Professional Documents

Culture Documents

Metal System Datasheets PDF

Uploaded by

Eduardo Mateo ArdilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Metal System Datasheets PDF

Uploaded by

Eduardo Mateo ArdilCopyright:

Available Formats

PRODUCT SPECIFICATIONS

Metal X

The Metal X is a revolutionary 3D printer that prints metal powder bound in a plastic matrix to eliminate safety risks associated

with traditional metal 3D printing methods while enabling new features like close-cell infill for reduced part weight and cost. It’s

up to 10x less expensive than alternative metal additive manufacturing technologies — and up to 100x less than traditional

fabrication technologies like machining or casting. Affordable, reliable, and easy to use, the Metal X print system gives you

everything you need to go from design to fully functional metal parts faster than ever before.

Printer Process Atomic Diffusion Additive Manufacturing (ADAM)

Properties

Build Volume 300 x 220 x 180 mm (11.8 x 8.7 x 7.1 in)

Machine Size 575 x 467 x 1,120 mm (22.7 x 18.4 x 44.1 in), 75 kg (160 lbs)

Print Chamber Heated

Print Bed Heated, vacuum-sealed print sheet, auto bed leveling

Print System Two nozzles — Metal material and release material

Power Requirements 100–120 / 200-240 VAC (12A / 6A), IEC 60320 type C20

Materials Metal Material Stainless steel (17-4 PH, 316L*), Tool steel (H13, A2, D2), Inconel

625, Copper, Titanium-6Al-4V*

Release Material Ceramic (consumed at 1:10 ratio to metal spools, on average)

Media (Spools) Filament fed, bound powder

Part Max Part Size 250 x 183 x 150 mm (9.8 x 7.2 x 5.9 in), 10kg

Properties

Supports Metal material with ceramic release layer

Layer Height 50µm and 125µm post-sinter

Software Supplied Software Eiger Cloud (Other options available at cost)

Security Two-factor authentication, org admin access, single sign-on

FRONT VIEW SIDE VIEW

44”

22” 18”

* Materials currently under development. Note: All specifications are approximate and subject to change without notice.

REV 2.4 - 02/25/2020 markforged.com F-PR-5000

PRODUCT SPECIFICATIONS

Wash-1

The first step in transforming a printed “green” part into fully dense metal is debinding. The Wash-1 immerses the green part in

a specialized fluid which dissolves the primary binding material, leaving the part semi-porous so the remaining binder can easily

burn off during sintering. This debinding step purifies the final metal part and helps keep your sintering furnace clean.

Debinder Materials Supported All metals

Properties

Fluid (Solvent) Opteon SF79, Opteon SF80, or Tergo Metal Cleaning Fluid

Controller Integrated control system

Workholding Stainless steel basket

Washing Size 356 x 254 x 203 mm (14 x 10 x 8 in)

Washing Volume 18,356 cm3 (1,120 in3)

Safety & Environmental Req. External exhaust

Installation

Safety Control Low fluid shutoff control

High vapor pressure shutoff control

Regulatory Refer to MSDS

Emissions Low emission design to conserve solvent

Power 110-120 VAC single phase, 11A / 1,320W peak draw

Physical External Dimensions 609 x 685 x 1,067 mm (24 x 27 x 42 in)

Dimensions

Weight 136 kg (300 lbs)

FRONT VIEW SIDE VIEW TOP VIEW

27”

42”

24”

Note: All specifications are approximate and subject to change without notice.

REV 2.3a - 03/13/2020 markforged.com F-PW-0001

PRODUCT SPECIFICATIONS

Sinter-1

The Markforged Sinter-1 is a high-performing, high-value furnace that is ideal for small batch production. Built on 30 years

of Metal Injection Molding (MIM) technology, it’s affordable and reliable. Featuring 4,760 cm3 of active hot zone, the Sinter-1

effortlessly converts washed parts into their high-quality dense final metallic form in as few as 26 hours.

