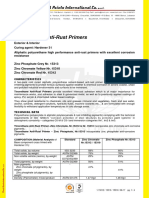

Technical Data Sheet

Material Code: 1803RG19320

Material Description: APCOSHIELD PY905SG GREY RAL 7016 20KG

Product specification

Chemistry Polyester

Physical Appearance Free flow powder

Specific Gravity 1.6 ± 0.2

Application Dry Film Thickness ASTM D 1186 50-80 micron

Curing Schedule 190 deg C for 10 min EMT

Film performance

Test description Test Method Specification

Colour / shade Visual Grey RAL 7016

Gloss @ 60°head ASTM D 523 75 +/- 5 units

Impact resistance ASTM D 2794 100 kg.cm

Scratch resistance ISO12137 2 KG

Cross Cut Adhesion ASTM D 3359 GT=0

Flexibility Cylindrical Mandrel ASTM D 522 12.5 mm

Humidity Resistance ASTM D2247 1000 Hrs

Salt Spray Resistance ASTM B117 1000 Hrs

All tests are carried on 0.8mm CRCA panel treated by Tri-cationic Phosphating process with coating weight of 2-3 gm/sq.mt except Salt Spray Resistance test & Humidity resistance

test which are carried on ACT panels, followed by powder coating at DFT 60-70 microns cured at 190°C for 10 minutes (EMT)

Application guide & recommendation:

Pre-treatment All substrates are to be cleaned & should be free from grease, oil & dust.

A suitable chromate conversion coating is recommended for Aluminum substrate.

Passivated Zinc phosphate coating is recommended for steel substrate

Application voltage 60 – 90 KV

Earthing Proper & good

Compress air Free from moisture, oil, dust & other impurities through flat jet spray nozzle

Thorough cleaning of the application & recovery system required between each change in powder to avoid contaminations & defects

Shelf life and Storage:

Shelf life of six months from the date of manufacturing if, stored in closed store in dry & cool atmosphere below 30°C & 60% RH. Avoid exposure

to direct sunlight, heat and high humidity. Partly used material must be tightly closed after each removal and stored carefully inside the carton to

avoid contamination & absorption of moisture.

Product Performance may vary with colour, shade, substrate type & thickness, application conditions & parameters and surface preparation etc. It is recommended to test on each

proposed substrate to confirm acceptability.

The information and recommendations presented here are compiled with the utmost care, but cannot be extended to cover every possible area. They are intended to serve as non-

binding guidelines and must be adapted to the prevailing conditions.

Asian Paints PPG Pvt. Ltd. reserves the right without notice to alter or change the content of this product Specification sheet. PS/APPPG/01-2012 – Version 1

Corporate office: ASIAN PAINTS PPG PVT LTD. 2nd Floor, Plot No 5, Gaiwadi Industrial Estate, Near Kamath Club, S V Road, Goregaon (West), Mumbai - 400062

Page 1 of 1

You might also like

- Essential Rubber Formulary: Formulas for PractitionersFrom EverandEssential Rubber Formulary: Formulas for PractitionersRating: 3 out of 5 stars3/5 (1)

- E578-07 (2013) Standard Test Method For Linearity of Fluorescence Measuring SystemsDocument3 pagesE578-07 (2013) Standard Test Method For Linearity of Fluorescence Measuring SystemsislamakthamNo ratings yet

- TDS ML160V - Ral 7032 - OutdoorDocument2 pagesTDS ML160V - Ral 7032 - Outdoorhoang BuiNo ratings yet

- TDS PRIMER 193V - EnglishDocument2 pagesTDS PRIMER 193V - Englishhoang BuiNo ratings yet

- TDS Nitoflor SL3000 UT Saudi ArabiaDocument5 pagesTDS Nitoflor SL3000 UT Saudi ArabiaShaikhRizwanNo ratings yet

- Glass Fiber Reinforced PBT Material Injection Molding Grade Pellets / GranulesDocument2 pagesGlass Fiber Reinforced PBT Material Injection Molding Grade Pellets / GranulesmuthuNo ratings yet

