Professional Documents

Culture Documents

L3636 WJWJWN

L3636 WJWJWN

Uploaded by

ielvis souzaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

L3636 WJWJWN

L3636 WJWJWN

Uploaded by

ielvis souzaCopyright:

Available Formats

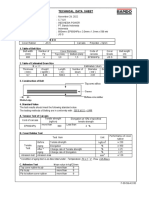

Skirting System

Selection Guide

Durometer Max. Order Max. Belt

Skirting Type P/N Material Temp. Range

Shore A Length** Speed***

SKIRTING SYSTEMS

Martin® ApronSeal™ Single Skirting 100724 EPDM Rubber 70 300’ 600 -20° to 250°F (-29° to 121°C)

Martin ApronSeal™ Single Skirting

®

100724-0660 EPDM Rubber 60 300’ 600 -20° to 250°F (-29° to 121°C)

Martin® ApronSeal™ Single Skirting - High Temp* 100724-XXH High-Temp Rubber 70 12’ & 24’ 700 -70° to 400°F (-57° to 204°C)

Martin® ApronSeal™ Single Skirting - Food Grade* 100724-XXF Food-Grade Rubber 65 12’ & 24’ 600 -70° to 275°F (-57° to 135°C)

Martin® ApronSeal™ Single Skirting HD 100723 EPDM Rubber 70 300’ 750 -20° to 250°F (-29° to 121°C)

Martin® ApronSeal™ Single Skirting HD 100808 EPDM Rubber 70 300’ 750 -20° to 250°F (-29° to 121°C)

Martin® ApronSeal™ Single Skirting HD 100808-60 EPDM Rubber 60 300’ 750 -20° to 250°F (-29° to 121°C)

Martin ApronSeal™ Single Skirting HD*

®

100723-XXM MSHA-Approved 60 300’ 750 -20° to 250°F (-29° to 121°C)

Martin ApronSeal™ Single Skirting XHD

®

100845 EPDM Rubber 60 200’ 750 -20° to 250°F (-29° to 121°C)

Martin® ApronSeal™ Double Skirting 100873 EPDM Rubber 70 300’ 600 -20° to 250°F (-29° to 121°C)

Martin® ApronSeal™ Double Skirting HD 100861 EPDM Rubber 70 300’ 750 -20° to 250°F (-29° to 121°C)

Martin® Self Adjusting Skirting 37911-R EPDM Rubber 70 100’ 600 -20° to 250°F (-29° to 121°C)

REPLACEMENT RUBBER

Rubber Secondary* 100746 SBR Rubber 75 300’ 600 -20° to 250°F (-29° to 121°C)

DCI Replacement* 100736 SBR Rubber 75 300’ 600 -20° to 250°F (-29° to 121°C)

ARGONICS SNAP-LOC™ Dust Seal Replacement* 100792 SBR Rubber 60 300’ 600 -20° to 250°F (-29° to 121°C)

Notes: Part Numbers with XX: Replace “XX” with 12 or 24 for skirt length. * Skirting System Not Shown. ** Order by 1-foot increments up to 300-foot lengths, except those noted

12 and 24 foot only. *** If your belt speed exceeds what is listed above, please contact Martin Engineering.

Chute Wall

Free Belt Area: Space between the outside chute wall and the edge of the Wear Liner

conveyor belt. Information given assumes there is no belt wander.

Trough Angle: The angle at which the belt edges are elevated to carry the

material load. Conveyor Belt

Wear Liner: Martin Engineering recommends the use of properly installed

Free Belt Area

wear liner inside the chute to protect the skirtboard sealing system.

