Professional Documents

Culture Documents

Data Sheet 1996-06-01: Applications Designation

Uploaded by

Enoc AndradeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Data Sheet 1996-06-01: Applications Designation

Uploaded by

Enoc AndradeCopyright:

Available Formats

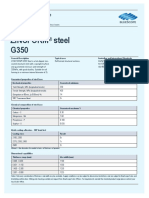

DATA SHEET 1996-06-01

EXTRA HIGH STRENGTH STRUCTURAL PLATE

WELDOX 900 is a general structural steel with a minimum yield strength of 900 N/mm2 intended for applications where its high strengh permits

weight savings to be made. The plate has very good cold bending properties and very good weldability. WELDOX 900 can be obtained with

guaranteed impact toughness at temperatures down to 60°C (76°F). WELDOX 900 totally fulfils the requirements on the corresponding steel

grades and qualities according to EN 10 137 part 1 and 2.

APPLICATIONS Dumptrucks, loaders, industrial trucks, excavators, bulldozers, forestry machines, buckets, cranes,

lifting equipment etc.

DESIGNATION WELDOX 900 D with impact testing at 20°C (4 °F). Corresponds to S 890 Q

WELDOX 900 E with impact testing at 40°C (40 °F). Corresponds to S 890 QL

WELDOX 900 F with impact testing at 60°C (76 °F). Corresponds to S 890 QL1

CHEMICAL COMPOSITION C* Si* Mn* P S B* Nb* Cr* V*

Al* Cu* Ti* Mo* Ni* N CEV

(ladle analysis) total typical

max max max max max max max max max max max min max max max value1)

% % % % % % % % % % % % % % % %

0,20 0,50 1,60 0,020 0,010 0,005 0,04 0,70 0,06 0,30 0,04 0,018 0,70 2,0 0,015 0,56

1)

CEV typical value, for information

*) Intentional alloying elements.

MECHANICAL PROPERTIES Plate thickness Yield strength Tensile strength Elongation 1)

mm Rp 0,2 min Rm A5 min A50 min 2)

N/mm2 N/mm2 % %

4 50 900 9401100 12 16

(50) 80,0 830 8801100 12 16

1)

For transverse test pieces. Values for longitudinal test pieces are 2 units higher.

2)

Testing by agreement.

IMPACT PROPERTIES Minimum values of impact energy for tests on transverse 1)

and Charpy V test pieces.

Minimum values of impact energy in J at test temperatures 2) in °C

Steel grade 0 20 40 60

WELDOX 900 D 30 27

WELDOX 900 E 35 30 27

WELDOX 900 F 40 35 30 27

1)

Unless otherwise agreed, transverse impact testing according to EN 10 137 option 3 will apply.

If only longitudinal impact testing shall apply, it has to be specified in the order.

2)

If the test temperature is not specified, the test will be carried out at the lowest test temperature.

TESTING Testing in accordance with EN 10 137-1 and EN 10 137-2.

DELIVERY CONDITION Quenched and tempered, Q.

DIMENSIONS WELDOX 900 is supplied in plate thicknesses of 480 mm. More detailed information on dimensions is

provided in our brochure E-40.

Certain width restrictions may apply.

Plate thicker than 80 mm only after specific agreement.

TOLERANCES According to EN 10 029.

Tolerances on thickness according to Class A.

Tolerances on flatness according to Class N.

(Normal tolerances)

SURFACE FINISH According to EN 10 163-2.

Requirements according to Class A.

Repair conditions according to Subclass 1.

Repair by welding is allowed, option 14 according to EN 10 137-2.

E-108 Åkerbloms Tryckeri AB, Nyköping 1996

GENERAL TECHNICAL According to our brochure En-40, General Product Information.

DELIVERY REQUIREMENTS WELDOX 900 conforms to all technical requirements of S890 in EN 10 137-2.

Option 3 and 14 are applied.

HEAT TREATMENT WELDOX 900 has obtained it's mechanical properties by a quenching and tempering process.

AND FABRICATION The mechanical properties can not be retained after PWHT at tempertures above 550°C (1020°F).

WELDOX 900 is not suited for applications requiring hot working at temperatures above 550°C

(1020°F) since the material may then loose it's good properties.

For information concerning welding and fabrication, see our brochures listed below or consult our

Technical Customer Service.

