Professional Documents

Culture Documents

Sinter 2

Uploaded by

dOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sinter 2

Uploaded by

dCopyright:

Available Formats

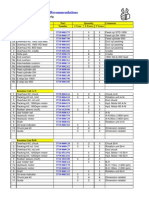

PRODUCT SPECIFICATIONS

Sinter-2

With an expansive active hot zone (19,644 cm3 / 1,199 in3), the Sinter-2 is the perfect solution for mid-volume batch production

and for larger parts. Create high-purity metal parts by using sintering technology built with a carbon-free retort. This workhorse

furnace is enabled with rapid cooling technology and can process the full range of commercial-grade metals from their washed

state into dense metal parts in as few as 30 hours.

Furnace Materials Supported Chemically debound Metal X-printed parts

Properties

Heating Element Kanthal

Controller Pre-programmed automatic cycling

Sinter Run Time 30 hours,* 17 hours (Small Parts Express Run)**

Peak Internal Temp. 1,300° C / 2,372° F

Sintering Capacity Rectangle w/radius top — 248 mm ID x 406 mm L (9.8 in ID x 16 in L)

Sintering Workload 12,135 cm3 (741 in3)

Sintering Surface Area 1,644 cm2 (254.8 in2) for stackable ceramic setter plate

Setter Plate Dimensions Top plate: 24.0cm W x 41.0cm D, (9.4in W x 16.1in D)

Bottom plate: 17.0cm W x 41.0cm D, (6.7in W x 16.1in D)

Gas Types Argon, argon / hydrogen mix

Retort High purity refractory retort (carbon-free)

RF Module Operating Band 2.4 GHz Wi-Fi Standards 802.11 b/g/n

Safety & Environmental Req. External exhaust (100–150 CFM)

Installation

Power 200–240 V, 3 phase (3 wire), 30 A

346–416 V, 3 phase (4 wire), 30 A

Physical External Dimensions 1,370 x 810 x 1,520 mm (54 x 32 x 60 in)

Dimensions

Weight 350 kg (772 lbs)

FRONT VIEW SIDE VIEW MAX SINTER VOLUME

60”

48” 28”

* May vary by material, operating environment, run mass, electrical frequency, etc. Note: All specifications are approximate and subject to change without notice.

** Express Run enabled for 17-4 PH parts where brown (washed and dried) mass totals 250 grams or less

REV 2.7 - 2022/07/20 markforged.com F-SR-0002

You might also like

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PFrom EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNo ratings yet

- Metal X - Sinter 1Document3 pagesMetal X - Sinter 1larasNo ratings yet

- Metal System Datasheets PDFDocument4 pagesMetal System Datasheets PDFEduardo Mateo ArdilNo ratings yet

- Tetra AntennaDocument2 pagesTetra AntennaMadhusudanan78No ratings yet

- 12MB650 8ΩDocument2 pages12MB650 8ΩDiego PauloNo ratings yet

- Ficha Tecnica Multisplit X PowerDocument8 pagesFicha Tecnica Multisplit X PowerPreinscripciones ZIN3No ratings yet

- Extended LF Ferrite Transducer Extended LF Ferrite TransducerDocument2 pagesExtended LF Ferrite Transducer Extended LF Ferrite TransducerPasseii DiretoNo ratings yet

- Extended Low Frequency Transducer Key FeaturesDocument2 pagesExtended Low Frequency Transducer Key FeaturesOmarNo ratings yet

- 18LW2400 8Ω PDFDocument3 pages18LW2400 8Ω PDFGustavo MuñozNo ratings yet

- Keyfeatures: Model Code InfoDocument2 pagesKeyfeatures: Model Code InfoDiego Eduardo Flores JimenezNo ratings yet

- SikaWrap PS 103C PdsDocument4 pagesSikaWrap PS 103C PdsPedro OscarNo ratings yet

- Service Manual: Argentine ModelDocument39 pagesService Manual: Argentine ModelDiego BandeiraNo ratings yet

