Professional Documents

Culture Documents

Group 4 - CHE 37 - Theoretical Background

Uploaded by

Vince Nixau PadelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Group 4 - CHE 37 - Theoretical Background

Uploaded by

Vince Nixau PadelCopyright:

Available Formats

Department of Chemical Engineering

College of Engineering

Xavier University – Ateneo de Cagayan

Final Design Project

Reactors with Multiple Reactions

In partial fulfillment to the requirements of the course

CHE 37

Chemical Reaction Engineering

by

Ocho, Joli Andrea

Padel, Vince Nixau

Polito, Elijah Ramm

BS ChE – 3

to

Engr. Jayhiel S. Malila, MS

Course Instructor

November 24, 2022

CHE 37 – Chemical Reaction Engineering Page 1

SECTION I

From a realistic perspective, what occurs in a chemical reactor does not have only

one reaction, most of the time multiple reactions occur. Although some of these reactions

are desired, some are undesirable reactions. The reduction of undesirable reactions that

occur with the desired reaction contributes to a chemical plant's economic success. A

single reaction differs from multiple reactions in such a way that a single reaction requires

only one rate expression to describe its kinetic behavior, whereas multiple reactions

require multiple rate expressions. The four basic types of multiple reactions are series,

parallel, independent, and complex reactions. Series reactions is also called consecutive

reactions

CHE 37 – Chemical Reaction Engineering Page 2

SECTION II

A. Establishing the General Schematic Diagram and Mathematical Equations

Before we begin solving the problem, we will first identify the nomenclature of the given

problem. A is the K-benzoate, R is the lumped intermediates, and K-terephthalate is represented

by S. The k1 and E1 are the rate constant and the activation energy in the reaction of A to R in the

series reaction. The k2 and E2 are the rate constant and activation energy in the reaction of R to

S in the series reaction. Lastly, k3 and the E3 are the rate constant and activation energy in the

autocatalytic reaction. The Ci is the concentration of the i constituent. The

P, R, T, and t are the Pressure, Universal Gas Constant, Temperature,

and time. To start with solving the problem, we will establish the

foundation of all CRE’s problems, the General Mole Balance Equation.

𝑉 𝑑𝑁𝑖

𝐹𝑖𝑂 − 𝐹𝑖 + ∫0 𝑟𝑖 𝑑𝑉 = 𝑑𝑡

[equation 1]

For the batch reactor, which is the reactor in the first two conditions, there

is no inflow or outflow. From the General Mole Balance Equation, the

equation for the batch reactor in terms of the moles is as follows:

𝑑𝑁𝑖

= 𝑟𝑖 𝑉 [equation 2]

Figure 1. Batch Reactor 𝑑𝑡

𝑁𝑖

The equation 2 can be expressed in terms of the concentration as 𝐶i = 𝑉

.

𝑑𝑁𝑖

𝑑𝑡

= 𝑟𝑖 𝑉

𝑑(𝑁𝑖 )

= 𝑟𝑖

𝑑𝑡𝑉

𝑑𝐶𝑖

𝑑𝑡

= 𝑟𝑖 𝑉 [equation 3]

For the CSTR, there is no accumulation, and it is perfectly mixed. The equation for the continuous

stirred tank reactor is as follows:

𝐹𝑖 −𝐹𝑖𝑂

𝑉

= 𝑟𝑖 [equation 4]

In terms of concentration 𝐹𝑖 = 𝐶𝑖 ∅𝑣 ,

𝐶𝑖 ∅𝑣 − 𝐶𝐴𝑂 ∅𝑣𝑜

= 𝑟𝐴

𝑉

For liquid phase, the volumetric flow rate is constant.

