Professional Documents

Culture Documents

Automatic Inspection of Artillery Shell Radiographs

Uploaded by

nanocardosoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Automatic Inspection of Artillery Shell Radiographs

Uploaded by

nanocardosoCopyright:

Available Formats

i c 1L1_ 1 ('(ri-,,6

AUTOMATIC INSPECTION

AUTOMATIC INSPECTION OF

OF ARTILLERY

ARTILLERY SHELL

SHELL RADIOGRAPHS*

J. J. Pearson,

Pearson, W. G.

G. Eppler,

Eppler, O.

O. Firschein, M.

M. H. Jacoby, J.

H. Jacoby, J. Keng, and S.

Keng, and S. M.

M. Jaffey

Jaffey /

Lockheed

Lockheed Palo

Palo Alto Research

Research Laboratory

Laboratory

Palo Alto, California

Palo California 94304

94304

Abstract

Techniques for

Techniques for the

the automatic defects, such

automatic detection of defects, such as cracks and

and cavities

cavities in

in radiographs

radiographs of

of artillery

artillery

shells,

shells, have

have been

been developed and demonstrated.

demonstrated. Because the defect

Because the subtle and

defect indications are subtle and ride

ride on

on an

an

intensity

intensity trend

trend that

that varies

varies greatly

greatly across the field,

across the field, it

it is

is necessary to precede the

the detection

detection algorithms

algorithms by

by

pre-processing

pre -processing steps

steps which

which "flatten"

"flatten" the

the trend

trend and

and emphasize the defects. The

emphasize the The algorithms are described and

examples

examples of

of their

their performance are are shown.

shown.

Introduction

A set

set of algorithms has been

been developed and

and demonstrated

demonstrated for

for the

the automatic

automatic evaluation

evaluation of

of radiographs

radiographs ofof

artillery shells. The techniques lead

artillery shells. lead to

to accept

accept/reject

/reject decisions

decisions based on the presence ofof certain

certain specified

specified

classes

classes of defects the high explosive (HE)

defects in the (HE) region of the

the shell.

shell. Among the

the defect

defect classes

classes are

are small

small and

and

large

large cavities,

cavities, cracks,

cracks, pipes,

pipes, annular

annular rings, foreign inclusions,

rings, foreign inclusions, regions and base

regions of high porosity, and base separa-

separa-

tions. Such inspections

inspections are

are currently performed by human inspectors.

inspectors. The defect indications havehave low

low

contrast,

contrast, against

against aa high contrast background, and some

contrast background, some of them

them have

have dimensions comparable

comparable to

to the

the grain

grain size

size

of the film.

film.

A previous

previous paper reported successful

successful detection

detection of

of aa restricted

restricted set

set of

of these

these defects

defects using

using images

images scanned

scanned

with a microdensitometer.'l' the previous and

microdensitometer.(1) Both the and present

present investigations

investigations were

were performed

performed using

using Lockheed's

Lockheed's

general

general purpose

purpose interactive image processing system.

interactive image system.

The equipment

equipment configuration proposed for

for implementing

implementing the

the techniques

techniques at

at the

the required

required speeds

speeds isis shown

shown in

in

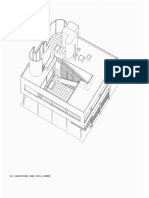

Fig. 1. The

Fig. 1. the diagram

The limiting blocks in the diagram are the

the scanner

scanner-integrator

-integrator for

for image

image quality,

quality, and

and the

the array

array

for computational speed.

processor for speed. Experiments indicate

indicate that

that use of

of aa high

high resolution

resolution 1.5

1.5 inch

inch vidicon

vidicon

camera,

camera, followed

followed by logarithmic digitization and nine frames

by logarithmic frames of digital integration,

integration, can

can reduce

reduce the

the entire

entire TV

TV

contribution to less

less than

than 0.006D.

0.006D. Thus, the

the system

system can

can provide

provide sufficient

sufficient image

image quality

quality for

for successful

successful oper-

oper-

ation of the

the detection algorithms.

algorithms.

REFRESH

LIGHT TV i DIGITIZER/

MEMORY NO. 1

TABLE SCANNER INTEGRATOR

140 K

DATA HOST COMPUTER ARRAY PROCESSOR

TERMINAL

DATA PROGRAM

DATA CORE

CORE CORE

PROGRAM CORE

1

REFRESH

DISC

MEMORY NO. 2 DISPLAY

128 K

Fig.

Fig. 11 Diagram of

Block Diagram of Proposed

Proposed System

System for

for Real

Real-Time

-Time Implementation of

of Automatic

Automatic Inspection

Inspection Algorithms

Algorithms

The

The processing

processing algorithms into four

algorithms can be divided into four major groups,

groups, (1)

(1) shell positioning and and boundary

boundary defin-

defin-

ition, (2)

ition, (2) detection and quantitative measurement,

measurement, (3)

(3) major defect detection, and and (4) basebase separation

detection. Two of the

the defect types,

types, base

base separation

separation and

and major

major defects

defects are

are singled

singled out

out for

for special

special treatment

treatment

because

because of different processing requirements.

requirements. For all processing except Base Separation

Separation Detection,

Detection, the

the

horizontal

horizontal and

and vertical distance between

between pixels

pixels was

was 500

500 microns

microns (i.e.,

(i.e., approximately

approximately5050pixels

pixels/inch).

/inch). Fig.

Fig. 2

shows

shows aa typical

typical digital

digital image

image which

which occupies

occupies a region approximately 175175 x 375

375 pixels. In the case of of Base

Base

Separation

Separation Detection,

Detection, higher

higher resolution is

is required and a pixel spacing of 125

125 microns (i.e.,

(i.e., approximately

approximately

200 pixels

pixels/inch)

/inch) was

was used.

*- This

This work was

was carried out

out for the U.S.

U.S. Army Advanced Research and Development

Development Command,

Command, Dover,

Dover, New

New Jersey,

Jersey,

Contract DAAK10-78-C-0010.

Contract DAAK10 -78 -C -0010.

214 /I SPIE

214 SPIE Vol.

Vol. 155

155 Image

Image Understanding

Understanding Systems

Systems &

8- Industrial

Industrial Applications

Applications (19781

(1978)

Downloaded From: http://proceedings.spiedigitallibrary.org/ on 10/13/2015 Terms of Use: http://spiedigitallibrary.org/ss/TermsOfUse.aspx

AUTOMATIC INSPECTION

AUTOMATIC INSPECTION OF

OF ARTILLERY

ARTILLERY SHELL

SHELL RADIOGRAPHS

RADIOGRAPHS

Definition

Shell Positioning and Boundary Definition

In

In an

an operational system, the radiograph will be

operational system, be posi-

tioned

tioned inin front

front of

of the

the television

television camera

camera with small but

with small but

unknown translational

translational and angular misalignments.

misalignments. It is is

necessary toto determine these

these misalignments and pass

pass them

them

to

to devices/systems

devices /systems which

which bring

bring the

the image accurate

image into accurate

alignment. This can be accomplished by

alignment. by mechanically

mechanically

the film

moving the film or

or (as

(as required

required by

by high-

high-throughput sys-

throughput sys-

tems) by

tems) by electronically moving thethe scan

scan on the vidicon

camera tube.

tube. Once

Once the image has

the image has been aligned correctly,

correctly,

it

it is

is necessary

necessary to

to determine the boundary

determine the boundary between the

the

charge area and thethe shell

shell casing.

casing. This boundary is is used

to

to guide

guide and

and limit certain of of the

the processing

processing operations.

operations.

