Professional Documents

Culture Documents

VEZ-2Q26-M2-BS: Electrical Specifications

Uploaded by

Victor Hugo RojasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VEZ-2Q26-M2-BS: Electrical Specifications

Uploaded by

Victor Hugo RojasCopyright:

Available Formats

VEZ-2Q26-M2-BS

Brand Name MARK 10 POWERLINE

Ballast Type Electronic Dimming

Starting Method Programmed Start

Lamp Connection Series

Input Voltage 277

Electrical Specifications Input Frequency 60 HZ

Status Active

Lamp Type Num. Rated Min. Input Input Power Ballast Factor MAX Power Lamp B.E.F.

of Lamp Start Current (Watts) (min/max) THD Factor Current

Lamps Watts Temp (Amps) (min/max) % Crest Factor

(°F/C)

CFQ26W/G24Q 2 26 50/10 0.21 16/58 0.05/1.05 10 0.98 1.6 1.81

* 2 26 50/10 0.21 16/58 0.05/1.05 10 0.98 1.6 1.81

CFTR26W/GX24Q

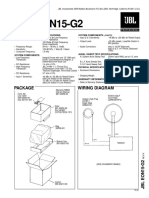

Wiring Diagram Enclosure

DIMMER RED

BLACK RED

YELLOW

WHITE BALLAST YELLOW

BLUE

BLUE

LINE DIAG. 132

The wiring diagram that appears above is

for the lamp type denoted by the asterisk (*)

Enclosure Dimensions

OverAll (L) Width (W) Height (H) Mounting (M)

Standard Lead Length (inches)

4.98 " 3.00 " 1.29 " 2.00 "

4 49/50 3 1 29/100 2

12.6 cm 7.6 cm 3.3 cm 5.1 cm

Revised 09/10/2002

Data is based upon tests performed by Philips Lighting Electronics N.A. in a controlled environment and is representative of relative performance. Actual performance can vary

depending on operating conditions. Specifications are subject to change without notice. All specifications are nominal unless otherwise noted.

PHILIPS LIGHTING ELECTRONICS N.A.

10275 WEST HIGGINS ROAD · ROSEMONT, IL 60018

Tel: 800-322-2086 · Fax: 888-423-1882 · www.philips.com/advance

Customer Support/Technical Service: 800-372-3331 · OEM Support: 866-915-5886

VEZ-2Q26-M2-BS

Brand Name MARK 10

POWERLINE

Ballast Type Electronic Dimming

Starting Method Programmed Start

Electrical Specifications Lamp Connection Series

Input Voltage 277

Notes: Input Frequency 60 HZ

Section I - Physical Characteristics

Status Active

1.1 Ballast shall be physically interchangeable with standard electromagnetic or standard electronic ballasts, where applicable.

1.2 Ballast shall be available in a plastic/metal can or all metal can construction to meet all plenum requirements.

1.3 Ballast shall be provided with poke-in wire trap connectors or integral leads color coded per ANSI C82.11.

Section II - Performance Requirements

2.1 Ballast shall be Programmed Start.

2.2 Ballast shall contain auto restart circuitry in order to restart lamps without resetting power.

2.3 Ballast shall operate from 60 Hz input source of 120V, 277V or 347V as applicable with sustained variations of +/- 10% (voltage and

frequency).

2.4 Ballast shall be high frequency electronic type and operate lamps at a frequency above 42 kHz to avoid interference with infrared devices

and eliminate visible flicker.

2.5 Ballast shall have a Power Factor greater than 0.98 at full light output and greater than 0.90 throughout the dimming range for primary

lamp.

2.6 Ballast shall have a minimum ballast factor of 1.00 at maximum light output and 0.05 at minimum light output for primary lamp application.

2.7 Ballast shall provide for a Lamp Current Crest Factor of 1.7 or less.

2.8 Ballast input current shall have Total Harmonic Distortion (THD) of less than 10% at maximum light output when operated at nominal line

voltage with primary lamp. Total Harmonic Current (THC) at minimum light output shall not exceed THC at maximum light output.

2.9 Ballast shall have a Class A sound rating.

2.10 Ballast shall have a minimum starting temperature of 10C (50F) for primary lamp.

2.11 Ballast shall provide Lamp EOL Protection Circuit for all T5, T5/HO, and CFL lamps.

2.12 Ballast shall control lamp light output from 100% - 5% relative light output for T8 and CFL lamps and 100% - 1% relative light output for

T5/HO lamps.

