Professional Documents

Culture Documents

BABBITT P-Met-542SPR-1

Uploaded by

jpolancosOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BABBITT P-Met-542SPR-1

Uploaded by

jpolancosCopyright:

Available Formats

DATA SHEET

March 2007

TOA-001

P♦MET 542

Arc Spray Wire

DESCRIPTION

P♦Met 542 is a high tin, lead free Babbitt wire specifically designed for spraying in arc spray and flame

spray systems. It produces dense, well-bonded coatings particularly applicable to high speed and

heavy duty bearings.

TYPICAL DEPOSIT CHARACTERISTICS: SURFACE PREPARATION:

• Typical Hardness Nil Surface should be clean, white metal,

• Bond Strength 3000 psi with no oxides (rust), dirt, grease, or oil

• Deposit Rate 48 lbs /hr/100A on the surface to be coated. Note: It is

• Deposit Efficiency 70% best not to handle surfaces after

• Wire Coverage 0.9oz/sq.ft/mil cleaning.

• Surface Texture *Variable Recommended method of preparation

is, to grit blast with 24 mesh aluminum

• Machineability Good

oxide, rough grind, or rough machine in

a lathe.

* Depends on air pressure.

APPLICATION: SPECIFICATION:

• Bearing Surfaces Babbitt

NOMINAL CHEMICAL COMPOSISTION (wt%):

Sb Cu Sn

7.0 3.0 Bal

RECOMMENDED SPRAY PARAMETERS:

Diameter Air Pressure Voltage Amperage Standoff

1/16” (1.6mm) *50 - 60 psi *21 - 23 *100 - 200 *4 – 8 in (10 - 20cm)

* Parameters are typical and may vary depending on equipment used. Contact your equipment manufacture for optimum spray parameters.

STANDARD SIZES & PACKAGING:

Diameter Packaging Part Number

1/16 (1.6mm) 25# LLWS 542062LWS01

The properties listed are typical and not to be construed as guaranteed values. Actual properties may vary depending on customer operating conditions. Polymet makes

no warranties, express or implied, including, but not limited to, the implied warranties of merchantability and fitness for a particular purpose, except as expressly stated in

Polymet’s terms and conditions.

10073 Commerce Park Drive, Cincinnati, OH 45246 / Phone: 513-874-3586 / Fax: 513-8742880

E-Mail: sales@polymet.us

You might also like

- PH12-3G-10-82-T001 - R1 (2500sqmm TDS) With Annexures PDFDocument34 pagesPH12-3G-10-82-T001 - R1 (2500sqmm TDS) With Annexures PDFVijai PrasathNo ratings yet

- What Is The Difference Between MCB, MCCB, ELCB, and RCCB - EEPDocument5 pagesWhat Is The Difference Between MCB, MCCB, ELCB, and RCCB - EEPcurazaq100% (1)

- Climaxportable Lathe Pl3000-EDocument6 pagesClimaxportable Lathe Pl3000-EjpolancosNo ratings yet

- Chimney Lighting BOQDocument10 pagesChimney Lighting BOQabhey21No ratings yet

- LS Catalogue HCCDocument10 pagesLS Catalogue HCCVICTOR JOSE VILORIANo ratings yet

- Polymet MET-273 - Equiv TAFA 95 MXCDocument1 pagePolymet MET-273 - Equiv TAFA 95 MXCRobert Stuart100% (2)

- Spanish Style SardinesDocument2 pagesSpanish Style Sardinesjpolancos67% (3)

- PMET 542 - BabbittDocument1 pagePMET 542 - Babbitt.xNo ratings yet

- PMET 273 - Amorphous AlloyDocument1 pagePMET 273 - Amorphous Alloy.xNo ratings yet

- PMET 292 Nano AlloyDocument1 pagePMET 292 Nano Alloy.xNo ratings yet

- Polymet PMET 877-MonelDocument1 pagePolymet PMET 877-MonelgersomNo ratings yet

- P MET 223 Chromium Carbide: Arc Spray WireDocument2 pagesP MET 223 Chromium Carbide: Arc Spray WireYONH YUNIOR TICONA CALLANo ratings yet

- P MET 720: March 2007 TIBA-004Document1 pageP MET 720: March 2007 TIBA-004elias667No ratings yet