Figure 2. Continuous Stirring Tank Reactor

𝐶𝐴 ∅𝑣 − 𝐶𝐴𝑂 ∅𝑣

= 𝑟𝐴

𝑉

∅𝑣 (𝐶𝐴 − 𝐶𝐴𝑂 )

= 𝑟𝐴

𝑉

∅𝑣 (𝐶𝐴 − 𝐶𝐴𝑂 )

=𝑉

𝑟𝐴

CHE 37 – Chemical Reaction Engineering Page 3

(𝐶𝐴 − 𝐶𝐴𝑂 ) 𝑉

=

𝑟𝐴 ∅𝑣

(𝐶𝐴 −𝐶𝐴𝑂 )

𝑟𝐴

= 𝜏 [equation 5]

𝑉

𝜏 = ∅ is termed space time.

𝑣

For the rate of reactions, multiple reactions can be accounted for a one species. In the reaction

of K-benzoate (A), there are no multiple reactions. The rate of reaction is as follows:

−𝑟𝐴 = 𝑘1 𝐶𝐴 [equation 6]

The reaction rate for the lumped intermediates accounts the reaction happened in the series

reaction and the autocatalytic reaction.

𝑟𝑅 = 𝑟𝑅 𝑠𝑒𝑟𝑖𝑒𝑠 1 + 𝑟𝑅 𝑠𝑒𝑟𝑖𝑒𝑠 2 + 𝑟𝑅𝑎𝑢𝑡𝑜𝑐𝑎𝑡𝑎𝑙𝑦𝑡𝑖𝑐

𝑟𝑅 = 𝑘1 𝐶𝑅 − 𝑘2 𝐶𝑅 − 𝑘3 𝐶𝑅 𝐶𝑆 [equation 7]

For the reaction rate of the K-terephthalate,

𝑟𝑆 = 𝑟𝑆𝑠𝑒𝑟𝑖𝑒𝑠 + 𝑟𝑆 𝑎𝑢𝑡𝑜𝑐𝑎𝑡𝑎𝑙𝑦𝑡𝑖𝑐

𝑟𝑆 = 𝑘2 𝐶𝑅 − 𝑘3 𝐶𝑅 𝐶𝑆 [equation 8]

As the rate constant is a function of temperature, changing the temperature affects the value of

the rate constant. To obtain the new rate constant when the temperature changes, we use:

𝐸

−

𝑘(𝑇𝑜 ) = 𝐴𝑒 𝑅𝑇𝑜

This is for the initial temperature. For the new temperature:

𝐸

𝑘(𝑇) = 𝐴𝑒 −𝑅𝑇

Taking the ratio:

𝐸

𝑘(𝑇) 𝐴𝑒 −𝑅𝑇

= 𝐸

𝑘(𝑇𝑜 ) −

𝐴𝑒 𝑅𝑇𝑜

𝐸

𝑘(𝑇) 𝑒 −𝑅𝑇

= 𝐸

𝑘(𝑇𝑜 ) −

𝑒 𝑅𝑇𝑜

𝑘(𝑇) 𝐸 1 1

− ( − )

= 𝑒 𝑅 𝑇 𝑇𝑜

𝑘(𝑇𝑜 )

1 1

Taking the -1 in (𝑇 − 𝑇 )

𝑜

CHE 37 – Chemical Reaction Engineering Page 4

𝑘(𝑇) 𝐸 1 1

( − )

= 𝑒 𝑅 𝑇𝑜 𝑇

𝑘(𝑇𝑜 )

𝐸 1 1

( − )

𝑘(𝑇) = 𝑘(𝑇𝑜 )𝑒 𝑅 𝑇𝑜 𝑇 [equation 9]

B. Derivation of the Mathematical Equation

For this derivation let us use the Chemical Reaction Engineering Algorithm.

