Professional Documents

Culture Documents

Data Sheet: Chemical Composition

Uploaded by

avikOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Data Sheet: Chemical Composition

Uploaded by

avikCopyright:

Available Formats

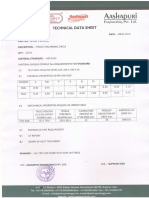

DATA SHEET 2000-06-06

560T

™

(ARMOX 560S)

CHEMICAL C Si Mn P S Cr Ni Mo B

COMPOSITION max max max max max max max max

(ladle analysis) % % % % % % % % %

0,371) 0,1 – 0,7 1,2 0,012 0,005 1,01) 1,81) 0,7 0,005

The steel is grain-refined.

1)

For plate thicknesses > 30 mm C < 0,46, Cr < 1,5 and Ni < 2,8

MECHANICAL Hardness Charpy-V –40°C1) Yield strength Tensile strength Elongation

PROPERTIES HBW 10x10 test specimen2) Rp0,2 N/mm2 Rm N/mm2 A5% A50%

530–590 Min. 15 Joule Min. 1300 1600–1900 Min. 7 Min. 9

1)

Average of three tests. Transverse to rolling direction.

Single value min 70% of specified average.

2)

For plate thicknesses under 12 mm subsize Charpy V-specimens are used. The specified

minimum value is then proportional to the specimens cross-section.

TESTING Brinell hardness test EN ISO 6506-1 Each heat treatment individual

Charpy impact test EN 10 045-1 Each heat and thickness

Tensile testing EN 10 002-1 Each heat and thickness (thickness <20 mm)

Ultrasonic testing SEL 072/077 CL. 3 Each plate in thickness 60–100 mm

DELIVERY CONDITION Quenched and tempered.

DIMENSIONS ARMOX 560T is supplied in plate thicknesses 5–100 mm. Plate thicknesses > 25 mm are supplied with

mill edge or by special agreement only. More detailed information on dimensions is provided in our Gene-

ral Information brochure.

TOLERANCES Dimensional tolerances according to EN 10 029 excluding thickness tolerances

– Thickness tolerances:

Plate thickness Standard By special agreement

in mm Tolerances in mm Tolerances in mm

< 13 -0,0 + 0,6 –0,2 +0,4

13 < 20 + 0,8 –0,2 +0,6

20 < 40 + 1,0 –0,2 +0,8

40 < 60 + 1,4 –0,3 +1,1

60 < 80 + 1,6 –0,3 +1,3

80 - 100 + 2,0 –0,4 +1,6

E-196, SSAB Oxelösund AB, ARMOX is trademark for armour plate manufactured by SSAB Oxelösund AB

Other thickness tolerances by special agreement.

Dimensional tolerances for plate with mill edge according to special agreement.

Flatness tolerances according to class N or according to special agreement.

SURFACE CONDITION According to EN 10 163-2 Class B Subclass 3.

GENERAL TECHNICAL According to EN 10 021 and EN 10 204. Unless otherwise agreed, inspection documents

DELIVERY CONDITION are issued in English with certificates of 3.1B type.

HEAT TREATMENT ARMOX 560T may not be heated above 200°C (400°F) if guaranteed hardness is to be maintained.

AND FABRICATION For further information on machining, bending, cutting and welding, please see special

brochure or contact us.

Appropriate health and saftey precautions must be taken when welding, cutting, grinding or otherwise

working on the product. Grinding, especially of primer coated plates, may produce dust with high

particle concentration. Our Technical Customer Service Department will provide further information on

request.

SSAB Oxelösund AB Phone. Fax Telex

S-613 80 Oxelösund +46 155-25 40 00 +46 155-25 40 73 50950 SSAB S

You might also like

- Data SheetDocument1 pageData SheetavikNo ratings yet

- Ae 370 TDocument1 pageAe 370 TavikNo ratings yet

- Data SheetDocument1 pageData SheetavikNo ratings yet

- Strenx 700MC Plus: General Product DescriptionDocument1 pageStrenx 700MC Plus: General Product DescriptionMircea FloreaNo ratings yet

- Data Sheet 2008 Strenx#174 700MC D E 2017-04-20 PDFDocument2 pagesData Sheet 2008 Strenx#174 700MC D E 2017-04-20 PDFangelokyoNo ratings yet