- PMET 720-420 StainlessDocument1 pagePMET 720-420 Stainless.xNo ratings yet

- Ndless Ring With A Circular Cross Section Ing: MaterialDocument32 pagesNdless Ring With A Circular Cross Section Ing: Materialscrollock0428No ratings yet

- PMET 885 - Nickel 5 AluminumDocument1 pagePMET 885 - Nickel 5 Aluminum.xNo ratings yet

- EagleBurgmann CobaSeal ENDocument3 pagesEagleBurgmann CobaSeal ENCuong TranHungNo ratings yet

- Sikagrout - 280 HsDocument3 pagesSikagrout - 280 HsWiwin RamadhaniNo ratings yet

- Cojinete Acero - GGB-SHB-Case-Hardened-Steel-Bearings-DatasheetDocument2 pagesCojinete Acero - GGB-SHB-Case-Hardened-Steel-Bearings-DatasheetneodymioNo ratings yet

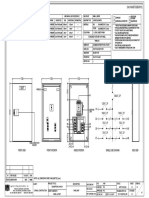

- 01 - Panel Mdp-Panel LayoutDocument1 page01 - Panel Mdp-Panel LayoutEdison EstrellaNo ratings yet

- 316lesrvar Ft003-Uk PDFDocument2 pages316lesrvar Ft003-Uk PDFRaj RajeshNo ratings yet

- Datasheet - Afrox Stainshield Plus Shielding GasDocument2 pagesDatasheet - Afrox Stainshield Plus Shielding GasDries VandezandeNo ratings yet

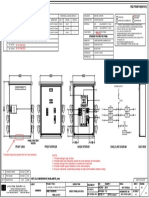

- 07 - Panel Whpb-Panel LayoutDocument1 page07 - Panel Whpb-Panel LayoutEdison EstrellaNo ratings yet

- Rod Seals: Technical DetailsDocument2 pagesRod Seals: Technical DetailsRPINILLA (EICO S.A.)No ratings yet

- Hiking Superior Industrial Co., Limited: Certificate of Detailed QualityDocument1 pageHiking Superior Industrial Co., Limited: Certificate of Detailed QualityCarlos CordovaNo ratings yet

- Resutile Topcoat SD System Guide SWDocument4 pagesResutile Topcoat SD System Guide SWServandoNo ratings yet

- T700S Technical Data Sheet 1 PDFDocument2 pagesT700S Technical Data Sheet 1 PDFGustavoNo ratings yet

- T700S Technical Data Sheet 1 PDFDocument2 pagesT700S Technical Data Sheet 1 PDFgk9No ratings yet

- Aladin 21 SprayDocument1 pageAladin 21 SprayTRIFLOW INDIANo ratings yet

- Blastrite Sinterblast - StarblastDocument1 pageBlastrite Sinterblast - StarblastYoutube For EducationNo ratings yet

- Wear Reducing Technology in Severe Pumping ServicesDocument29 pagesWear Reducing Technology in Severe Pumping ServicesDaniel EsparzaNo ratings yet

- Eutectic 19400: Atomized Martensitic Stainless Steel Alloy PowderDocument2 pagesEutectic 19400: Atomized Martensitic Stainless Steel Alloy PowderYeison Piedrahita PérezNo ratings yet

- T300 R6 - 04132018Document2 pagesT300 R6 - 04132018Suraj_73No ratings yet

- Mineral Slag BlastingDocument2 pagesMineral Slag BlastingtestNo ratings yet

- Compact Seal Type 0820Document6 pagesCompact Seal Type 0820scuff08No ratings yet

- T300 Technical Data Sheet 1 PDFDocument2 pagesT300 Technical Data Sheet 1 PDFmaraNo ratings yet

- Polywear 60 GtawDocument1 pagePolywear 60 GtawFlori MovNo ratings yet

- Polywear 50 Gtaw 1Document1 pagePolywear 50 Gtaw 1Flori MovNo ratings yet

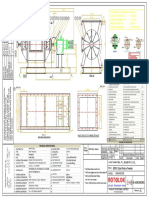

- 02 - Socket Panel B (50 Assy) - Panel LayoutDocument1 page02 - Socket Panel B (50 Assy) - Panel LayoutaaronmyrroNo ratings yet

- T700S R4 - 04132018 ActualDocument2 pagesT700S R4 - 04132018 ActualVaibhav AnuseNo ratings yet

