Professional Documents

Culture Documents

Ficha Tecnica Glass Beads

Uploaded by

hdcghumanoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ficha Tecnica Glass Beads

Uploaded by

hdcghumanoCopyright:

Available Formats

Glass Beads

Glass Beads are a spherical abrasive manufactured from chemically inert soda lime glass.

Glass Beads are used for cleaning, finishing, light peening, deburring, sanitizing, descaling,

coating removal, polishing and surface blending.

Glass Beads produce a bright satin finish; finer beads produce a smoother non glare finish,

while larger beads produce a deeper textured finish. Blasting with Glass Bead does not

produce any dimension changes to the part base surface.

Chemical Composition:

SiO2 Na2O K2O CaO MgO Al2O3

71-73% 13-15% 0.2-0.6% 8-10% 3-5% 0.5-2%

Physical Properties:

Hardness Specific Bulk Shape Free Free iron Free Iron

Mohs Gravity Density Silica Colour

6-7 2.4-2.6 1.5 Spherical NL ≤1% Clear

g/ cm3 g/ cm3

Grits Available:

Size mesh Size inch Size um %round

25-45 0.0278-0.0139 710-355 65

30-40 0.0234-0.0165 600-425 65

40-60 0.0165-0.0098 425-250 75

40-70 0.0165-.0083 425-212 70

50-70 0.0117-0.0083 300-212 75

50-80 0.0117-0.0070 300-180 70

60-120 0.0098-0.0049 250-125 80

70-140 0.0083-0.0041 212-106 80

100-170 0.0059-0.0035 150-90 85

120-270 0.0049-0.0021 125-53 85

170-325 0.0035-0.0017 90-45 85

Standards:

GB/T24722-2009, BS6088—1981 from UK,

AASHTO M247—1981 from United State,

EN1423—1997,EN1424—1998 from Europe, L2521 from Korea,

JIS R3301 from Japan, etc.

Application:

Glass beads is used for cleaning, surface finishing and sanitizing of metallic parts, especially

effective on stainless steel, food processing equipment, medical instruments.

Shot peening of aircraft engine blades, turbine rotors, gears, bricks, shafts, steam and gas

turbine components.

Glass beads also used for road marking.

You might also like

- Mesh Size Tyler Astm-E11 Bs-410 Din-4188Document4 pagesMesh Size Tyler Astm-E11 Bs-410 Din-4188Yoyon SuparionoNo ratings yet

- Renold Inox Catalogo PDFDocument1 pageRenold Inox Catalogo PDFsawnico sawNo ratings yet

- Silica/Sand Specifications: Particle Size Analysis and PropertiesDocument1 pageSilica/Sand Specifications: Particle Size Analysis and PropertiesforuzzNo ratings yet

- Fused Silica DatasheetDocument2 pagesFused Silica DatasheetLuis Antonio SotoNo ratings yet

- General Catalogue VOL1Document330 pagesGeneral Catalogue VOL1lifib23970No ratings yet

- Garnet Opta MineralsDocument2 pagesGarnet Opta MineralsMaison Braúl ManriqueNo ratings yet

- 316L Stainless Steel PipeDocument9 pages316L Stainless Steel PipeSmail MiloudiNo ratings yet

- Sieve SizeDocument3 pagesSieve SizeSse SteelNo ratings yet

- Reade Particle Size Conversion AnsiDocument1 pageReade Particle Size Conversion AnsijhscribdaccNo ratings yet

- NyaDocument1 pageNyaahmat kharisNo ratings yet

- Raycut Fiber Laser PerformanceDocument4 pagesRaycut Fiber Laser Performancemojtaba ranjbarNo ratings yet

- Sieves Comparision PDFDocument1 pageSieves Comparision PDFDilnesa EjiguNo ratings yet

- Semi-Finished PC Polarized Lens (Index of Refraction: 1.523)Document22 pagesSemi-Finished PC Polarized Lens (Index of Refraction: 1.523)api-3749285No ratings yet

- AISI Type 302 Stainless Steel (UNS S30200) : Chemical CompositionDocument4 pagesAISI Type 302 Stainless Steel (UNS S30200) : Chemical CompositionnagboccaNo ratings yet

- Butterfly Valve DatasheetDocument2 pagesButterfly Valve DatasheetKanthan DevanNo ratings yet

- Technical Data of Black and Hot Dip Galvanized Steel Pipes Conforming To Astm A 53 Grade A & B Sch-40Document5 pagesTechnical Data of Black and Hot Dip Galvanized Steel Pipes Conforming To Astm A 53 Grade A & B Sch-40mechmohsin4745No ratings yet

- Inch MM Wire No. Wire Dia. Wire No.2 Wire Dia.2 Wire No.4 Wire Dia.5 Wire No.6 Wire Dia.7Document1 pageInch MM Wire No. Wire Dia. Wire No.2 Wire Dia.2 Wire No.4 Wire Dia.5 Wire No.6 Wire Dia.7Anbarasan PerumalNo ratings yet