2.13 Ballast shall ignite the lamps at any light output setting without first going to another output setting.

2.14 Ballast shall tolerate sustained open circuit and short circuit output conditions.

Section III - Regulatory Requirements

3.1 Ballast shall not contain any Polychlorinated Biphenyl (PCB).

3.2 Ballast shall be Underwriters Laboratories (UL) listed, Class P and Type 1 Outdoor; and Canadian Standards Association (CSA) certified

where applicable.

3.3 Ballast shall comply with ANSI C62.41 Category A for Transient protection.

3.4 Ballast shall comply with ANSI C82.11 where applicable.

3.5 Ballast shall comply with the requirements of the Federal Communications Commission (FCC) rules and regulations, Title 47 CFR part 18,

Non-Consumer (Class A) for EMI/RFI (conducted and radiated).

3.6 Ballast shall comply with NEMA 410 for in-rush current limits.

Section IV - Other

4.1 Ballast shall be manufactured in a factory certified to ISO 9001 Quality System Standards.

4.2 Ballast shall carry a ____ warranty from date of manufacture against defects in material or workmanship for operation at a maximum case

temperature of ____ (Go to our web site for up to date warranty information: www.philips.com/advancewarranty.

4.3 Manufacturer shall have a twenty-year history of producing electronic ballasts for the North American market.

4.4 Ballast shall be controlled by a compatible Mark 10 Powerline two-wire dimmer.

4.5 Ballast shall be Philips Advance part # _____________ or approved equal.

Revised 09/10/2002

Data is based upon tests performed by Philips Lighting Electronics N.A. in a controlled environment and is representative of relative performance. Actual performance can vary

depending on operating conditions. Specifications are subject to change without notice. All specifications are nominal unless otherwise noted.

PHILIPS LIGHTING ELECTRONICS N.A.

10275 WEST HIGGINS ROAD · ROSEMONT, IL 60018

Tel: 800-322-2086 · Fax: 888-423-1882 · www.philips.com/advance

Customer Support/Technical Service: 800-372-3331 · OEM Support: 866-915-5886

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Liebherr A-900-1031 Service Manuel-Part 8 - Electricity PDFDocument486 pagesLiebherr A-900-1031 Service Manuel-Part 8 - Electricity PDFSami Enis Arıoğlu92% (12)

- BT RRM 16 схемаDocument17 pagesBT RRM 16 схеманикNo ratings yet

- Control Plan For Lighting ProductDocument6 pagesControl Plan For Lighting ProductpapplionNo ratings yet

- Customer: Project: Sheet No. Title: Sheet Contents: Drawn Dwg. No. Approved Revision Date ScaleDocument6 pagesCustomer: Project: Sheet No. Title: Sheet Contents: Drawn Dwg. No. Approved Revision Date ScaleLionel BacaniNo ratings yet

- Pipes On DeckDocument34 pagesPipes On DeckNataly Janataly100% (1)

- Common Electrical Symbols: Symbol Description Symbol DescriptionDocument3 pagesCommon Electrical Symbols: Symbol Description Symbol DescriptionMoleen Magsino67% (6)

- Scala and Spark For Big Data AnalyticsDocument874 pagesScala and Spark For Big Data AnalyticsSneha SteevanNo ratings yet

- Bonus 6 - Mastering ASP - NET Core SecurityDocument147 pagesBonus 6 - Mastering ASP - NET Core SecurityDark Shadow100% (1)

- VEZ-1T42-M2-LD: Electrical SpecificationsDocument2 pagesVEZ-1T42-M2-LD: Electrical SpecificationsVictor Hugo RojasNo ratings yet

- Ballast Advance-VC-2S85-TP-f48Document1 pageBallast Advance-VC-2S85-TP-f48Raymond VoldinoNo ratings yet

- R-2E75-S-TP: Electrical SpecificationsDocument1 pageR-2E75-S-TP: Electrical SpecificationsJon GosnellNo ratings yet

- Advance REL-2P32-SCDocument2 pagesAdvance REL-2P32-SCHector CardosoNo ratings yet

- BS-527 enDocument2 pagesBS-527 enThanosEleftheroudisNo ratings yet

- Cafterial SDB Electrical PLanDocument1 pageCafterial SDB Electrical PLanAmos KormeNo ratings yet