- ZBT 10004759365 enDocument1 pageZBT 10004759365 enRicardo FernandesNo ratings yet

- Tinorethane Anti-Rust PrimersDocument4 pagesTinorethane Anti-Rust PrimersAbed samadsureyft7vewyrNo ratings yet

- S-Oil+hydro+fluid TDS PDFDocument1 pageS-Oil+hydro+fluid TDS PDFphucdc095041No ratings yet

- Sikafloor - 325: 2-Part PUR Resin Self Smoothing Screed and Seal CoatDocument6 pagesSikafloor - 325: 2-Part PUR Resin Self Smoothing Screed and Seal CoatmilanbrasinaNo ratings yet

- Polypropylene Impact Co Polymer Injection Molding: Provisional Technical DatasheetDocument2 pagesPolypropylene Impact Co Polymer Injection Molding: Provisional Technical DatasheetMohit MohataNo ratings yet

- Sikafloor - 264 EngDocument5 pagesSikafloor - 264 Engbassem kooliNo ratings yet

- Product Datasheet: BU Powder CoatingsDocument1 pageProduct Datasheet: BU Powder CoatingsVasudev BhanajiNo ratings yet

- Polypropylene Random Co Polymer Injection Molding & ISBM: Provisional Technical DatasheetDocument2 pagesPolypropylene Random Co Polymer Injection Molding & ISBM: Provisional Technical DatasheetMohit MohataNo ratings yet

- TDS Pe 008 Up4806hDocument2 pagesTDS Pe 008 Up4806hariefNo ratings yet

- Utek PYJ9114 SMC SHEETDocument2 pagesUtek PYJ9114 SMC SHEETFrederik TjonnelandNo ratings yet

- Linear Low Density Polyethylene Injection MoldingDocument2 pagesLinear Low Density Polyethylene Injection MoldingakshayNo ratings yet

- Marpol - Coatings - Series - Tech - Specs PDFDocument12 pagesMarpol - Coatings - Series - Tech - Specs PDFYashwant RajeshirkeNo ratings yet

- Protective & Marine Coatings: Zinc Clad XIDocument4 pagesProtective & Marine Coatings: Zinc Clad XIfdpc1987No ratings yet

- Barrier 80 PDFDocument5 pagesBarrier 80 PDFBalaji GuruNo ratings yet

- AkzoNobel - QN102QF - Interpon ACE 2000Document3 pagesAkzoNobel - QN102QF - Interpon ACE 2000Eslam FaroukNo ratings yet

- Especificaciones Pintura Macropoxi NavalDocument4 pagesEspecificaciones Pintura Macropoxi NavalVicenteRojasLeonNo ratings yet

- LIQUI MOLY P004096-Motorbike-4T-Synth-10W-40-Street-Race-26-en - GBDocument1 pageLIQUI MOLY P004096-Motorbike-4T-Synth-10W-40-Street-Race-26-en - GBHicham BenNo ratings yet

- DTM Bonding Primer: Protective & Marine CoatingsDocument4 pagesDTM Bonding Primer: Protective & Marine CoatingsAna CabreraNo ratings yet

- Ube Nylon 5034bDocument1 pageUbe Nylon 5034bDiegoTierradentroNo ratings yet

- TDS 37942 Barrier 80 S Euk GBDocument5 pagesTDS 37942 Barrier 80 S Euk GBHung Mai VanNo ratings yet

- 1035 TD 20 Product Data Sheet ViscopasteDocument2 pages1035 TD 20 Product Data Sheet ViscopasteUrooj IlyasNo ratings yet

- Hi Solid PolyurethaneDocument4 pagesHi Solid PolyurethaneafvasquezNo ratings yet

- Jotatemp 1000 Ceramic Technical Data SheetDocument5 pagesJotatemp 1000 Ceramic Technical Data SheetGurdeep Sungh AroraNo ratings yet

- Jotamastic 87 AluminiumDocument5 pagesJotamastic 87 AluminiumBiju_PottayilNo ratings yet

