Professional Documents

Culture Documents

Journal-And-Thrust-Bearings (Elliot)

Uploaded by

Thanh Toan LeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Journal-And-Thrust-Bearings (Elliot)

Uploaded by

Thanh Toan LeCopyright:

Available Formats

PRODUCT

Journal and Thrust Bearings

The bearings that you choose for your rotating equipment can mean the difference between reliable operation and

costly repairs. Bearing design, style, size, material, fit, and manufacturing processes all play an important role in the

overall performance of your equipment.

At Elliott Group, we work with you to ensure you make the right bearing choice to increase the reliability of your

machines. For nearly 100 years, we have been designing and manufacturing high-quality journal and thrust bearings

that improve the operational performance and reliability of axial compressors, centrifugal compressors, steam

turbines, and expanders used throughout the world. Our design and engineering expertise allows us to produce

bearings that fit perfectly and work flawlessly. This results in lower maintenance costs, extended operating life, and

fewer unplanned outages.

Our full-range of bearing services includes:

• Fabrication of new journal and thrust bearings

• Bearing repair and babbitt services

• Reverse engineering

• On-demand emergency services

• 24/7 support

Journal Bearings

Elliott’s spherical seat journal bearings are developed based on years of experience, testing, and application in

the field. Each bearing is skillfully designed to follow and absorb movement for increased reliability, improved wear

resistance, and reduced mechanical losses. We also offer a copper-backed option for high-speed applications

to reduce bearing pad temperatures. Our journal bearings can also be instrumented with resistance temperature

detectors (RTDs) or thermocouples (TCs) to monitor bearing temperature and equipment health.

Although Elliott recommends that older-style journal bearings be upgraded to spherical seat, Elliott also

manufactures fixed profile (liner-type) and other styles of tilting pad journal bearings when the modern spherical seat

design is not an option.

Spherical Seat Journal Bearing Benefits

• Improved rotor dynamics

• Streamlined maintenance

• Reduced maintenance costs

• Improved reliability

• Reduced bearing temperature

and improved heat dissipation

(copper-backed)

Thrust Bearings Modern Manufacturing

Elliott’s modern self-leveling thrust bearings have superior

wear resistance, improved flexibility, and can carry a higher

load than older style non-equalized or non-self-leveling

thrust bearings. We also offer an offset pivot option to further

increase load-carrying capabilities.

In addition to self-leveling, Elliott offers a directed lube design

that consumes less oil, has low mechanical loss, and has the

highest load-carrying capability.

Both styles can also be instrumented with RTDs or TCs to

monitor bearing temperature, and both have copper-backed

options for high-speed applications to reduce bearing pad

temperatures.

Elliott is at the forefront of bearing design. We use modern

manufacturing techniques and innovative equipment at our

state-of-the art bearing manufacturing facility to produce

steel and copper-backed journal and thrust bearings of all

sizes. Our skilled technicians focus on building the highest-

quality bearings that meet your exact specifications.

Our bearing manufacturing facility includes:

• 5-axis CNC machining to fabricate bearings of any size

from start to finish

• Centrifugal casting machine to ensure the strongest

bond integrity and safeguard the babbitt against

Self-Leveling and Directed Lube Thrust Bearing Benefits impurities, gases, or imperfections

• Improved wear resistance • Coordinate measuring machine to measure and inspect

with extreme accuracy

• Even load distribution to all pads

• Environmentally controlled clean room for final

• Improved reliability

dimensional inspection and bearing assembly

• Reduced oil requirements (directed lube)

• Reduced bearing temperature and improved heat

dissipation (copper-backed)

At Elliott, we specialize in manufacturing both journal and thrust bearings for your rotating equipment. We have the bearing

manufacturing facility, engineering expertise, and technical know-how to design and manufacture the bearings that you

need for your axial compressors, centrifugal compressors, steam turbines, and expanders. Contact Elliott today at

info@elliott-turbo.com to learn more about bearing upgrades and other component upgrades that can improve the reliability

of your turbomachinery.