Schematic

Let us start with our General Mole Balance Equation

GMBE:

𝑉 𝑑𝑁𝐴

𝐹𝐴0 − 𝐹𝐴 + ∫0 𝑟𝐴 𝑑𝑉 = [equation 1]

𝑑𝑡

Now let us derive for a batch reactor

We will make the following assumptions

Assumptions:

1) No in and out flow rate(𝐹𝐴0 = 𝐹𝐴 = 0), therefore

𝑉 𝑉

𝑑𝑁𝐴 𝑑𝑁𝐴

𝐹𝐴0 − 𝐹𝐴 + ∫ 𝑟𝐴 𝑑𝑉 = → ∫ 𝑟𝐴 𝑑𝑉 =

0 𝑑𝑡 0 𝑑𝑡

𝑉

2) Perfectly mixed (∫0 𝑟𝐴 𝑑𝑉 = 𝑟𝐴 𝑉 ), therefore

𝑉

𝑑𝑁𝐴 𝑑𝑁𝐴

∫ 𝑟𝐴 𝑑𝑉 = → 𝑟𝐴 𝑉 =

0 𝑑𝑡 𝑑𝑡

𝑉

𝑑𝑁𝐴 𝑑𝑁𝐴

∫ 𝑟𝐴 𝑑𝑉 = → 𝑟𝐴 𝑑𝑉 =

0 𝑑𝑡 𝑑𝑡

Performance equation of Batch reactor

𝑑𝑁𝐴

= 𝑟𝐴 𝑉 [Equation 2]

𝑑𝑡

Now let us derive for a Continuously stirred tank

Assumptions:

𝑑𝑁𝐴

1) Steady State( = 0)

𝑑𝑡

𝑉 𝑉

𝑑𝑁𝐴

𝐹𝐴0 − 𝐹𝐴 + ∫ 𝑟𝐴 𝑑𝑉 = → 𝐹𝐴0 − 𝐹𝐴 + ∫ 𝑟𝐴 𝑑𝑉 = 0

0 𝑑𝑡 0

CHE 37 – Chemical Reaction Engineering Page 5

𝑉

2) Perfectly mixed(∫0 𝑟𝐴 𝑑𝑉 = 𝑟𝐴 𝑉)

𝑉

𝐹𝐴0 − 𝐹𝐴 + ∫ 𝑟𝐴 𝑑𝑉 = 0 → 𝐹𝐴0 − 𝐹𝐴 + 𝑟𝐴 𝑉 = 0

0

Isolate V

Algebraic form of performance equation

𝐹 −𝐹

𝑉 = 𝐴 𝑟 𝐴0[equation 4],

𝐴

After acquiring the performance equations using the General Mole Balance

Equation (GMBE). Let us get the Stoichiometry:

Stoichiometry:

We will be expressing our performance equations in terms of concentration

Batch reactor

𝑑𝑁𝐴

= 𝑟𝐴 𝑉 [Equation 2]

𝑑𝑡

𝑁𝐴

Recall: 𝐶𝐴 = 𝑉

𝑑𝑁𝐴

= 𝑟𝐴 𝑉

𝑑𝑡

𝑑(𝑁𝐴 )

= 𝑟𝐴

𝑑𝑡(𝑉)

𝑑𝐶𝐴

= 𝑟𝐴 [Equation 3]

𝑑𝑡

CSTR

𝐹𝐴 −𝐹𝐴0

𝑉= [Equation 4]

𝑟𝐴

Recall:𝐹𝑖 = 𝐶𝑖 𝜙𝑉

𝐶𝐴 𝜙𝑉 − 𝐶𝐴0 𝜙𝑉0

𝑉=

𝑟𝐴

For liquid phase, Volumetric flow rate is constant (𝜙𝑉 = 𝜙𝑉0 )

𝐶𝐴 𝜙𝑉 − 𝐶𝐴0 𝜙𝑉0 𝜙𝑉 (𝐶𝐴 − 𝐶𝐴0 )

𝑉= → 𝑉=

𝑟𝐴 𝑟𝐴

CHE 37 – Chemical Reaction Engineering Page 6

1 𝜙𝑉 (𝐶𝐴 − 𝐶𝐴0 )

(𝑉 = )