- Model 7041-A Flange-Ansi Class 125/150Document2 pagesModel 7041-A Flange-Ansi Class 125/150Zaira LorenaNo ratings yet

- R2T Hose Data Sheet PDFDocument1 pageR2T Hose Data Sheet PDFNagarjunSHNo ratings yet

- Lq-Tec: Catalogue of The Aluminium Alloy WireDocument3 pagesLq-Tec: Catalogue of The Aluminium Alloy Wirerubens072No ratings yet

- Abrasive Grit and Particle ConversionsDocument2 pagesAbrasive Grit and Particle ConversionsEn Tip100% (2)

- Booth Extr. Catalogue Oct. 2011Document78 pagesBooth Extr. Catalogue Oct. 2011paresh100% (1)

- Is4522. GR5Document10 pagesIs4522. GR5kaushikNo ratings yet

- Aluminium IndustrialDocument150 pagesAluminium IndustrialAhtesham AnsariNo ratings yet

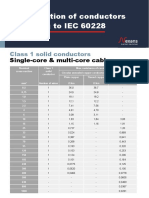

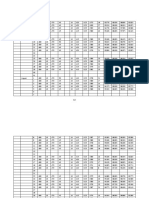

- Classification of Conductors According To IEC 60228Document3 pagesClassification of Conductors According To IEC 60228Jacob de Wilde100% (1)

- Matrics Printers Guides PrintheadsDocument6 pagesMatrics Printers Guides Printheadszocky74No ratings yet

- Duplex Stainless Steel Round BarDocument3 pagesDuplex Stainless Steel Round Barashok sanghviNo ratings yet

- Salem Product CatalogueDocument6 pagesSalem Product Cataloguedramilt0% (1)

- Product Zoom 18 - EshopDocument16 pagesProduct Zoom 18 - EshopkenywkNo ratings yet

- New Microsoft PowerPoint Presentation (1) (تم حفظه تلقائيا) PDFDocument26 pagesNew Microsoft PowerPoint Presentation (1) (تم حفظه تلقائيا) PDF123No ratings yet

- Steel Weight NamoDocument3 pagesSteel Weight NamoPaul MathewNo ratings yet

- ΚΑΜΠΥΛΕΣ - ΣΥΣΤΟΛΕΣDocument8 pagesΚΑΜΠΥΛΕΣ - ΣΥΣΤΟΛΕΣvasilis1990No ratings yet

- General ManagerDocument7 pagesGeneral Managerოთო აბაშიძეNo ratings yet

- Design of TbeamDocument7 pagesDesign of TbeamJJ TevesNo ratings yet

- Macaron Shrink Ratio: 2 / 1: Colored Heat Shrink / Red / BlueDocument2 pagesMacaron Shrink Ratio: 2 / 1: Colored Heat Shrink / Red / BlueLogistica 2 essaperuNo ratings yet

- Spheroidal Graphite (Nodular) Cast Iron:: Product Type Grade of Product Sub GradeDocument5 pagesSpheroidal Graphite (Nodular) Cast Iron:: Product Type Grade of Product Sub GradeAnonymous iztPUhIiNo ratings yet

- Calculation of Thrust Block For Rajauli ProjectDocument1 pageCalculation of Thrust Block For Rajauli ProjectAbhishek sNo ratings yet

- Conduit Installation Manhours Per Linear MeterDocument4 pagesConduit Installation Manhours Per Linear MeterAbdullahHusainNo ratings yet

- Stainless Steel Flexible Hose AssembliesDocument10 pagesStainless Steel Flexible Hose AssembliesDkdkkdNo ratings yet

- Mekanika TeknikDocument10 pagesMekanika TeknikfebirivandaNo ratings yet

- British Standard Roller Chain Renold JeffreyDocument1 pageBritish Standard Roller Chain Renold JeffreyImran sharifNo ratings yet

- Mekanika TeknikDocument10 pagesMekanika TeknikfebirivandaNo ratings yet

- Technical Data Sheet Product CatalogueDocument16 pagesTechnical Data Sheet Product CatalogueKamalNo ratings yet

- Butterfly Valve B7GDocument3 pagesButterfly Valve B7GJorgeCabreraCoronelNo ratings yet

- Diamond and CBN WheelsDocument22 pagesDiamond and CBN WheelsM. AguiarNo ratings yet

- Jayant Test SievesDocument2 pagesJayant Test SievesM PankajNo ratings yet

- 6 ResultsDocument2 pages6 ResultsKHAIRUNISANo ratings yet

- 2wt Arita Ci Bfly VLV Uni Flanged MalaysiaDocument2 pages2wt Arita Ci Bfly VLV Uni Flanged MalaysiaannaomarNo ratings yet

- Xi-An Howah Industry Technology Co., LTD - Magnesium AnodesDocument6 pagesXi-An Howah Industry Technology Co., LTD - Magnesium AnodesSetiawan WijayantoNo ratings yet

- General ReferenceDocument28 pagesGeneral ReferenceJeya VasanthNo ratings yet

- BS6195 Type 4 Data SheetDocument1 pageBS6195 Type 4 Data SheetStone123456789No ratings yet

