Professional Documents

Culture Documents

Ae 370 T

Uploaded by

avikOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ae 370 T

Uploaded by

avikCopyright:

Available Formats

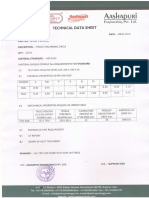

DATA SHEET 2000-06-06

370T

(ARMOX 370S C 9640X0052, MIL-A-12560, ARMOX 816 MVEE 816, ARMOX 370 TL 2350-0000)

CHEMICAL C Si Mn P S Cr Ni Mo B

COMPOSITION max max max max max max max max

(ladle analysis) % % % % % % % % %

0,32 0,1 0,4 1,2 0,015 0,010 1,01) 1,81) 0,7 0,005

The steel is grain-refined.

1)

For plate thicknesses >100 mm Cr £ 1,5 and Ni £ 3,5

MECHANICAL Plate thickn. Hardness Charpy-V 40°C1) Yield strength Tensile strength Elongation

PROPERTIES mm HBW 10x10 test specimen2) Rp0,2 N/mm2 Rm N/mm2 A5% A50%

Class 1 3 < 20 380430 Min. 20 Joule Min. 1000 11501350 Min. 10 Min. 12

20 < 40 340390 Min. 25 Joule Min. 900 10501250 Min. 11 Min. 13

40 80 300350 Min. 30 Joule Min. 850 9501150 Min. 12 Min. 14

Class 2 3 150 280330 Min. 40 Joule Min. 800 9001100 Min. 13 Min. 15

1)

Average of three tests. Transverse to rolling direction.

Single value min 70% of specified average.

2)

For plate thicknesses under 12 mm subsize Charpy V-specimens are used. The specified

minimum value is then proportional to the specimens cross-section.

TESTING Brinell hardness test EN ISO 6506-1 Each heat treatment individual

Charpy impact test EN 10 045-1 Each heat and thickness >4 mm

Tensile testing EN 10 002-1 Each heat and thickness <60 mm

Ultrasonic testing SEL 072/077 CI. 3 Each plate in thickness 60150 mm

DELIVERY CONDITION Quenched and tempered.

DIMENSIONS ARMOX 370T is supplied in plate thicknesses 3150 mm. More detailed information on dimensions is

provided in our General Information brochure.

TOLERANCES Dimensional tolerances according to EN 10 029 excluding thickness tolerances

Thickness tolerances:

Plate thickness Standard By special agreement

in mm Tolerances in mm Tolerances in mm

< 13 0,0 + 0,8 -0,2 +0,6 or +/ 0,4

13 < 20 + 1,0 -0,2 +0,8 or 0,5

20 < 40 + 1,2 -0,2 +1,0 or 0,6

40 < 60 + 1,6 -0,3 +1,3 or 0,8

60 < 80 + 2,0 -0,3 +1,7 or 1,0

80 < 110 + 2,4 -0,4 +2,0 or 1,2

110 150 + 3,0 -0,5 +2,5 or 1,5

E-194, SSAB Oxelösund AB, ARMOX is trademark for armour plate manufactured by SSAB Oxelösund AB

Other thickness tolerances by special agreement.

Dimensional tolerances for plate with mill edge according to special agreement.

Flatness tolerances according to class N or according to special agreement.

SURFACE CONDITION According to EN 10 163-2 Class B Subclass 3.

GENERAL TECHNICAL According to EN 10 021 and EN 10 204. Unless otherwise agreed, inspection documents

DELIVERY CONDITION are issued in English with certificates of 3.1B type.

HEAT TREATMENT ARMOX 370T may not be heated above the temperature listed below if guaranteed hardness

is to be maintained.

Thicknesses range Max heating temperature

Class 1 3 < 20 mm 400°C

20 < 40 mm 500°C

40 80 mm 550°C

Class 2 3 150 mm 600°C

For further information on machining, cutting and welding, please see special

brochure or contact us.

Appropriate health and saftey precautions must be taken when welding, cutting, grinding or otherwise

working on the product. Grinding, especially of primer coated plates, may produce dust with high particle

concentration. Our Technical Customer Service Department will provide further information on request.