𝜙𝑉 𝑟𝐴

𝑉 𝐶𝐴 − 𝐶𝐴0

=

𝜙𝑉 𝑟𝐴

𝑉

Where 𝜙 = 𝜏

𝑉

𝑉 𝐶𝐴 − 𝐶𝐴0 𝐶𝐴 − 𝐶𝐴0

= → 𝜏=

𝜙𝑉 𝑟𝐴 𝑟𝐴

𝐶𝐴 −𝐶𝐴0

𝜏= [equation 5]

𝑟𝐴

The next step after deriving our stoichiometry would be to derive our rate law

Rate Law

For A:

−𝑟𝐴 = 𝑘1 𝐶𝐴

For lumped intermediates:

𝑟𝑅 = 𝑟𝑅𝑠𝑒𝑟𝑖𝑒𝑠 1 + 𝑟𝑅𝑠𝑒𝑟𝑖𝑒𝑠 2 + 𝑟𝑅𝑎𝑢𝑡𝑜𝑐𝑎𝑡𝑎𝑙𝑦𝑡𝑖𝑐

𝑟𝑅 = 𝑘1 𝐶𝑅 − 𝑘2 𝐶𝑅 − 𝑘3 𝐶𝑅 𝐶𝑆

For S:

𝑟𝑆 = 𝑟𝑆𝑠𝑒𝑟𝑖𝑒𝑠 + 𝑟𝑆𝑎𝑢𝑡𝑜𝑐𝑎𝑡𝑎𝑙𝑦𝑡𝑖𝑐

𝑟𝑆 = 𝑘2 𝐶𝑅 − 𝑘3 𝐶𝑅 𝐶𝑆

Combine the rate law and stoichiometry

For Batch:

= 𝑟𝐴 [Equation 3]

𝑑𝐶𝐴

𝑑𝑡

For A:

= −𝑘1 𝐶𝐴[Equation 10]

𝑑𝐶𝐴

𝑑𝑡

For Lumped Intermediates:

𝑑𝐶𝑅

= 𝑘1 𝐶𝑅 − 𝑘2 𝐶𝑅 − 𝑘3 𝐶𝑅 𝐶𝑆

𝑑𝑡

[Equation 11]

For S:

= 𝑘2 𝐶𝑅 − 𝑘3 𝐶𝑅 𝐶𝑆 [Equation 12]

𝑑𝐶𝑆

𝑑𝑡

CHE 37 – Chemical Reaction Engineering Page 7

For CSTR:

𝜏 = 𝐴 𝑟 𝐴0 [Equation 5]

𝐶 −𝐶

𝐴

For A:

𝜏=

𝐶𝐴 −𝐶𝐴0

−𝑘1 𝐶𝐴

[Equation 13]

For Lumped Intermediates:

𝐶 −𝐶𝐴0

𝜏 = 𝑘 𝐶 −𝑘𝐴 𝐶 −𝑘 𝐶 𝐶

[Equation 14]

1 𝑅 2 𝑅 3 𝑅 𝑠

For S:

𝜏=𝑘

𝐶𝐴 −𝐶𝐴0

[Equation 15]

2 𝐶𝑅 −𝑘3 𝐶𝑅 𝐶𝑠

CHE 37 – Chemical Reaction Engineering Page 8

SECTION III

As mentioned, reactors with multiple reactions are common in the industry. In a study by Van

Woezik, & Westerterp (2002), a semi-batch reactor was used in the nitric acid oxidation of 2-

octanol. The runaway behavior and its thermally safe operations of the process was studied.

The study focuses on the thermal dynamics of a semi-batch reactor that performs multiple

exothermic liquid-liquid reactions. During the reaction, 2-octanone is formed, which can then

be oxidized to form undesirable carboxylic acids. The runaway behavior of 2-octanol nitric

acid oxidation to 2-octanone and subsequent oxidation products such as carboxylic acids has

been experimentally studied. When the reaction transitions towards acids is accompanied by

a temperature runaway, a dangerous situation can occur. The operation conditions, such as

dosing time and coolant temperature, are studied and discussed in order to achieve a high

yield under safe conditions. The oxidation of 2-octanol (A) to 2-octanone (P) and further

oxidation products (X) can be described with the following reaction equations:

where B is the nitrosonium ion, which also causes an autocatalytic behavior. The reaction

rates in the acid phase can be expressed on the basis of a second order reaction:

where CA,Org, CP,Org and CB,Aq are the bulk concentrations of 2-octanol (A), 2-octanone (P) and

nitrosonium ion (B) in the organic phase (Org) and Aqueous phase (Aq), respectively. The

kinetic constants knol and knone can be described with:

where k∞, E/R and mH0 are the pre-exponential factor, the activation temperature and the