Trough Angle

Form No. L3636-11/15

© Martin Engineering Company 2010, 2015

Martin® ApronSeal™ Martin® ApronSeal™ Martin® ApronSeal™ Martin® Self-Adjusting

Single Skirting Single Skirting HD Double Skirting Skirting

Angle Clamp Angle Clamp

Angle Clamp

Martin® Wear Liner

Martin® Wear Liner Pressure Arm

Martin® Wear Liner Martin® Wear Liner

Rubber Skirting

Conveyor Belt

Conveyor Belt

Conveyor Belt

Conveyor Belt

35° Belt

35° Belt 35° Belt 35° Belt

MINIMUM FREE BELT AREA—IN. (MM)

Trough Martin® ApronSeal™ Skirting Martin® Self-Adjusting

Angle Single Skirting Single Skirting HD Single Skirting XHD Double Skirting Double Skirting HD Skirting

0° 2.14 (54) 2.97 (76) 3.50 (89) 2.14 (54) 2.97 (76) 1.50 (38)

20° 2.58 (66) 3.74 (95) 4.25 (108) 2.58 (66) 3.74 (95) 1.50 (38)

35° 2.87 (73) 4.18 (106) 4.75 (121) 2.87 (73) 4.18 (106) 1.50 (38)

45° 3.01 (77) 4.38 (111) 5.00 (127) 3.01 (77) 4.38 (111) 1.50 (38)

Martin Engineering USA SNAP-LOC™ is a trademark of Argonics, Inc.,

One Martin Place Maquette, MI. U.S.A. who is not affiliated with

Neponset, IL 61345-9766 USA Martin Engineering in any way.

800 544 2947 or 309 852 2384

Fax 800 814 1553

www.martin-eng.com

Form No. L3636-11/15

© Martin Engineering Company 2010, 2015

You might also like

- The Gods Never Left Us - The Long Awaited Sequel To The Worldwide Best-Seller Chariots of The Gods (PDFDrive)Document155 pagesThe Gods Never Left Us - The Long Awaited Sequel To The Worldwide Best-Seller Chariots of The Gods (PDFDrive)Jake AmbersonNo ratings yet

- Exercise Therapy For The Management of Osteoarthritis of The Hip JointDocument33 pagesExercise Therapy For The Management of Osteoarthritis of The Hip JointVictor Andrés Olivares IbarraNo ratings yet

- How A TV Station WorksDocument6 pagesHow A TV Station WorksAnil Kumar100% (1)

- Water Well Drilling Rig ManufacturersDocument1 pageWater Well Drilling Rig ManufacturersKGR RigsNo ratings yet

- OTR Tyre Awareness PDFDocument313 pagesOTR Tyre Awareness PDFHugh O'Brien Gwaze100% (1)

- CV-X Series Setup Manual (3D) - ESPDocument122 pagesCV-X Series Setup Manual (3D) - ESPJuan Antonio SánchezNo ratings yet

- Design, Installation and Maintenance of Conveyor Skirting Arrangements at Transfer PointsDocument9 pagesDesign, Installation and Maintenance of Conveyor Skirting Arrangements at Transfer PointsAdhieNo ratings yet

- Process Control PDFDocument99 pagesProcess Control PDFmoreharish10No ratings yet

- Presentasi Conveyor PDFDocument23 pagesPresentasi Conveyor PDFWirsa RinekoNo ratings yet

- Merkel Chevron Seal Set Es, Esv: MaterialDocument2 pagesMerkel Chevron Seal Set Es, Esv: MaterialPedro Samuel Brito LopesNo ratings yet

- Activity 3-IVDocument2 pagesActivity 3-IVKimberly FrancoNo ratings yet

- BMD 1Document19 pagesBMD 1Gokul Bhise8380090023No ratings yet

- Slurrystorage 2Document12 pagesSlurrystorage 2Андрей БелоусовNo ratings yet

- Silam Belts For The Food IndustryDocument2 pagesSilam Belts For The Food IndustryPeter CropsNo ratings yet

- Vee Pack Sets: Technical DetailsDocument2 pagesVee Pack Sets: Technical DetailsRPINILLA (EICO S.A.)No ratings yet

- Vee Pack Sets: Technical DetailsDocument2 pagesVee Pack Sets: Technical DetailsAlejandro MejíasNo ratings yet