- 57tw 0230-0367ra InstructionsDocument4 pages57tw 0230-0367ra InstructionsErnesto AmezcuaNo ratings yet

- EMG 40TW Wiring DiagramDocument4 pagesEMG 40TW Wiring DiagramРубен БогдаянNo ratings yet

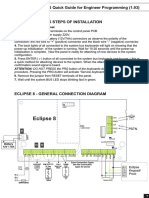

- Eclipse 8 Address Quick Guide (1-1Document12 pagesEclipse 8 Address Quick Guide (1-1Salah SalahNo ratings yet

- 15 KV Current Transformer: Indoor 60 HertzDocument2 pages15 KV Current Transformer: Indoor 60 HertzWilliam Yoel CcalloNo ratings yet

- SEVS18-002 Specification For SEVD-11EDocument15 pagesSEVS18-002 Specification For SEVD-11Eraza23950% (2)

- Advance Iopa1p32lwn35iDocument3 pagesAdvance Iopa1p32lwn35i이경식No ratings yet

- Diode SMDJ5Document4 pagesDiode SMDJ5Pyro PyroNo ratings yet

- A-60 120 PDFDocument9 pagesA-60 120 PDFautreraNo ratings yet

- 1.5Smcj Series: PB FeaturesDocument6 pages1.5Smcj Series: PB FeaturesCarlos Enrique Silva AguileraNo ratings yet

- 707tw 0230-0119rdDocument4 pages707tw 0230-0119rdLoic TrocmeNo ratings yet

- GSM Controller: Ordering InformationDocument3 pagesGSM Controller: Ordering InformationSai VivekNo ratings yet

- MJE15032 (NPN), MJE15033 (PNP) Complementary Silicon Plastic Power TransistorsDocument6 pagesMJE15032 (NPN), MJE15033 (PNP) Complementary Silicon Plastic Power TransistorsTyron DsouzaNo ratings yet

- 5130 Excavator Electrical System: Electrical Schematic Symbols and DefinitionsDocument2 pages5130 Excavator Electrical System: Electrical Schematic Symbols and DefinitionsGilvan JuniorNo ratings yet

- Installation Information Emg Model: S/S/89, 81-Tw Combination SystemDocument5 pagesInstallation Information Emg Model: S/S/89, 81-Tw Combination SystemJuninho ESPNo ratings yet

- MJE15034 NPN, MJE15035 PNP Complementary Silicon Plastic Power TransistorsDocument6 pagesMJE15034 NPN, MJE15035 PNP Complementary Silicon Plastic Power TransistorsMehmet ÇatçatNo ratings yet

- Installation Information Emg Models: S/S/S Combination SystemsDocument4 pagesInstallation Information Emg Models: S/S/S Combination SystemsacemusNo ratings yet

- Technical Data Sheet Power LED @150ma Current: 34-03UYC/S599Document8 pagesTechnical Data Sheet Power LED @150ma Current: 34-03UYC/S599Jeannot MpianaNo ratings yet

- Installation Information Emg Model: 707-TwDocument4 pagesInstallation Information Emg Model: 707-TwAgus MulyaNo ratings yet

- Data Sheet Prolec - 1500 Kva - 22860V - 480-240VDocument2 pagesData Sheet Prolec - 1500 Kva - 22860V - 480-240VAlfrhNo ratings yet

- CQ-ES7880AZ: Am/Fm/Mpx Electronic Tuning RADIO With 6-Disc CD ChangerDocument28 pagesCQ-ES7880AZ: Am/Fm/Mpx Electronic Tuning RADIO With 6-Disc CD Changerdiablohuno100% (1)

- 15 KV Voltage Transformer: Indoor 60 HertzDocument2 pages15 KV Voltage Transformer: Indoor 60 HertzJonathan Mauricio Santamaria PlazasNo ratings yet

- Regulators: Integrated Circuits GroupDocument1 pageRegulators: Integrated Circuits GroupKSNo ratings yet

- Service Manual: TV-C142SDocument11 pagesService Manual: TV-C142SAndré LeftNo ratings yet

- Opto TLP290 AcDocument10 pagesOpto TLP290 AcFrancisco MagyarNo ratings yet

- Emg 707 Instruction de Montage en 29250Document4 pagesEmg 707 Instruction de Montage en 29250Arturo VelázquezNo ratings yet

- 4 Pin Dip Phototransistor Photocoupler EL817-G Series: FeaturesDocument14 pages4 Pin Dip Phototransistor Photocoupler EL817-G Series: FeaturesGilson3DNo ratings yet