- Alarko Ahu SelectionDocument9 pagesAlarko Ahu SelectionYonael TesfayeNo ratings yet

- X-Ray Baggage Scanner Dual View W100H100 PopDocument1 pageX-Ray Baggage Scanner Dual View W100H100 PopoklanNo ratings yet

- Key Features:: Maximum Output 460 MM SVG TransducerDocument2 pagesKey Features:: Maximum Output 460 MM SVG Transduceradalberto teranNo ratings yet

- Technical Data Scaba Frielas PDFDocument1 pageTechnical Data Scaba Frielas PDFNicole FelicianoNo ratings yet

- Technische Manual DUCT SL2 53MDocument68 pagesTechnische Manual DUCT SL2 53MhakoNo ratings yet

- 18 LW 1400Document2 pages18 LW 1400Andrei ZamfirNo ratings yet

- Ficha Tecnica - Empalmadora de Mano EX39 - KomshineDocument7 pagesFicha Tecnica - Empalmadora de Mano EX39 - KomshineluisfernandortNo ratings yet

- The Use and Misuse of CentrifugesDocument2 pagesThe Use and Misuse of CentrifugesChandrasekar Srinivas MohanNo ratings yet

- Car 1811 Milti Brochure JGPDocument8 pagesCar 1811 Milti Brochure JGPSBiomédicas Peruanas SrlNo ratings yet

- HB-4600031013-04-03-HD-001 (Bomba de Agua de SelloDocument2 pagesHB-4600031013-04-03-HD-001 (Bomba de Agua de SelloOscar GuerraNo ratings yet

- Model 7012 HP SpecificationsDocument2 pagesModel 7012 HP SpecificationsMuhammad FaizalNo ratings yet

- Arlon 38NDocument4 pagesArlon 38NRavindrakumar ParvathiniNo ratings yet

- LF Drivers - 18.0 Inches: Eighteen Sound SRLDocument2 pagesLF Drivers - 18.0 Inches: Eighteen Sound SRLKevin MaduranNo ratings yet

- X1 MaterialData 420SS 062519Document2 pagesX1 MaterialData 420SS 062519Nicola MerzagoraNo ratings yet

- 8270 - T44pdfDocument4 pages8270 - T44pdfriscorenan22No ratings yet

- CDP Mini Split Quick ReferenceDocument7 pagesCDP Mini Split Quick ReferenceMiguel GomezNo ratings yet

- DDE 4742 Data Sheet Dg-EnGDocument2 pagesDDE 4742 Data Sheet Dg-EnGMuhammad ArifNo ratings yet

- 4220 09 445 TXX - en GBDocument1 page4220 09 445 TXX - en GBBao Quoc MaiNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1AV2132B Simotics GP - 132 M - Im B3 - 4PDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1AV2132B Simotics GP - 132 M - Im B3 - 4PSedlynNo ratings yet

- Optronics AFL HS Fiber Solution SpesificationDocument16 pagesOptronics AFL HS Fiber Solution SpesificationblegedesNo ratings yet

- MTS101# 2GD-21Document2 pagesMTS101# 2GD-21NataliaNo ratings yet

- Microdyn Bio Cel L 2Document2 pagesMicrodyn Bio Cel L 2antegeia2222No ratings yet

- 4220 06 445 TXX - en GBDocument1 page4220 06 445 TXX - en GBBao Quoc MaiNo ratings yet

- Plugin 739129Document2 pagesPlugin 739129Sohaib AbidNo ratings yet

- C200 HPNG - 331043A - LowresDocument2 pagesC200 HPNG - 331043A - LowresOmar SelamiNo ratings yet

- 0.8mm THK Pennar Metal Deck PropertiesDocument4 pages0.8mm THK Pennar Metal Deck PropertiesSathwik kattaNo ratings yet

- Data Sheet ITE 3P2D Version1 0 EDocument2 pagesData Sheet ITE 3P2D Version1 0 EGeorgeNo ratings yet