- Strenx 700MC D e 2017-04-20Document2 pagesStrenx 700MC D e 2017-04-20Amandeep SinghNo ratings yet

- TDC 09 - R1 - S690 QL & Weldox 700Document2 pagesTDC 09 - R1 - S690 QL & Weldox 700Thennarasu VelloreNo ratings yet

- Domex 355 MC: High Strength Cold Forming SteelDocument2 pagesDomex 355 MC: High Strength Cold Forming SteelKhantoNo ratings yet

- Data Sheet Strenx 700 MCDocument3 pagesData Sheet Strenx 700 MCRoger BandeiraNo ratings yet

- Data Sheet 2008 Strenx 700 MC 20170420 254 371857150 enDocument2 pagesData Sheet 2008 Strenx 700 MC 20170420 254 371857150 enmarkoNo ratings yet

- Strenx 960: General Product DescriptionDocument2 pagesStrenx 960: General Product DescriptionJean Paulo SalvatiNo ratings yet

- SSAB Domex 420MC: General Product DescriptionDocument2 pagesSSAB Domex 420MC: General Product DescriptionpeterNo ratings yet

- Data Sheet Strenx 650 MCDocument3 pagesData Sheet Strenx 650 MCRoger BandeiraNo ratings yet

- Rs Pro p40 WW PotmetersDocument1 pageRs Pro p40 WW PotmetersMartien BakkerNo ratings yet

- Ficha Técnica - XABO 500 - ThyssenkruppDocument3 pagesFicha Técnica - XABO 500 - ThyssenkruppDiego Ramírez ParraNo ratings yet

- Data Sheet 2006 Strenx 700 20170420 121 371857150 enDocument2 pagesData Sheet 2006 Strenx 700 20170420 121 371857150 enRodrigoNo ratings yet

- CRCA (Cold Rolled Close Annealed Coils) Specifications: As Per IsDocument2 pagesCRCA (Cold Rolled Close Annealed Coils) Specifications: As Per Isray_k_9177100% (9)

- Ew 700Document2 pagesEw 700Stefano BarbieriNo ratings yet

- Steel: Nisco Wear Plate NM400Document2 pagesSteel: Nisco Wear Plate NM400Paolo Sebastián Bernal GómezNo ratings yet

- Data Sheet 1996-06-01: Applications DesignationDocument2 pagesData Sheet 1996-06-01: Applications DesignationEnoc AndradeNo ratings yet

- Datasheet Strenx 700E - en - 2016Document3 pagesDatasheet Strenx 700E - en - 2016peterNo ratings yet

- Table1. The Deposition Parameters of The As Prepared FilmsDocument3 pagesTable1. The Deposition Parameters of The As Prepared FilmsNader HemayaNo ratings yet

- SWG 30 WDocument1 pageSWG 30 WRajesh RoyNo ratings yet

- 1 4571 PDFDocument7 pages1 4571 PDFSiis IngenieriaNo ratings yet

- Data Sheet 2007en Strenx® 700 CR 2021-05-04Document2 pagesData Sheet 2007en Strenx® 700 CR 2021-05-04Idan FriedbergNo ratings yet

- Material Data Sheet: DescriptionDocument7 pagesMaterial Data Sheet: DescriptionCharles SedilloNo ratings yet

- Stainless Steel 1.4401 316Document3 pagesStainless Steel 1.4401 316Luis LoayzaNo ratings yet

- 107 - WELDOX - 700 - UK - Data SheetDocument2 pages107 - WELDOX - 700 - UK - Data SheetLuis AguilarNo ratings yet

- 168 Hardox 450 Uk Data SheetDocument2 pages168 Hardox 450 Uk Data SheetBambang WibisonoNo ratings yet

- Electro Slag Refining: N.B. BallalDocument34 pagesElectro Slag Refining: N.B. Ballalamit gajbhiyeNo ratings yet

- Steel X20Cr13: EN 10250-4:1999, Number: 1.4021Document4 pagesSteel X20Cr13: EN 10250-4:1999, Number: 1.4021AdamNo ratings yet