Orientation and

Orientation and Position Determination

A line

line near the

the bottom of the

the shell

shell is

is read

read into

into the

the

from the

computer from the display

display memory.

memory. The intensity

intensity values

values

along such a line

line increase

increase from

from the

the center

center outward

outward to

to the

the

metal casing where the

metal casing the radiograph

radiograph has

has minimum

minimum optical

optical

density, see

density, see Fig.

Fig. 3.

3. The left

left and

and right

right charge

charge/casing

/casing

boundaries are detected by searching

searching from

from the

the (approxi-

(approxi-

mate)

mate) center outward toto the

the first

first local

local maximum. The

process is

process is repeated to

to find

find the

the left

left and

and right

right boundaries

boundaries

Fig.

Fig. 2 2 Example of Unprocessed Artillery Shell

Shell for aa line

for line near the

the top

top of

of the

the shell.

shell. The midpoints

Radiograph. between boundaries

boundaries are determined forfor the

the upper and

and lower

lower

Fig. 33

Fig. Intensity Values Along Horizontal Fig. 44 Intensity Values Along Vertical Cursor

Cursor

Cursor in Fig.

Fig. 2.

2. Fig. 2.

in Fig. 2.

lines

lines and

and the

the average

average of

of the

the two

two is

is used

used as

as the

the estimate

estimate of

of horizontal

horizontal offset.

offset. The angular misalignment is

is

computed by determining

computed determining the angle of the

the line

line between

between the

the upper and lower

lower midpoints.

midpoints,

Charge Region

Charge Region Boundary Determination

The left and

The left and right boundaries are found

right boundaries found for

for all lines

lines in

in much the

the same

same way as described previously.

previously. One

important

important difference

difference isis that

that it

it is

is not

not necessary to start

necessary to the boundary

start the boundary search in the

search in the center;

center; instead,

instead, only a

narrow strip

narrow strip around the boundary for

around the for the

the adjacent line

line must be searched.

searched. A second

second difference is

is that

that in

in the

the

curved base

base region the

the search direction must be changed from

from horizontal

horizontal to

to vertical;

vertical; this

this is

is necessary

necessary to

to

the search as

make the as nearly normal to

to the

the boundary

boundary as possible.

possible.

Detection and Quantitative Measurement

This function is

This function is conceptually identical

identical to the

the one

one previously reported.

reported. The algorithms take

take as

as input

input aa

digital image at

digital image at 500

500 micron pixel spacing and produce as output

output a printed report giving quantitative

quantitative

SP/E Vol.

SPIE Vol.155155

Image Understanding

/mage Systems &

Understanding industrial&Applications

Systems Industrial (1978)

Applications

/ 215 (1978)

Downloaded From: http://proceedings.spiedigitallibrary.org/ on 10/13/2015 Terms of Use: http://spiedigitallibrary.org/ss/TermsOfUse.aspx

PEARSON, EPPLER, FIRSCHEIN,

PEARSON, EPPLER, FIRSCHEIN, JACOBY, KENG, JAFFEY

JACOBY, KENG,

information

information on

on all

all flaws

flaws within

within the

the charge

charge region (except for

region (except for base

base separation).

separation).

Field

Field Flattening

Flattenin

Large

Large density

density variations

variations occur within the charge region due to to shell

shell geometry (i.e.,

(i.e., diameter,

diameter, casing

casing

thickness,

thickness, and

and compression band).

band). Figore

Figure 33 shows

shows the intensity variation

the intensity variation along

along the row designated by by the

the

horizontal

horizontal cursor

cursor inin Fig.

Fig. 2.

2. Similarly,

Similarly, Fig.

Fig. 44 shows

shows the

the intensity

intensity variation

variation along the

the column designated by

the

the vertical

vertical cursor Fig. 2.

cursor in Fig. 2. These systematic intensity

intensity variations are

are extremely

extremely large

large compared

compared with

with

intensity

intensity changes

changes caused

caused by

by flaws

flaws and

and therefore

therefore must

must be

be removed before the

removed before the flaws

flaws can be

be detected.

detected. Comparison

Figs. 33 and

of Figs. and 44 shows that the horizontal variation is

shows that is much better behaved

behaved (in

(in the

the sense

sense of

of being

being approxi-

approxi-

mated by a low

low-order

-order polynomial) the vertical

polynomial) than the vertical variation.

variation. For

For this

this reason the field

field flattening

flattening algorithm

algorithm

takes

takes its

its input

input from

from refresh

refresh memory

memory one

one horizontal

horizontal row

row at

at aa time, fits the

time, fits the intensity variation in in the

the charge

region with

region with aa polynomial,

polynomial, subtracts thethe estimated intensity

intensity from

from the

the actual intensity,

intensity, and

and writes

writes the

the differ-

differ-

ence (i.e., the

ence (i.e., field flattened image)

the field image) back out to

to refresh memory.

memory.

great deal of effort has

A great has been

been devoted

devoted toto improving

improving field

field flattening

flattening techniques

techniques because

because residual

residual trends

trends

which

which remain

remain after

after field

field flattening determine the smallest flaws flaws which can be

be detected.

detected. The problem is is to

to

find

find aa method

method which

which fits

fits the

the systematic

systematic variation (which is

variation (which is particularly

particularly difficult due to to steep

steep slope

slope near thethe

shell casing)

shell casing) without

without following (and(and thereby subtracting out) out) the

the variation caused

caused by

by the

the flaws.

flaws. The follow-

follow-

ing techniques

ing techniques for

for fitting the horizontal intensity

fitting the intensity variation were investigated:

investigated: Single

Single-strip second-order

-strip second -order

polynomial; three

three-strip

-strip second-order

second -order polynomial; unbiased moving-

polynomial; unbiased moving-window unbiased moving-

window average; unbiased moving-window

window

average with

with wild

wild-point

-point rejection; single

single-strip fourth-order

-strip fourth -order polynomial three-strip

polynomial and three fourth-order

-strip fourth -order polynom-

polynom-

ial. The which gives

The technique which gives the

the best

best result

result isis the

the fourth

fourth-order operating separately

-order polynomial operating separately on

on strips

strips

first 25

from the first 25%,

%, middle

middle 50%,

50 %,and

and last

last 25%

25% of

of the

the pixels

pixels within

within aa single line.

line.

of the

The result of the field

field flattening

flattening operation

operation is

is shown

shown in

in Figs.

Figs. 5 5-7. Fig. 5,

-7. In Fig. 5, the

the estimated

estimated systematic

systematic

trend has

trend has been

been subtracted

subtracted and the difference

and the factor of

difference multiplied by a factor of eight;

eight; the

the flaws

flaws are

are quite

quite apparent

apparent

in this

in this figure

figure while they could not be observed at all in the input

while they input image,

image, Fig.

Fig. 2.

2. Fig.

Fig. 66 gives the

the column

average

average for 16 successive

for 16 successive rows; shows that the

rows; it shows the residual trend is is less

less than

than +2 counts

counts referred

referred toto the

the input

input

image which

image which represents approximately

approximately +0.007D

+0.007D film-

film-density

density oror +0.03 flaw thickness.

+0.03 inch of flaw thickness. Fig.