- G2whe-21 SuperwaveDocument2 pagesG2whe-21 SuperwaveИван КадигробNo ratings yet

- Created by Jesus, Guardiola Date of Configuration: 26th September, 2019Document12 pagesCreated by Jesus, Guardiola Date of Configuration: 26th September, 2019Rob CasterNo ratings yet

- HERTZ TechSheet DST30.3B Rev17ADocument1 pageHERTZ TechSheet DST30.3B Rev17ARenato de CastroNo ratings yet

- Bose Designmax DM3CDocument4 pagesBose Designmax DM3CAmit KidechaNo ratings yet

- Bose Designmax DM3CDocument4 pagesBose Designmax DM3CAmit KidechaNo ratings yet

- Model: Doosan Infracore Co., LTDDocument9 pagesModel: Doosan Infracore Co., LTDAndrea T FilottoNo ratings yet

- AirHarmony-4000 Data Sheet-V3.9Document7 pagesAirHarmony-4000 Data Sheet-V3.9Rimson JunioNo ratings yet

- AWD-100-500-Datasheet Antenna ExpertDocument1 pageAWD-100-500-Datasheet Antenna Expertson nguyenNo ratings yet

- Ds311 Specification Sheet EnglishDocument4 pagesDs311 Specification Sheet EnglishYonatan Tarazona HilarioNo ratings yet

- Prose Mb-G64o9x65v-00Document3 pagesProse Mb-G64o9x65v-00hasib_muhammedNo ratings yet

- 1MB1553-1AA42-3AA4-Z B02+H19 Datasheet enDocument2 pages1MB1553-1AA42-3AA4-Z B02+H19 Datasheet enranjithNo ratings yet

- UnionTech RSPro 1400 TDS Flyer EN 201803 v5 FinalDocument2 pagesUnionTech RSPro 1400 TDS Flyer EN 201803 v5 FinalrahulNo ratings yet

- UHP-M 1.2m Single Polarization Class3 Antenna Datasheet (AXXS12MAC-3NX)Document3 pagesUHP-M 1.2m Single Polarization Class3 Antenna Datasheet (AXXS12MAC-3NX)JesusAlainMedinaApaico100% (2)

- Prose 6w22me-01 - 1.0Document3 pagesProse 6w22me-01 - 1.0dwiki.marchiano86No ratings yet

- Ds311 Specification Sheet EnglishDocument4 pagesDs311 Specification Sheet EnglishAntonio BocanegraNo ratings yet

- 3 DBD HD Omni Antenna 420-470Mhz, Low Pim: DescriptionDocument1 page3 DBD HD Omni Antenna 420-470Mhz, Low Pim: DescriptionBao Quoc MaiNo ratings yet

- SPESIFIKASI TEKNIS SMKN 2 WONOSARI PENGELASAN REVISI GMBRDocument3 pagesSPESIFIKASI TEKNIS SMKN 2 WONOSARI PENGELASAN REVISI GMBRYusuf ArdiansyahNo ratings yet

- 18LW1400 8ΩDocument3 pages18LW1400 8ΩAgus Dari JombangNo ratings yet

- Primeline Antenna, Ultra High Performance, High Cross Polar Discrimination, Dual Polarized, 8 FTDocument2 pagesPrimeline Antenna, Ultra High Performance, High Cross Polar Discrimination, Dual Polarized, 8 FTDocument OrizaNo ratings yet

- Da8 44ac4Document3 pagesDa8 44ac4Masood AhmedNo ratings yet

- Key Features: G40 SeriesDocument2 pagesKey Features: G40 SeriesJIMNo ratings yet

- The Masterbuilder - July 2013 - Concrete SpecialDocument286 pagesThe Masterbuilder - July 2013 - Concrete SpecialChaitanya Raj GoyalNo ratings yet

- LRB PS Inr18650b4 Rev7Document10 pagesLRB PS Inr18650b4 Rev7jeznerNo ratings yet