- Analysis On Shielding Effectiveness of Board Level Shielding With Apertures - Interference TechnologyDocument2 pagesAnalysis On Shielding Effectiveness of Board Level Shielding With Apertures - Interference Technologydbm010102No ratings yet

- Strenx 700: General Product DescriptionDocument2 pagesStrenx 700: General Product DescriptionpeterNo ratings yet

- S355J2+N Steel PlateDocument2 pagesS355J2+N Steel PlateAmanNo ratings yet

- Material Etg 88/100Document1 pageMaterial Etg 88/100Admir Atko JusićNo ratings yet

- Pipeliner 7P+: Conformances Key FeaturesDocument2 pagesPipeliner 7P+: Conformances Key FeaturesAnand GNo ratings yet

- Abl 16.000MHZ B2 PDFDocument3 pagesAbl 16.000MHZ B2 PDFkarthik4096No ratings yet

- Ultra High Spec Grade - Amorim TD1120Document2 pagesUltra High Spec Grade - Amorim TD1120hendro suprianto nugrohoNo ratings yet

- S275JR PDFDocument1 pageS275JR PDFEmrahCayboylu100% (1)

- Composition % Combination of Properties: The Benefits of Cal Wrought CNCDocument6 pagesComposition % Combination of Properties: The Benefits of Cal Wrought CNCAshesh MokidiNo ratings yet

- Technical Data - Epoxy Dotted PaperDocument1 pageTechnical Data - Epoxy Dotted PaperMly Saad BoudiafNo ratings yet

- IOCL-EKC-STATIONARY CASCADE-DIA 559 X 06 CYLINDER X 3000 LTR-SHEET 1 OF 5-REV.01Document1 pageIOCL-EKC-STATIONARY CASCADE-DIA 559 X 06 CYLINDER X 3000 LTR-SHEET 1 OF 5-REV.01subudhiprasannaNo ratings yet

- Quality Assurance Plan For Is 2062 E250 GR BRDocument2 pagesQuality Assurance Plan For Is 2062 E250 GR BRSUBHOMOYNo ratings yet

- Conarc85 EngDocument2 pagesConarc85 EngRaviTeja Bhamidi100% (1)

- Alexandrite: Structural & Mechanical PropertiesDocument2 pagesAlexandrite: Structural & Mechanical PropertiesalifardsamiraNo ratings yet

- 316lesrvar Ft003-Uk PDFDocument2 pages316lesrvar Ft003-Uk PDFRaj RajeshNo ratings yet

- Galvaspan G550Document2 pagesGalvaspan G550eli abdul rohimNo ratings yet

- Specification For Approval: 1.materialDocument1 pageSpecification For Approval: 1.materialvvvNo ratings yet

- Diodo SS32 A 310Document2 pagesDiodo SS32 A 310Ramíro ChocotecóNo ratings yet

- Photoconductive Cell: VT900 SeriesDocument1 pagePhotoconductive Cell: VT900 Seriesyunkino polertivNo ratings yet

- Domex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelDocument2 pagesDomex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelHugo RodriguezNo ratings yet

- Technical Data SheetDocument1 pageTechnical Data SheetSilversnape00No ratings yet

- S690 RQT701 High Strength Steel - Murray PlateDocument2 pagesS690 RQT701 High Strength Steel - Murray PlateAydın DemiralNo ratings yet

- S690 RQT701 High Strength Steel - Murray PlateDocument2 pagesS690 RQT701 High Strength Steel - Murray PlateAak Gayo100% (1)

- Hardox 400 PlateDocument3 pagesHardox 400 PlateAli TalebiNo ratings yet

- Stratasys - MSS FDM ABSplusP430Document2 pagesStratasys - MSS FDM ABSplusP430feltofsnakeNo ratings yet

- Data Sheet 2007 Strenx 700 CR 2017-04-20 52 371857150 enDocument2 pagesData Sheet 2007 Strenx 700 CR 2017-04-20 52 371857150 enThainã NavarroNo ratings yet

- Data Sheet: Applications Designation Chemical CompositionDocument2 pagesData Sheet: Applications Designation Chemical CompositionManankNo ratings yet

- T, RTFF ": Technical DataDocument1 pageT, RTFF ": Technical DataNirmit GandhiNo ratings yet

- Asugal Albi 4540Document2 pagesAsugal Albi 4540dyetex100% (1)