Fig. 77 gives the

the

standard

standard deviation

deviation of

of the

the noise for the

noise for the same 16

16 rows;

rows; it

it shows that

that the

the noise varies across

across the

the shell

shell reaching

reaching

aa maximum

maximum of

of 33 counts (i.e., 0.O1D

counts (i.e., 0.0ID or 0.05

0.05 inch)

inch) in the

the center.

center. This noise is is the

the sum

sum of

of aa constant

constant component

component

due

due to

to film granularity

granularity and

and aa component due to television electronics which varies with with log

log amp

amp gain

gain (there-

(there-

fore is

fore is maximum

maximum at

at the

the center

center of the

the shell).

shell).

Low-Pass

Low -Pass Filtering

Filtering

Figures 88-10

-10 show

show that

that noise

noise caused

caused by

by film

film granularity

granularity

and television electronics is

and is large

large compared

compared with

with field

field

flattening residuals.

flattening residuals. This noise noise is

is characterized

characterized byby

frequency (i.e.,

high spatial frequency (i.e., only

only aa small

small amount

amount of

of

correlation between adjacent pixels) and and therefore

therefore can

can

be reduced

be reduced by

by spatial

spatial low low-pass filtering. However, care

-pass filtering. care

be taken

must be taken toto choose

choose filter

filter parameters

parameters which

which reduce

reduce

the noise

the noise as

as much as possible without significantly

significantly

reducing the

reducing the amplitude of variations caused caused by

by flaws.

flaws. The

chosen is

filter chosen is aa 33 xx 3 3-pixel moving-window

-pixel moving -window average. The The

reasons for

reasons for this

this choice

choice are:are:

moving-window

The moving - windowaverage

average can

can be

be computed faster than

computed faster than

other more general

other general filter

filter functions.

functions.

The 33 x 33-pixel

-pixel size

size is

is compatible

compatible with

with the

the television

resolution; the

resolution; the to

la diameter

diameter ofof the

the television

television image

image

spread function

function isis 2.5

2.5 pixels.

pixels.

The 33 x 33-pixel

-pixel size

size represents

represents approximately 1/16 x

approximately 1/16

1/16 inch

1/16 inch referred the radiograph and therefore

referred to the therefore does

does

filter out

not filter out defects

defects which

which are

are potential

potential flaws.

flaws.

The 33 xx 33-pixel low-pass

-pixel low -pass filter

filter reduces random

reduces the random

noise byby (almost)

(almost) aa factor

factor ofof three

three and

and makes

makes it

it less

less

flattening residuals.

than field flattening residuals.

Fig. 55

Fig. of Field

Result of Field Flattening

Flattening with

witha aThree

Three-

-

Strip, Fourth

Strip, Fourth-Order Polynomial.

-Order Polynomial.

result of

The result of low

low-pass

-pass filtering

filtering is

is given

given in

in Fig.

Fig. 8,

8, which that the

which shows that the flaws

flaws are

are still

still clearly

clearly visible

visible and

and

the noise

the is markedly reduced.

noise is reduced. The rectangular

rectangular grid

grid pattern

pattern was superimposed

superimposed to

to aid

aid the

the discussion

discussion inin the

the

section.

next section.

Threshold Computation

Pixels within cracks,

cracks, cavities, and

and porosities

porosities have

have intensity

intensity values

values which

which are

are lower

lower than

than "normal"

"normal" and

and

within foreign

pixels within foreign inclusions

inclusions have

have intensity

intensity values

values which

whichare

are higher

higherthan

than"normal

"normal".

". However the the problem

problem

216 //SPIE

216 SPIEVol.Vol.

155 image Understanding

155 Image Systems & Systems

Understanding Industrial Applications

& Industrial(1978)Applications (1978)

Downloaded From: http://proceedings.spiedigitallibrary.org/ on 10/13/2015 Terms of Use: http://spiedigitallibrary.org/ss/TermsOfUse.aspx

OF ARTILLERY

INSPECTION OF

AUTOMATIC INSPECTION RADIOGRAPHS

SHELL RADIOGRAPHS

ARTILLERY SHELL

"Vv,

Fig. 6 6

Fig. Field

Residual Trend Remaining After Field Fig. 77

Fig. Remaining

Standard Deviation of Noise Remaining

Column. Average

Flattening; Computed as the Column

Flattening; Flattening; Computed

Field Flattening;

After Field 16

from 16

Computed from

16 Rows

of 16 Cursor

Rows Centered on the Horizontal Cursor Centered, on the

Rows Centered

Rows Cursor

the Horizontal Cursor

2.

in Fig. 2. 2.

Fig. 2.

in Fig.

complicated by the

is complicated

is fact that

the fact "normal" values

these "normal"

that these (outside

values (outside

which a pixel is

of which as a defect)

is classified as throughout

vary throughout

defect) vary

region. The principal cause of

the charge region. of this threshold

this threshold

is the

variation is the noise

the spatial variation of the in

shown in

noise shown

7.

Fig. 7.

In order to compute these

to compute spatially-dependent

these spatially- thresholds,

dependent thresholds,

region is

the charge region divided into

is divided 24 x x2525-pixel

into 24 -pixel areas as

areas as

shown by the grid in in Fig. 8. Within each

Fig. 8. each window, the histo-

the histo-

the 600 intensity values

gram of the values isis computed and used to

used to

determine intensity value which is greater than

that intensity

determine that the

than the

intensity of 10% of the

intensity pixels in the window;

the pixels window; Fig. shows

Fig. 99 shows

the table

the values corresponding to the grid superimposed

table of values

8. If it

Fig. 8.

on Fig. is assumed

it is the window

that the

assumed that defect-

windowisis inina adefect -

free area, and

free area, and the is normally distributed,

noise is

the noise distributed, then this

then this

intensity represents

intensity 1.30 value of the noise

the 1.3a

represents the noise, in image

in. the image

-pass filtering. This value is

low-pass

before low

before is approximately 3.2a3.2CT

for the noise after low

for filtering so

-pass filtering

low-pass that fewer

so that than 0.1%

fewer than 0.1%

the noise

of the pixels are

noise pixels are less this threshold value

less than this (i.e.,

value (i.e.,

cause

cause false alarms).

two drawbacks: (1)

has two

The approach described above has Comput-

(1) Comput-

ing histograms is

ing is a relatively time-consuming

relatively time operatian, and

-consuming operation, and

The computed

( 2 ) The

(2) threshoId is

computed threshold lowered in

(e.g., lowered

is affected (e.g., the

in the

case of cavities)

case the presence of flaws

cavities) by the in the

flaws in window.

the window.

Fig. 8 Result of Low -Pass Filtering

Low-Pass Using a

Filtering Using, in an

these problems might be overcome in

Both of these operational

an operational

3 x 33-Pixel Moving- Window Average.

-Pixel Moving-Window Average. inspection system by

inspection by computing the threshold table

computing the given by

table given by

Superimposed Grid Shows 24

Grid Shows 25-Pixel

24 xx 25 -Pixel once and

Fig. 99 once

Fig. for all

and for all from the a shell

the radiograph of a known

shell known

Areas Used to Position --

to Compute Position -free. Such an approach will work even though

flaw-free.

be flaw

to be the

though the

Dependent Threshold. radiographs vary

radiographs vary (due inevitable changes

to inevitable

(due to changes in film and

developer, etc.)

developer, because the

etc,) because major trend

the major is still

trend is removed by the field flattening

still removed operation and

flattening operation noise

the noise

and the

source variation

source is repeatable.

variation is

in Fig.