SSAB Oxelösund AB Phone. Fax Telex

S-613 80 Oxelösund +46 155-25 40 00 +46 155-25 40 73 50950 SSAB S

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Data SheetDocument1 pageData SheetavikNo ratings yet

- Data Sheet: Chemical CompositionDocument1 pageData Sheet: Chemical CompositionavikNo ratings yet

- Strenx 700MC Plus: General Product DescriptionDocument1 pageStrenx 700MC Plus: General Product DescriptionMircea FloreaNo ratings yet

- Domex 355 MC: High Strength Cold Forming SteelDocument2 pagesDomex 355 MC: High Strength Cold Forming SteelKhantoNo ratings yet

- STK 400Document5 pagesSTK 400Nizar NazriNo ratings yet

- 107 - WELDOX - 700 - UK - Data SheetDocument2 pages107 - WELDOX - 700 - UK - Data SheetLuis AguilarNo ratings yet

- 9SMNPB28K-14.00 Hex Tc.Document1 page9SMNPB28K-14.00 Hex Tc.Mechtek LabNo ratings yet

- TDC 09 - R1 - S690 QL & Weldox 700Document2 pagesTDC 09 - R1 - S690 QL & Weldox 700Thennarasu VelloreNo ratings yet

- Plinth Area Estmate For Laboratory, Test Range ,& ListDocument20 pagesPlinth Area Estmate For Laboratory, Test Range ,& ListShailendraNo ratings yet

- Stainless Steel 1.4571Document4 pagesStainless Steel 1.4571ANKUSH PARMARNo ratings yet

- Data Sheet: Applications Designation Chemical CompositionDocument2 pagesData Sheet: Applications Designation Chemical CompositionManankNo ratings yet

- 1 4571 PDFDocument7 pages1 4571 PDFSiis IngenieriaNo ratings yet

- Data Sheet 2008 Strenx#174 700MC D E 2017-04-20 PDFDocument2 pagesData Sheet 2008 Strenx#174 700MC D E 2017-04-20 PDFangelokyoNo ratings yet

- Aaepl: TDC No. AAEPL/RM/lDocument2 pagesAaepl: TDC No. AAEPL/RM/lSandip PandeNo ratings yet

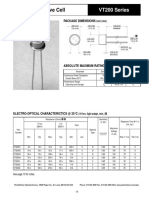

- Photoconductive Cell: VT900 SeriesDocument1 pagePhotoconductive Cell: VT900 Seriesyunkino polertivNo ratings yet

- Engineering DetailDocument30 pagesEngineering DetailSatyaprakash PrakashNo ratings yet

- I Grade I: No.: Date - No. NoDocument1 pageI Grade I: No.: Date - No. NoMechtek LabNo ratings yet

- Leichtmetall Data Sheet EN AW 6082T6Document1 pageLeichtmetall Data Sheet EN AW 6082T6Satendra ThakurNo ratings yet

- Technical Data - Epoxy Dotted PaperDocument1 pageTechnical Data - Epoxy Dotted PaperMly Saad BoudiafNo ratings yet

- Data Sheet 2008 Strenx 700 MC 20170420 254 371857150 enDocument2 pagesData Sheet 2008 Strenx 700 MC 20170420 254 371857150 enmarkoNo ratings yet

- Stainless Steel 1.4401 316Document3 pagesStainless Steel 1.4401 316Luis LoayzaNo ratings yet

- Data Sheet Raex 450Document3 pagesData Sheet Raex 450Amit GauravNo ratings yet

- SSAB Domex 420MC: General Product DescriptionDocument2 pagesSSAB Domex 420MC: General Product DescriptionpeterNo ratings yet

- Strenx 700MC D e 2017-04-20Document2 pagesStrenx 700MC D e 2017-04-20Amandeep SinghNo ratings yet

- NIC Components NACC SeriesDocument3 pagesNIC Components NACC SeriesNICCompNo ratings yet

- Material Data Sheet: DescriptionDocument7 pagesMaterial Data Sheet: DescriptionCharles SedilloNo ratings yet

- Ew 700Document2 pagesEw 700Stefano BarbieriNo ratings yet

- Product Specifications: Specifications For Continuous Cast ProductsDocument4 pagesProduct Specifications: Specifications For Continuous Cast ProductsvejanidbNo ratings yet

- Material Data Sheet: Description, ApplicationDocument5 pagesMaterial Data Sheet: Description, ApplicationCharles SedilloNo ratings yet

- JIS G3131 Hot JIS G3131 Hot - Rolled Steel Rolled Steel: Remark: All Values Are Only For ReferenceDocument1 pageJIS G3131 Hot JIS G3131 Hot - Rolled Steel Rolled Steel: Remark: All Values Are Only For ReferenceKenvi AlarconNo ratings yet

- T, RTFF ": Technical DataDocument1 pageT, RTFF ": Technical DataNirmit GandhiNo ratings yet

- SA/AS1548 - 7 - 460R: XlerplateDocument3 pagesSA/AS1548 - 7 - 460R: XlerplatenavNo ratings yet

- MT Series: SpecificationsDocument2 pagesMT Series: SpecificationsEnrique Sanchez (KicKeWoW)No ratings yet