Furnace Materials Supported Chemically debound Metal X-printed parts

Properties

Heating Element Kanthal

Controller Pre-programmed automatic cycling

Sinter Run Time 26 hours*

Peak Internal Temp. 1,300° C / 2,372° F

Sintering Capacity Rectangle w/radius top — 141 mm ID x 305 mm L (5.55 in ID x 12 in L)

Sintering Workload 3,020 cm3 (184 in3)

Sinter Surface Area 348 cm2 (53.9 in2) for single ceramic setter plate

Setter Plate Dimensions 11.4cm W x 30.4cm D, (4.5in W x 12.0in D)

Gas Types Argon, argon / hydrogen mix

Retort High purity refractory retort (carbon-free)

Safety & Environmental Req. External exhaust (100–150 CFM)

Installation

Power 200–240 V single phase 30A, recommend wiring 50A

Physical External Dimensions 1,270 x 510 x 720 mm (50 x 20 x 28 in)

Dimensions

Weight 136 kg (300 lbs)

FRONT VIEW SIDE VIEW

28”

42” 20”

* May vary by material. Note: All specifications are approximate and subject to change without notice.

REV 2.4 - 02/25/2020 markforged.com F-SR-0001

PRODUCT SPECIFICATIONS

Sinter-2

With an expansive active hot zone (19,644 cm3 / 1,199 in3), the Sinter-2 is the perfect solution for mid-volume batch production

and for larger parts. Create high-purity metal parts by using sintering technology built with a carbon-free retort. This workhorse

furnace is enabled with rapid cooling technology and can process the full range of commercial-grade metals from their washed

state into dense metal parts in as few as 30 hours.

Furnace Materials Supported Chemically debound Metal X-printed parts

Properties

Heating Element Kanthal

Controller Pre-programmed automatic cycling

Sinter Run Time 30 hours*

Peak Internal Temp. 1,300° C / 2,372° F

Sintering Capacity Rectangle w/radius top — 248 mm ID x 406 mm L (9.8 in ID x 16 in L)

Sintering Workload 12,135 cm3 (741 in3)

Sintering Surface Area 1,644 cm2 (254.8 in2) for stackable ceramic setter plate

Setter Plate Dimensions Top plate: 24.0cm W x 41.0cm D, (9.4in W x 16.1in D)

Bottom plate: 17.0cm W x 41.0cm D, (6.7in W x 16.1in D)

Gas Types Argon, argon / hydrogen mix

Retort High purity refractory retort (carbon-free)

Safety & Environmental Req. External exhaust (100–150 CFM)

Installation

Power 200–240 V, 3 phase (3 wire), 30 A

346–416 V, 3 phase (4 wire), 30 A

Physical External Dimensions 1,370 x 810 x 1,520 mm (54 x 32 x 60 in)

Dimensions

Weight 350 kg (772 lbs)

FRONT VIEW SIDE VIEW MAX SINTER VOLUME

X 406.0 mm

Y 236.0 mm

Z2

Z1 Z2 114.3 mm

R Z1 26.0 mm

R 123.0 mm

X

Y

60”

R X 378.0 mm

Z2 Y 166.0 mm

Z1 Z2 197.2 mm

Z1 165.0 mm

R 123.0 mm

X

48” 28” Y

* May vary by material, operating environment, run mass, electrical frequency, etc. Note: All specifications are approximate and subject to change without notice.