- CameronBOP Rubbers TemperatureDocument1 pageCameronBOP Rubbers TemperatureMarc LefrancqNo ratings yet

- Vee Pack Sets: Technical DetailsDocument2 pagesVee Pack Sets: Technical DetailsRPINILLA (EICO S.A.)No ratings yet

- Technical Details: Vee Pack SetsDocument2 pagesTechnical Details: Vee Pack SetsJosé HurtadoNo ratings yet

- T 13 PG 35-36 PDFDocument2 pagesT 13 PG 35-36 PDFJossimar PerezNo ratings yet

- TRB E-Catalogue For Conveyor Belt-Indonesia Purpose Distributed by CV. TakinoDocument34 pagesTRB E-Catalogue For Conveyor Belt-Indonesia Purpose Distributed by CV. TakinoErlina SihotangNo ratings yet

- Aptan Product InformationDocument2 pagesAptan Product Informationpassions4friendsNo ratings yet

- Densit WearCast 2000 11-17 1515493405Document2 pagesDensit WearCast 2000 11-17 1515493405Cioz NguyenNo ratings yet

- Ceptor - X: 1. Product IntroductionDocument2 pagesCeptor - X: 1. Product IntroductionvietkhamNo ratings yet

- T 14pg 37-38 PDFDocument2 pagesT 14pg 37-38 PDFJossimar PerezNo ratings yet

- Technical Details: Vee Pack SetsDocument2 pagesTechnical Details: Vee Pack SetsJosé HurtadoNo ratings yet

- P B M T: Remcote Utyl Astic APEDocument2 pagesP B M T: Remcote Utyl Astic APEIm ChinithNo ratings yet

- 88 Imi ImiplastDocument2 pages88 Imi ImiplastEngr KamalNo ratings yet

- Brandt Sabre Shaker System FlyerDocument2 pagesBrandt Sabre Shaker System FlyerAndre YudhistiraNo ratings yet

- Dyna Flight 08Document12 pagesDyna Flight 08surachsNo ratings yet

- Brosur Breaker SOOSAN SB Series (New)Document8 pagesBrosur Breaker SOOSAN SB Series (New)HidayatNo ratings yet

- Maxx Surya Heat Resistant BeltsDocument4 pagesMaxx Surya Heat Resistant BeltsVicky ImmanuelNo ratings yet

- M5010 Flat TopDocument2 pagesM5010 Flat TopĐăng Điệp NguyễnNo ratings yet

- Rain Sheds Rightangle Boots Straight BootsDocument2 pagesRain Sheds Rightangle Boots Straight BootsEhab Abd-allaNo ratings yet

- Skirt Board Rubber Sheet: Abrasion & Impact Resistant - Fire & Chemical Resistant - Good Mechanical StrengthDocument1 pageSkirt Board Rubber Sheet: Abrasion & Impact Resistant - Fire & Chemical Resistant - Good Mechanical StrengthDwi SetyaoneNo ratings yet

- InsufineMineral TDSDocument2 pagesInsufineMineral TDSEgyp XsNo ratings yet

- BDM BRMDocument1 pageBDM BRMAndres CastiblancoNo ratings yet

- SF-MFTNC Cert s-914-2Document1 pageSF-MFTNC Cert s-914-2Juan Víctor JiménezNo ratings yet

- Data Sheet PLIED - 1500 MM X 1250-5 PlyDocument1 pageData Sheet PLIED - 1500 MM X 1250-5 PlySales support TechnicalNo ratings yet

- Cushion-Mount Plus Plate Mounting Tapes With Easy Mount AdhesiveDocument6 pagesCushion-Mount Plus Plate Mounting Tapes With Easy Mount AdhesiveSerhan ÜnverNo ratings yet

- 3M Standart SeriesDocument4 pages3M Standart SeriesSerhan ÜnverNo ratings yet

- Mini Split Kit Fix-it-Foot-SpecDocument2 pagesMini Split Kit Fix-it-Foot-SpecAmic BanatNo ratings yet

