Professional Documents

Culture Documents

PMET 710 - 304 Stainless

Uploaded by

.xCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PMET 710 - 304 Stainless

Uploaded by

.xCopyright:

Available Formats

Technical Datasheet

PMET 710 304 Stainless

June 2, 2015

PRODUCT OVERVIEW

PMET 710 is a 304 stainless steel wire specifically designed for arc spraying. It produces a dense, well-bonded coating with excel-

lent machinability and wear and corrosion resistance. PMET 710 is widely used for machine element repair, dimensional restora-

tion and wear resistance applications. It has relatively high shrink characteristics and should not be used for coatings over 0.075

inches thick.

TYPICAL DEPOSIT CHARACTERISTICS: SURFACE PREPARATION

Typical Hardness: HRB 95-100

Surface should be clean, white metal, with no oxides (rust), dirt,

Bond Strength: 4650 psi

grease, or oil on the surface to be coated. Note: It is best not to

Deposit Rate: 10 lbs/hr/100A

handle surfaces after cleaning.

Deposit Efficiency 75%

Recommended method of preparation is to grit blast with 24

Wire Coverage: 0.8 oz/ft2 / mil mesh aluminum oxide, rough grind, or rough machine in a

Surface Texture *Variable lathe.

Machinability Good

* Depends on air pressure used

APPLICATION

Part Restoration

SPECIFICATION

Resurface

- Paper Mill Cylinders 304 SS

- Rams

- Shafts

- Pump Plungers

NOMINAL CHEMICAL COMPOSITION

(wt%)

Cr Ni Mn Si Fe

19.0 9.3 2.0 1.0 Bal

RECOMMENDED SPRAY PARAMETERS:

Diameter Air Pressure Voltage Amperage Standoff

1/16” (1.6mm) *50-60 psi *28-30 *100-200 *4-6 in (8-15 cm)

STANDARD SIZES & PACKAGING:

Diameter Packaging Part Number

1/16” (1.6mm) 22# LWS 710062LWS01

7397 Union Centre Blvd. West Chester, OH 45014 / Phone: 513-874-3586 / Fax: 513-874-2880

E-mail: sales@polymet.us

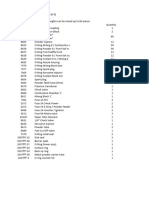

You might also like

- Met Jet 4L 500 Hour Spares ListDocument1 pageMet Jet 4L 500 Hour Spares List.xNo ratings yet

- Presentacion FERRESOLDADocument9 pagesPresentacion FERRESOLDA.xNo ratings yet

- PS-10-17 en AqDocument16 pagesPS-10-17 en Aq.xNo ratings yet

- Dynamic Balancing MachineDocument4 pagesDynamic Balancing Machine.x100% (1)

- List PTC AsmeDocument2 pagesList PTC Asme.x100% (1)

- PMET 292 Nano AlloyDocument1 pagePMET 292 Nano Alloy.xNo ratings yet

- PMET 542 - BabbittDocument1 pagePMET 542 - Babbitt.xNo ratings yet

- Polymet Full Product CatalogueDocument2 pagesPolymet Full Product Catalogue.xNo ratings yet

- PMET 885 - Nickel 5 AluminumDocument1 pagePMET 885 - Nickel 5 Aluminum.xNo ratings yet

- PMET 720-420 StainlessDocument1 pagePMET 720-420 Stainless.xNo ratings yet

- ASM Material Data Sheet 304Document2 pagesASM Material Data Sheet 304.xNo ratings yet

- ASM Material Data Sheet 316Document2 pagesASM Material Data Sheet 316.xNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Molten SaltDocument27 pagesMolten SaltvesipkaNo ratings yet

- The Vortex Atom - A Victorian Theory of Everything - by Helge Kragh !!!!! PDFDocument83 pagesThe Vortex Atom - A Victorian Theory of Everything - by Helge Kragh !!!!! PDFBodan NedNo ratings yet

- Corn RefineryDocument31 pagesCorn RefineryAmit Arora100% (1)

- Analysis of Nitrate, Nitrite, and (15N) Nitrate in Biological FluidsDocument8 pagesAnalysis of Nitrate, Nitrite, and (15N) Nitrate in Biological FluidsGoim ArrafiNo ratings yet

- Junker Gas Calorimeter: Theoretical DescriptionDocument2 pagesJunker Gas Calorimeter: Theoretical DescriptionParamjeet SinghNo ratings yet