- S355 420 460 Toughcore Voestalpine EN 020720Document4 pagesS355 420 460 Toughcore Voestalpine EN 020720Joost de HaanNo ratings yet

- Photoconductive Cell: VT200 SeriesDocument1 pagePhotoconductive Cell: VT200 SeriesMohamed El GlafiNo ratings yet

- 02 Track 2 - Wu 0 A Comprehensive Characterization of NEXMET 1000 Formability-2019 - FinalDocument21 pages02 Track 2 - Wu 0 A Comprehensive Characterization of NEXMET 1000 Formability-2019 - FinalSilverio AcuñaNo ratings yet

- CRCA (Cold Rolled Close Annealed Coils) Specifications: As Per IsDocument2 pagesCRCA (Cold Rolled Close Annealed Coils) Specifications: As Per Isray_k_9177100% (9)

- SRF1306 1391564Document4 pagesSRF1306 1391564Nelson Pimiento SerranoNo ratings yet

- Data Sheet Strenx 650 MCDocument3 pagesData Sheet Strenx 650 MCRoger BandeiraNo ratings yet

- CuETP PDFDocument2 pagesCuETP PDFlovelyshreeNo ratings yet

- DB Alform M-Series E 14112012Document3 pagesDB Alform M-Series E 14112012Puđa TomicaNo ratings yet

- ASTM A333 GR.6 Seamless Low Temperature Pipes PDFDocument7 pagesASTM A333 GR.6 Seamless Low Temperature Pipes PDFraditya putraNo ratings yet

- 1.4435 - C Stainless Steel DetailsDocument3 pages1.4435 - C Stainless Steel DetailsmeenakshiNo ratings yet

- 304 - X5CrNi18 10 Nr.1.4301 ENG PDFDocument2 pages304 - X5CrNi18 10 Nr.1.4301 ENG PDFGaurav AggarwalNo ratings yet

- Material Data Sheet: Eos Maragingsteel Ms1Document5 pagesMaterial Data Sheet: Eos Maragingsteel Ms1cute7707No ratings yet

- Stainless Steel 1.4404 316lDocument3 pagesStainless Steel 1.4404 316lDilipSinghNo ratings yet

- Stainless Steel 1.4404 316lDocument3 pagesStainless Steel 1.4404 316lDilipSinghNo ratings yet

- Eos Stainless Steel 316 LDocument5 pagesEos Stainless Steel 316 LsameeraNo ratings yet

- Certificate of ConformanceDocument1 pageCertificate of ConformanceedwinNo ratings yet

- Geomembrane HDPE Smooth Black PDFDocument1 pageGeomembrane HDPE Smooth Black PDFandriarisetiawan0% (1)

- SPR 700 Resist GuideDocument4 pagesSPR 700 Resist GuideWill LivernoisNo ratings yet

- Armox 370T Class 1: General Product DescriptionDocument2 pagesArmox 370T Class 1: General Product DescriptionSuneelNo ratings yet

- Data PDA & Kalendering ABT 1Document16 pagesData PDA & Kalendering ABT 1fatmaNo ratings yet

- 46 Capwap Jemb Kebun Durian Tahap 1Document14 pages46 Capwap Jemb Kebun Durian Tahap 1fatmaNo ratings yet

- NiAll-IN625-M270 Material Data Sheet 10-11 en PDFDocument5 pagesNiAll-IN625-M270 Material Data Sheet 10-11 en PDFqualityfreekNo ratings yet

- Manufacturing Tolerances For Moulded & Extruded RubberDocument1 pageManufacturing Tolerances For Moulded & Extruded RubberStephenNo ratings yet

- Extracts of ASTM A 106Document4 pagesExtracts of ASTM A 106RAGHVENDRA PRATAP SINGHNo ratings yet

- Photoconductive Cell: VT300 SeriesDocument1 pagePhotoconductive Cell: VT300 SeriesMohamed El GlafiNo ratings yet

- Steel X20Cr13: EN 10250-4:1999, Number: 1.4021Document4 pagesSteel X20Cr13: EN 10250-4:1999, Number: 1.4021AdamNo ratings yet

- E VR E: Sample PaperDocument4 pagesE VR E: Sample PaperavikNo ratings yet

- PR VESSEL FABRICATION - Awareness Session - 16.11.19Document50 pagesPR VESSEL FABRICATION - Awareness Session - 16.11.19avik100% (1)

- When You Go in Search of Honey, You Must Expect To Be Stung by Bees. Joseph JoubertDocument24 pagesWhen You Go in Search of Honey, You Must Expect To Be Stung by Bees. Joseph JoubertavikNo ratings yet