Fabrication Brochure No:

Drilling

Countersinking

Tapping En-10

Flame Cutting

Welding En-11

Bending

Shearing En-12

Turning

Milling En-13

Appropriate health and saftey precautions must be taken when welding, cutting,grinding or otherwise

working on the product. Grinding, especially of primer coated plates, may produce dust with high

particle concentration. Our Technical Customer Service Department will provide further information

on request.

You might also like

- Ew 700Document2 pagesEw 700Stefano BarbieriNo ratings yet

- Data Sheet Strenx 700 MCDocument3 pagesData Sheet Strenx 700 MCRoger BandeiraNo ratings yet

- Data Sheet Strenx 650 MCDocument3 pagesData Sheet Strenx 650 MCRoger BandeiraNo ratings yet

- Torque Transfer Standard: Special FeaturesDocument4 pagesTorque Transfer Standard: Special FeaturesdabafiNo ratings yet

- Data Sheet 2008 Strenx 700 MC 20170420 254 371857150 enDocument2 pagesData Sheet 2008 Strenx 700 MC 20170420 254 371857150 enmarkoNo ratings yet

- Data SheetDocument1 pageData SheetavikNo ratings yet

- Anexa 19Document2 pagesAnexa 19pokemon69No ratings yet

- Union TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20Document2 pagesUnion TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20brunizzaNo ratings yet

- Data Sheet 2008 Strenx#174 700MC D E 2017-04-20 PDFDocument2 pagesData Sheet 2008 Strenx#174 700MC D E 2017-04-20 PDFangelokyoNo ratings yet

- Hyundai Supercored 71HDocument9 pagesHyundai Supercored 71HPongwitt BoonayamaneeNo ratings yet

- X ENP Data Sheet Technical Information ASSET DOC 2591592Document9 pagesX ENP Data Sheet Technical Information ASSET DOC 2591592Milos VukobratNo ratings yet

- Strenx 700MC D e 2017-04-20Document2 pagesStrenx 700MC D e 2017-04-20Amandeep SinghNo ratings yet

- SSAB Domex 420MC: General Product DescriptionDocument2 pagesSSAB Domex 420MC: General Product DescriptionpeterNo ratings yet

- Technical Brief Galal Make SleevesDocument1 pageTechnical Brief Galal Make SleevesSELVAGANAPATHINo ratings yet

- Adi Design DataDocument14 pagesAdi Design DatalucianoNo ratings yet

- Fisa Tehnica Pentur Cablu Anti Incendiu JHSTH-2x2x0.8x500MDocument2 pagesFisa Tehnica Pentur Cablu Anti Incendiu JHSTH-2x2x0.8x500MSava SergiuNo ratings yet

- bk2 Datasheet enDocument3 pagesbk2 Datasheet enGustavo José BolsoniNo ratings yet

- Torque Reference Transducer: Special FeaturesDocument6 pagesTorque Reference Transducer: Special FeaturesdabafiNo ratings yet

- HV Full CatalogueDocument17 pagesHV Full CataloguemaggamNo ratings yet

- Eng Ds Xftc310 A4Document4 pagesEng Ds Xftc310 A4Zoltán SoósNo ratings yet

- Primacore MW 71Document2 pagesPrimacore MW 71rjan7peNo ratings yet

- Steel X20Cr13: EN 10250-4:1999, Number: 1.4021Document4 pagesSteel X20Cr13: EN 10250-4:1999, Number: 1.4021AdamNo ratings yet

- Specification For HV Transformer (Hyundai Heavy Industries CO., LTD.)Document32 pagesSpecification For HV Transformer (Hyundai Heavy Industries CO., LTD.)Oleksandr RakshaNo ratings yet

- Power Relay JSL Series: 1 POLE - 8A Polarized Latching TypeDocument7 pagesPower Relay JSL Series: 1 POLE - 8A Polarized Latching Typeleontin_mariciuica4480No ratings yet

- 52 PAP enDocument2 pages52 PAP enGulf Trans PowerNo ratings yet

- Gb8417domex500mc PDFDocument2 pagesGb8417domex500mc PDFMario MereniNo ratings yet

- TDC 09 - R1 - S690 QL & Weldox 700Document2 pagesTDC 09 - R1 - S690 QL & Weldox 700Thennarasu VelloreNo ratings yet

- Semiconductor Technical Data: Mechanical CharacteristicsDocument3 pagesSemiconductor Technical Data: Mechanical CharacteristicsAjay TomarNo ratings yet

- Fireproof ROOF Panels Technical InformationDocument4 pagesFireproof ROOF Panels Technical InformationMarko MiticNo ratings yet

- Domex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelDocument2 pagesDomex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelHugo RodriguezNo ratings yet