REV 2.4 - 02/25/2020 markforged.com F-SR-0002

You might also like

- Metal X - Sinter 1Document3 pagesMetal X - Sinter 1larasNo ratings yet

- Metal X: 85 School ST, Watertown, MA 02472 All Specifications Approximate and Subject To Change Without NoticeDocument4 pagesMetal X: 85 School ST, Watertown, MA 02472 All Specifications Approximate and Subject To Change Without NoticeslobamsNo ratings yet

- Sinter 2Document1 pageSinter 2dNo ratings yet

- Product Specifications for Wash-1 DebinderDocument1 pageProduct Specifications for Wash-1 DebinderJuan PachecoNo ratings yet

- Sinter-1 DatasheetDocument1 pageSinter-1 DatasheetJuan PachecoNo ratings yet

- 420 SS/BronZE 3D PRINTDocument2 pages420 SS/BronZE 3D PRINTNicola MerzagoraNo ratings yet

- Quality of Your Lab Quality of Your LabDocument4 pagesQuality of Your Lab Quality of Your LabJagdish RajanNo ratings yet

- FDF-2 Confirm Spec20180814ADocument5 pagesFDF-2 Confirm Spec20180814AMark Vista AgusNo ratings yet

- Deep F.C KitDocument6 pagesDeep F.C KitVipul SharmaNo ratings yet

- Allen-Bradley 30.5mm 3-Hole EnclosureDocument2 pagesAllen-Bradley 30.5mm 3-Hole EnclosureCARLOS COANo ratings yet

- Part 6 - Asphalt TestingDocument36 pagesPart 6 - Asphalt TestingSanjeev ViswambharanNo ratings yet

- Bie - Jade 200 - en - 2012Document12 pagesBie - Jade 200 - en - 2012aidma05No ratings yet

- Ficha Tecnica D12000Document1 pageFicha Tecnica D12000Nguyễn Hữu ĐồngNo ratings yet

- F-PR-5000 Metal X 3D Printer SpecificationsDocument1 pageF-PR-5000 Metal X 3D Printer SpecificationsKKK BitchNo ratings yet

- K-CV-KT20 Coperion K-Tron Product Specification Volumetric Twin Screw Compact FeederDocument2 pagesK-CV-KT20 Coperion K-Tron Product Specification Volumetric Twin Screw Compact FeederARK MurpheyNo ratings yet

- (C30) Technical Specification - ENDocument14 pages(C30) Technical Specification - ENhicham1963No ratings yet

- Global 3D Pramaan 160: Print Area Print Resolution ConnectivityDocument12 pagesGlobal 3D Pramaan 160: Print Area Print Resolution ConnectivityRichard WorkbenchNo ratings yet

- Technical Data Sheet: Stirling Ultracold ULT25NEU Ultra-Low Temperature FreezerDocument2 pagesTechnical Data Sheet: Stirling Ultracold ULT25NEU Ultra-Low Temperature FreezerKrishna KumarNo ratings yet

- Rubber Tile: Roppe Corporation - 1602 North Union Street - Fostoria, OH 44830 - (800) 537-9527 - 12/10/2020 - Page 1Document2 pagesRubber Tile: Roppe Corporation - 1602 North Union Street - Fostoria, OH 44830 - (800) 537-9527 - 12/10/2020 - Page 1Jose Carlos Guillen ZambranoNo ratings yet

- Humboldt: Humboldt HS-5001EZ Nuclear Density GaugeDocument2 pagesHumboldt: Humboldt HS-5001EZ Nuclear Density GaugeSofiaIsabelaPalaciosRosellNo ratings yet

- SPESIFIKASI TEKNIS SMKN 2 WONOSARIDocument3 pagesSPESIFIKASI TEKNIS SMKN 2 WONOSARIYusuf ArdiansyahNo ratings yet

- Plastic Steel Putty A v3Document2 pagesPlastic Steel Putty A v3feri.ferdianto02No ratings yet

- Mds Rheinzink-Artcolor Skygrey 04 2018 de enDocument3 pagesMds Rheinzink-Artcolor Skygrey 04 2018 de encarlosNo ratings yet

- Bakelite PF 31Document3 pagesBakelite PF 31dioguitomsolhaNo ratings yet

- F PR 5000 Gen2Document1 pageF PR 5000 Gen2muhammad asadullahNo ratings yet

- APEX DYNAMICS PLANETARY GEARBOX CompressedDocument23 pagesAPEX DYNAMICS PLANETARY GEARBOX CompressedDioNo ratings yet