- 1.9.1.2-80T - 18 8 Stainless SteelDocument4 pages1.9.1.2-80T - 18 8 Stainless SteelDevan ShanmughaNo ratings yet

- SSR Sello GiroDocument7 pagesSSR Sello GiroRPINILLA (EICO S.A.)No ratings yet

- Wall-Colmonoy Wallex-21 ENG January2021-1Document3 pagesWall-Colmonoy Wallex-21 ENG January2021-1pranav kariaNo ratings yet

- Eutectic 29029Document2 pagesEutectic 29029Imam SitumeangNo ratings yet

- Phenoline 187 Finish PDSDocument2 pagesPhenoline 187 Finish PDSalejandroNo ratings yet

- Bitumastic 300M: Selection & Specification DataDocument4 pagesBitumastic 300M: Selection & Specification DataSHAIK ASIMUDDINNo ratings yet

- GGB BP25 Metafram Oil Impregnated Sintered Bronze Bearings DatasheetDocument2 pagesGGB BP25 Metafram Oil Impregnated Sintered Bronze Bearings DatasheetDominik WojtasNo ratings yet

- Phenoline 187 Primer and FinishDocument2 pagesPhenoline 187 Primer and Finish이선엽No ratings yet

- 2018 Stonage Fittings and Accessories WebDocument35 pages2018 Stonage Fittings and Accessories WeblupiNo ratings yet

- Merkel Wiper As: Design NotesDocument1 pageMerkel Wiper As: Design NotesraulNo ratings yet

- DG2/40 HS: Flat Transmission Belts Technical Data SheetDocument2 pagesDG2/40 HS: Flat Transmission Belts Technical Data Sheetdirkz26No ratings yet

- B-TDM-M: Decorative Grade Non Heat Sealable Metallized BOPP FilmDocument2 pagesB-TDM-M: Decorative Grade Non Heat Sealable Metallized BOPP FilmSayed FathyNo ratings yet

- Neo Backer RodDocument2 pagesNeo Backer RodhazelNo ratings yet

- Raptor Black: Technical Data Sheet & Process GuideDocument7 pagesRaptor Black: Technical Data Sheet & Process GuideroyNo ratings yet

- Winkel Wincut Stainless Steel OilDocument1 pageWinkel Wincut Stainless Steel Oilgopalakrishna100% (1)

- Stoody 130Document1 pageStoody 130Cheker HaddedNo ratings yet

- 350xt Data Sheet EnglishDocument1 page350xt Data Sheet Englishanon_726020506No ratings yet

- Abrasive Jet MachiningDocument20 pagesAbrasive Jet MachiningAman C GoudNo ratings yet

- T700S Technical Data Sheet PDFDocument2 pagesT700S Technical Data Sheet PDFjairoNo ratings yet

- Torayca Carbon T1100G-Technical-Data-Sheet-1 PDFDocument2 pagesTorayca Carbon T1100G-Technical-Data-Sheet-1 PDFd25932373No ratings yet

- MBR500 Drum CutterDocument1 pageMBR500 Drum CutterpranantioNo ratings yet

- Sikawrap® Hex-230 C: Product Data SheetDocument4 pagesSikawrap® Hex-230 C: Product Data SheetArindam SarkarNo ratings yet

- GGB DU Metal Polymer Anti Friction Plain Bearings DatasheetDocument2 pagesGGB DU Metal Polymer Anti Friction Plain Bearings Datasheetmichael KetselaNo ratings yet

- Product Specifications: Specification Sheet 12 1/4" (311 MM)Document1 pageProduct Specifications: Specification Sheet 12 1/4" (311 MM)WHWENNo ratings yet

- Strainers: Technical SpecificationsDocument2 pagesStrainers: Technical SpecificationsjpolancosNo ratings yet

- Rotary Feeder RotolokDocument1 pageRotary Feeder RotolokjpolancosNo ratings yet

- ALFA LAVAL Oil-Water Separator Stationary-MobileDocument4 pagesALFA LAVAL Oil-Water Separator Stationary-MobilejpolancosNo ratings yet

- OLYMPUS Ultrasonic Thickness Gauge 26MGDocument2 pagesOLYMPUS Ultrasonic Thickness Gauge 26MGjpolancosNo ratings yet

- Hardness Tester - Time TH130 TH134Document1 pageHardness Tester - Time TH130 TH134jpolancosNo ratings yet