- DV PlugCodeGuideDec 2017Document19 pagesDV PlugCodeGuideDec 2017INo ratings yet

- Borehole 6 Project Electrical Installation: Floor PlanDocument1 pageBorehole 6 Project Electrical Installation: Floor PlanbekeleNo ratings yet

- Borehole 6 Project Electrical Installation: Floor PlanDocument1 pageBorehole 6 Project Electrical Installation: Floor PlanbekeleNo ratings yet

- Low Power Low Offset Voltage Dual Comparators Az393Document9 pagesLow Power Low Offset Voltage Dual Comparators Az393David J. Pinto ApazaNo ratings yet

- Borehole 6 Project Electrical Installation: Floor PlanDocument1 pageBorehole 6 Project Electrical Installation: Floor PlanbekeleNo ratings yet

- Description Features: Ait Semiconductor IncDocument8 pagesDescription Features: Ait Semiconductor Incteranet tbtNo ratings yet

- H.5375s Salinity IndicatorDocument20 pagesH.5375s Salinity IndicatortosveNo ratings yet

- Service Manual Service Manual: TX-NR900/EDocument82 pagesService Manual Service Manual: TX-NR900/EfaroltekNo ratings yet

- FSP 2161Document12 pagesFSP 2161Bin WangNo ratings yet

- Amc7135 Led Driver DatasheetDocument6 pagesAmc7135 Led Driver DatasheetJose BenavidesNo ratings yet

- JBL EON15-G2: Technical ManualDocument34 pagesJBL EON15-G2: Technical ManualNorberto NetoNo ratings yet

- EL303X Series EL304X Series EL306X Series EL308X Series: FeaturesDocument14 pagesEL303X Series EL304X Series EL306X Series EL308X Series: FeaturesIsidro MendozaNo ratings yet

- VMR 13Document4 pagesVMR 13Kishore KNo ratings yet

- 500KV CT Ca550 3000a PDFDocument3 pages500KV CT Ca550 3000a PDFHafiz Bilal AhmadNo ratings yet

- Srs z1Document8 pagesSrs z1TrentungcaysoBombodealopNo ratings yet

- Installation Information Emg Models: SPC / RPC (Active/Passive Pickup Inputs)Document4 pagesInstallation Information Emg Models: SPC / RPC (Active/Passive Pickup Inputs)vinssonareyahoo.comNo ratings yet

- X-Series: Installation Information Emg Model: 89-XDocument4 pagesX-Series: Installation Information Emg Model: 89-XM. S.No ratings yet

- Ampli RFDocument1 pageAmpli RFEmmanuel AvegnonNo ratings yet

- Datasheet PC13Document11 pagesDatasheet PC13Cuong TranNo ratings yet

- Type Number Key: VFD 007 El 43 ADocument5 pagesType Number Key: VFD 007 El 43 AOsbaldoSolorzanoHerreraNo ratings yet

- AP8263Document10 pagesAP8263SamerNo ratings yet

- Installation Information Emg Model: 57 Pickup: SpecificationsDocument4 pagesInstallation Information Emg Model: 57 Pickup: SpecificationsaxemanarnabNo ratings yet

- Prueba de Descarga Baterias Dcbus - Sec-J - Att - J - 11 - App1Document4 pagesPrueba de Descarga Baterias Dcbus - Sec-J - Att - J - 11 - App1Victor Hugo RojasNo ratings yet

- Vertiv BatteryReplacement DS EN NA PM 02 208Document2 pagesVertiv BatteryReplacement DS EN NA PM 02 208Victor Hugo RojasNo ratings yet

- Alphacell XTV Battery: User GuideDocument34 pagesAlphacell XTV Battery: User GuideVictor Hugo RojasNo ratings yet

- Optimizer2008 2Document99 pagesOptimizer2008 2Victor Hugo RojasNo ratings yet

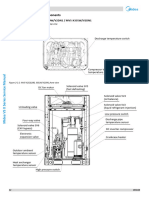

- Parte Interna de CondensadorasDocument2 pagesParte Interna de CondensadorasVictor Hugo RojasNo ratings yet

- PpmptecrefDocument5 pagesPpmptecrefVictor Hugo RojasNo ratings yet

- Ch08 Project SchedulingDocument51 pagesCh08 Project SchedulingTimothy Jones100% (1)