- Borstar® HE6062: PolyethyleneDocument3 pagesBorstar® HE6062: PolyethyleneShashank SaxenaNo ratings yet

- Me6052 PDS Reg - World en V4 PDS World 4158 10058878Document3 pagesMe6052 PDS Reg - World en V4 PDS World 4158 10058878TANMAY NAYAKNo ratings yet

- Rayjet400 Technical - Datasheet 8 22Document2 pagesRayjet400 Technical - Datasheet 8 22bambilovespascalNo ratings yet

- 300.024 Lustran Elite 1891Document2 pages300.024 Lustran Elite 1891Enrique ChavezNo ratings yet

- Bambu Lab P1S Tech SpecsDocument1 pageBambu Lab P1S Tech SpecsEdem KougniganNo ratings yet

- Vegavib 63: Relay (DPDT) Vibrating Level Switch With Tube Extension For Granuled Bulk SolidsDocument2 pagesVegavib 63: Relay (DPDT) Vibrating Level Switch With Tube Extension For Granuled Bulk SolidsNurocman KelikNo ratings yet

- Annexure I - PB Spctrum BiocidesDocument2 pagesAnnexure I - PB Spctrum BiocidessardiusbiocidesNo ratings yet

- Differential Pressure Recorder Data SheetDocument8 pagesDifferential Pressure Recorder Data SheetEdmund LimNo ratings yet

- Press brakeDocument8 pagesPress braked54ddqcpfqNo ratings yet

- ULF Single Table Fiber Laser Cutting Machine Technical SpecificationsDocument21 pagesULF Single Table Fiber Laser Cutting Machine Technical SpecificationsAbubaker KakuleNo ratings yet

- Mechanical Engineering Laboratories Name of The DepartmentDocument15 pagesMechanical Engineering Laboratories Name of The Departmentaviraj2007No ratings yet

- Carmel1400M-Brochure 09.2261Document2 pagesCarmel1400M-Brochure 09.2261Ragil AjiNo ratings yet

- Filtros VikingDocument10 pagesFiltros VikingRodrigo SantosNo ratings yet

- Idea 30Document2 pagesIdea 30Milos StevanovicNo ratings yet

- Caring Formula High Flow Glass Filled PA6Document3 pagesCaring Formula High Flow Glass Filled PA6ratz23695No ratings yet

- 3SU12002PS101AA0 enDocument4 pages3SU12002PS101AA0 enaaaguilarmNo ratings yet

- Cold Feed Extruders: Common Applications & MaterialsDocument2 pagesCold Feed Extruders: Common Applications & Materialspanama sunpowerNo ratings yet

- Durastar DS1910HFDocument2 pagesDurastar DS1910HFEvelyn SigoliNo ratings yet

- UnionTech RSPro 1400 TDS Flyer EN 201803 v5 FinalDocument2 pagesUnionTech RSPro 1400 TDS Flyer EN 201803 v5 FinalrahulNo ratings yet

- Balto FlakeDocument5 pagesBalto FlakeBiju_PottayilNo ratings yet

- Digital Ultrasonic Cleaner 0212Document4 pagesDigital Ultrasonic Cleaner 0212DINESHNo ratings yet

- Physical: .100" × .100" Latch/Ejector, Straight and Right Angle D3000 SeriesDocument5 pagesPhysical: .100" × .100" Latch/Ejector, Straight and Right Angle D3000 SeriessatyaNo ratings yet

- Jotamastic 80: Technical Data SheetDocument14 pagesJotamastic 80: Technical Data SheetCv RONATAMA GUSLHANNo ratings yet

- Z-ABS Technical Data Sheet Eng-1Document2 pagesZ-ABS Technical Data Sheet Eng-1PeroNo ratings yet