- NSR M2031 - PH24-NSR-B2A - Survey - AIRDOC - Smart LTE 2024Document18 pagesNSR M2031 - PH24-NSR-B2A - Survey - AIRDOC - Smart LTE 2024threesome.efryllapinaNo ratings yet

- 7.5L EngineDocument32 pages7.5L EngineSalvador Gasca100% (1)

- Research Project ReportDocument21 pagesResearch Project ReportinternationalbankNo ratings yet

- Chapter 3 Dec 50143Document29 pagesChapter 3 Dec 50143Kohilan VenugopalNo ratings yet

- PDocument7 pagesPCamushakaNo ratings yet

- Practice Final Exam For CH 1-10 IT Essentials PC Hardware and Software Version 4.1Document10 pagesPractice Final Exam For CH 1-10 IT Essentials PC Hardware and Software Version 4.1Raine Bao75% (4)

- Retail Analysis With Walmart DataDocument2 pagesRetail Analysis With Walmart DataSriram100% (9)

- Recruitment (Robotic) Process Automation (RPA)Document6 pagesRecruitment (Robotic) Process Automation (RPA)Anuja BhakuniNo ratings yet

- Pile Length CalculationDocument3 pagesPile Length CalculationCivilax.comNo ratings yet

- Introduction To ERPDocument3 pagesIntroduction To ERPmaheshNo ratings yet

- Guide For System Center Hyper-V Management Pack For Windows Server 2012 R2Document9 pagesGuide For System Center Hyper-V Management Pack For Windows Server 2012 R2George RaduNo ratings yet

- 4 Bit Manchester AdderDocument14 pages4 Bit Manchester AdderHacking_Deface0% (2)

- MATLABDocument208 pagesMATLABJhonattan Pardo100% (1)

- Diamec U6 Spare PartDocument3 pagesDiamec U6 Spare PartJairo Boechat JuniorNo ratings yet

- Cooling Load Calculation Sheet: X X X X X X X X X X X X X X X X Cfm/Person Cfm/DoorDocument6 pagesCooling Load Calculation Sheet: X X X X X X X X X X X X X X X X Cfm/Person Cfm/Doorashfaq-matte-799375% (4)

- Solved Problems: Problem (7.1)Document13 pagesSolved Problems: Problem (7.1)Rafi SulaimanNo ratings yet

- Iroquois Clothes and WampumDocument3 pagesIroquois Clothes and Wampumapi-254323856No ratings yet

- Sustainable Development TriangleDocument5 pagesSustainable Development TriangleWhilteNo ratings yet

- UntitledDocument92 pagesUntitledgirishwalkeNo ratings yet

- Low Power CMOS VLSI Design: Aditya Japa Assistant Professor (ECE) KL Hyderabad 12/07/2021Document14 pagesLow Power CMOS VLSI Design: Aditya Japa Assistant Professor (ECE) KL Hyderabad 12/07/2021karthikNo ratings yet

- CNC Macine Dimesions-ModelDocument1 pageCNC Macine Dimesions-ModelNaveen PrabhuNo ratings yet

- How To Broadcast BEx Workbooks Using BW Pre-Calc Server and Through Process ChainsDocument25 pagesHow To Broadcast BEx Workbooks Using BW Pre-Calc Server and Through Process ChainskomlevsNo ratings yet

- 40 Must Know Web 2.0 EdutoolsDocument521 pages40 Must Know Web 2.0 EdutoolsDaniela BozganNo ratings yet

- Potential Businesses in Batangas CityDocument24 pagesPotential Businesses in Batangas CityMichael DimayugaNo ratings yet

- Gamma-J Usb Web Store SrsDocument44 pagesGamma-J Usb Web Store Srsaditya181987No ratings yet

- Lecture 03Document42 pagesLecture 03Laís Medeiros100% (1)

- THURBONDocument2 pagesTHURBONNick NumlkNo ratings yet

- Arduino DisassemblyDocument2 pagesArduino DisassemblyJose100% (1)