- Cable Schedule - Instrument - Surfin - Malanpur-R0Document3 pagesCable Schedule - Instrument - Surfin - Malanpur-R0arunpandey1686No ratings yet

- IJISRT23JUL645Document11 pagesIJISRT23JUL645International Journal of Innovative Science and Research TechnologyNo ratings yet

- Parts List 38 254 13 95: Helical-Bevel Gear Unit KA47, KH47, KV47, KT47, KA47B, KH47B, KV47BDocument4 pagesParts List 38 254 13 95: Helical-Bevel Gear Unit KA47, KH47, KV47, KT47, KA47B, KH47B, KV47BEdmundo JavierNo ratings yet

- A Project Diary-Wps OfficeDocument4 pagesA Project Diary-Wps OfficeSameer ShaikhNo ratings yet

- Module 1 Dynamics of Rigid BodiesDocument11 pagesModule 1 Dynamics of Rigid BodiesBilly Joel DasmariñasNo ratings yet

- Disbursement VoucherDocument7 pagesDisbursement VoucherDan MarkNo ratings yet

- Integra Facade BrochureDocument2 pagesIntegra Facade BrochureHarshit PatadiyaNo ratings yet

- File 1038732040Document70 pagesFile 1038732040Karen Joyce Costales MagtanongNo ratings yet

- Sample TRM All Series 2020v1 - ShortseDocument40 pagesSample TRM All Series 2020v1 - ShortseSuhail AhmadNo ratings yet

- Cot Observation ToolDocument14 pagesCot Observation ToolArnoldBaladjayNo ratings yet

- Assembly and RiggingDocument52 pagesAssembly and RiggingPokemon Go0% (1)

- Iot Based Garbage and Street Light Monitoring SystemDocument3 pagesIot Based Garbage and Street Light Monitoring SystemHarini VenkatNo ratings yet

- Pin Joint en PDFDocument1 pagePin Joint en PDFCicNo ratings yet

- Woldia University: A Non Ideal TransformerDocument24 pagesWoldia University: A Non Ideal TransformerKANDEGAMA H.R. (BET18077)No ratings yet

- Bulk Separator - V-1201 Method StatementDocument2 pagesBulk Separator - V-1201 Method StatementRoshin99No ratings yet

- Nptel Online-Iit KanpurDocument1 pageNptel Online-Iit KanpurRihlesh ParlNo ratings yet

- Activity 6 Product Disassembly ChartDocument5 pagesActivity 6 Product Disassembly Chartapi-504977947No ratings yet

- Dark Energy Survey DES CollaborationDocument38 pagesDark Energy Survey DES CollaborationgeorgcantorNo ratings yet

- Model Personal StatementDocument2 pagesModel Personal StatementSwayam Tripathy100% (1)

- Datasheet - HK ml7012-04 3364913Document22 pagesDatasheet - HK ml7012-04 3364913kami samaNo ratings yet

- Project ProposalDocument2 pagesProject Proposalqueen malik80% (5)

- Building g5Document45 pagesBuilding g5ammarsteel68No ratings yet

- Rewriting Snow White As A Powerful WomanDocument6 pagesRewriting Snow White As A Powerful WomanLaura RodriguezNo ratings yet

- Denial of LOI & LOP For Ayurveda Colleges Under 13A For AY-2021-22 As On 18.02.2022Document1 pageDenial of LOI & LOP For Ayurveda Colleges Under 13A For AY-2021-22 As On 18.02.2022Gbp GbpNo ratings yet

- Eea2a - HOLIDAY HOMEWORK XIIDocument12 pagesEea2a - HOLIDAY HOMEWORK XIIDaksh YadavNo ratings yet

- Cognitive-Behavioral Interventions For PTSDDocument20 pagesCognitive-Behavioral Interventions For PTSDBusyMindsNo ratings yet

- Unit 1: Power and Responsibility: 1. Important Leadership QualitiesDocument6 pagesUnit 1: Power and Responsibility: 1. Important Leadership QualitiesTrần Thanh MinhNo ratings yet

- Din 48204Document3 pagesDin 48204Thanh Dang100% (4)

- Finite State MachineDocument75 pagesFinite State Machinecall_asitNo ratings yet