- Questionnaire On EthnocentrismDocument14 pagesQuestionnaire On Ethnocentrismkalpa vrikshaNo ratings yet

- Editing Packs I Maybe Will NeedDocument3 pagesEditing Packs I Maybe Will NeedMijo SusićNo ratings yet

- Lesson Worksheet: 6.1A MeanDocument7 pagesLesson Worksheet: 6.1A Meanwaiman fuNo ratings yet

- Opposition To Motion For Judgment On PleadingsDocument31 pagesOpposition To Motion For Judgment On PleadingsMark Jaffe100% (1)

- 3rd Term s1 Agricultural Science 1Document41 pages3rd Term s1 Agricultural Science 1Adelowo DanielNo ratings yet

- A Branding Effort of Walt DisneyDocument17 pagesA Branding Effort of Walt DisneyKanishk GuptaNo ratings yet

- TUF-2000M User Manual PDFDocument56 pagesTUF-2000M User Manual PDFreinaldoNo ratings yet

- 3500 System Datasheet: Bently Nevada Asset Condition MonitoringDocument11 pages3500 System Datasheet: Bently Nevada Asset Condition MonitoringRujisak MuangsongNo ratings yet

- Module 9 School AgeDocument16 pagesModule 9 School AgeMichelle FactoNo ratings yet

- Thermo King CG 2000Document155 pagesThermo King CG 2000Connie TaibaNo ratings yet

- Orphanage Project ProposalDocument3 pagesOrphanage Project ProposaldtimtimanNo ratings yet

- Guide To Manually Importing/Transferring Your Livery For FH4/FM7/FH3 PCDocument12 pagesGuide To Manually Importing/Transferring Your Livery For FH4/FM7/FH3 PCLennike SantosNo ratings yet

- SDS enDocument6 pagesSDS enAnup BajracharyaNo ratings yet

- Regulator With NRVDocument2 pagesRegulator With NRVBiswanath LenkaNo ratings yet

- Tugas Moneter CH 4 - Dewi Lucky Aryanti Sinaga F1119025Document4 pagesTugas Moneter CH 4 - Dewi Lucky Aryanti Sinaga F1119025Scream InungNo ratings yet

- Ashirvad SWR and SWR PLUS - Price List - 02nd April 2022Document14 pagesAshirvad SWR and SWR PLUS - Price List - 02nd April 2022Magnum ConstructionsNo ratings yet

- Westermo MRD 330-3xx & GreenBow IPSec VPN Client Software ConfigurationDocument12 pagesWestermo MRD 330-3xx & GreenBow IPSec VPN Client Software ConfigurationgreenbowNo ratings yet

- Maintenance Repair Overhaul: Safely To New Horizons Ensuring Your Aircraft Is Ready Whenever Duty CallsDocument10 pagesMaintenance Repair Overhaul: Safely To New Horizons Ensuring Your Aircraft Is Ready Whenever Duty CallsSuryaNo ratings yet

- Node MCU CarDocument4 pagesNode MCU CarYusuf MuhthiarsaNo ratings yet

- Teit Cbgs Dmbi Lab Manual FH 2015Document60 pagesTeit Cbgs Dmbi Lab Manual FH 2015Soumya PandeyNo ratings yet

- Robert Plank's Super SixDocument35 pagesRobert Plank's Super SixkoyworkzNo ratings yet

- Computation of Total Income: Zenit - A KDK Software Software ProductDocument2 pagesComputation of Total Income: Zenit - A KDK Software Software ProductKartik RajputNo ratings yet

- Chapter 9 CompensationDocument24 pagesChapter 9 CompensationSophie CheungNo ratings yet

- Management of Health Care Services For Ood Victims: The Case of The Shelter at Nakhon Pathom Rajabhat University Central ThailandDocument7 pagesManagement of Health Care Services For Ood Victims: The Case of The Shelter at Nakhon Pathom Rajabhat University Central ThailandAnonymous C06qenyfkmNo ratings yet

- Vol 17 No 3 and No 4 Fort Laramie and The Sioux War of 1876Document19 pagesVol 17 No 3 and No 4 Fort Laramie and The Sioux War of 1876Лазар СрећковићNo ratings yet

- 02 - STD - Bimetal Overload Relay - (2.07 - 2.08)Document2 pages02 - STD - Bimetal Overload Relay - (2.07 - 2.08)ThilinaNo ratings yet