- Ground Modular Terminal Block - USLKG 10: Jul 7, 2022, 7:41 PM Page 1Document25 pagesGround Modular Terminal Block - USLKG 10: Jul 7, 2022, 7:41 PM Page 1javierNo ratings yet

- E-Shell® 300 Series - 3D Printing Materials - EnvisionTECDocument3 pagesE-Shell® 300 Series - 3D Printing Materials - EnvisionTECdamboNo ratings yet

- Magnetic Stirrer HotplateDocument4 pagesMagnetic Stirrer HotplateumarNo ratings yet

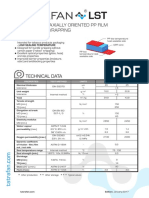

- Coextruded Biaxially Oriented PP Film For Tobacco Wrapping: Technical DataDocument2 pagesCoextruded Biaxially Oriented PP Film For Tobacco Wrapping: Technical DataJan GawełNo ratings yet

- İldam: DF-600 - 600 Liter DF-450 - 450 Liter DF-340 - 340 LiterDocument2 pagesİldam: DF-600 - 600 Liter DF-450 - 450 Liter DF-340 - 340 Literragunatharao0% (1)

- SuprapackDocument5 pagesSuprapackFernando Moreno pereiraNo ratings yet

- 9791 TechdataDocument2 pages9791 TechdataSajith AliNo ratings yet

- Magelis XBT N - R - RT - xbtn400Document4 pagesMagelis XBT N - R - RT - xbtn400Armando HernandezNo ratings yet

- DDE 4742 Data Sheet Dg-EnGDocument2 pagesDDE 4742 Data Sheet Dg-EnGMuhammad ArifNo ratings yet

- Meiko K-Tronic Dishwasher Installation ManualDocument32 pagesMeiko K-Tronic Dishwasher Installation ManualEduardo Mateo ArdilNo ratings yet

- Delcos 3000 PDFDocument28 pagesDelcos 3000 PDFAnonymous ZLFAEi100% (1)

- Metal System Datasheets PDFDocument4 pagesMetal System Datasheets PDFEduardo Mateo ArdilNo ratings yet

- Meiko K-Tronic Dishwasher Installation ManualDocument32 pagesMeiko K-Tronic Dishwasher Installation ManualEduardo Mateo ArdilNo ratings yet

- Quick Reference Guide: Delcos 1000Document2 pagesQuick Reference Guide: Delcos 1000Eduardo Mateo Ardil50% (2)

- Delivery ProgramDocument7 pagesDelivery ProgramEduardo Mateo ArdilNo ratings yet

- DEF CON 24 - Eric-Escobar-Rogue-Cell-Towers-UPDATED PDFDocument66 pagesDEF CON 24 - Eric-Escobar-Rogue-Cell-Towers-UPDATED PDFEduardo Mateo Ardil100% (1)

- The Pandemic VentilatorDocument9 pagesThe Pandemic VentilatorAbeer AhmedNo ratings yet

- Industry Standards & Regulations: ASME - Performance Test Codes CollectionDocument2 pagesIndustry Standards & Regulations: ASME - Performance Test Codes Collectionismael7901No ratings yet

- Wet Towel Dryer AirflowDocument3 pagesWet Towel Dryer Airflowdendisneha reddy80% (5)

- Bearing Capacity of Mat FoundationsDocument7 pagesBearing Capacity of Mat FoundationsConstructora Ingenieria AlemanNo ratings yet

- Physics Oscillator ReportDocument14 pagesPhysics Oscillator ReportarushiNo ratings yet

- CLMD4A AutomotiveG9 10Document25 pagesCLMD4A AutomotiveG9 10Eiay CommsNo ratings yet

- Mechanical Professional ElectiveDocument310 pagesMechanical Professional ElectivearunrajNo ratings yet

- 11th Physics EM Slow Learners Study Materials English Medium PDF DownloadDocument162 pages11th Physics EM Slow Learners Study Materials English Medium PDF Downloaddhanasekaran1504No ratings yet