- Gas Cutting - JKPDocument19 pagesGas Cutting - JKPavikNo ratings yet

- E450HIDocument2 pagesE450HIavikNo ratings yet

- Is - 412Document12 pagesIs - 412raje_58No ratings yet

- WP DeltaV Software Update Deployment PDFDocument8 pagesWP DeltaV Software Update Deployment PDFevbaruNo ratings yet

- Copy of HW UMTS KPIsDocument18 pagesCopy of HW UMTS KPIsMohamed MoujtabaNo ratings yet

- Northbrook CollegeDocument10 pagesNorthbrook CollegeDaniyal AsifNo ratings yet

- Radial Lead Varistors LA Varistor SeriesDocument13 pagesRadial Lead Varistors LA Varistor SeriesLeman SihotangNo ratings yet

- Amino AcidsDocument17 pagesAmino AcidsSiddharth Rohilla100% (2)

- JAR Part 66 Examination Mod 03Document126 pagesJAR Part 66 Examination Mod 03Shreyas PingeNo ratings yet

- Ahsan Menu KolachiDocument12 pagesAhsan Menu Kolachisalman GtrNo ratings yet

- 3M Window Film PR SeriesDocument3 pages3M Window Film PR SeriesPhan CrisNo ratings yet

- Mock Test MCQ 2017Document18 pagesMock Test MCQ 2017Alisha ChopraNo ratings yet

- Government of Tamilnadu Directorate of Legal Studies: Inter-Collegeiate State Level Moot Court Competition-2022Document30 pagesGovernment of Tamilnadu Directorate of Legal Studies: Inter-Collegeiate State Level Moot Court Competition-2022Divya SrinimmiNo ratings yet

- Paes 406Document12 pagesPaes 406Denver LangahinNo ratings yet

- DocumentDocument6 pagesDocumentGlennford Loreto SuyatNo ratings yet

- JOHARI Window WorksheetDocument2 pagesJOHARI Window WorksheetAnonymous j9lsM2RBaINo ratings yet

- Continuous Microbiological Environmental Monitoring For Process Understanding and Reduced Interventions in Aseptic ManufacturingDocument44 pagesContinuous Microbiological Environmental Monitoring For Process Understanding and Reduced Interventions in Aseptic ManufacturingTorres Xia100% (1)

- Module 6 - Addictions Prayer ServiceDocument6 pagesModule 6 - Addictions Prayer Serviceapi-450520432No ratings yet

- TextDocument3 pagesTextKristineNo ratings yet

- Open Courses Myanmar Strategic English Week 4: U Yan Naing Se NyuntDocument24 pagesOpen Courses Myanmar Strategic English Week 4: U Yan Naing Se NyuntYan Naing Soe NyuntNo ratings yet

- MediclaimDocument3 pagesMediclaimPrajwal ShettyNo ratings yet

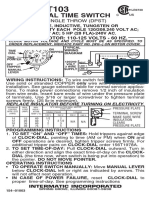

- T103 InstructionsDocument1 pageT103 Instructionsjtcool74No ratings yet

- Pentacon Six-02Document28 pagesPentacon Six-02Melissa Moreira TYNo ratings yet

- Safety at Hand PDFDocument48 pagesSafety at Hand PDFAdesijiBlessingNo ratings yet

- Project Report On MKT Segmentation of Lux SoapDocument25 pagesProject Report On MKT Segmentation of Lux Soapsonu sahNo ratings yet

- Tda12110h1 N300Document1 pageTda12110h1 N300rolandseNo ratings yet

- Tarot Cards: Cheat SheetDocument1 pageTarot Cards: Cheat SheetDipti100% (7)

- 20BCEC1109, 20BCE1170, 20BCE1233 - IOT Final ReportDocument40 pages20BCEC1109, 20BCE1170, 20BCE1233 - IOT Final Reportharsh chauhanNo ratings yet

- 168 Visual Perceptual SkillsDocument3 pages168 Visual Perceptual Skillskonna4539No ratings yet

- Digital Habits Across Generations: Before ReadingDocument3 pagesDigital Habits Across Generations: Before ReadingSharina RamallahNo ratings yet

- Sulzer Centrifugal Pumps - Basic OperationDocument26 pagesSulzer Centrifugal Pumps - Basic OperationMarcelo PerettiNo ratings yet

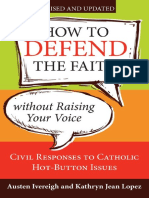

- How To Defend The Faith Without Raising Your VoiceDocument139 pagesHow To Defend The Faith Without Raising Your VoiceCleber De Souza Cunha100% (2)

- 13 Methods To Increase Your Conditioning - Strength by SkylerDocument5 pages13 Methods To Increase Your Conditioning - Strength by SkylerMarko Štambuk100% (1)