Hammett’s reaction rate coefficient, respectively. H0 is Hammett’s acidity function.

CHE 37 – Chemical Reaction Engineering Page 9

Solving the heat and mass balances over the reactor with the appropriate initial conditions

yields the temperature in the reactor as well as the concentrations of the reactants and

products as a function of time. The following conditions are assumed in the model for the

semi-batch reactor considered in this work: uniform reaction temperature, heat capacities and

volumes are additive, only the aqueous nitric acid phase is involved in the reactions, the nitric

acid phase is the continuous phase; no phase inversion occurs, there is no change in the

volume of the individual phases, and the reactants' mutual solubility is low.

CHE 37 – Chemical Reaction Engineering Page 10

References:

Van Woezik, B. A. A., & Westerterp, K. R. (2002). Runaway behavior and thermally safe

operation of multiple liquid–liquid reactions in the semi-batch reactor. Chemical

Engineering and Processing: Process Intensification, 41(1), 59–77.

doi:10.1016/s0255-2701(01)00106-4

CHE 37 – Chemical Reaction Engineering Page 11

You might also like

- O Level Biology Practice Questions And Answers EnzymesFrom EverandO Level Biology Practice Questions And Answers EnzymesRating: 5 out of 5 stars5/5 (1)

- GROUP 4 - Final Design ProjectDocument48 pagesGROUP 4 - Final Design ProjectVince Nixau PadelNo ratings yet

- Introduction To Reaction KineticsDocument4 pagesIntroduction To Reaction KineticsJbreNo ratings yet

- Solution Manual Leven Spiel PDFDocument362 pagesSolution Manual Leven Spiel PDFNiax Photos100% (3)

- Chapter #3#Document30 pagesChapter #3#wallelgn temaNo ratings yet

- Chapter #3F#Document30 pagesChapter #3F#fikadubiruk87No ratings yet

- CRT Solid LiqdDocument13 pagesCRT Solid LiqdRashmi SahooNo ratings yet

- Che 307 Lec4Document10 pagesChe 307 Lec4Zabo TrewNo ratings yet

- Solution Manual LevenSpiel by 13BCH@ITNUDocument370 pagesSolution Manual LevenSpiel by 13BCH@ITNUManishMakwana87% (156)

- Reactor Computations PFR-100v0.5Document10 pagesReactor Computations PFR-100v0.5Evan DulayNo ratings yet

- Ch1 Synopsis Part2Document27 pagesCh1 Synopsis Part2Vijayalaxmi JNo ratings yet

- Reaction Kinetics Studies in A Batch Reactor: NtroductionDocument15 pagesReaction Kinetics Studies in A Batch Reactor: NtroductionYasmin KayeNo ratings yet

- S.6 Chemical KineticsDocument10 pagesS.6 Chemical Kineticsk75544863No ratings yet

- Chemical EquilibriumDocument38 pagesChemical Equilibriumpemzyboi07No ratings yet

- 4 1-StoichiometryDocument29 pages4 1-StoichiometryPatricia DavidNo ratings yet

- Reaction Rate Theories and CatalysisDocument7 pagesReaction Rate Theories and CatalysisJosephine ChenNo ratings yet

- CHE3017L01 Grp. 3 ECR EPDocument9 pagesCHE3017L01 Grp. 3 ECR EPDaniella Nicole MendozaNo ratings yet