- Chemflake SpecialDocument5 pagesChemflake Specialmajmor-1No ratings yet

- TDS Penguard Pro JotunDocument5 pagesTDS Penguard Pro JotunLuka BornaNo ratings yet

- Polypropylene Impact Co Polymer Injection Molding: Provisional Technical DatasheetDocument2 pagesPolypropylene Impact Co Polymer Injection Molding: Provisional Technical DatasheetMohit MohataNo ratings yet

- Polypropylene Homo Polymer Injection Molding: Provisional Technical DatasheetDocument2 pagesPolypropylene Homo Polymer Injection Molding: Provisional Technical DatasheetMohit MohataNo ratings yet

- Envirolastic 980 PADocument4 pagesEnvirolastic 980 PAdneradNo ratings yet

- Pink Anti Static Bag BondlineDocument2 pagesPink Anti Static Bag Bondlineeky susilowatiNo ratings yet

- Sigma Prime 200Document7 pagesSigma Prime 200Kue Nai NaiNo ratings yet

- Polyurea 1044 Standard Pure TDS ENDocument4 pagesPolyurea 1044 Standard Pure TDS ENnsh.gnkinfraNo ratings yet

- Chemflake SpecialDocument5 pagesChemflake SpecialBiju_PottayilNo ratings yet

- COLORBONDUltra ACTIVATETDS200706Document4 pagesCOLORBONDUltra ACTIVATETDS200706Ramiro RivasNo ratings yet

- Sealtite Sealant Butyl Tape: DescriptionDocument2 pagesSealtite Sealant Butyl Tape: DescriptionSantoshNo ratings yet

- Lacqare Technical DataDocument3 pagesLacqare Technical DataMahmoud MassadNo ratings yet

- TDS 0038 DisboPOX-230-SF 201908Document7 pagesTDS 0038 DisboPOX-230-SF 201908Insafians PowerNo ratings yet

- 1eshacoat6s enDocument2 pages1eshacoat6s enAhmed TahsinNo ratings yet

- Esd Jotun PaintDocument3 pagesEsd Jotun PaintMohd Ridzuan Abdul AzizNo ratings yet

- TDS Pe 001 Uf1810Document2 pagesTDS Pe 001 Uf1810asrilNo ratings yet

- Sherwin Williams - Heatflex Hi-Temp 1200 DatasheetDocument4 pagesSherwin Williams - Heatflex Hi-Temp 1200 DatasheetAce AceNo ratings yet

- High Density Polyethylene Injection MoldingDocument2 pagesHigh Density Polyethylene Injection MoldingQuality teamNo ratings yet

- Engen Premium EP SeriesDocument2 pagesEngen Premium EP SeriesNunoNo ratings yet

- Jotamastic 80 Aluminium - TDSDocument6 pagesJotamastic 80 Aluminium - TDSTeknik produksi wikonNo ratings yet

- Nukote STDocument4 pagesNukote STMarco Dos Santos NevesNo ratings yet

- Jotamastic 80: Technical Data SheetDocument5 pagesJotamastic 80: Technical Data SheetArif dwi prasetyoNo ratings yet

- TDS 31002 Primax Protect Euk GBDocument3 pagesTDS 31002 Primax Protect Euk GBBalaji Guru0% (1)

- Resicoat V - F R4 ESDocument3 pagesResicoat V - F R4 ESABHISHEK SINGHNo ratings yet

- TDS EU G-Energy X Hydro Bio EngDocument2 pagesTDS EU G-Energy X Hydro Bio EngАлексей ДэконNo ratings yet

- JotundatasheetsDocument172 pagesJotundatasheetsAli MudhafarNo ratings yet

- iKOTE AC 40 (DEC-2023) V1.3Document2 pagesiKOTE AC 40 (DEC-2023) V1.3nguyen hoang AnhNo ratings yet

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingFrom EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingNo ratings yet

- Patriot 5510Document2 pagesPatriot 5510Forum Pompierii0% (1)