- Chemical Reaction Practice TestDocument9 pagesChemical Reaction Practice TestMarivic Bernardo GalvezNo ratings yet

- J.J.E. Herrera Velázquez Et Al - Instability Suppression by Sheared Flow in Dense Z-Pinch DevicesDocument8 pagesJ.J.E. Herrera Velázquez Et Al - Instability Suppression by Sheared Flow in Dense Z-Pinch DevicesImsaa4No ratings yet

- 103 NOT OUT Organic ChemistryDocument1 page103 NOT OUT Organic ChemistryJeevan KumarNo ratings yet

- Dangerous Goods BookletDocument20 pagesDangerous Goods Bookletsandhyashenoy20065963No ratings yet

- MYSOP - CornellDocument2 pagesMYSOP - CornellPankajMahajanNo ratings yet

- EagleBurgmann EA560 enDocument3 pagesEagleBurgmann EA560 enDenim BeširovićNo ratings yet

- Atomic Structures Formulas and NamesDocument4 pagesAtomic Structures Formulas and NamesKyla Mari ValduezaNo ratings yet

- NORYL™ Resin - SE1GFN2 - Asia - Technical - Data - Sheet PDFDocument3 pagesNORYL™ Resin - SE1GFN2 - Asia - Technical - Data - Sheet PDFbhushansalunkeNo ratings yet

- Investigation On The Inverse Emulsion Polymerization of Acrylic AcidDocument4 pagesInvestigation On The Inverse Emulsion Polymerization of Acrylic AcidbltzkrigNo ratings yet

- 13) 2008 The Effect of Changing Loads Affecting The Martensite Steel On Itsstructure and The Barkhausen Noise LevelDocument7 pages13) 2008 The Effect of Changing Loads Affecting The Martensite Steel On Itsstructure and The Barkhausen Noise LevelGabriela TarazonaNo ratings yet

- Capítulo 2, TermodinámicaDocument64 pagesCapítulo 2, TermodinámicaISABELLA CUESTAS ACOSTANo ratings yet

- LCNG Vs CNG in USDDocument9 pagesLCNG Vs CNG in USDUJJWALNo ratings yet

- Activated Sludge ProcessesDocument15 pagesActivated Sludge ProcesseskkakskNo ratings yet

- Mineral Water Plant Gayatri DeviDocument24 pagesMineral Water Plant Gayatri DeviRishabh GuptaNo ratings yet

- Prestressed Concrete Structures: Prepared By: Dr. Amlan K. Sengupta Dr. Devdas MenonDocument11 pagesPrestressed Concrete Structures: Prepared By: Dr. Amlan K. Sengupta Dr. Devdas MenonJeffrey Carlo Viduya AgliamNo ratings yet

- PaperDocument35 pagesPaperRashmi SharmaNo ratings yet

- Animal Manure - 2020 - Waldrip - Organomineral Fertilizers and Their Application To Field CropsDocument15 pagesAnimal Manure - 2020 - Waldrip - Organomineral Fertilizers and Their Application To Field CropsEduardo GuimaraesNo ratings yet

- Mec281 NotesDocument498 pagesMec281 NotesRasyidi AhmadNo ratings yet

- Recovery of Active Cathode Materials From Lithium-Ion Batteries UsingDocument9 pagesRecovery of Active Cathode Materials From Lithium-Ion Batteries UsingEnzo BelliniNo ratings yet

- Accord Chemistry CartridgeDocument2 pagesAccord Chemistry Cartridgegzapata31No ratings yet

- Worksheet 2.dna and RnaDocument2 pagesWorksheet 2.dna and RnaTeam kalogxz CompilationNo ratings yet

- Experiment No. 15 "Microbiology of Water": Apparatus/ Materials RequiredDocument2 pagesExperiment No. 15 "Microbiology of Water": Apparatus/ Materials Requireddavid5king-3119No ratings yet

- Viscosity Study Vol2no5 - 15Document4 pagesViscosity Study Vol2no5 - 15Luchian StefanNo ratings yet

- Jet-Lube Korr-Guard Storage Compound PDFDocument1 pageJet-Lube Korr-Guard Storage Compound PDFDon HowardNo ratings yet

- EDI FlexAir Threaded Spec SheetDocument2 pagesEDI FlexAir Threaded Spec Sheetomega AlfaNo ratings yet