- Problem Set #6 AnswersDocument3 pagesProblem Set #6 AnswersStefan BamNo ratings yet

- FE-based multiscale modelling of soft acoustic metamaterialsDocument8 pagesFE-based multiscale modelling of soft acoustic metamaterialsDonald ZekaNo ratings yet

- PHD ThesisDocument310 pagesPHD ThesisOlivia OeyNo ratings yet

- Lecture 1 - Unit 1 - DSP (BEC-42) NewDocument21 pagesLecture 1 - Unit 1 - DSP (BEC-42) NewDr. Satish ChandraNo ratings yet

- Shandong Licun Power Plant generator start-stop and inspectionDocument19 pagesShandong Licun Power Plant generator start-stop and inspectionRuben MaychelNo ratings yet

- 1TRIGODocument7 pages1TRIGOCielo Pabilan ObemioNo ratings yet

- Silicon Zener Diodes for Stabilizing and Clipping CircuitsDocument4 pagesSilicon Zener Diodes for Stabilizing and Clipping CircuitsMohamad Toufan AkbarNo ratings yet

- Starling EngineDocument7 pagesStarling EngineLuis ParadaNo ratings yet

- Statistics Lesson 1: Binomial, Poisson, Normal DistributionsDocument25 pagesStatistics Lesson 1: Binomial, Poisson, Normal DistributionsAlicia YipNo ratings yet

- 420F Backhoe Loader SKR00001-UP (MACHINE) POWERED BY C4.4 Engine (SEBP5986 - 55) - DocumentaciónDocument7 pages420F Backhoe Loader SKR00001-UP (MACHINE) POWERED BY C4.4 Engine (SEBP5986 - 55) - DocumentaciónRosa ChNo ratings yet

- Permeabilité-Peila-clay SoilDocument7 pagesPermeabilité-Peila-clay SoilMoez SelmiNo ratings yet

- Electrical Room Structural DesignDocument131 pagesElectrical Room Structural DesignGee - FNo ratings yet

- Elements of Airplane PerformanceDocument10 pagesElements of Airplane PerformanceMani RaoNo ratings yet

- 6.2 Trigonometric Functions - Unit Circle Approach-John HodgsonDocument2 pages6.2 Trigonometric Functions - Unit Circle Approach-John Hodgsonjohn hodgsonNo ratings yet

- Size ReductionDocument39 pagesSize ReductionAstra BeckettNo ratings yet

- A Fast On-Board Integrated Battery Charger For Evs Using An Asymmetrical Six-Phase MachineDocument6 pagesA Fast On-Board Integrated Battery Charger For Evs Using An Asymmetrical Six-Phase MachineMusfiqul AzadNo ratings yet

- Mastery Test in Science 1Document3 pagesMastery Test in Science 1Michelle SegoviaNo ratings yet

- Shishuvan - STD 7 (2021-22) - IntegersDocument10 pagesShishuvan - STD 7 (2021-22) - IntegersHardik ViraNo ratings yet

- Machine learning designs 1D photonic crystals for visible light spectraDocument18 pagesMachine learning designs 1D photonic crystals for visible light spectrayassinebouazziNo ratings yet

- Potable Water Expansion Tank Sizing ProgramDocument2 pagesPotable Water Expansion Tank Sizing ProgramChaosNo ratings yet

- Premium Industrial NDT SolutionsDocument16 pagesPremium Industrial NDT SolutionsSiva ShankarNo ratings yet

- Industrial training report at COURSERA wind energyDocument11 pagesIndustrial training report at COURSERA wind energyAAKIB QURESHINo ratings yet

- How To Fix A Washing Machine: 9 Common Problems: Attempting RepairsDocument6 pagesHow To Fix A Washing Machine: 9 Common Problems: Attempting RepairsLouieGonzalesNo ratings yet