The table in that the

shows that

Fig. 99 shows derived threshold is set approximately

automatically-derived

the automatically- counts below

-4 counts

approximately 22-4 below

the in the

trend in

the trend image. This indicates

the original image. that the

indicates that system can

the system film-density

detect film

can detect variations of

-density variations 0.007D

of 0.007D

0.014D caused

to 0.014D

to flaws in

by flaws

caused by in the range 0.03

the range 0.07 inch deep.

0.03 to 0.07 deep.

SP /EVol.

SPIE Vol. 155

155/mage

/mageUnderstanding

UnderstandingSystems Industrial Applications

Systems&& Industrial 11978)/ / 217

Applications (1978} 217

Downloaded From: http://proceedings.spiedigitallibrary.org/ on 10/13/2015 Terms of Use: http://spiedigitallibrary.org/ss/TermsOfUse.aspx

PEARSON, EPPLER, FIRSCHEIN,

PEARSON, EPPLER, JACOBY, KENG,

FIRSCHEIN, JACOBY, KENG, JAFFEY

JAFFEY

*

0 243 241 238 242 244 0

0 240 237 233 240 239 251

249 241 240 237 242 240 248

245 241 239 238 242 242 248

240 238 241 239 241 246 246

241 241 239 240 241 243 247

242 240 237 232 239 242 243

241 238 233 228 238 234 245

238 238 226 226 230 239 242

241

241 236 224 218 226 238 242

237 233 221 219 221 235 243

238 235

235 224 223 229 238 244

238 237 229 224 230 240 243

240 237 229 222 227 238 241

239 236 226 224 228 236 242

237 238 233 225 234 240 243

Fig.

Fig. 9 Position-Dependent

Position Computed

Threshold Values Computed

-Dependent Threshold Fig. 10

Fig. 10 Pixels

Result of Marking Anomalous Pixels

for the Corresponding

for Corresponding 24 25-Pixel

24 xx 25 -Pixel Areas

Areas Shown and Eliminating all Pixels Outside

all Pixels Outside

in Fig.

in 8, These Values are

Fig. 8. Deter-

Derived by Deter-

are Derived Region,

the Charge Region.

mining that Intensity Which Is Greater Than 10%

mining that 10%

of the Pixels in Window.

the Window.

in the

Thresholding and

Thresholding, Masking Anomalies

and Ma.sking

This algorithm takes

This takes as the filtered,

inputs the

its inputs

as its fieId-flattened

filtered, field -flattened image shown in Fig.

shown in and the

Fig. 88 and position--

the position

dependent threshold values

dependent threshold values given by Fig. 9. It

Fig. 9. produces as

It produces as output image, Fig.

output an image, in which

10, in

Fig. 10, all pixels

which all hav-

pixels hav-

intensity less

ing intensity

ing than the

less than lower threshold

the lower marked with

are marked

threshold are value 501

the value

with the those above the

501 and those threshold

the upper threshold

given the value 502. The Defect Processing System

are given,

are these marks to

System uses these distinguish between

to distinguish foreign

"between foreign

inclusions and

inclusions and cavities,

cavities, etc. having values

Pixels having

etc. Pixels (i.e., in

values between these two thresholds (i.e., "normal" range)

the "normal"

in the range)

zero.

are given the value zero.

are

Proces s ing

De fe ct Processing

Defect

The purpose

The of this

purpose of this final is to associate defect pixels

final step is into aa defect

pixels into group based

defect group on aa pre-

based on pre-specifled

specified

distancecriterion;

inter -pixeldistance

inter-pixel measure the

criterion; measure the defect width, orientation, area, and

length, width,

defect length, location;

and location;

identify type of

the type

identify the and test whether it passes the

defect; and

of defect; for that

the requirements for class of

that class defect. From

of defect.

calculations, the

these calculations,

these the report of the

report of inspection results

the inspection is generated.

results is generated.

Ma.lor

Major Defect Detection

One problem,

One which can occur in the case of very wide flaws

problem which is that

flaws is that the flattener mistakes

field flattener

the, field the flaw

mistakes the flaw

for the

for removes it.

the intensity trend and removes field flattener

fact that the field

it. The fact is blind

flattener is to horizontal

"blind to horizontal flaws can

flaws can

Fig. 5,

inferred from Fig.

be inferred band has

the compression band

5, which shows that the has been removed entirely. For

removed entirely. this reason

For this

another set of operations,

another set operations, referred to Detection, is

Defect Detection,

to as Major Defect necessary to

is necessary find horizontal

to find such

flaws such

horizontal flaws

transverse cracks

as transverse

as rings.

cracks and annular rings.

Masking

Unsharp Masking

The this set

between this

The primary difference 'between operations and

of operations

set of and the previously is

ones described previously

the ones is the substitution

the substitution

of a spatial high filter for

-pass filter

high-pass for the flattener. The

the field flattener. The high -pass filter

high-pass (also known

filter (also masking)

known as unsharp masking)

develops an output

develops output image in which the

in which output intensity

the output intensity isis the between the

difference 'between

the difference input intensity

the input (at

intensity (at

pixel) and

corresponding pixel)

the corresponding

the theaverage

and the intensitiesinina a

inputintensities

averageofofinput window WW wide and H high. For the

window the

results which

results follow, the values W == 1,

which follow, 1, HH == 7, used. This has

were used.

7, were has the effect of differentiating in

of differentiating the

in the

vertical direction so that the process is sensitive to

is sensitive horizontal flaws;

to horizontal flaws; Fig. 13 shows

Fig. 13 the result

shows the result for large

for large

that it

"be noted that

should, be

transverse cracks. It should it isis only the outlines

only the (rather than

outlines (rather the included

than the which

areas) which

included areas)

are detected..

are detected. This is because the

is because differentiation process

the differentiation process is blind, toto steady

is blind steady-state values. Therefore, this

-state values. this

approach is measuring and

is not capable of measuring making decisions

/or making

and/or based on flaw area. Another drawback

decisions based drawback of this

of this

approach is the output of

is that the the high

of the -pass filter

high-pass across the

moving across

filter moving the boundary of horizontal defect

wide horizontal

of aa wide defect isis

aa pair of pulses

pair of with the

pulses with same amplitude

the same amplitude but opposite polarity. This

opposite polarity. This makes it impossible to

makes it to determine whether

is a crack or aa foreign

the flaw is

the inclusion.

foreign inclusion.

218

218 // SPIE

SPIE Vol.

Vol. 155

155 Image

/mage Understanding

Understanding Systems

Systems &

& Industrial

Industrial Applications

Applications (1978)

(19781

Downloaded From: http://proceedings.spiedigitallibrary.org/ on 10/13/2015 Terms of Use: http://spiedigitallibrary.org/ss/TermsOfUse.aspx

AUTOMATIC INSPECTION

AUTOMATIC INSPECTION OF

OF ARTILLERY

ARTILLERY SHELL

SHELL RADIOGRAPHS

RADIOGRAPHS

Figures

Figures 12

12 and 13 show

and 13 show the

the trend

trend and

and noise, respectively,

noise, respectively,

for

for the

the same

same 1616 rows

rows that

that were

were used for Figs.

used for Figs. 6 6 and 7.

7. Like

the field-flattener,

the field -flattener, the

the high-pass

high -pass filter

filter gain

gain was set to

was set to

eight. Comparison of of Figs.