- Item Conductive Tile Static-Disiipative TileDocument3 pagesItem Conductive Tile Static-Disiipative Tilebheemannadora sappaNo ratings yet

- Load Cell For Tension/Compression Applications: Technical DataDocument3 pagesLoad Cell For Tension/Compression Applications: Technical DataDfunz WilphenNo ratings yet

- Sensor de Presión MH-1Document4 pagesSensor de Presión MH-1Sergio Suárez RiesgoNo ratings yet

- Stainless Steel 1.4401 316Document3 pagesStainless Steel 1.4401 316Luis LoayzaNo ratings yet

- 1 4501 Super Duplex TubesDocument3 pages1 4501 Super Duplex TubesAlma JakirovićNo ratings yet

- Datasheet Strenx 700E - en - 2016Document3 pagesDatasheet Strenx 700E - en - 2016peterNo ratings yet

- sb8 Datasheet enDocument3 pagessb8 Datasheet ensrinivas raghavanNo ratings yet

- Common Mode Chokes Pwc0603St Series: PWC 0603 S T 900 SDocument8 pagesCommon Mode Chokes Pwc0603St Series: PWC 0603 S T 900 SscribdpinoNo ratings yet

- EI ServicesDocument2 pagesEI ServicesAnonymous P8Bt46mk5INo ratings yet

- 33kv Techni8cal Specification Edited FormatDocument16 pages33kv Techni8cal Specification Edited Formatvikas kumarNo ratings yet

- Bushings PDFDocument32 pagesBushings PDFRacha AmelNo ratings yet

- Prysmian - TECSUN XPVXDocument5 pagesPrysmian - TECSUN XPVXsydneyaus2005No ratings yet

- Aoi-01-Eng-2024Document81 pagesAoi-01-Eng-2024Kuldeep ShekhawatNo ratings yet

- sb14 Beam Datasheet en PDFDocument3 pagessb14 Beam Datasheet en PDFJosé TimanáNo ratings yet

- Phoenix 7018 Phoenix 6013Document1 pagePhoenix 7018 Phoenix 6013Pedro SilvaNo ratings yet

- Annealed Engineering Steel C45E / 1042 (ASTMDocument2 pagesAnnealed Engineering Steel C45E / 1042 (ASTMkazdoelahNo ratings yet

- Strenx 700 MC: Advanced High Strength SteelDocument2 pagesStrenx 700 MC: Advanced High Strength SteeldbaNo ratings yet

- 1N4001GP, 1N4002GP, 1N4003GP, 1N4004GP, 1N4005GP, 1N4006GP, 1N4007GPDocument5 pages1N4001GP, 1N4002GP, 1N4003GP, 1N4004GP, 1N4005GP, 1N4006GP, 1N4007GPOSCAR SALVADORNo ratings yet

- SMDDocument6 pagesSMDJose SCNo ratings yet

- Safety Maintenance and Operating Instruction: SHOMAL Engineering & Manufacturing Co. (PIROOZ)Document9 pagesSafety Maintenance and Operating Instruction: SHOMAL Engineering & Manufacturing Co. (PIROOZ)shakouri1370_8902064No ratings yet

- Avery Tronix Load Cell T302Document4 pagesAvery Tronix Load Cell T302Cardoso MalacaoNo ratings yet

- Tecsun (PV) Pv1 F Cable For Photovoltaics: EnergyDocument5 pagesTecsun (PV) Pv1 F Cable For Photovoltaics: Energyrommy_boy330No ratings yet

- Resultado Del PiloteDocument2 pagesResultado Del PiloteMarino DugaroNo ratings yet

- J0231 LV TR - FINAL变压器2Document21 pagesJ0231 LV TR - FINAL变压器2SerhiiNo ratings yet

- Conarc 49C: Basic ElectrodeDocument2 pagesConarc 49C: Basic ElectrodeMark Williams100% (1)

- MelfprofDocument14 pagesMelfprofFunnypoumNo ratings yet

- Scope: Ferritic Heat-Resistant Steel TK 1.4762Document5 pagesScope: Ferritic Heat-Resistant Steel TK 1.4762Siis IngenieriaNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- ASTM A537 Standard SpecificationDocument4 pagesASTM A537 Standard SpecificationLeon SanchezNo ratings yet

- SB 135Document4 pagesSB 135AnilNo ratings yet

- ExamsGrade API-571 Exam Questions AnswersDocument10 pagesExamsGrade API-571 Exam Questions AnswersLamont Bauch100% (6)