- Loctite 243™: Cone 35/2°ti at Shear Rate 129 S 350Document4 pagesLoctite 243™: Cone 35/2°ti at Shear Rate 129 S 350jpolancosNo ratings yet

- Pulley Vbelt SPB Taper BoreDocument3 pagesPulley Vbelt SPB Taper BorejpolancosNo ratings yet

- Flexible Adhesive For Performance Assembly: 1.1. ProcessingDocument4 pagesFlexible Adhesive For Performance Assembly: 1.1. ProcessingjpolancosNo ratings yet

- Air Permeability ConversionsDocument1 pageAir Permeability ConversionsjpolancosNo ratings yet

- Ips-Mehtalia Pvt. LTDDocument26 pagesIps-Mehtalia Pvt. LTDMvv SatyanarayanaNo ratings yet

- Binding Wire From Tata PDFDocument2 pagesBinding Wire From Tata PDFHiren DesaiNo ratings yet

- Roll Form Strander - NEWDocument8 pagesRoll Form Strander - NEWAbdul HarisNo ratings yet

- EIM Self Assessment Guide NewDocument3 pagesEIM Self Assessment Guide NewRicalyn BelarminoNo ratings yet

- Accc/Tw Lisbon (310) : Data SheetDocument1 pageAccc/Tw Lisbon (310) : Data SheetkmiqdNo ratings yet

- NEC Article 645.5: 645.5 Supply Circuits and Interconnecting CablesDocument2 pagesNEC Article 645.5: 645.5 Supply Circuits and Interconnecting CablesFran Eduardo Amaya100% (1)

- Band Heaters Mica THINBANDDocument24 pagesBand Heaters Mica THINBANDEliasNo ratings yet

- Insulation Resistance TestingDocument3 pagesInsulation Resistance TestingAlexander ChuaNo ratings yet

- A640Document3 pagesA640Wagner Santana100% (1)

- Mod. PDG-2/EV: Demonstration Panel For The Electric Testing Carried Out in Industrial BuildingsDocument2 pagesMod. PDG-2/EV: Demonstration Panel For The Electric Testing Carried Out in Industrial BuildingsderbalijalelNo ratings yet

- Lubricool-22G MantapDocument3 pagesLubricool-22G MantapMarco PoloNo ratings yet

- Npqs ContentDocument1 pageNpqs ContentGaryNo ratings yet

- Fuel Level Sensor Wiring Harness ReplacementDocument3 pagesFuel Level Sensor Wiring Harness ReplacementgrafpapNo ratings yet

- 9110 PDFDocument15 pages9110 PDFPawan KumarNo ratings yet

- 0100CT1901 Sec-01 PDFDocument44 pages0100CT1901 Sec-01 PDFBobby FischerNo ratings yet

- Specifications: Feature Capacity (U.S. Tons) 15 20 25 30 40 45 50 60Document1 pageSpecifications: Feature Capacity (U.S. Tons) 15 20 25 30 40 45 50 60Toni RenedoNo ratings yet

- FullcatalogDocument150 pagesFullcatalogapi-93088241No ratings yet

- Electrical Final CircuitsDocument5 pagesElectrical Final CircuitsLawrence Wahome ngariNo ratings yet

- ELR-517.16 Use of Isolated Ground ReceptaclesDocument3 pagesELR-517.16 Use of Isolated Ground ReceptaclesJOSE LUIS FALCON CHAVEZNo ratings yet

- Intermediate Metallic Conduit (IMC)Document9 pagesIntermediate Metallic Conduit (IMC)vanjoseph01No ratings yet

- RT Sensitivity Calculation - TwiDocument2 pagesRT Sensitivity Calculation - TwiTomy GeorgeNo ratings yet

- 0 PRO Sigma 688 ENDocument12 pages0 PRO Sigma 688 ENayoub ramziNo ratings yet

- When and Where To Use TinningDocument4 pagesWhen and Where To Use TinningVatsalNo ratings yet

- Bright 1958 Automation and ManagementDocument25 pagesBright 1958 Automation and ManagementGrupo sufrimiento, salud mental y trabajo.No ratings yet

- Gujarat VibrantDocument2 pagesGujarat Vibrantshivamdubey12No ratings yet

- McGILL Product Guide 2018 PDFDocument12 pagesMcGILL Product Guide 2018 PDFRobert TiinNo ratings yet