1250 Scott Street Extension

Donora, PA 15033-2249

Phone: 724-379-5440

Fax: 724-379-5535

Email: info@elliott-turbo.com

www.elliott-turbo.com

© 2018 Elliott Group SVS.4100.0718

You might also like

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsFrom EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsRating: 4 out of 5 stars4/5 (1)

- Slewing Bearings by Liebherr: Application-Optimised, Reliable and RobustDocument24 pagesSlewing Bearings by Liebherr: Application-Optimised, Reliable and Robustrobson2015No ratings yet

- Descriptive Pamphlet of the Richmond Mill Furnishing WorksFrom EverandDescriptive Pamphlet of the Richmond Mill Furnishing WorksNo ratings yet

- Slewing Drives by LiebherrDocument8 pagesSlewing Drives by LiebherrKaromah SembodoNo ratings yet

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreFrom EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreRating: 4.5 out of 5 stars4.5/5 (11)

- Mining Machinery Spare PartsDocument9 pagesMining Machinery Spare PartsGary LiNo ratings yet

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- Drilling Solutions CatalogDocument15 pagesDrilling Solutions Catalogعلی محمودیNo ratings yet

- Performance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallFrom EverandPerformance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallRating: 4 out of 5 stars4/5 (8)

- Tarby TitanDocument4 pagesTarby TitanAlberto HerreraNo ratings yet

- Scheerer Bearing Mining AggregateDocument8 pagesScheerer Bearing Mining AggregateJosé Del Orbe GarcíaNo ratings yet

- TheNewSRB SellSheet 06-10-10376Document2 pagesTheNewSRB SellSheet 06-10-10376AvinashNo ratings yet

- Guias Lineales - Catalogo CromsteelDocument28 pagesGuias Lineales - Catalogo CromsteelTomas SeifertNo ratings yet

- Antifriction Bearings, Linear Systems: The Special Solution For Every IndustryDocument16 pagesAntifriction Bearings, Linear Systems: The Special Solution For Every IndustryWong DaNo ratings yet

- Pioneer Castor Catalogue 2010Document28 pagesPioneer Castor Catalogue 2010Shaheen S. RatnaniNo ratings yet

- Elliott CompressorsDocument7 pagesElliott CompressorsQuarkantNo ratings yet

- Seismoflex CatalogueDocument10 pagesSeismoflex CatalogueNikhil DwivediNo ratings yet

- CYCLOTRONDocument25 pagesCYCLOTRONsaifNo ratings yet

- Kingsbury Bearing PDFDocument32 pagesKingsbury Bearing PDFdfNo ratings yet

- FAG-Gearboxes Need Rolling BearingsDocument10 pagesFAG-Gearboxes Need Rolling BearingsUMAMAHESWARAN03No ratings yet

- Liebherr Travel Drives FR PDFDocument10 pagesLiebherr Travel Drives FR PDFMohamed SalamNo ratings yet

- Elecon Conveyor Idlers CatalogueDocument10 pagesElecon Conveyor Idlers CatalogueB DAS100% (1)

- Tornillos Bolas Recirculantes HiwinDocument179 pagesTornillos Bolas Recirculantes HiwinJesus SerranoNo ratings yet

- Bearings For Cone Crushers: Serving Industries WorldwideDocument4 pagesBearings For Cone Crushers: Serving Industries WorldwideJgonzalez GonzalezNo ratings yet

- Hydrodinamic BearingsDocument8 pagesHydrodinamic BearingsdigecaNo ratings yet

- Medium & High Voltage and High Speed Motors PDFDocument16 pagesMedium & High Voltage and High Speed Motors PDFSandeep SinghNo ratings yet

- Xtek Crane BrochureDocument8 pagesXtek Crane BrochureBeniamine SarmientoNo ratings yet

- Bearing Product Catalog: Manufacturers of Ball and Roller BearingsDocument52 pagesBearing Product Catalog: Manufacturers of Ball and Roller BearingsLeonardNo ratings yet

- Cooper Pocket Catalogue 2017 TCM 12-271535Document188 pagesCooper Pocket Catalogue 2017 TCM 12-271535adasdasasNo ratings yet

- Newco Butterfly Valves1Document24 pagesNewco Butterfly Valves1adil_farooq_6No ratings yet

- Industrial Training Presentation NBCDocument31 pagesIndustrial Training Presentation NBCSuraj Singh Mehta100% (2)

- RevTech2013 WcollectionDocument44 pagesRevTech2013 Wcollectionhandoko pocaNo ratings yet

- BearingsDocument4 pagesBearingsmmrashid1904No ratings yet

- Lotustoyota2zz FinalDocument8 pagesLotustoyota2zz FinalManuel Elias Espinoza HuamanNo ratings yet