Figs. 66 and

and 12

12 shows

shows that

that the

the high

high--

pass filter

pass filter is

is more effective in in eliminating thethe trend

trend than

than

the

the polynomial field-f

polynomial field lattener, and

-flattener, and Figs.

Figs. 77 and 13 show the

and 13 the

random noise almost identical.

noise outputs are almost identical.

Low-Pass

Low -Pass Filter

explained previously,

As explained previously, the

the random

random noise

noise component

component can can

be

be reduced by a spatial

spatial low

low-pass

-pass filter.

filter. Moving window

with window

averages with window sizes

sizesofof3 3x x3 3-pixel and 9 9 x x1 1-pixel

-pixel and -pixel

were investigated.

investigated. The wide, shortshort window

window was expected

expected to to

enhance horizontal flaws

enhance flaws but its

its performance was not not better

better

than

than the

the 33 x 3-pixel

3 -pixelwindow;

window; therefore

therefore thethe square

square window

window

was used.

was used.

Thre shpj d Coinputat

Threshold ion

Computation

Experiments

Experiments were

were conducted in which it

it was determined

determined

that

that the

the use

use of

of aa spatially

spatially variable

variable threshold (computed as

threshold (computed as

improve the

described previously did not improve the performance

performance for

for

rings or transverse cracks.

either annular rings cracks. Therefore,

Therefore, a

constant threshold value of 235 was used.

constant used.

Fig. 11

Fig. 11 Result of

of Spatial

Spatial High

High-Pass

-Pass Filter

(Unsharp Masking)

*vr3.3.1,3..irv4trA,

E

Fig.

Fig. 12 Trend Remaining

Residual Trend Remaining After

After High

High-Pass

-Pass Fig. 13

Fig. 13 of Noise Remaining

Standard Deviation of Remaining

Filtering;

Filtering; Computed

Computed As the Column

As the After Field Flattening;

Flattening; Computed

Computed from

from

Average of

of 16

16 Rows

Rows in

in Flaw

Flaw-Free

-Free Region. 16 Rows in

16 in Flaw

Flaw-Free Region.

-Free Region.

Thresholding and Masking Anomalies

Thresholding

operation is

This operation is exactly the same

same as described previously;

previously; the

the result shown

shown in

in Fig.

Fig. 14.

14.

Trim to

to Charge Region

All pixels

pixels outside the charge

outside the charge area are eliminated;

eliminated; this

this is

is accomplished

accomplished using the

the previously

previously computed

computed left

left

and right boundaries. In In addition, small horizontal strips at

addition, small at the

the top and bottom of the

the rotating ringring are

are

eliminated. This isis necessary

necessary since

since the

the high

high-pass

-pass filter (unlike the

filter (unlike the field

field-flattener)

-flattener) picks

picks upup these

these transi-

transi-

tions as

as can

can be seen

seen in

in Fig.

Fig. 14.

14. The vertical locations

locations of

of these

these strips

strips is

is determined

determined as

as aa fixed

fixed distance

distance

top-center

from the top- center of

of the

the shell

shell in

in the

the base region. The result of all these trimming

trimming operations

operations is is shown

shown

15.

in Fig. 15.

SPIE Vol.

SPIE Vol. 155 Image Understanding

155 /mage Understanding Systems

Systems8-& Industrial

Industrial Applications

Applications (1978)

(1978) // 219

219

Downloaded From: http://proceedings.spiedigitallibrary.org/ on 10/13/2015 Terms of Use: http://spiedigitallibrary.org/ss/TermsOfUse.aspx

PEARSON, EPPLER,

PEARSON, JACOBY, KENG, JAFFEY

FIRSCHEIN, JACOBY,

EPPLER, FIRSCHEIN, JAFFEY

Proce s s ing

De £ec t Processing

Defect

associated into

are associated

The anomalous pixels are "based

groups based

into groups

their distance to

OD. their

on other pixels

to other in that

pixels in group. Groups

that group.

having more

having more than the prescribed

than the (e.g., 30

area (e.g.,

prescribed area pixels)

30 pixels)

flaws with the

reported as flaws

are reported result shown

the result in Fig.

shown in 16.

Fig. 16.

further to

flaws are processed further

These flaws their

determine their

to determine

length, width

location, length,

location, angle. These descriptors

and angle.

width and

in a series of

are used in Boolean logic

of Boolean (based

operations (based

logic operations

the inspection

on the specifications) to

inspection specifications) whether

determine whether

to determine

the shell should be

the shell rejected.

be rejected.

Base Detection

Base Separation Detection

Base separation is type of defect

Is a type occurs when

which occurs

defect which

separates from the metal casing in

explosive separates

the explosive

the the

in the

'base

base region. This subtle flaw flaw must be detected the

in the

detected in

trend caused

intensity trend

presence of a dominant intensity the

by the

caused by

explosive /metal transition

explosive/metal and random

transition and noise caused

random noise caused by

granularity and

film granularity electronics. The detec-

and television electronics.

tion is the fact

is complicated by the that the

fact that flaw is

the flaw quite

is quite

narrow, being on the

narrow, the order of inch wide. For

0.01 inch

of 0.01 For this

reason, a magnified television

reason, image is

television image in which

used in

is used

the pixel spacing is

the 125|im (i.e.,

is 125µm pixels/inch).

200 pixels/inch).

(i.e., 200

14

Fig. 14

Fig. Pixels

Result of Masking Anomolous Pixels

Fixed Threshold Values

Using Fixed

15

Fig. 15 Result of Pixels at

Eliminating Pixels

of Eliminating the

at the 16

Fig. 16

Fig. Flaws in Fig.

Flaws 11 Identified

Fig. 11 the

Identified by the

of the

Bottom of

Top and Bottom Band

Rotating Band

the Rotating Defect Processing System. The Associa-

Processing System.

and Outside the Region.

Charge Region.

the Charge tion Distance

tion Pixels and

Distance Used Was +5 Pixels

Was 30

the Required Area Was

the Pixels.

30 Pixels.

Determine Base Location

Determine Base Location

first step

The first is to determine the

step is location of

the precise location the metal case

of the in the

case in region. This is

base region.

the base accom-

is accom-

each separate

intensity values within each

plished by examining the intensity and taking

column and

separate column the boundary

as the

taking as estimate

boundary estimate

that pixel

that pixel having the largest derivative. These

largest derivative. boundary estimates

These boundary are refined

estimates are by fitting

refined by themwith

fitting them least-

witha aleast -

squares, second -order polynomla1.

second-order polynomial.

Compute Average In Layers Along Base

Compute

reduce the film

In order to reduce

In television system

film and television noise, it

system noise, is necessary

it is to filter

necessary to data by

the data

filter the by an averag-

an averag-

the signal

ing operation. To enhance the

ing caused by

signal caused the flaw,

by the this averaging

flaw, this should be

averaging should carried out

be carried along the

out along flaw.

the flaw.

220 /SPIE

220 SPIE 155 Image

Vol.Vol. Understanding

155 Image Understanding Industrial Applications

Systems 8- Systems & Industrial (1978)Applications (1.978)

Downloaded From: http://proceedings.spiedigitallibrary.org/ on 10/13/2015 Terms of Use: http://spiedigitallibrary.org/ss/TermsOfUse.aspx

AUTOMATIC INSPECTION

AUTOMATIC OF ARTILLERY

INSPECTION OF RADIOGRAPHS

SHELL RADIOGRAPHS

ARTILLERY SHELL

BOUNDARY OF

BOUNDARY SHELL CASING

OF SHELL

350 USED IN

USED IT

SECOND-DEC REEFFIT

IN SECOND-DEGREE

300 SECOND - DEGREE POLYNOM I AL FIT,

z

250

W 200

á POINTS NOT

150 USED IN FIT y°

,

o 10 20

20 30

30 40'

10 50

SD

ROWS FROM

ROWS BOUNDARY

FROM CASING BOUNDARY

Fig. 17

Fig. 17 Removing the

Result of Removing

Result Trend from

the Trend from Fig.