- Cre Lab AssignmentDocument7 pagesCre Lab AssignmentRidaNo ratings yet

- Chemical Kinetic 2Document5 pagesChemical Kinetic 2azadqayoommalikNo ratings yet

- Collision theory Arrhenius equation and transition state theoryDocument32 pagesCollision theory Arrhenius equation and transition state theorySakshit MahajanNo ratings yet

- Chemical Equilibrium NoteDocument33 pagesChemical Equilibrium NotePrecious AjiboyeNo ratings yet

- Experiment 6Document11 pagesExperiment 6CarlosLorenzoSaninNo ratings yet

- Che 307 Lec3Document14 pagesChe 307 Lec3Zabo TrewNo ratings yet

- M Ole Balances: 3.1 Translating Between Concentration and ConversionDocument7 pagesM Ole Balances: 3.1 Translating Between Concentration and ConversionJonathan ByamunguNo ratings yet

- Kathmandu University CSTR Lab ReportDocument19 pagesKathmandu University CSTR Lab ReportBishal LamichhaneNo ratings yet

- Cinética de Las Reacciones Químicas 1818 PDFDocument22 pagesCinética de Las Reacciones Químicas 1818 PDFJuly JBNo ratings yet

- Chemical Engineering ThermodynamicsDocument8 pagesChemical Engineering ThermodynamicsP P DNo ratings yet

- TMP 7421Document14 pagesTMP 7421FrontiersNo ratings yet

- 8b - Series ReactionsDocument16 pages8b - Series ReactionsGRAZIELLA CZARINA MARIE LABRADORNo ratings yet

- Chemical Equilibrium Expressions and CalculationsDocument8 pagesChemical Equilibrium Expressions and CalculationsLeilanie Javier GuerreroNo ratings yet

- Researchers Have Been Studied Nonlinear Interdisciplinary Field, From Chemistry To Mathematics, Physics, Biology and EngineeringDocument10 pagesResearchers Have Been Studied Nonlinear Interdisciplinary Field, From Chemistry To Mathematics, Physics, Biology and EngineeringAaaereNo ratings yet

- A) Consider The Two Steps Kinetic Process:: Fecha de Entrega: 06 de Septiembre de 2018Document2 pagesA) Consider The Two Steps Kinetic Process:: Fecha de Entrega: 06 de Septiembre de 2018Fernando GomezNo ratings yet

- Inorganic Chemistry: Learning Module inDocument16 pagesInorganic Chemistry: Learning Module inKevinNo ratings yet

- CSTR Experiment ManualDocument5 pagesCSTR Experiment ManualEvan DulayNo ratings yet

- CRT Solid LiquidDocument14 pagesCRT Solid LiquidRashmi SahooNo ratings yet

- CHE S402 Chapter5 Rate Equations For Fluid Solid Reactions Kinetic ModelsPart2Document9 pagesCHE S402 Chapter5 Rate Equations For Fluid Solid Reactions Kinetic ModelsPart2Rashmi SahooNo ratings yet

- Stoichiometry and reaction ratesDocument18 pagesStoichiometry and reaction ratesPatricia DavidNo ratings yet

- Handout No. 7 in General Chemistry 2Document10 pagesHandout No. 7 in General Chemistry 2Portgas D. AceNo ratings yet

- Chapter 2 Process Modelling Fundamental RelationsDocument28 pagesChapter 2 Process Modelling Fundamental Relationsnik farisNo ratings yet

- CL208_324_Week12 (1)Document7 pagesCL208_324_Week12 (1)chintujajor24No ratings yet

- Reactive Energy BalanceDocument12 pagesReactive Energy BalanceGrey DaveNo ratings yet

- Chapter #2#Document39 pagesChapter #2#wallelgn temaNo ratings yet

- MT1 Formula SheetDocument2 pagesMT1 Formula SheetIan Christopher RomanNo ratings yet

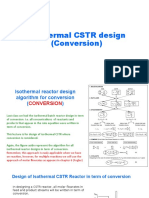

- Lecture 8 Isothermal CSTR Design (Conversion)Document11 pagesLecture 8 Isothermal CSTR Design (Conversion)Mhmad E. HerzallahNo ratings yet