- Chemical Anchoring (C)Document11 pagesChemical Anchoring (C)R Hadiono (Ryendra)No ratings yet

- Martin Apron Seal Skirting System: 2-Piece 1-Piece Heavy-Duty 1-PieceDocument2 pagesMartin Apron Seal Skirting System: 2-Piece 1-Piece Heavy-Duty 1-Piececristian W. saravia vegaNo ratings yet

- Fluid Power Tee SealsDocument2 pagesFluid Power Tee Sealsmetall 4uNo ratings yet

- Belt SpecificationDocument11 pagesBelt SpecificationnomidangerousNo ratings yet

- Doshin Comp Seal JointDocument2 pagesDoshin Comp Seal JointHushes CheongNo ratings yet

- 2012 C150-170 English WebDocument4 pages2012 C150-170 English WebrcaletaNo ratings yet

- X2543 enUS 2543 FlexLagRubber 021621Document2 pagesX2543 enUS 2543 FlexLagRubber 021621German RestrepoNo ratings yet

- Rema SlideDocument4 pagesRema SlidedexNo ratings yet

- Trelleborg Pneumatic Fender PDFDocument16 pagesTrelleborg Pneumatic Fender PDFJeff TrinidadNo ratings yet

- Tds Wikon Ip. C 7&8Document1 pageTds Wikon Ip. C 7&8deni prastikoNo ratings yet

- Splicing Instruction For Trellex Steelcord Conveyor Belts: 1067 (42") ST 5700 14: 10 DIN XDocument6 pagesSplicing Instruction For Trellex Steelcord Conveyor Belts: 1067 (42") ST 5700 14: 10 DIN XnicolasNo ratings yet

- SKF 140X170X15 HMSA10 RGRadial Shaft Seal With Rubber Outside Diameter and Single Sealing Lip, For Oil or Grease SpecificationDocument3 pagesSKF 140X170X15 HMSA10 RGRadial Shaft Seal With Rubber Outside Diameter and Single Sealing Lip, For Oil or Grease Specificationyaman.kumarNo ratings yet

- GPT 1-15 LineBackerDocument4 pagesGPT 1-15 LineBackerazadeazNo ratings yet

- Polygomma EPDM Roofing Membrane CatalogueDocument4 pagesPolygomma EPDM Roofing Membrane Cataloguepolygomma Industries Pvt. LtdNo ratings yet

- Mason Industries Mercer Rubber Expansion JointsDocument122 pagesMason Industries Mercer Rubber Expansion Jointsjonathan watsonNo ratings yet

- Product Specification: Manufacturer: Big Foot Systems Product Name: Standard FramesDocument3 pagesProduct Specification: Manufacturer: Big Foot Systems Product Name: Standard FramesRoger ChetcutiNo ratings yet

- 10 Sinter Cast LinersDocument1 page10 Sinter Cast LinersRajesh SinghaiNo ratings yet

- E3120.07vratex - Pvcexcon 3F30 PG62 V07V20 As Ar Fa FR AtexDocument1 pageE3120.07vratex - Pvcexcon 3F30 PG62 V07V20 As Ar Fa FR AtexCustomer ServiceNo ratings yet

- DynamometersWeb Strap Pullers HI-TOOLDocument1 pageDynamometersWeb Strap Pullers HI-TOOLPrince MinhasNo ratings yet

- Skim CoatDocument28 pagesSkim CoatParmasamy SubramaniNo ratings yet

- Tds-Manual DamperDocument4 pagesTds-Manual Dampersabir hussainNo ratings yet

- Belt Conveyors: Mechanical Engineering Department Carlos III UniversityDocument21 pagesBelt Conveyors: Mechanical Engineering Department Carlos III UniversityLUIS ISAAC LEON PARONo ratings yet