Fig. 18 Perpendicular

Profile Perpendicular

Average Intensity Profile

the Base Region. The

Intensities in the

Intensities Case-HE

to Case Boundary Used

-HE Boundary in Detection

Used in

Sector

the Sector

is Computed as the

Trend is of Base Separation

for Each Layer Parallel to

Average for the

to the

Base. The Difference HasHas Been Multi-

Been Multi-

12 to

Factor of 12

plied by a Factor Enhance

to Enhance

the Contrast.

the

In the

In the case of base

case of this direction

separation, this

base separation, direction is known because

is known because the follows the

the flaw follows base boundary;

the base there-

boundary; there-

fore, the

fore, the intensity isis averaged within

within "layers" parallel to

"layers" parallel the boundary

to the determined from

boundary determined second-degree

thesecond

fromthe -degree

This averaging is

polynomial. This is carried out

out over a "sector" comparable to

having aa width comparable

"sector" having the length

to the typical

of typical

length of

base f1aws. This process is

base separation flaws. is conceptually simi1ar to

coneeptua11y similar moving-window

(curved) moving-

to aa (curved) window average height

whose height

average whose

is

is 1 pixel and

1 pixel and whose width is is the sector width;

the sector this sense

in this

width; in the operation

sense the analogoustotothe

operation isis analogous low-pass

thelow -pass

filtering operations used in

filtering the main

in, the portion of

main portion shell. The result of the

the shell.

of the the filtering is shown

filtering is in Fig.

shown in 17

Fig. 17

and, the

and solid curve

the solid in Fig.

curve in 18.

Fig, 18.

Compute Deviation

Compute Smoothed Curve

Deviation From Smoothed Curve

The measured intensities are

average intensities

measured average least-squares,,

usinga aleast-

fittedusing

arefitted second-degree

squares, second polynomial. Points in

-degree polynomial.

the region where

the region are not used in

base separation can occur are

where base, in deriving the this

the, polynomial approximation; this

prevents from influencing

prevents flaws from fit. The resulting curve for an image

the fit.

influencing the separation is

'base separation

image, with base as

shown, as

is shown

the dashed,

the dashed line 18. A significant

Fig. 18.

in Fig.

line in significant deviation

deviation between

'between the actual, and

the actual the fitted

and the data signals

fitted data the

signals the

separation.

presence of a base separation.

Thresholding

The threshold

The threshold valuevalue (beyond which the shell is

(beyond which, is rejected as having a base separation) separation) varies from from shell to

shell, to

he 11 bbecause

sshell hang ing film

e c au s e of cchanging s en s i, t, i v i t y variations

response. These sensitivity

film response. a c c ommod a t e d by

a r e accommodated

va r i a t ion s are t he

c ompu t in g the

'by computing

threshold for

threshold for each

each image on differences

based on

image based intensity values

between intensity

differences between values at certain prescribed points on the

at certain the

in tensity profile. Once

intensity One e the

the threshold

t hr e s ho1d is c ompu ted, it

is computed, it is s imp1e matter

is aa simple to determine

ma 11 e r to whethe r the

de t e rmine whether dev iati on

t he deviation

is too

is large and

too large and print out this result on

this result on the -generated report.

computer-generated

the computer report.

Ac kn ow 1 e dg erne n t

Acknowledgement

Many of the concpets

concpets and algorithms were based on Dr. M.

of Dr.

those of

on those A. Fischler,

M. A. now of

Fischler, now International,

SRI International,

of SRI

who led in the

led the algorithm development in study.

previous study.

the previous

Reference

1.

1. Pearson, J.

Pearson, J. J., M. A.,

Fischler, M.

J., Fischler, Firschein, 0.,

A., Firschein, Jacoby, M.,

O., Jacoby, "Application of Image

M., "Application Techniques

Image Processing Techniques

to Automatic

to Automatic Radiographic Inspection Proceedings of

", Proceedings

Inspection", EIA Seventh

the EIA

of the Annual AIPR Symposium.

Seventh Annual

SPIE Vol.

SP/E Vol. 155155 Understanding

Image

Image Systems Systems

Understanding Applications

8- IndustrialEt Industrial (1978) / 221

Applications (1978

Downloaded From: http://proceedings.spiedigitallibrary.org/ on 10/13/2015 Terms of Use: http://spiedigitallibrary.org/ss/TermsOfUse.aspx

You might also like

- Handbook of Series for Scientists and EngineersFrom EverandHandbook of Series for Scientists and EngineersRating: 3 out of 5 stars3/5 (1)

- Individual Performance Commitment and Review Form (Ipcrf) For Teacher I - IiiDocument8 pagesIndividual Performance Commitment and Review Form (Ipcrf) For Teacher I - IiiNida Viojan AbasoloNo ratings yet

- 1986-Pacific-Sierra-Accurate Laboratory Boresight Alignment of Transmitter Receiver Optical AxesDocument8 pages1986-Pacific-Sierra-Accurate Laboratory Boresight Alignment of Transmitter Receiver Optical AxesLK DAINo ratings yet

- StrataCamMini BrochureDocument2 pagesStrataCamMini BrochureLuis GutierrezNo ratings yet

- Vozoff 1972 Geophysics PDFDocument44 pagesVozoff 1972 Geophysics PDFWilhelmBerrocalNo ratings yet

- Part 2 2018Document10 pagesPart 2 2018kssaludesNo ratings yet

- Grade 4 5 7 8 9 Music Rubrics For 4th Quarter ExamDocument6 pagesGrade 4 5 7 8 9 Music Rubrics For 4th Quarter ExamJep Jep PanghulanNo ratings yet

- OPSD - Worksheets - Alternative Spellings - SuperC - HiresDocument1 pageOPSD - Worksheets - Alternative Spellings - SuperC - HiresTeresa GattNo ratings yet

- S.No Experiment Name 1.) Engeneering Physics Lab (Phy 101L) B.Tech 1St YearDocument3 pagesS.No Experiment Name 1.) Engeneering Physics Lab (Phy 101L) B.Tech 1St YearSURESH SURAGANINo ratings yet

- Table of Specification AutorecoveredDocument2 pagesTable of Specification AutorecoveredJohn Jabez LuceroNo ratings yet

- E-Mai L:: Daspr I Yar Anj An111@gmai L - ComDocument5 pagesE-Mai L:: Daspr I Yar Anj An111@gmai L - Compraveen nairNo ratings yet

- StrataCam BrochureDocument2 pagesStrataCam BrochureLuis GutierrezNo ratings yet

- Edoc - Pub - Rohen39s Photographic Anatomy Flash Cards 2008 MasDocument4 pagesEdoc - Pub - Rohen39s Photographic Anatomy Flash Cards 2008 MasAnonymous NK07LsS9lNo ratings yet

- Tempo Rubato in The EighteenthDocument143 pagesTempo Rubato in The EighteenthLuis Quijano100% (1)