- Chemical Engineering Thermodynamics ExplainedDocument10 pagesChemical Engineering Thermodynamics ExplainedP P DNo ratings yet

- Days 1 and 2: Introduction and Overview: Definitions Of, and Notation For, Reaction RatesDocument13 pagesDays 1 and 2: Introduction and Overview: Definitions Of, and Notation For, Reaction RatesClarence AG YueNo ratings yet

- Chapter 4 Gen. Chem 2Document29 pagesChapter 4 Gen. Chem 2John Victor MalupaNo ratings yet

- División Académica de Ingeniería y Arquitectura: Dimensional ConsistencyDocument11 pagesDivisión Académica de Ingeniería y Arquitectura: Dimensional ConsistencyTano TGNo ratings yet

- Module 02 Solutions Thermodynamics Theory SummaryDocument19 pagesModule 02 Solutions Thermodynamics Theory SummaryVanNo ratings yet

- Me/Au 010 506 Thermodynamics: Noel Joseph GomezDocument7 pagesMe/Au 010 506 Thermodynamics: Noel Joseph GomezmujeebNo ratings yet

- A. The Title: Reaction Rate B. Date of The Experiment Begin: Tuesday / April, 4Document37 pagesA. The Title: Reaction Rate B. Date of The Experiment Begin: Tuesday / April, 4NurvitaEkaWulanNo ratings yet

- Introduction VenturiDocument8 pagesIntroduction VenturiRoger FernandezNo ratings yet

- Tarea 5-Equipo18Document33 pagesTarea 5-Equipo18Sarita Betancur RamírezNo ratings yet

- Improvements of Hierarchical Algorithm For Equilibrium CalculationDocument7 pagesImprovements of Hierarchical Algorithm For Equilibrium CalculationandrestomasNo ratings yet

- GenChem2 Chemical EquilibriumDocument2 pagesGenChem2 Chemical Equilibriumjohn carlo roblesNo ratings yet

- Fluid Mechanics Course Notes from University of BenghaziDocument13 pagesFluid Mechanics Course Notes from University of BenghaziMohammed AlryaniNo ratings yet

- Electro-Gravity Via Goemetric Chronon Field and On The Origin of MassDocument78 pagesElectro-Gravity Via Goemetric Chronon Field and On The Origin of Masseytan_ilNo ratings yet

- Chemical Kinetics: The Iodine Clock Reaction RateDocument13 pagesChemical Kinetics: The Iodine Clock Reaction RateHân LêNo ratings yet

- Beige and Brown Geometric Modern Research Project Presentation 1Document25 pagesBeige and Brown Geometric Modern Research Project Presentation 1Vince Nixau PadelNo ratings yet

- CHE 42 - Problem Set 1 - Phase EquilibriumDocument3 pagesCHE 42 - Problem Set 1 - Phase EquilibriumVince Nixau PadelNo ratings yet

- MIDTERM EXAM PART 1 Chete 43 ADocument2 pagesMIDTERM EXAM PART 1 Chete 43 AVince Nixau PadelNo ratings yet

- Lesson 1-6 Mechanical Properties of MaterialsDocument4 pagesLesson 1-6 Mechanical Properties of MaterialsVince Nixau PadelNo ratings yet

- CBSE Class 10 Science Revision Notes Chapter - 2 Acids, Bases and SaltsDocument11 pagesCBSE Class 10 Science Revision Notes Chapter - 2 Acids, Bases and Saltsmilind dhamaniyaNo ratings yet

- Fairfield Institute of Management & Technology E-Commerce: Lab/Practical File Subject Code: 112Document24 pagesFairfield Institute of Management & Technology E-Commerce: Lab/Practical File Subject Code: 112AYUSHNo ratings yet

- Chapter 24 Study QuestionsDocument3 pagesChapter 24 Study QuestionsAline de OliveiraNo ratings yet