- Goulds - ICO I-Frame SeriesDocument16 pagesGoulds - ICO I-Frame SeriesAlexNo ratings yet

- American Roller Bearings: Focused On Aluminum ProcessingDocument4 pagesAmerican Roller Bearings: Focused On Aluminum ProcessingjaviervbNo ratings yet

- BSA Lead Screws: Easy Running, Precise and Cost-Effective PositioningDocument16 pagesBSA Lead Screws: Easy Running, Precise and Cost-Effective PositioningDavid FrazãoNo ratings yet

- Surface Belt Structure: Cema C & D SeriesDocument8 pagesSurface Belt Structure: Cema C & D SeriesSari Ully SibaraniNo ratings yet

- Gear Manufacturing MethodDocument89 pagesGear Manufacturing MethodRamalingam AlagarajaNo ratings yet

- NOV Prochem Bulletin 720 - v02Document10 pagesNOV Prochem Bulletin 720 - v02saulomonNo ratings yet

- CCL Bridge Bearings BrochureDocument20 pagesCCL Bridge Bearings BrochureMILL3482No ratings yet

- Extruder GB Rating PDFDocument19 pagesExtruder GB Rating PDFDwi HaadiNo ratings yet

- Industrial Training Presentation NBCDocument31 pagesIndustrial Training Presentation NBCsarvesh50% (2)

- GyratoryCrusher Brochure PDFDocument8 pagesGyratoryCrusher Brochure PDFHerfer FmasNo ratings yet

- Wärtsilä Seals and Bearings Linesafe DatasheetDocument4 pagesWärtsilä Seals and Bearings Linesafe DatasheetFERMIN ARTEAGANo ratings yet

- Technoroll BrosureDocument13 pagesTechnoroll BrosurephitokrioNo ratings yet

- Wheels & Castors: Carrying Industrial Loads Since 1976Document32 pagesWheels & Castors: Carrying Industrial Loads Since 1976GM HerbalsNo ratings yet

- MBF Coal Pulverizers - Foster WheelerDocument4 pagesMBF Coal Pulverizers - Foster WheelerThanhluan NguyenNo ratings yet

- HHE-VL-Recip-Compressor-Flyer-June-2021-pdf - Original FileDocument2 pagesHHE-VL-Recip-Compressor-Flyer-June-2021-pdf - Original Fileaatishsehgal94No ratings yet

- Scheerer Bearing Rebuild ReconditionFINALDocument4 pagesScheerer Bearing Rebuild ReconditionFINALChristian OvalleNo ratings yet

- Wartsila O P Transverse ThrusterDocument8 pagesWartsila O P Transverse ThrusterionesqNo ratings yet

- Sai Extrumech Alias Sai EngineeringDocument18 pagesSai Extrumech Alias Sai EngineeringsaiextrumechNo ratings yet

- Spherical Roller Bearing SKF CatlougeDocument72 pagesSpherical Roller Bearing SKF Catlougemrkadu_61No ratings yet

- LPG - CNG Cylinders: Cym Materiales S.ADocument8 pagesLPG - CNG Cylinders: Cym Materiales S.AJati PangarsoNo ratings yet

- Coal Shearer (Underground Mining Machine)Document16 pagesCoal Shearer (Underground Mining Machine)Donald Berbatov SilitongaNo ratings yet

- Diamond America Catalog 0221Document16 pagesDiamond America Catalog 0221panama sunpowerNo ratings yet

- Submersible Pump SetsDocument193 pagesSubmersible Pump Setskalicharan1350% (2)

- CTC Series CatalogueDocument40 pagesCTC Series CatalogueMattyNo ratings yet

- TM Rev PDFDocument18 pagesTM Rev PDFHarshavardhan KutalNo ratings yet

- l5 Steam Turbines PDFDocument9 pagesl5 Steam Turbines PDFMax Peter100% (1)

- Inside A GE LM6000 (CF6-80C2) Gas TurbineDocument23 pagesInside A GE LM6000 (CF6-80C2) Gas TurbineJesusMaldonadoNo ratings yet

- Tecumseh Description1Document7 pagesTecumseh Description1Wiraindo AirconNo ratings yet

- May Thuy Khi Cau Hoi On Tap NewDocument29 pagesMay Thuy Khi Cau Hoi On Tap NewKhang DangNo ratings yet