- Wright MusicalTimes 1993Document2 pagesWright MusicalTimes 1993elouchNo ratings yet

- Qdoc - Tips Geological Field Report of Gilgit Baltistan by ArsDocument43 pagesQdoc - Tips Geological Field Report of Gilgit Baltistan by Arsshams asimNo ratings yet

- El ABC y XYZ de La ApiculturaDocument460 pagesEl ABC y XYZ de La ApiculturaJesus Tapia85% (20)

- Educ 104Document1 pageEduc 104Mariel DolinoNo ratings yet

- Francis PowerpointDocument21 pagesFrancis Powerpointfrancisekemini6807No ratings yet

- 2semi-Dlp SCIENCE 8 W5Document5 pages2semi-Dlp SCIENCE 8 W5Lovely Grace GarvezNo ratings yet

- Part V. Accelerator Technology 119-153Document12 pagesPart V. Accelerator Technology 119-153Alessandro LaraNo ratings yet

- Institute of Geophysics and Problems of The Earth: An Innovative Technology For Remote Sounding of Mineral DepositsDocument33 pagesInstitute of Geophysics and Problems of The Earth: An Innovative Technology For Remote Sounding of Mineral Deposits雷鸣No ratings yet

- Atonality, Modality, and Incantation in Two Works For Trumpet by Andre Jolivet, With A Discussion of His Technical and Aesthetic PrinciplesDocument201 pagesAtonality, Modality, and Incantation in Two Works For Trumpet by Andre Jolivet, With A Discussion of His Technical and Aesthetic PrinciplesweichiuanluNo ratings yet

- 2semi-Dlp SCIENCE 8 W4Document5 pages2semi-Dlp SCIENCE 8 W4Lovely Grace GarvezNo ratings yet

- Unidad Educativa Fiscal Abdón Calderón Vicerrectorado 2019-2020Document4 pagesUnidad Educativa Fiscal Abdón Calderón Vicerrectorado 2019-2020Ceci RamosNo ratings yet

- Varadan Et Al., 1985Document3 pagesVaradan Et Al., 1985xowaf70826No ratings yet

- My PR DLL 1 - DownloadDocument4 pagesMy PR DLL 1 - DownloadRevilla Marco Robles RatillaNo ratings yet

- LP 2 Lesson 8Document4 pagesLP 2 Lesson 8Bainaot Abdul SumaelNo ratings yet

- ELS DLL-August 29-September 1, 2023Document7 pagesELS DLL-August 29-September 1, 2023Floreann BascoNo ratings yet

- THEORY SriYantraDocument26 pagesTHEORY SriYantraantonio_ponce_1No ratings yet

- Jaba Tan Pelajaran Negeri Johor Peperiksaan Percubaan Penilaian Menengah RendahDocument37 pagesJaba Tan Pelajaran Negeri Johor Peperiksaan Percubaan Penilaian Menengah RendahsensnaliquidNo ratings yet

- Introduction To Seismic Interpretation El AmalDocument33 pagesIntroduction To Seismic Interpretation El AmalFredrick Oshogbunu Ovakporaye100% (1)

- Absortion Apectra On BoneDocument2 pagesAbsortion Apectra On BoneAngelNo ratings yet

- 2epresent &unctions:, Esson #OpyrightDocument4 pages2epresent &unctions:, Esson #Opyrightanon-579447No ratings yet

- Action Stories - Spring 1948Document132 pagesAction Stories - Spring 1948ulixesfoxNo ratings yet

- ReportDocument31 pagesReportkim hwiNo ratings yet

- My PR DLL 3 - DownloadDocument6 pagesMy PR DLL 3 - DownloadRevilla Marco Robles RatillaNo ratings yet

- Jurassic World The Park Is OpenDocument25 pagesJurassic World The Park Is OpenYasbroNo ratings yet

- Ece Request For PrintingDocument32 pagesEce Request For PrintingJude GrefielNo ratings yet

- As Lo 2009Document1 pageAs Lo 2009nizzazaNo ratings yet

- Rafika PIL FreshwaterDocument3 pagesRafika PIL FreshwaterRafika MahdavikiaNo ratings yet

- Uwe Zscherpel-Computed RadiographyDocument42 pagesUwe Zscherpel-Computed Radiographyrafeeq ahamedNo ratings yet

- Social Science Weekly Lesson Plan FormatDocument5 pagesSocial Science Weekly Lesson Plan Formatapi-351804626No ratings yet

- Schoenberg - HandelDocument12 pagesSchoenberg - HandelDimitris ChrisanthakopoulosNo ratings yet

- Dayanandasagarcol L Egeofengi Neer I NG: Shavi Gemal L Eshwar Ahi L L S, Kumar Aswamylayout, Bangal or E-560078.)Document6 pagesDayanandasagarcol L Egeofengi Neer I NG: Shavi Gemal L Eshwar Ahi L L S, Kumar Aswamylayout, Bangal or E-560078.)SanthoshNo ratings yet

- (A) Parabola /parabola (Mersenne Telescope)Document9 pages(A) Parabola /parabola (Mersenne Telescope)Laura PerozaNo ratings yet

- Vibration-Based Fault Diagnosis Approach For PermaDocument7 pagesVibration-Based Fault Diagnosis Approach For PermaKawthar AlamehNo ratings yet

- GR.8.DLL Earthq.Document3 pagesGR.8.DLL Earthq.Sheryl MoslaresNo ratings yet

- Scan Feb 12, 2024Document1 pageScan Feb 12, 2024Sangeeta BasakNo ratings yet

- E.syntax - Modal & Primary Auxiliaries - 1Document13 pagesE.syntax - Modal & Primary Auxiliaries - 1Sri Indah AnandaNo ratings yet

- Skills 1st SceondaryDocument49 pagesSkills 1st SceondaryHany FaroukNo ratings yet

- HK RHJA Company AppraisalDocument3 pagesHK RHJA Company AppraisalMOHD AZHAR BIN MOHD AKBARNo ratings yet

- Types of Union StructuralDocument4 pagesTypes of Union StructuralCarlos BustamanteNo ratings yet

- Types of Union StructuralDocument4 pagesTypes of Union StructuralCarlos BustamanteNo ratings yet

- Kimberly Acoustic Discrimination of FricativeDocument4 pagesKimberly Acoustic Discrimination of Fricative백지원No ratings yet

- A Brief Analysis of Debussy'sDocument114 pagesA Brief Analysis of Debussy'sNatasha NepgenNo ratings yet

- Grade 12 Comp Art Week 1Document7 pagesGrade 12 Comp Art Week 1Raizza Vanizza SiguenzaNo ratings yet

- DLL Indian ArtDocument5 pagesDLL Indian ArtJanelle Kia ArizoNo ratings yet

- Week 9Document3 pagesWeek 9Evan Maagad LutchaNo ratings yet

- MIL-C-60418 Revision BDocument31 pagesMIL-C-60418 Revision BnanocardosoNo ratings yet

- Metal Forming FormabilityDocument7 pagesMetal Forming FormabilitynanocardosoNo ratings yet

- Trajectory Optimization of A Deflectable Nose Missile - 2017 - Defence TechnologDocument6 pagesTrajectory Optimization of A Deflectable Nose Missile - 2017 - Defence TechnolognanocardosoNo ratings yet

- Dynamic Evaluation of Bi Modular Charge System For 155 MM Artillery GunDocument3 pagesDynamic Evaluation of Bi Modular Charge System For 155 MM Artillery GunnanocardosoNo ratings yet