- Renold Sd-Catalogo PDFDocument4 pagesRenold Sd-Catalogo PDFsawnico sawNo ratings yet

- Acoples EstrellaDocument23 pagesAcoples EstrellaEdgardoJesusQuinteroAponteNo ratings yet

- Tyler: ASTM Sieve Chart and EquivalentsDocument1 pageTyler: ASTM Sieve Chart and EquivalentsWilder CubaNo ratings yet

- Conductor Construction For Insulated Cables and WiresDocument4 pagesConductor Construction For Insulated Cables and Wires陆华林No ratings yet

- Katalog Komposisi Lengkap New VersionDocument8 pagesKatalog Komposisi Lengkap New VersionSontani PurnamaNo ratings yet

- Typical Set of Wire Mesh Dimensions Pages From Ken Sutherland - Filters and Filtration Handbook (2008, Elsevier Science) - 2Document2 pagesTypical Set of Wire Mesh Dimensions Pages From Ken Sutherland - Filters and Filtration Handbook (2008, Elsevier Science) - 2Mohammad TaherNo ratings yet

- Lec # 5 Manufacturing Models and MatricesDocument35 pagesLec # 5 Manufacturing Models and MatricesEman ShahidNo ratings yet

- Lean ManufacturingDocument3 pagesLean ManufacturinganurajNo ratings yet

- Repair WeldsDocument57 pagesRepair WeldsJoseph Jordan Aguilar OndeNo ratings yet

- European Steel and Alloy GradesDocument3 pagesEuropean Steel and Alloy Gradesfarshid KarpasandNo ratings yet

- Research Proposal Write UpDocument26 pagesResearch Proposal Write UpRhyssa BacaniNo ratings yet

- CWI Qustion BankDocument35 pagesCWI Qustion Bankprabhu100% (1)

- Surface Preparation of Galvanized Steel SurfacesDocument2 pagesSurface Preparation of Galvanized Steel SurfacesFernando AlvarengaNo ratings yet

- Engineer's Training Manual-2023Document16 pagesEngineer's Training Manual-2023Jagannath EpeeliNo ratings yet

- MDSP T4Document100 pagesMDSP T4Arnz BibosoNo ratings yet

- Butyl & Chloroprene 2003Document16 pagesButyl & Chloroprene 2003Suyash TrivediNo ratings yet

- EPDM SpecsDocument1 pageEPDM SpecsRosendo GarcíaNo ratings yet

- Implementing A Total Productive Maintenance Approach Into An Impr (074-115)Document42 pagesImplementing A Total Productive Maintenance Approach Into An Impr (074-115)Fadi AtigNo ratings yet

- BESWMCDocument2 pagesBESWMCLei SomodioNo ratings yet

- Rubber Hose Assemblies For Oil Suction ADocument8 pagesRubber Hose Assemblies For Oil Suction Ajeremytoh89100% (1)

- Multichoice Paper OneDocument4 pagesMultichoice Paper OneAhmed ShakirNo ratings yet

- Use The Figure Below To Answer The Following QuestionsDocument5 pagesUse The Figure Below To Answer The Following QuestionsSlock TruNo ratings yet

- Report - 1 Noquis, John Christian R.Document7 pagesReport - 1 Noquis, John Christian R.jcr noquisNo ratings yet

- Asme Marking-And-Mechanical-Properties-Of-Steel-FastenersDocument3 pagesAsme Marking-And-Mechanical-Properties-Of-Steel-Fastenersjyoti prakash singhNo ratings yet

- CNC-Lab Mechanical ManualDocument21 pagesCNC-Lab Mechanical ManualHaresh RaisinghaniNo ratings yet

- Craigtools 300 PDFDocument58 pagesCraigtools 300 PDFroshan mungurNo ratings yet

- Preserv Cu WDDocument3 pagesPreserv Cu WDamitabhsrivastavaNo ratings yet

- Ultimate Adjustable SawhorseDocument22 pagesUltimate Adjustable SawhorseNorbert VesztergomNo ratings yet

- Product Catalogue SANWEI CompressedDocument74 pagesProduct Catalogue SANWEI CompressedJaime Rousseau TNo ratings yet

- Oracal 5200Document2 pagesOracal 5200Nenad MihajlovicNo ratings yet

- Newslettersummer 06Document8 pagesNewslettersummer 06निखिल बायवारNo ratings yet

- Who Invented Plastic - Google SearchDocument1 pageWho Invented Plastic - Google SearchmolloygraceNo ratings yet

- 3d Printing Dissertation TopicsDocument6 pages3d Printing Dissertation TopicsHelpWithPaperWritingSingapore100% (1)

- Axxanol 34CDDocument2 pagesAxxanol 34CDSDR COMEXNo ratings yet

- The Conversion CycleDocument51 pagesThe Conversion CycleA c100% (1)

- Master - J Data SheetDocument1 pageMaster - J Data SheetRonald WongNo ratings yet