- 04 SRL MaintenanceDocument94 pages04 SRL Maintenancerana usman100% (1)

- Tutorial Letter 101/0/2015: Hydraulic Machines III (Theory) FMA3602Document15 pagesTutorial Letter 101/0/2015: Hydraulic Machines III (Theory) FMA3602anthonytichaonaNo ratings yet

- 1.layout Rig 1503 Meters - Dos Mud Pump-ModeloDocument1 page1.layout Rig 1503 Meters - Dos Mud Pump-ModeloJUAN JOSE VESGA RUEDANo ratings yet

- SV2 16F 5 Jan00 EdEDocument10 pagesSV2 16F 5 Jan00 EdESani PoulouNo ratings yet

- Catalog of RFL PUMP PDFDocument13 pagesCatalog of RFL PUMP PDFvasanth kumarNo ratings yet

- Rekapitulasi Data RST - Dompet Dhuafa - OdsDocument10 pagesRekapitulasi Data RST - Dompet Dhuafa - OdsSofian RNo ratings yet

- Performance of Hydraulic MachinesDocument14 pagesPerformance of Hydraulic MachinesVINAY CHANDWANINo ratings yet

- Lo3 PDFDocument25 pagesLo3 PDFUmair MaqboolNo ratings yet

- 2.3. Compressor Section: IAM SearchDocument13 pages2.3. Compressor Section: IAM SearchÄbdur RáhmánNo ratings yet

- SUMP PumpsDocument44 pagesSUMP PumpsRaghavendra NKNo ratings yet

- Fundamentals of Fluid Mechanics: Chapter 12 TurbinesDocument44 pagesFundamentals of Fluid Mechanics: Chapter 12 TurbinesRanga ChandimalNo ratings yet

- ASC GR110-200 Tab11 Parts List Screw Element 2989 0015 00-2946 0536 00Document3 pagesASC GR110-200 Tab11 Parts List Screw Element 2989 0015 00-2946 0536 00Noufou DarankoumNo ratings yet

- Module 5: Activity No. 2: P D D Q 150 GPM P PDocument4 pagesModule 5: Activity No. 2: P D D Q 150 GPM P PLeyzer MalumayNo ratings yet

- CBZ Horizontal Self-Priming Centrifugal Pump Catalogue: (m3/h) (M) (KW) (KW) (m3/h) (M) (KW) (KW)Document2 pagesCBZ Horizontal Self-Priming Centrifugal Pump Catalogue: (m3/h) (M) (KW) (KW) (m3/h) (M) (KW) (KW)rio100% (1)

- National Oilwell Varco - High Pressure, Positive Displacement, Reciprocating PumpsDocument2 pagesNational Oilwell Varco - High Pressure, Positive Displacement, Reciprocating Pumpsnoha azamaliNo ratings yet

- 7 Types of Pumps - GPTDocument3 pages7 Types of Pumps - GPTnatee8632No ratings yet

- Design of Rotor Storage Container For Turbine Rotor of PRMR ModifiedDocument23 pagesDesign of Rotor Storage Container For Turbine Rotor of PRMR ModifiedDavidPrasojoNo ratings yet

- Shop Rotorddynamic TestingDocument22 pagesShop Rotorddynamic TestingZeeshan AnwarNo ratings yet

- 43 Turbomachinery & 30 Pump Users Symposia (Pump & Turbo 2014) September 23-25, 2014 - Houston, TX - Pumpturbo - Tamu.eduDocument12 pages43 Turbomachinery & 30 Pump Users Symposia (Pump & Turbo 2014) September 23-25, 2014 - Houston, TX - Pumpturbo - Tamu.edukglorstadNo ratings yet

- Turbo MachinesDocument75 pagesTurbo Machinesyash_ganatra67% (3)

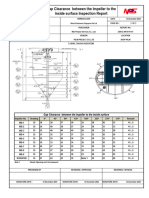

- Gap Clearance Between The Impeller To The Inside Surface Inspection ReportDocument1 pageGap Clearance Between The Impeller To The Inside Surface Inspection Reportคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Affinity Laws: Centrifugal PumpsDocument2 pagesAffinity Laws: Centrifugal PumpsPrudhvi RajNo ratings yet

- Pump Curve 250x350Document1 pagePump Curve 250x350reiNo ratings yet