- Technical Report 1 1999Document34 pagesTechnical Report 1 1999Sinan YıldızNo ratings yet

- BS en 10028-4-2017Document18 pagesBS en 10028-4-2017Ly KhoaNo ratings yet

- MMS Course FileDocument22 pagesMMS Course Filejohn_raju17No ratings yet

- Technical Information Technical Information: General Information R2 R15Document42 pagesTechnical Information Technical Information: General Information R2 R15safat parNo ratings yet

- Fracture and Fracture Toughness of Cast Irons: W. L. Bradley and M. N. SrinivasanDocument33 pagesFracture and Fracture Toughness of Cast Irons: W. L. Bradley and M. N. SrinivasanNarasimha Murthy InampudiNo ratings yet

- Steel Castings, Carbon, For General ApplicationDocument4 pagesSteel Castings, Carbon, For General ApplicationHussein BeqaiNo ratings yet

- Material 1.2379 - X153CrMoV12Document1 pageMaterial 1.2379 - X153CrMoV12johnnydoe90No ratings yet

- B139B139MDocument5 pagesB139B139MsivaNo ratings yet

- Heat TreatmentDocument20 pagesHeat Treatmentshanu100% (1)

- Lvsuysl Blikr DH Iysv) Píjsa RFKK Ifùk K¡ Fof'Kf"V: HKKJRH EkudDocument17 pagesLvsuysl Blikr DH Iysv) Píjsa RFKK Ifùk K¡ Fof'Kf"V: HKKJRH EkudshamrajjNo ratings yet

- AMS - SLB-410-13 Cr-Stainless Steel-80 KSI Min Yield Strength, Unified SpecDocument7 pagesAMS - SLB-410-13 Cr-Stainless Steel-80 KSI Min Yield Strength, Unified Speckrishna chiruNo ratings yet

- Alloy Data Sheet En-Aw 6063 (Almg0.7Si) : Type: General Extrusion Alloy)Document1 pageAlloy Data Sheet En-Aw 6063 (Almg0.7Si) : Type: General Extrusion Alloy)CocoNo ratings yet

- Astm A473-23Document6 pagesAstm A473-231965karanfil6No ratings yet

- Sae Ams 2759-1e-2014Document13 pagesSae Ams 2759-1e-2014Reza NooriNo ratings yet

- 82 Ti SPC One Toolpl 0990 (Tirfox) 1 2Document3 pages82 Ti SPC One Toolpl 0990 (Tirfox) 1 2pradeeepgargNo ratings yet

- Astm A193Document12 pagesAstm A193Brad BorgesNo ratings yet

- AISI 1035 cs46Document2 pagesAISI 1035 cs46Russell ShacklefordNo ratings yet

- A723A723M-18a 1.05 PDFDocument5 pagesA723A723M-18a 1.05 PDFist93993No ratings yet

- Curriculum of B.Tech (Metallurgical & Material Engineering)Document32 pagesCurriculum of B.Tech (Metallurgical & Material Engineering)iyomasaNo ratings yet

- Weldability of Structural Steel PDFDocument48 pagesWeldability of Structural Steel PDFsurawutwijarnNo ratings yet

- Life Management and Maintenance - BalticaDocument261 pagesLife Management and Maintenance - Balticabrunoreiscardoso0% (1)

- X12CrNiMoV12 3Document3 pagesX12CrNiMoV12 3manjunath k sNo ratings yet

- Hard Turning of Hot Work Tool Steel (Dac10)Document38 pagesHard Turning of Hot Work Tool Steel (Dac10)mohitkpatelNo ratings yet

- An Evaluation of The Cross-Tension Test of Resistance Spot Welds in High-Strength Dual-Phase SteelsDocument8 pagesAn Evaluation of The Cross-Tension Test of Resistance Spot Welds in High-Strength Dual-Phase SteelsMuhammad Bahtiyar FirdausNo ratings yet

- Behaviour of Materials Subject To Deep Subzero Temperatures - Preliminary Findings and IdeasDocument37 pagesBehaviour of Materials Subject To Deep Subzero Temperatures - Preliminary Findings and IdeaschetanzzgNo ratings yet

- CSWIP 31 Exam Question and AnswersDocument25 pagesCSWIP 31 Exam Question and AnswersIslam SahafayatNo ratings yet

- محاضرات في تصميم المعدات PDFDocument698 pagesمحاضرات في تصميم المعدات PDFRashaq AlheetyNo ratings yet