- Acer Aspire 4535 (Compal LA-4921P) PDFDocument57 pagesAcer Aspire 4535 (Compal LA-4921P) PDFMustafa AkanNo ratings yet

- Mark Dyczkowski and Trika Journal March 2015 Vol.1.No.1.Document10 pagesMark Dyczkowski and Trika Journal March 2015 Vol.1.No.1.Mark Dyczkoswki and Trika Journal100% (2)

- Goethe Zertifikat b1 HorenDocument2 pagesGoethe Zertifikat b1 HorenLevent75% (4)

- Agile Spotify - Team - HomeworkDocument8 pagesAgile Spotify - Team - Homeworksp76rjm7dhNo ratings yet

- Exam Unit 1 Out and About 1º BachilleratoDocument5 pagesExam Unit 1 Out and About 1º Bachilleratolisikratis1980No ratings yet

- LP Science WeatheringDocument4 pagesLP Science WeatheringHazel L Ibarra100% (1)

- Carbon Emission and Battery Monitoring SystemDocument17 pagesCarbon Emission and Battery Monitoring SystemIJRASETPublicationsNo ratings yet

- Sony STR Da80esDocument66 pagesSony STR Da80estelstarservicesNo ratings yet

- Conditions For The Emergence of Life On The Early Earth: Summary and ReflectionsDocument15 pagesConditions For The Emergence of Life On The Early Earth: Summary and Reflectionsapi-3713202No ratings yet

- Mikes ResumeDocument2 pagesMikes Resumeapi-312645878No ratings yet

- AllareDocument16 pagesAllareGyaniNo ratings yet

- Challenges Faced by Irregular StudentsDocument13 pagesChallenges Faced by Irregular StudentsTicag Teo80% (5)

- Man 400eDocument324 pagesMan 400eLopez Tonny100% (1)

- A Beginners Guide Sap Smart FormsDocument61 pagesA Beginners Guide Sap Smart FormsMuhammad ZeeshanNo ratings yet

- Band Theory and Bloch Theorem in Solid State PhysicsDocument8 pagesBand Theory and Bloch Theorem in Solid State PhysicsVicky VickyNo ratings yet

- SMD 40kHz Ultrasonic Transducer MA40H1SR RevGMay 7 2014Document9 pagesSMD 40kHz Ultrasonic Transducer MA40H1SR RevGMay 7 2014robert wengerNo ratings yet

- Kelley DavisDocument3 pagesKelley Davisapi-626701108No ratings yet

- Pcit Brochure TemplateDocument2 pagesPcit Brochure Templateapi-370829251No ratings yet

- Consumer Notebook Price List For September 2010Document4 pagesConsumer Notebook Price List For September 2010Anand AryaNo ratings yet

- Chapter 9: Operating SystemsDocument166 pagesChapter 9: Operating SystemsGazzzeeNo ratings yet

- What Is Managerial Economics? Explain Its Nature, Scope and ItsDocument9 pagesWhat Is Managerial Economics? Explain Its Nature, Scope and Itsn13shukla85% (20)

- Why War: Einstein and Freud's Little-Known Correspondence On Violence, Peace, and Human Nature by Maria PopovaDocument24 pagesWhy War: Einstein and Freud's Little-Known Correspondence On Violence, Peace, and Human Nature by Maria PopovaVagueBlurNo ratings yet

- Process Planning and Cost Estimation Question BankDocument13 pagesProcess Planning and Cost Estimation Question BanksanthoshjoysNo ratings yet

- Guidelines SLCM BWDocument60 pagesGuidelines SLCM BWpnaarayanNo ratings yet

- MKTM028 FathimathDocument23 pagesMKTM028 FathimathShyamly DeepuNo ratings yet

- Cell Organelles 11Document32 pagesCell Organelles 11Mamalumpong NnekaNo ratings yet

- Scotts S2048 S2554 Operators ManualDocument99 pagesScotts S2048 S2554 Operators ManualobixmtNo ratings yet