- Cushion-Mount Plus Plate Mounting Tapes With Easy Mount Adhesive High Plateside AdhesionDocument6 pagesCushion-Mount Plus Plate Mounting Tapes With Easy Mount Adhesive High Plateside AdhesionSerhan ÜnverNo ratings yet

- Aali Pant 2019, Coal Combustion Residue As Structural Fill Material For Reinforced Soil StructuresDocument10 pagesAali Pant 2019, Coal Combustion Residue As Structural Fill Material For Reinforced Soil StructuresSatya ChaitanyaNo ratings yet

- User ManualDocument98 pagesUser ManualGonzalo TapiaNo ratings yet

- Medical and Cardiac Risk Stratification and Exercise Prescription in Persons With CancerDocument7 pagesMedical and Cardiac Risk Stratification and Exercise Prescription in Persons With CancermarciarigaudNo ratings yet

- Big E Comments PDFDocument31 pagesBig E Comments PDFMustafa ErtekinNo ratings yet

- Samsung 732n Plus 932b Plus 932n Plus CH Ls17pea Ls19peb Ls19peaDocument85 pagesSamsung 732n Plus 932b Plus 932n Plus CH Ls17pea Ls19peb Ls19pearvs1797No ratings yet

- Gearless Xaf: Installation and MaintenanceDocument44 pagesGearless Xaf: Installation and MaintenanceyounesNo ratings yet

- Insect Control in Flour MillsDocument30 pagesInsect Control in Flour MillsDidier Sanon100% (2)

- Gandhi General Product CatalogueDocument70 pagesGandhi General Product CataloguePrajakta ParanjapeNo ratings yet

- Booklet Conical MountingsDocument41 pagesBooklet Conical MountingsAhmet HamamcıoğluNo ratings yet

- Plug Valve Repair KitDocument1 pagePlug Valve Repair Kitcmrig74No ratings yet

- EF3e Elem Quicktest 05Document3 pagesEF3e Elem Quicktest 05Ignacio OrmaecheaNo ratings yet

- 2020sep CV CBIS LohDuaneDocument5 pages2020sep CV CBIS LohDuaneLaura ParkaNo ratings yet

- Mathematics WaecDocument13 pagesMathematics WaecTunde Ipaye100% (1)

- Structural Design Manual: ALDOT Bridge BureauDocument59 pagesStructural Design Manual: ALDOT Bridge BureaukoreshNo ratings yet

- Frequently Asked Questions (FAQ) On Wastewater - Sewage Treatment Plants (STP)Document11 pagesFrequently Asked Questions (FAQ) On Wastewater - Sewage Treatment Plants (STP)Krishna SrikanthNo ratings yet

- NAME: Mildred R. Cajucom Grade & Section: 12 - Jacinto SUBJECT: Personal Development MODULE 1: Knowing OneselfDocument38 pagesNAME: Mildred R. Cajucom Grade & Section: 12 - Jacinto SUBJECT: Personal Development MODULE 1: Knowing OneselfAngelrose AbrisNo ratings yet

- Name Magecraft System Magecraft Specialization: El Melloi II Case Files MaterialsDocument3 pagesName Magecraft System Magecraft Specialization: El Melloi II Case Files MaterialsAniol Morató GilNo ratings yet

- Topic: Vidya Pratishthan'sDocument11 pagesTopic: Vidya Pratishthan'sJalo SutariNo ratings yet

- BOC Smoothcut 40 80 Plasma Cutter ManualDocument12 pagesBOC Smoothcut 40 80 Plasma Cutter ManualmickstaNo ratings yet

- PID Tuning Parameter TableDocument1 pagePID Tuning Parameter Tablesteam100deg1658No ratings yet

- Jet Fuel - DataDocument40 pagesJet Fuel - Datasanjana jainNo ratings yet

- Clank Laura Rules 4Document4 pagesClank Laura Rules 4Kyla BravanteNo ratings yet

- Topic 16 Types of Electric Circuit ComponentsDocument6 pagesTopic 16 Types of Electric Circuit ComponentsSunNo ratings yet