- MSDS 108 Sigma M 460 Air Compressor Fluid Tcm9 8533Document10 pagesMSDS 108 Sigma M 460 Air Compressor Fluid Tcm9 8533Anonymous xJahbl2WZNo ratings yet

- Unit6 Equipments and Cleaning Agents-1-1Document14 pagesUnit6 Equipments and Cleaning Agents-1-1pdp786No ratings yet

- Form 4 Acid Base and SaltDocument84 pagesForm 4 Acid Base and SaltbalqisNo ratings yet

- Rock Gem - January 2017Document84 pagesRock Gem - January 2017Carlos Rivera100% (1)

- AFW NewDocument4 pagesAFW NewJoão BaffiniNo ratings yet

- Pressure Test ProcedureDocument6 pagesPressure Test ProcedureAppleuk SudarNo ratings yet

- Brochure GC Trace 1300 PDFDocument4 pagesBrochure GC Trace 1300 PDFLUIS XVNo ratings yet

- Viking ProductCatalogue Gas CO2LP-1Document80 pagesViking ProductCatalogue Gas CO2LP-1NarendraNo ratings yet

- Warranty Book FullDocument28 pagesWarranty Book Fullrajanikant_singhNo ratings yet

- Combinatorial Chemistry: Medicinal Chemistry & Drug Discovery II (MSB)Document34 pagesCombinatorial Chemistry: Medicinal Chemistry & Drug Discovery II (MSB)Md. Abir Hossain100% (3)

- Applications of Kohlrausch LawDocument6 pagesApplications of Kohlrausch LawNadherdaman Alshamary100% (4)

- Shpa Standards of Practice For The Safe Handling of Cytotoxic DR 2005Document9 pagesShpa Standards of Practice For The Safe Handling of Cytotoxic DR 2005Lan FdzNo ratings yet

- Adobe Scan Aug 13, 2022Document15 pagesAdobe Scan Aug 13, 2022A MesihaNo ratings yet

- Symphony Soil: of TheDocument32 pagesSymphony Soil: of Theramoo.csaNo ratings yet

- Thermodynamics For Chemists, GlasstoneDocument533 pagesThermodynamics For Chemists, GlasstoneRowie Carpio100% (2)

- HZL Chanderiya Pyro Training ReportDocument48 pagesHZL Chanderiya Pyro Training Reportkunalmech100% (5)

- Experiment No 1 (Tray Dryer)Document8 pagesExperiment No 1 (Tray Dryer)mjunaidNo ratings yet

- Asres SimenehDocument73 pagesAsres SimenehBezakulu MinwouyeletNo ratings yet

- Absorber Design: Sizing A Packed TowerDocument24 pagesAbsorber Design: Sizing A Packed TowerMbarouk Shaame MbaroukNo ratings yet

- Practical 01 (Emergency and Laboratory Safety)Document28 pagesPractical 01 (Emergency and Laboratory Safety)Mr. GoogleNo ratings yet

- Vanders Human Physiology The Mechanisms of Body Function 14th Edition Widmaier Solutions ManualDocument26 pagesVanders Human Physiology The Mechanisms of Body Function 14th Edition Widmaier Solutions Manualconsignedurylic75hi100% (24)

- Ce 5230 Water Treatment Plant DesignDocument25 pagesCe 5230 Water Treatment Plant Designapi-297914209No ratings yet

- Kens Metal Brochure PDFDocument40 pagesKens Metal Brochure PDFMike0% (1)

- Basf MasterPozzolith 402R TdsDocument2 pagesBasf MasterPozzolith 402R TdsValentino ToplesNo ratings yet

- Antox 71 E Pickling Paste PDFDocument2 pagesAntox 71 E Pickling Paste PDFasaasd100% (1)

- HD 35-04 Provisions For The Use of Secondary and Recycled Materials (Nov 2004)Document16 pagesHD 35-04 Provisions For The Use of Secondary and Recycled Materials (Nov 2004)sandycastleNo ratings yet

- FTRC Week4 PracticeTestDocument13 pagesFTRC Week4 PracticeTestKARISSA MARA CRISOSTOMONo ratings yet