- ShafieiM2010 Article AnInvestigationIntoTheEffectOfDocument5 pagesShafieiM2010 Article AnInvestigationIntoTheEffectOfnanocardosoNo ratings yet

- A Comparative Study of Combustible Cartridge Case Mate - 2017 - Defence TechnoloDocument4 pagesA Comparative Study of Combustible Cartridge Case Mate - 2017 - Defence TechnolonanocardosoNo ratings yet

- Defence Technology: Vladimir Cech, Jiri JevickyDocument11 pagesDefence Technology: Vladimir Cech, Jiri JevickynanocardosoNo ratings yet

- Modeling of Cooling and Solidification of TNT Based Cast High Explosives ChargesDocument5 pagesModeling of Cooling and Solidification of TNT Based Cast High Explosives ChargesnanocardosoNo ratings yet

- Modified Point Mass Trajectory SimulationDocument51 pagesModified Point Mass Trajectory SimulationnanocardosoNo ratings yet

- Stanag 4355Document95 pagesStanag 4355nanocardoso100% (2)

- Lee-Kim2006 Article OptimizationOfMassBleedControlDocument7 pagesLee-Kim2006 Article OptimizationOfMassBleedControlnanocardosoNo ratings yet

- Numerical Study of Base Drag Reduction Using Locked Vortex Flow Management Technique For Lower Subsonic RegimeDocument4 pagesNumerical Study of Base Drag Reduction Using Locked Vortex Flow Management Technique For Lower Subsonic RegimenanocardosoNo ratings yet

- Drag Reduction With Optimum Designing of A Base Bleed Projectile Using Computational AnalysisDocument26 pagesDrag Reduction With Optimum Designing of A Base Bleed Projectile Using Computational AnalysisnanocardosoNo ratings yet

- Mil STD 746a PDFDocument10 pagesMil STD 746a PDFnanocardosoNo ratings yet

- Preparation of TetrazeneDocument54 pagesPreparation of TetrazenenanocardosoNo ratings yet

- Navier-Stokes Computations of Projectile Base Flow at Transonic Speeds With and Without Base InjectionDocument42 pagesNavier-Stokes Computations of Projectile Base Flow at Transonic Speeds With and Without Base InjectionnanocardosoNo ratings yet

- Equations of Motion of A Spin-Stabilized Projectile For Flight Stability TestingDocument12 pagesEquations of Motion of A Spin-Stabilized Projectile For Flight Stability TestingnanocardosoNo ratings yet

- Mil STD 746a PDFDocument10 pagesMil STD 746a PDFnanocardosoNo ratings yet

- CHDK 1.2.0 User Manual: What Is CHDK? Canon Hack Development KitDocument69 pagesCHDK 1.2.0 User Manual: What Is CHDK? Canon Hack Development Kitsica1234No ratings yet

- Function: % - Executes On Button Press in LoadimageDocument1 pageFunction: % - Executes On Button Press in Loadimageart101988No ratings yet

- Person To Camera Distance Measurement Based On Eye-DistanceDocument5 pagesPerson To Camera Distance Measurement Based On Eye-DistanceAlin CraciunNo ratings yet

- Nikon F2AS Dp12 ManualDocument46 pagesNikon F2AS Dp12 Manualvosacvohuong100% (1)

- Spesifikasi ACUSON SC2000 EchocardiographyDocument2 pagesSpesifikasi ACUSON SC2000 EchocardiographyRizki Try AtmantiNo ratings yet

- Industrial Borescope: Operating ManualDocument16 pagesIndustrial Borescope: Operating ManualFAISHAH ISAHAKNo ratings yet

- Kilfitt Catalogue 1960sDocument8 pagesKilfitt Catalogue 1960stom bNo ratings yet

- Lecture Notes On Remote Sensing & Gis: IV B. Tech II Semester (JNTU (A) - R13)Document13 pagesLecture Notes On Remote Sensing & Gis: IV B. Tech II Semester (JNTU (A) - R13)Kushana SaikirannNo ratings yet

- FumeFX Tutorial Just The BeginningDocument28 pagesFumeFX Tutorial Just The BeginningShuvrodeep DuttaNo ratings yet

- CT BR Aquilion LBDocument12 pagesCT BR Aquilion LBOsmanyNo ratings yet

- Reolink Go IP Camera Specifications PDFDocument1 pageReolink Go IP Camera Specifications PDFMarcos BajañaNo ratings yet

- Liquid Crystal Display (LCD)Document17 pagesLiquid Crystal Display (LCD)Mansunder SinghNo ratings yet

- Amateur PhotographerDocument70 pagesAmateur PhotographeryaretziNo ratings yet

- ImageProcessing4 ImageEnhancement (PointProcessing)Document28 pagesImageProcessing4 ImageEnhancement (PointProcessing)asif01cseNo ratings yet

- pm-56101-Technical-Data - Summilux-M 90 f-1.5 ASPH - eDocument9 pagespm-56101-Technical-Data - Summilux-M 90 f-1.5 ASPH - eaoctaNo ratings yet

- 40 Practical Photography Assignments To Inspire You - DIY PhotographyDocument30 pages40 Practical Photography Assignments To Inspire You - DIY Photographyjeffreygovender5745No ratings yet

- Star Safire 380-Hd A LTRDocument2 pagesStar Safire 380-Hd A LTRtomay777No ratings yet

- Nikon - D50 ManualDocument148 pagesNikon - D50 Manualtomjordan12321No ratings yet

- Photographer S Guide To The Sony A6400Document275 pagesPhotographer S Guide To The Sony A6400mynameisthisddddNo ratings yet

- CTsystems ComparisonChart ITN1013Document1 pageCTsystems ComparisonChart ITN1013RM100% (1)

- Stephen G. Anchell, Bill Troop - Film Developing Cookbook PDFDocument178 pagesStephen G. Anchell, Bill Troop - Film Developing Cookbook PDFajsikel100% (2)

- DP70 enDocument22 pagesDP70 enemadhsobhyNo ratings yet

- InFocus IN112 IN114 IN116 DatasheetDocument2 pagesInFocus IN112 IN114 IN116 Datasheethadi purwantoNo ratings yet

- Pure VB Pset in PictureboxDocument1 pagePure VB Pset in PictureboxbalabooksNo ratings yet

- Extraction of Cancer Cells From MRI Prostate Image Using MATLAB by Gopinath. N, SKPITDocument9 pagesExtraction of Cancer Cells From MRI Prostate Image Using MATLAB by Gopinath. N, SKPITகோபிநாத் நித்தியானந்தம்No ratings yet

- Manuel Garcia Evangelista Police Officer 3 Registered Criminologist InstructorDocument35 pagesManuel Garcia Evangelista Police Officer 3 Registered Criminologist InstructorBilly VoluntariosoNo ratings yet

- All Leica LensesDocument16 pagesAll Leica Lensesyomanuel1100% (4)

- Icru 87 Radiation Dose and Image-Quality Assessment in Computed TomographyDocument164 pagesIcru 87 Radiation Dose and Image-Quality Assessment in Computed TomographyDiego MauricioNo ratings yet

- TM220 - IM English (KARL STORZ)Document25 pagesTM220 - IM English (KARL STORZ)Huy Thịnh NguyễnNo ratings yet

- Types of PhotogrammetryDocument13 pagesTypes of PhotogrammetryaljonNo ratings yet